Sheet laser welding clamping system

A laser welding and clamping technology, which is applied to laser welding equipment, welding equipment, welding equipment, etc., to achieve the effects of improving stability, reducing workload, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

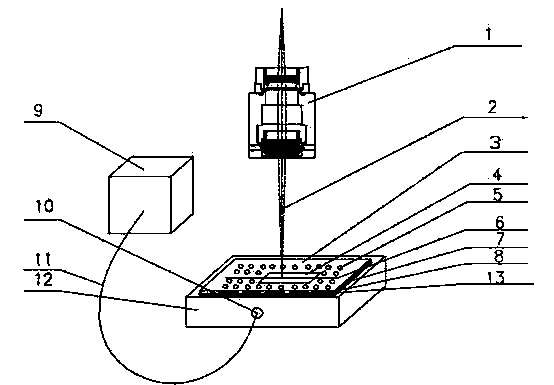

[0020] Embodiment 1: as figure 1 , Figure 4 , as shown, a thin plate laser welding clamping system, the clamping system includes a laser processing head 1, a clamp cavity base 12, and a vacuum adsorption system 9 connected to the clamp cavity base through a pipeline 11, the clamp An end cover 3 is also arranged on the base of the cavity. Through the vacuum adsorption system 9, the welded parts of the thin plate are always subjected to uniform and relatively large negative pressure during the welding process, so as to prevent problems caused by excessive heat input and output and clamping stability during the laser welding process of the thin plate. The thin plate is deformed, and the vacuum generated by the vacuum adsorption system can reach 88KPa, which further ensures the stability of the quality of the thin plate during the welding process.

Embodiment 2

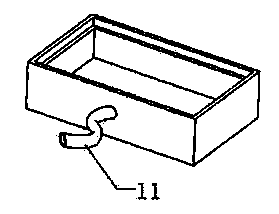

[0021] Embodiment 2: as figure 1 As shown, as an improvement of the present invention, the clamp cavity base 11 is made of high-strength steel material, and the interior is set as a cavity structure, and a through hole 10 is opened on the side wall, and the vacuum adsorption system 9 is connected with the vacuum adsorption system 9 through the pipeline 11. connect. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0022] Embodiment 3: as figure 1 , figure 2 As shown, as an improvement of the present invention, the end cap 3 is made of high-strength steel, and the middle of the end cap is opened with a groove 6 with a width of 2mm and a thickness of about 5mm, and a certain amount of circular passages are opened on both sides of the groove 6. Holes 5, two rows of through holes 5 on each side have corresponding square through holes 13 on their side walls, and are equipped with corresponding sliding catches 8, and the circular through holes 5 are controlled by the sliding of catches 8 in the corresponding square through holes 13 on and off. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com