Lithium-ion battery packaging housing and lithium ion battery comprising same

A lithium-ion battery and packaging shell technology, applied in the field of lithium-ion batteries, can solve the problems of reduced sealing performance, pinholes, cracks, affecting battery performance and working life, etc., to improve appearance, improve packaging reliability, and improve battery energy effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of lithium-ion battery packaging shell:

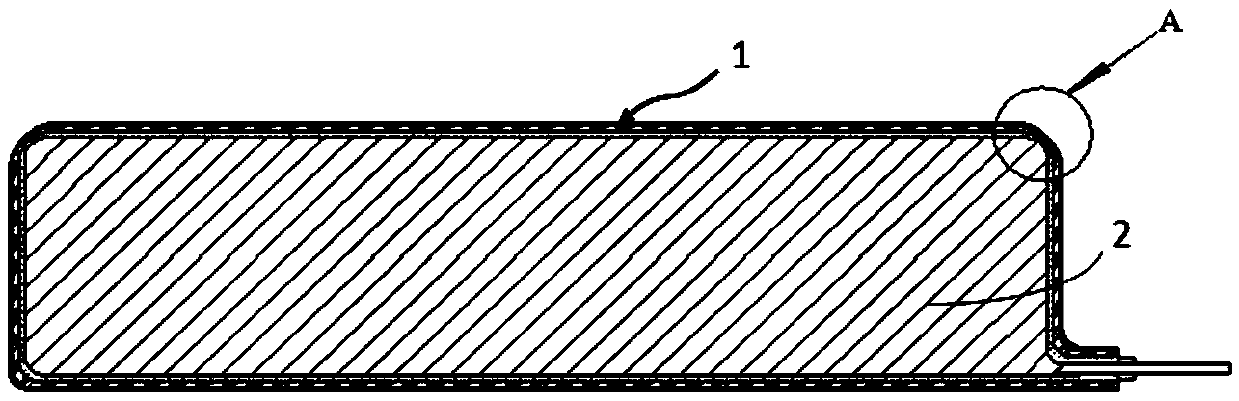

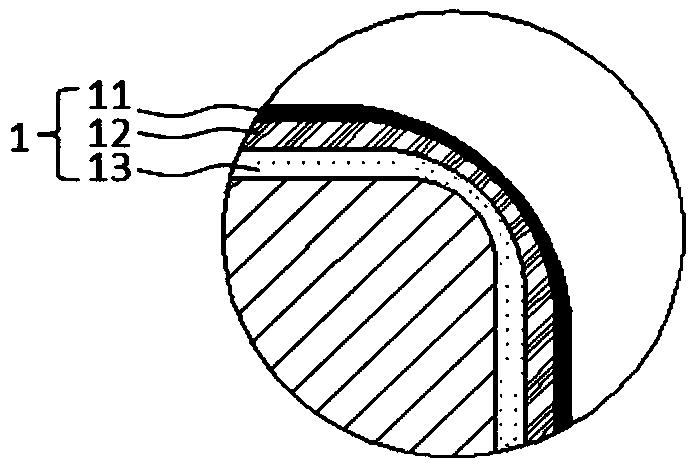

[0068] 1. The sealing shell layer 3 made of homopolypropylene material with a thickness of 25 μm is used to make the size matching the bare cell 2 by pressing a film, and then seal it after wrapping the bare cell; the schematic diagram is as follows Figure 7 and 8 shown; as Figure 8 As shown, the thickness of the sealing shell at the folded edge and the folded corner is not less than its thickness at the plane;

[0069] 2. Using a vacuum evaporation method, a 15 μm aluminum metal coating layer 4 is formed on the outer surface of the sealing shell layer 3; the schematic diagram is as follows Figure 9 , 10 shown; as Figure 10 As shown, the thickness of the metal coating layer at the folded edge and the folded corner is not less than the thickness at the plane, and the arc surface formed by the sealing shell layer and the metal coating layer is a coaxial arc surface;

[0070] 3. Using a spraying process, the me...

Embodiment 2

[0073] Preparation of lithium-ion battery packaging shell:

[0074] 1. The sealed shell layer 3 made of homopolypropylene material with a thickness of 20 μm is made to match the size of the bare cell 2 through injection molding technology, and sealed after wrapping the bare cell;

[0075] 2. Cut off the sealing edge on one side and perform thermal shaping to eliminate the sealing edge on one side;

[0076] 3. Then use a vacuum evaporation method to form a 12 μm aluminum metal coating 4 on the outer surface of the sealing shell 3;

[0077] 4. Using a spraying process, the metal coating 4 is sprayed to form an 8 μm plastic coating layer 5 made of polyamide resin.

[0078] The thicknesses of the sealing shell layer, the metal coating layer and the plastic coating layer of the prepared lithium-ion battery package shell at the folded edge and the corner are the same as the thicknesses at the plane respectively, and the sealing shell layer, the metal coating layer and the plastic c...

Embodiment 3

[0081] The sealing shell layer 3 made of homopolypropylene material with a thickness of 30 μm is used to make a film shell matching the size of the bare cell by pressing the film technology, and the bare cell is wrapped and packaged, such as Figure 12 to Figure 14 shown. Such as Figure 14 As shown, the thickness of the sealing shell at the folded edge and the folded corner is the same as the thickness at the plane. Cut off each package edge and perform thermal shaping to remove the sealing area. Then, a metal coating layer 4 made of aluminum with a thickness of 15 μm was formed on the outer surface of the sealing shell layer 3 by using a vacuum evaporation method. Afterwards, a spraying process is adopted to spray and form a 15 μm plastic coating layer 5 made of polyamide resin on the metal coating 4, such as Figure 15 , Figure 16 shown. Such as Figure 16 As shown, the thicknesses of the sealing shell, metal coating layer and plastic coating layer at the folded edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com