Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve resistance to burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

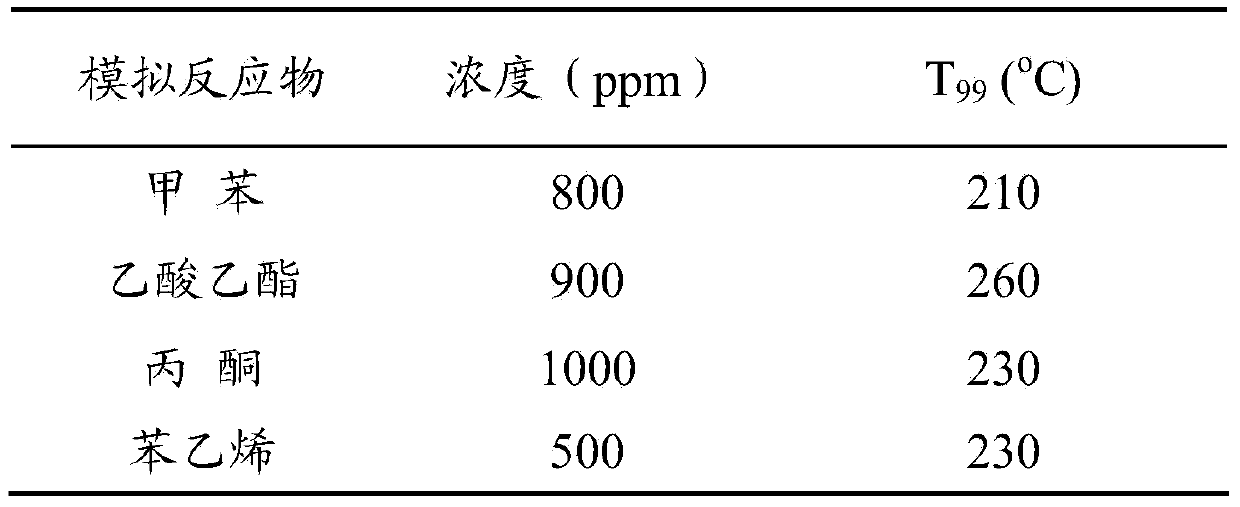

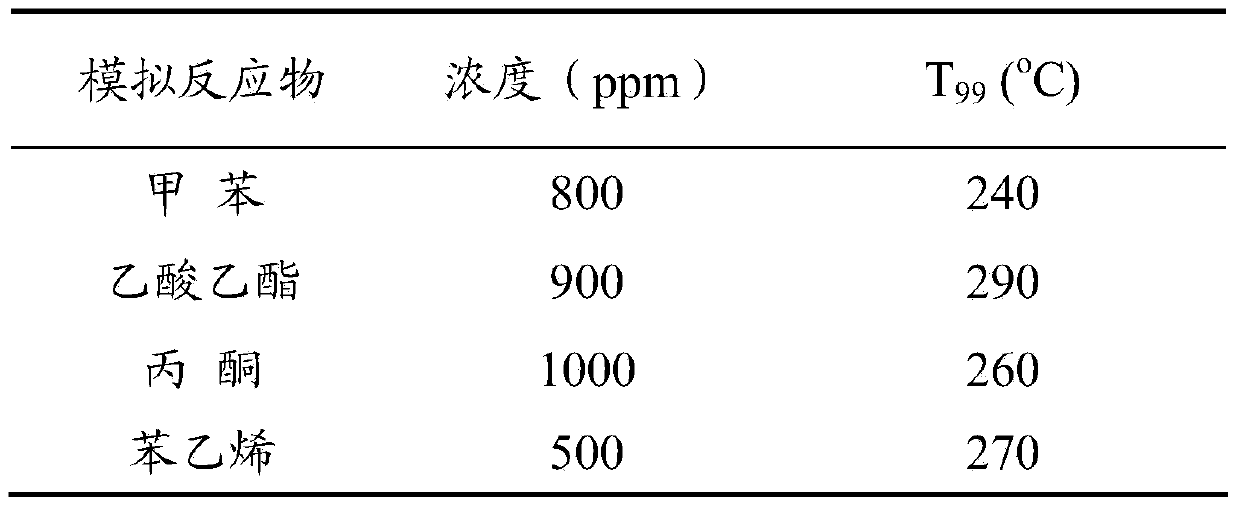

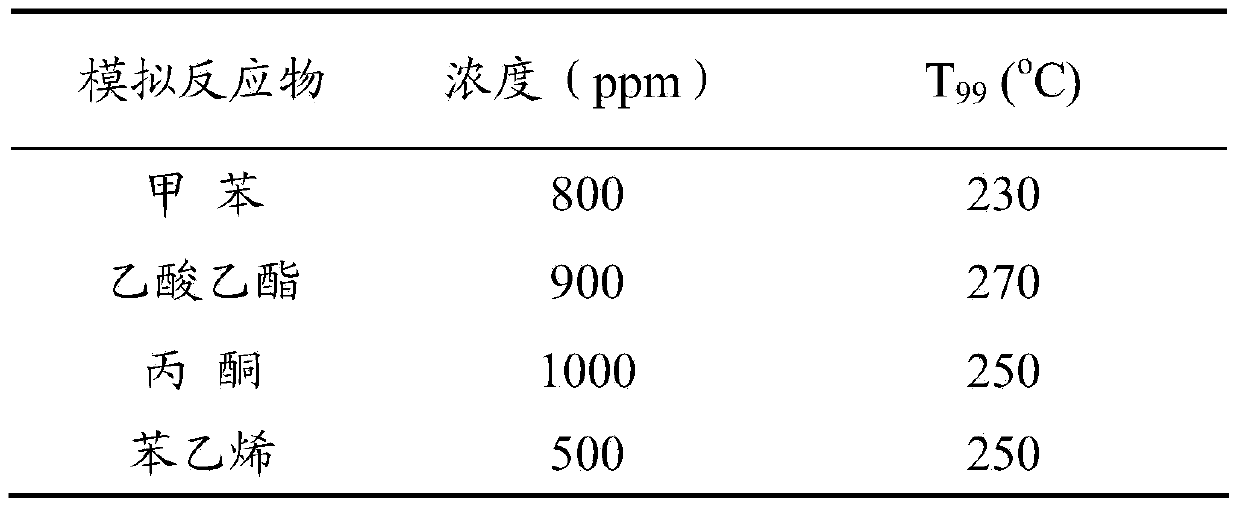

Monolithic Pd catalyst for purifying industrial organic waste gas and preparation method thereof

InactiveCN103240083AImprove oxidation capacityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumHeat stability

The invention relates to a monolithic Pd catalyst for catalytic purification of industrial organic waste gas and a preparation method thereof. The catalyst comprises a cerium-zirconium solid solution, La2O3, Nb2O5, Al2O3, noble metal Pd and a cordierite-honeycomb ceramic supporter. The preparation method comprises the following step: coating the cerium-zirconium solid solution, La2O3, Nb2O5, a pseudo-boehmite binding agent and the noble metal Pd on the surface of the cordierite-honeycomb ceramic supporter in twice, wherein the total mass of the cerium-zirconium solid solution, La2O3, Nb2O5 and Al2O3 coated for each liter of catalyst is 40g; and the loading amount of Pd contained in each liter of catalyst is 0.3g. The catalyst can prevent surface carbon deposition, and has satisfactory burning resistance and heat stability.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Ceramic silicone rubber composite with excellent burning resistance

The invention belongs to the field of macromolecular rubber materials, and relates to a silicone rubber composition, in particular to a ceramic silicone rubber composite with excellent burning resistance. The ceramic silicone rubber composite is prepared from, by weight, 100 parts of silicone rubber, 20-60 parts of formed ceramic filling, 5-15 parts of fluxing agent and 2-4 parts of vulcanizing agent, wherein the formed ceramic filling is the mixture of alumina silicate fibers and needle-like wollastonite, and the mass ratio of the alumina silicate fibers to the needle-like wollastonite is (15-25):(30-40). According to the ceramic silicone rubber composite with the excellent burning resistance, the compound of the alumina silicate fibers and the needle-like wollastonite is adopted as the formed ceramic filling to improve the thermal stability and burning resistance of the ceramic silicone rubber.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Ceramic organic composite binder for cubic boron nitride grinding wheels

InactiveCN103465178AImprove burn resistanceMaintains improved shape stabilityAbrasion apparatusPotassium feldsparCeramic

Owner:上海鑫轮超硬磨具有限公司

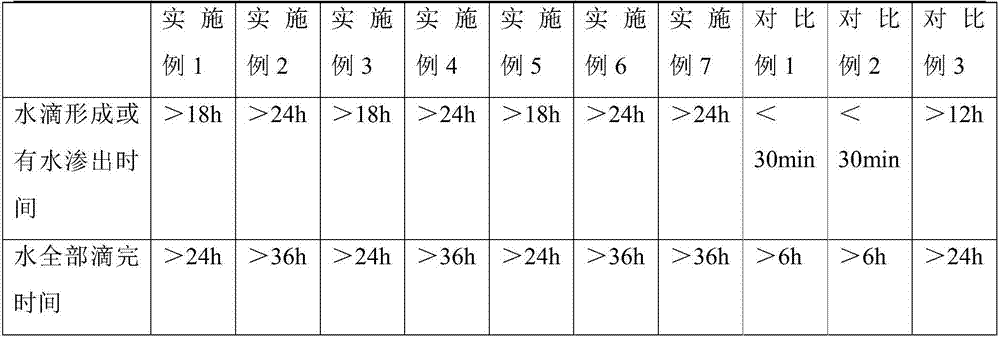

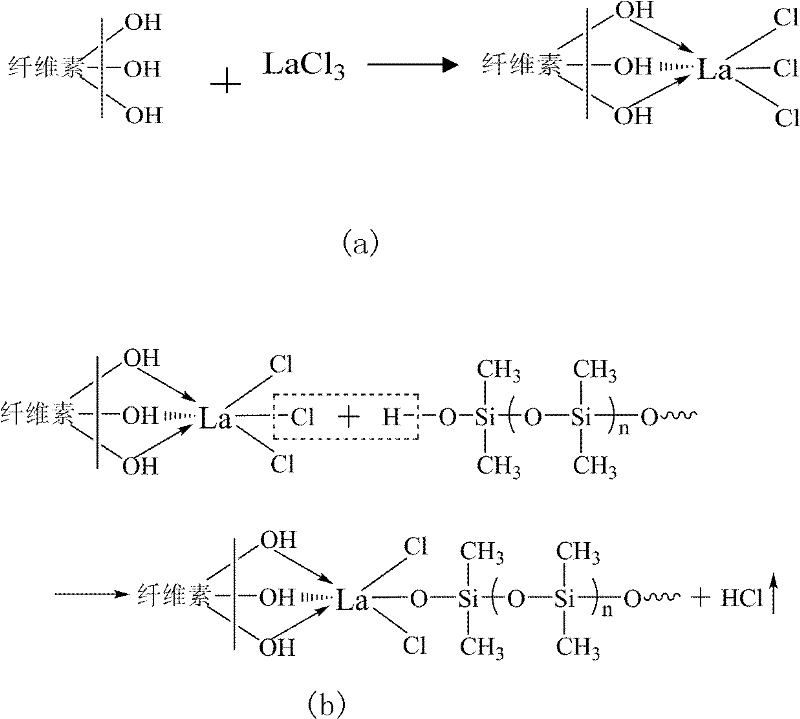

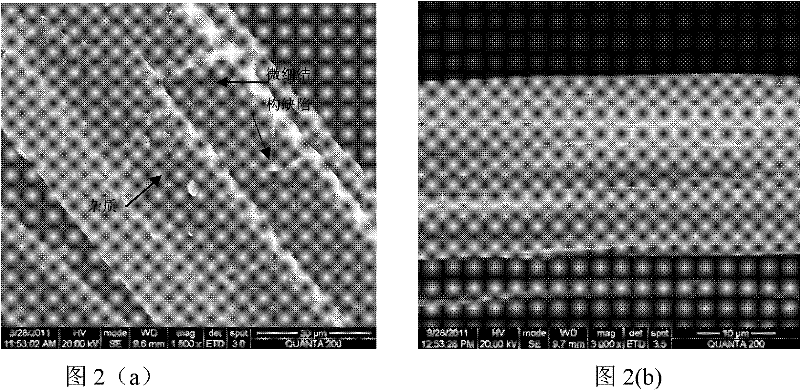

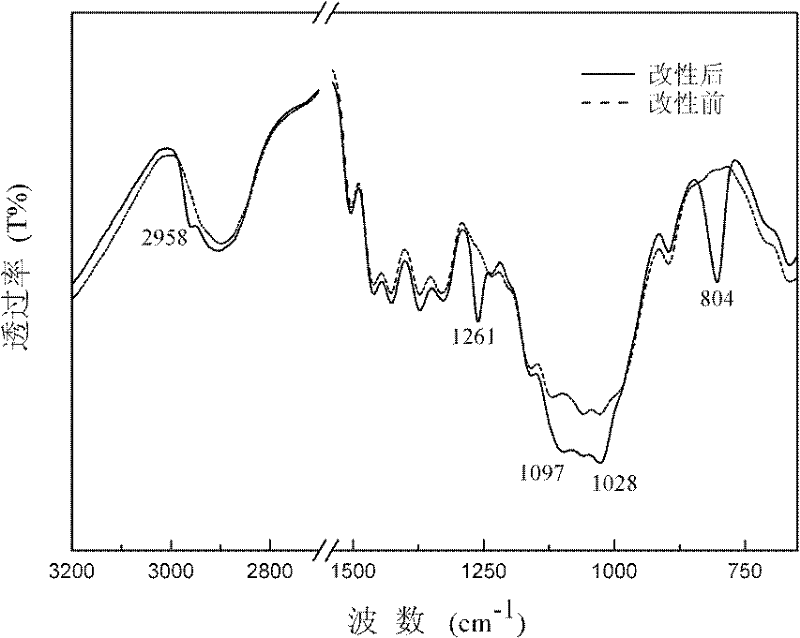

Environmentally friendly modified bast fiber containing functional structure, and preparation method thereof

InactiveCN102251386AThe preparation process is simple and controllableSimple preparation processVegetal fibresFiberHydrophobic polymer

The invention relates to an environmentally friendly modified bast fiber containing a rare earth-polysiloxane functional structure, and a preparation method thereof. The modified bast fiber is a novel bast fiber material prepared from natural bast fiber through a combined effect of rare earth lanthanum ions and silicone oil molecules on the natural bast fiber. The surface of the modified bast fiber does not have impurity phases. The modified bast fiber contains rare earth lanthanum ion-polysiloxane molecule chains with a hydrophobic property and a fire resistant property, thus a surface polarity and a hydrophilic property of the modified bast fiber are changed and the modified bast fiber can be dissolved well in a hydrophobic polymer material. The modified bast fiber does not have only excellent properties but also environmentally friendly and recyclable superiorities, and thus is expected to be composited further with a polymer to form a novel bast fiber-polymer environmentally friendly material with excellent mechanical properties, environmentally friendly characteristics, non-toxic characteristic and fire resistant characteristics. The modified bast fiber can be utilized widely for industries of automobiles, light rail, high-speed rail, office furniture, building and the like. The preparation method of the modified bast fiber containing a rare earth-polysiloxane functional structure has the advantages of simple operation, good suitability for large-scale production, environmentally friendly characteristic and good controllability.

Owner:陈明思

Low-pollution magnesium alloy welding material and preparation process thereof

ActiveCN102554492AHigh melting pointHigh strengthWelding/cutting media/materialsSoldering mediaChemical compositionBoiling point

The invention discloses a low-pollution magnesium alloy welding material and a preparation process of the low-pollution magnesium alloy welding material. The low-pollution magnesium alloy welding material comprises the following chemical compositions in percentage by weight: 5.5-6.5% of Zn, 0.1-0.8% of Nd, 0.20-1.0% of Ca, 0.1-0.9% of Mn, 0.1-0.4% of Al, 90.0-93.5% of Mg, a small amount of metal impurities, including Cu, Ni, Fe and Si. The low-pollution magnesium alloy welding material is prepared by a process comprising the following steps of: (1) smelting and casting; (2) homogenizing; and (3) hot extrusion and pulling and extracting. The low-pollution magnesium alloy welding material has the advantages of low pollution, high strength, simple preparation technology and low cost. By improving the boiling point of the magnesium alloy material, the welding dust can be reduced by more than 50% when being compared with the common magnesium alloy welding materials, and the melting deposition efficiency is higher than 80%.

Owner:DALIAN UNIV OF TECH

Internal combustion engine

ActiveCN106715865AIncrease supplyImprove resistance to burningLiquid coolingCoolant flow controlInternal combustion engineCylinder block

An oil jet (45) is provided in each cylinder in the lower part of a cylinder block (5). The oil jet (45) has a first injection nozzle (46) that injects lubricating oil toward the back of a piston (2) when a pressure control valve (51A) opens and a second injection nozzle (47) that injects lubricating oil toward the connection part of a lower link (7) and a control link (9) from the side of the control link (9), which is a direction perpendicular to the axis of a crankshaft, when a pressure control valve (51B) opens. Because of these features, lubricating oil can be continuously supplied to the connecting portions of the lower link (7) and the control link (9).

Owner:NISSAN MOTOR CO LTD

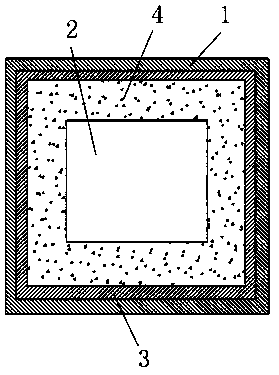

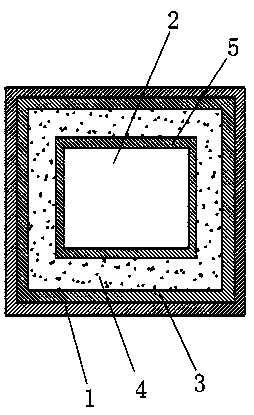

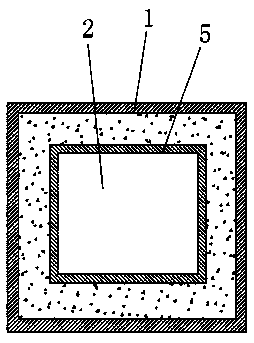

Structure of fire-proof explosion-proof type new energy vehicle battery

InactiveCN109256502AImprove securityEnsure safetyBattery isolationSurgical veterinaryPtru catalystNew energy

The invention discloses a structure of a fire-proof explosion-proof type new energy vehicle battery, comprising a sealed shell and a battery body arranged in the sealed shell. A fire-proof material filling cavity is arranged between the sealed shell and the battery body, and the fire-proof material filling cavity is filled with a dry powder extinguishing agent. A fire-proof plate is fixed on the inner surface of the sealed shell, and a filling cavity of the fire-proof material is arranged between the fire-proof plate and the battery body. The sealing shell material sequentially comprises a metal layer from the inside to the outside, polypropylene plastic layer, ceramic silicone rubber layer, wherein the ceramicized silicone rubber layer is formed in an amount of parts by weight of the ceramic silicone rubber layer, It is prepared from the following raw materials: 100 parts of silicone rubber, 40-80 parts of porcelain filler, 5-20 parts of flux, 0. 2-1.5 parts of platinum catalyst, 2-8parts of hydroxyl silicone oil and 2-4 part of vulcanizing agent, wherein that porcelain filler is a mixture of aluminum silicate fiber and acicular wollastonite, wherein the mass ratio of aluminum silicate fiber to acicular wollastonite is 15-25:30-40.

Owner:IANGSU COLLEGE OF ENG & TECH

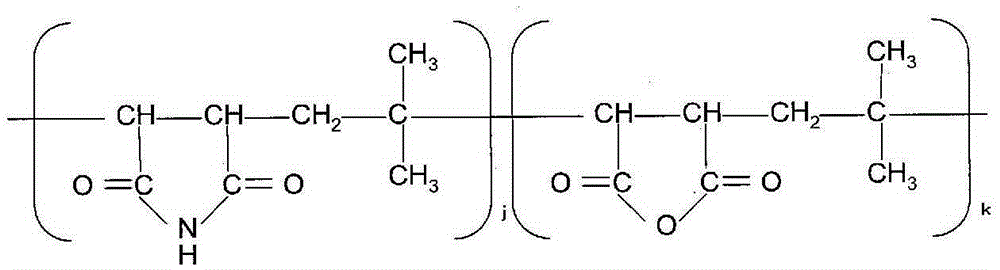

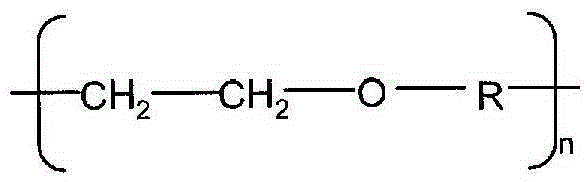

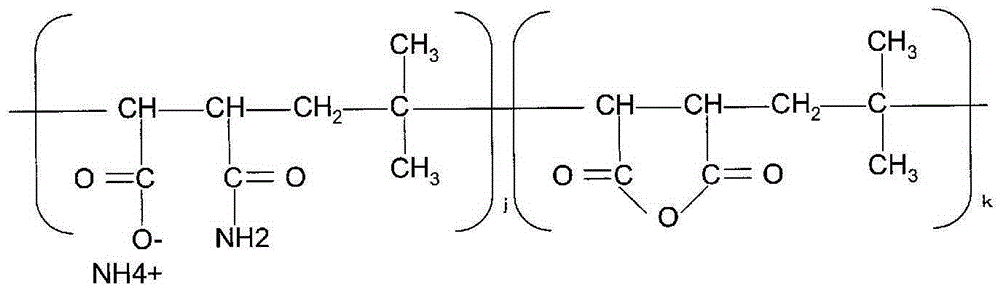

Aqueous lubricant for plastic working of metal material and having superior gas clogging resistance and post-moisture absorption workability

ActiveCN105358664AEasy to processImprove resistance to burningAdditivesBase-materialsSolid componentSolid fraction

[Problem] The present invention resolves the problems of conventional technology and has as the objective the providing of an aqueous lubricant that is for plastic working of a metal material and having superior gas clogging resistance, post-moisture absorption workability, and high workability at least equivalent to that of conventional applied aqueous lubricants and lubrication processing such as zinc phosphate + soap processing. [Solution] This aqueous lubricant for plastic working of a metal material is characterized by containing, in an aqueous medium: (A) a polymer, and / or a salt thereof, containing a carboxylic acid or a derivative thereof as a constituent monomer; (B) a silicon or phosphorus oxo acid of tungsten or a condensate and / or salt thereof; (C) the hydroxide of an alkali metal; and (D) a lubricating component. The aqueous lubricant for plastic working of a metal material is further characterized in that the solid fraction weight ratio (A) / [(A)+(B)+(C)+(D)] of component (A) and component (B), component (C), and component (D) is 0.05-0.4.

Owner:NIHON PARKERIZING

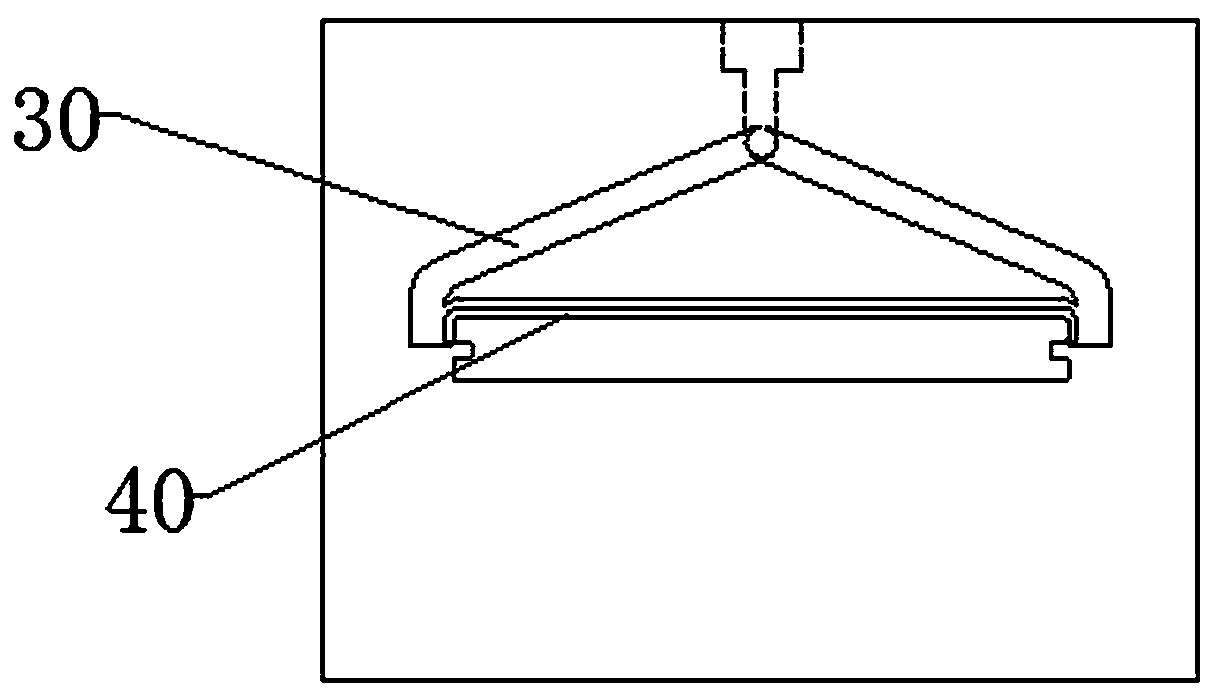

Printing plate with 3D effect and preparation method thereof

InactiveCN111231436ASimple production processIncrease productivityLamination ancillary operationsSynthetic resin layered productsUv protectionEmbossing

The invention relates to a printing plate, in particular to a printing plate with a 3D effect. The invention belongs to the technical field of plate manufacturing. The invention discloses a printing plate with a 3D effect. The printing plate comprises a base material layer, a color layer deposited on the base material layer and a UV protection layer covering the color layer. Wherein the base material layer comprises a core layer and a background film layer compounded with the core layer; textures of wood grains, decorative patterns or patterns are also embossed on the background film layer. According to the invention, the operation of engraving and then printing is subversively provided, the background film layer is pasted on the PE-based core material through the pasting method, then engraving and printing are carried out, and finally the UV protective layer is coated, so that compared with the prior art, the production process is greatly simplified, and the production efficiency is greatly improved; the product prepared by the method has the advantage of good 3D visual effect.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

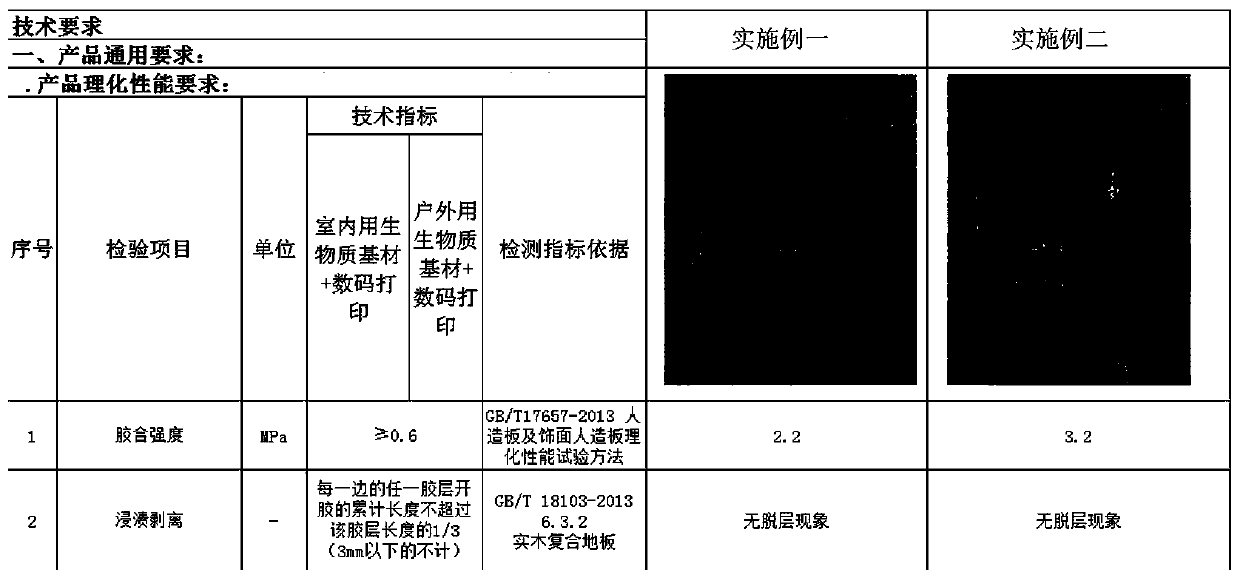

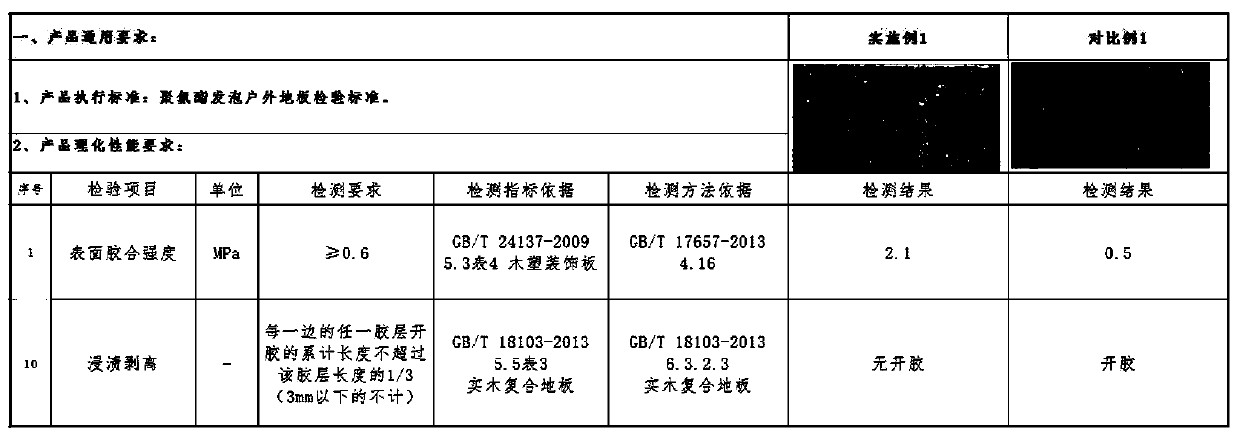

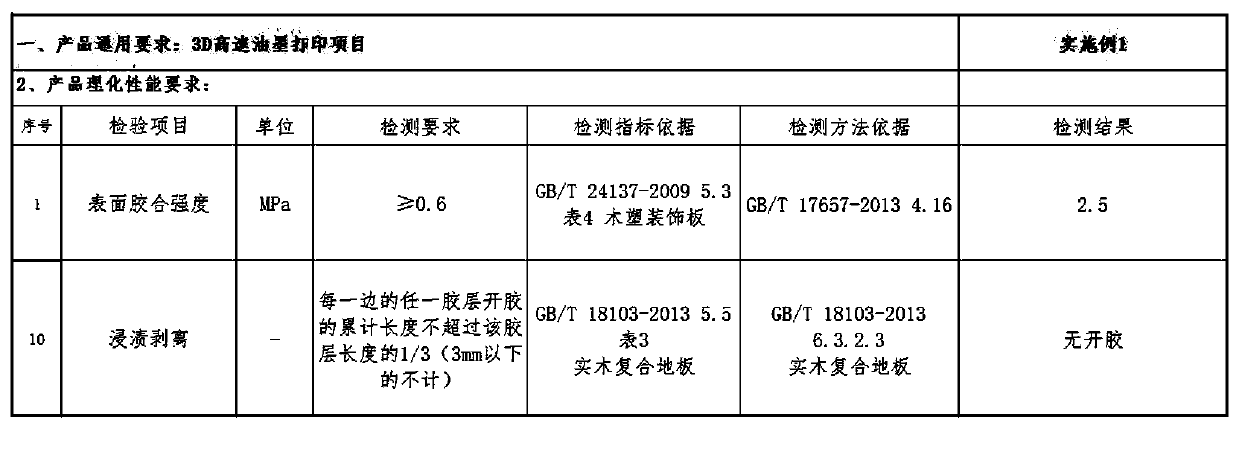

PU plate and preparation method thereof

ActiveCN111231463AAvoid crackingHigh bonding strengthSynthetic resin layered productsFlat articlesPlastic materialsBonding strength

The invention relates to the technical field of wood-plastic material production, in particular to a PU plate and a preparation method. The PU plate comprises an unfoamed PU surface layer and a foamedPU core layer, and further comprises a PU fusion layer located between the PU surface layer and the PU core layer. Wherein the PU fusion layer comprises a part of PU surface layer and a part of PU core layer, and a part of PU surface layer permeates into a part of PU core layer, so that the PU surface layer and the PU core layer form a continuous phase. PU plate, the PU plate is provided with therigid PU foam core and the flexible PU surface layer, and the PU fusion layer is formed between the PU surface layer and the PU foam core, so that the PU surface layer and the PU foam core form a continuous phase, the bonding strength between the PU foam core and the flexible PU surface layer is greatly improved, and the PU plate is not easy to crack.

Owner:ANHUI SENTAI WPC GRP CO LTD

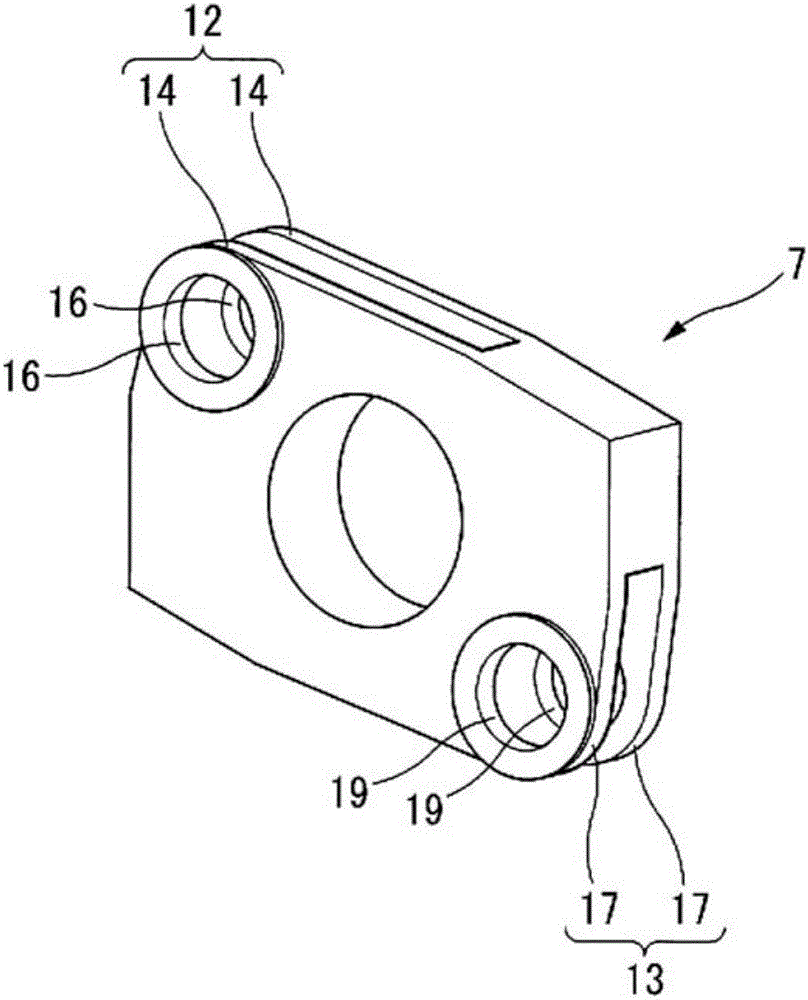

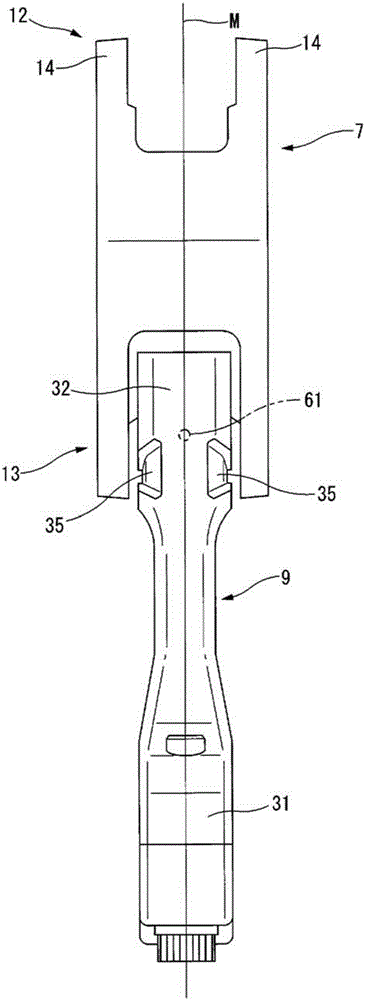

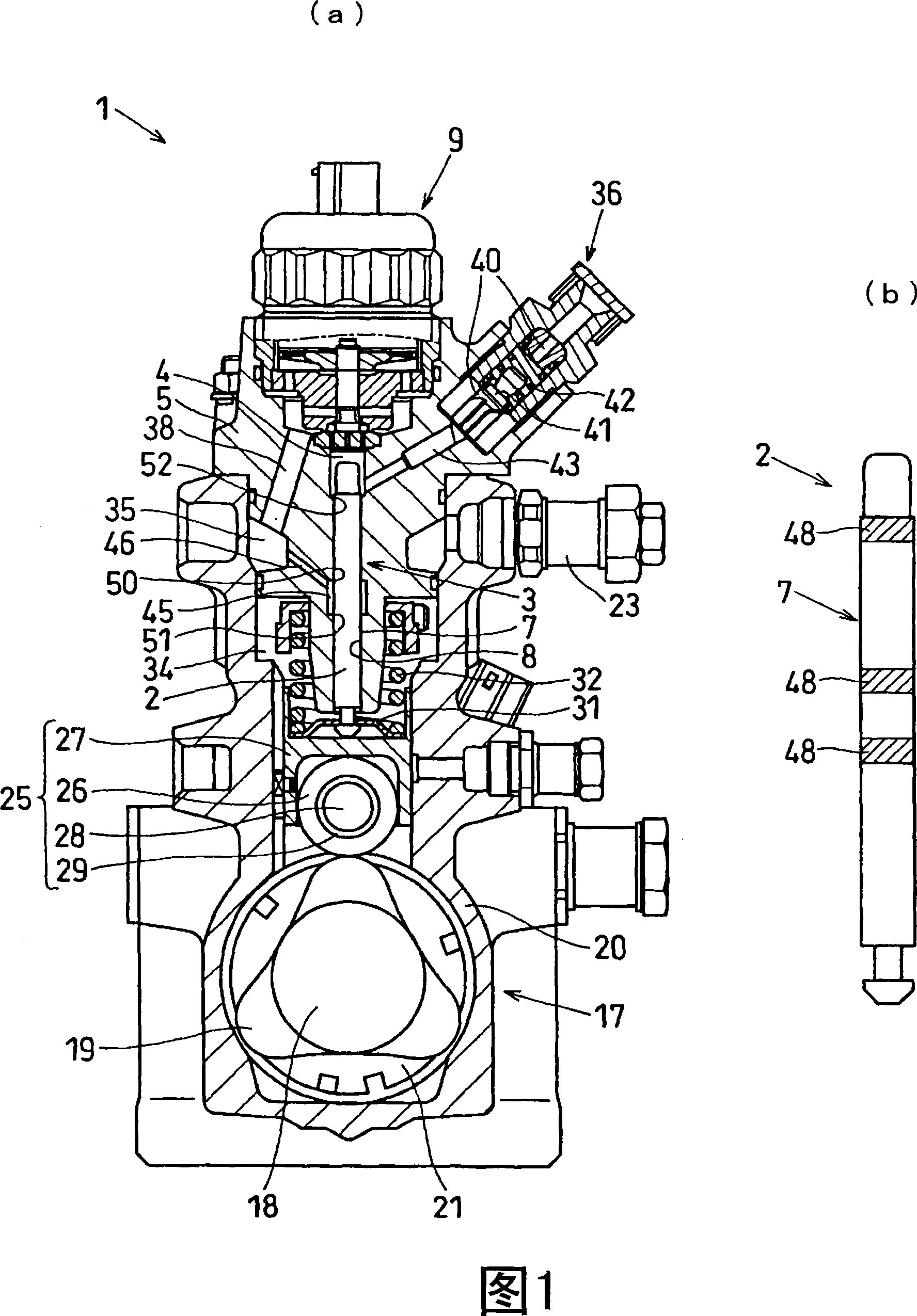

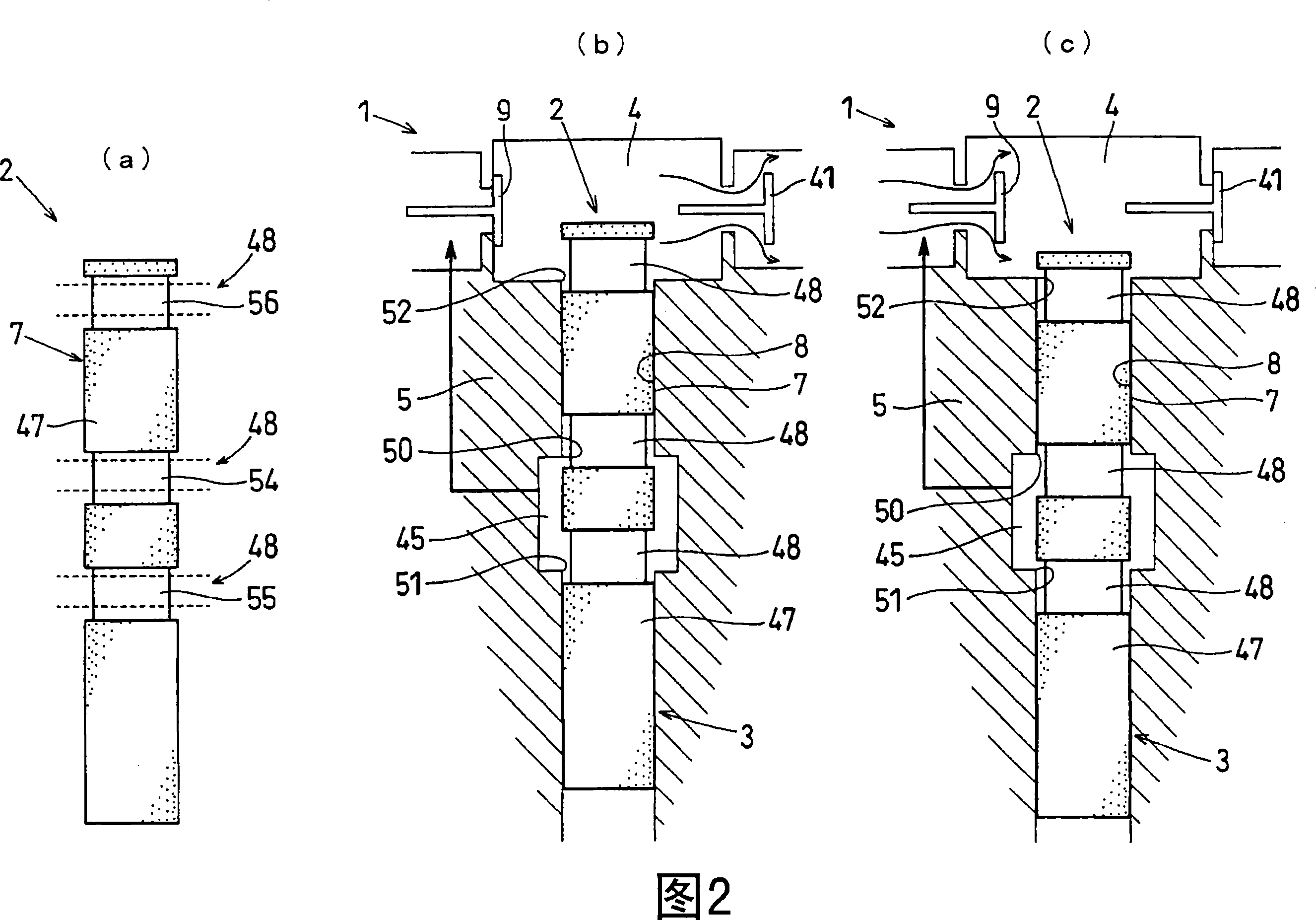

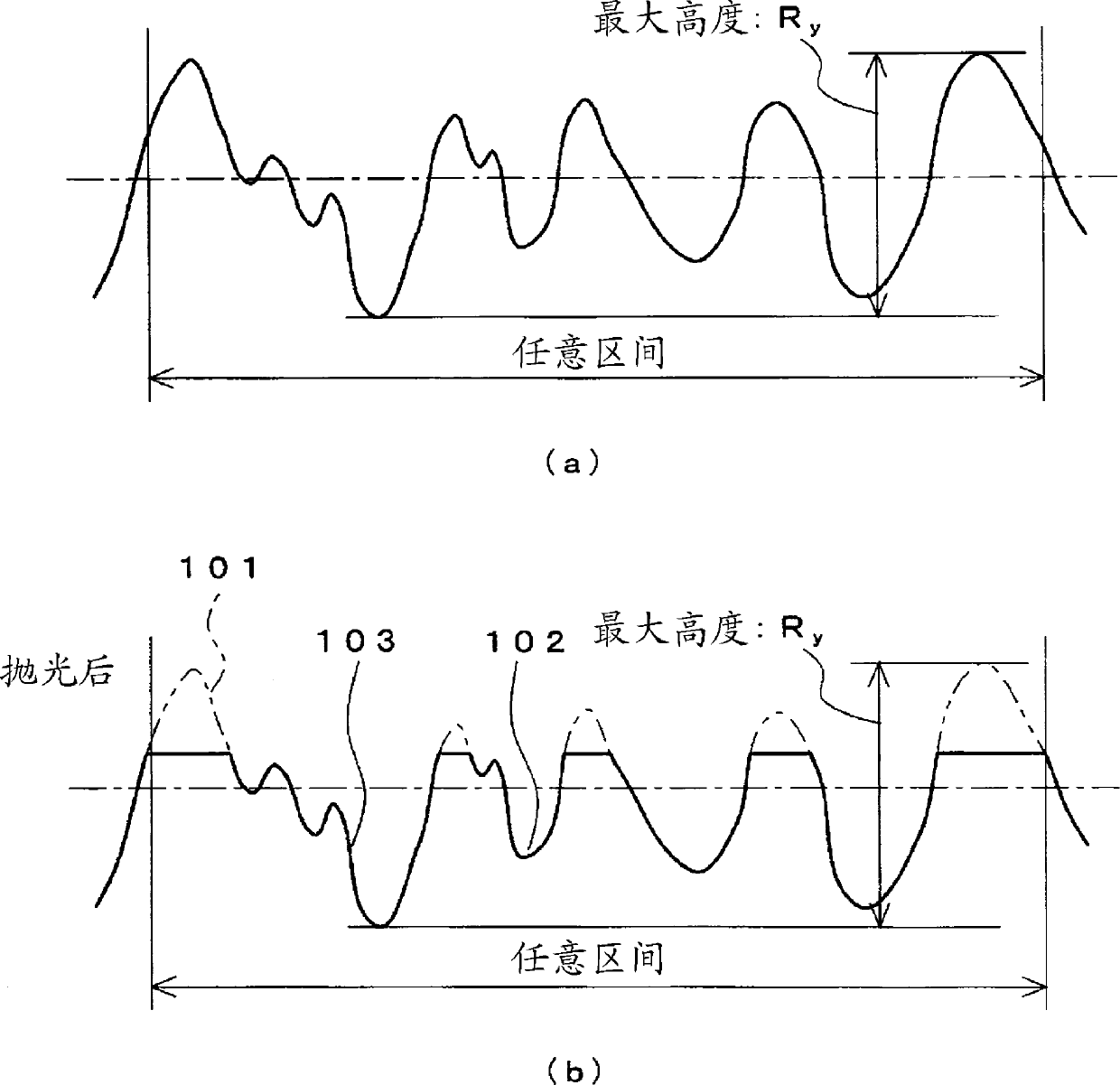

Supply pump

InactiveCN101191449ADoes not damage the peripheral surfaceDoes not damage the inner surface of the cylinderMachines/enginesFuel injecting pumpsSliding contactBiomedical engineering

The present invention provides a supply pump (1), in the supply pump (1), on the outer peripheral surface (7) subjected to coating treatment, a non-treatment part ( 48). The non-processing part (48) is arranged such that it includes a groove upper edge sliding contact portion (54) that is in sliding contact with the upper edge (50) of the groove (45), a groove that is in sliding contact with the lower edge (51) of the groove (45). At least one of the groove lower edge sliding contact portion (55) and the pressurization chamber lower edge sliding contact portion (56) slidingly contacting the lower edge (52) of the pressurization chamber (4). Thereby, the surface region with a high possibility of burn can be recessed with respect to the surface of the coating (47). Therefore, irrespective of the action of external force, the burn resistance of the outer peripheral surface (7) and the inner peripheral surface (8) can be improved. Moreover, since the non-processed part (48) is provided by masking, it is possible to provide a concave depression without damaging the outer peripheral surface (7) and the inner peripheral surface (8).

Owner:DENSO CORP

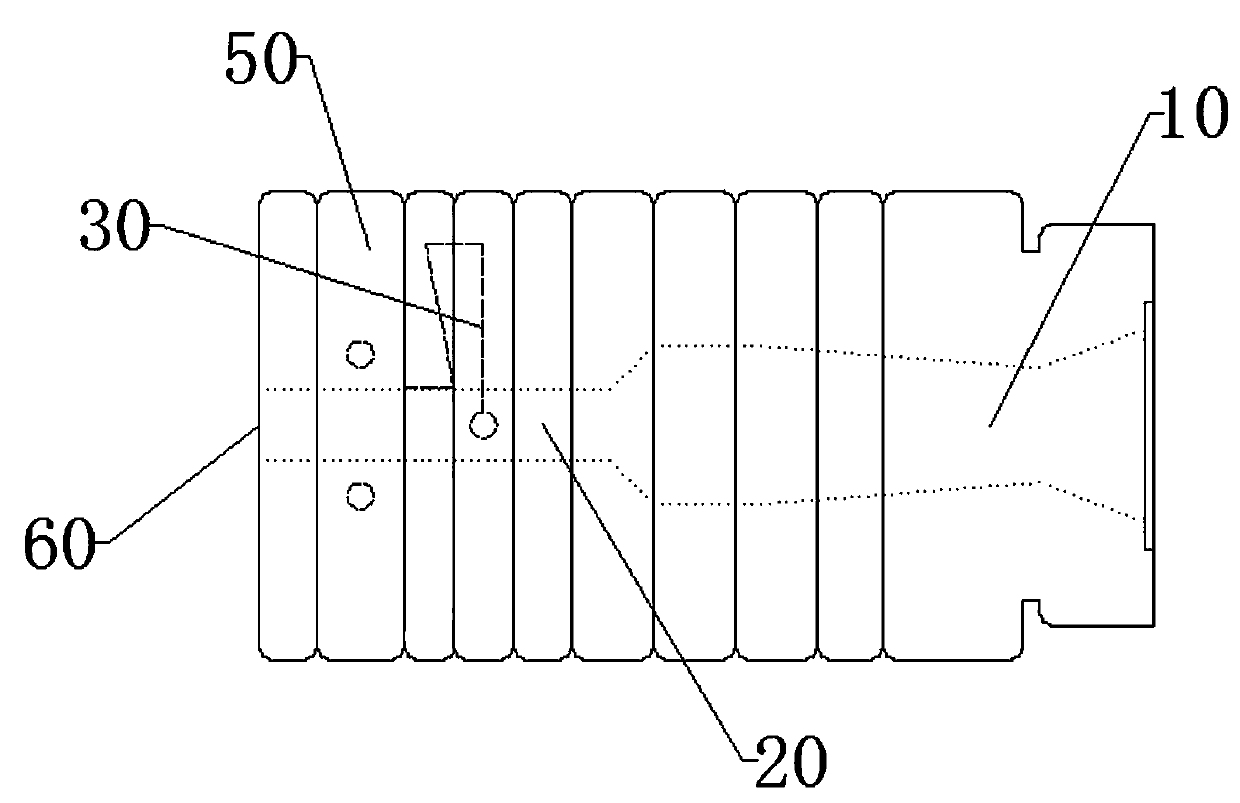

SPC-based 3D printing plate and preparation method thereof

InactiveCN111231430ASimplify the production processIncrease productivityLamination ancillary operationsSynthetic resin layered productsPolymer chemistryEngineering

The invention relates to an SPC-based 3D printing plate, and belongs to the technical field of plate manufacturing. The board comprises an SPC base material layer, a 3D printing color layer and a UV protection layer. Wherein the base material layer comprises an SPC core layer and a background film layer which is compounded with the SPC core layer through co-extrusion; wood grains, decorative patterns or pattern textures are also embossed on the background film layer; or the SPC base material layer comprises an SPC core layer and a background film layer which is compounded with the SPC core layer through online pressing, and the SPC base material layer further comprises a resin concave-convex effect layer which is arranged between the color layer and the UV protective layer. According to the invention, the background film layer which can be made of a PVC material is compounded on the SPC base material layer, so that (1) the PVC board base material is effectively replaced; the method comprises the following steps of (1) preparing a PVC board base material, (2) coating UV primer on the upper surface of the PVC board base material, (3) drying and curing the UV primer, (4) coating whiteUV finish paint, and (5) curing and drying UV white paint, so that the production process is simplified, and the production efficiency is improved.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

Silver tungsten carbide-molybdenum composite electrical contact material as well as skeleton powder and preparation method thereof

InactiveCN111001801AImprove adverse effectsImprove wettability relationshipElectric switchesLow voltageMolybdenum trioxide

The invention discloses a silver tungsten carbide-molybdenum composite electrical contact material as well as skeleton powder and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of ball-milling and mixing ultrafine tungsten carbide powder and nano molybdenum trioxide powder; enabling molybdenum trioxide to react with free carbon in tungsten carbide in a high-temperature inert atmosphere to form molybdenum dioxide, discharging carbon dioxide, mixing tungsten carbide, molybdenum trioxide and molybdenum dioxide mixed powder with a certain amount of pure silver powder, and sintering the mixture in a high-temperature reducing atmosphere to convert molybdenum dioxide and molybdenum trioxide powder into molybdenum powder; and then obtaining the compact ultrafine silver tungsten carbide-molybdenum composite material by adopting conventional pressing, sintering and infiltration processes. Compared with traditional silver tungsten carbide, the ultrafine silver tungsten carbide-molybdenum composite electrical contact material eliminates negative effects caused by free carbon, is higher in product compactness and strength, has very good wear resistance and burning loss resistance, and has a longer electrical life when used in a low-voltage electrical appliance.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

High-strength heat-resisting mica tape production technology

InactiveCN110406237AHigh strengthStrong resistance to combustionLaminationLamination apparatusWork in processMica

The invention discloses a high-strength heat-resisting mica tape production technology. The high-strength heat-resisting mica tape production technology comprises the following steps that mica paper is reinforced, a liquid reinforced raw material is prepared, the upper surface and the lower surface of the mica paper are sprayed, the mica paper is dried, cooled and wound after spraying is completed, and the reinforced mica paper is obtained; turning and gluing are carried out, and the upper surface and the lower surface of the reinforced mica paper are coated with binding agents; a manufacturing layer is bonded, and glass fiber cloth is attached to the upper surface and the lower surface of the mica paper to obtain a semi-finished mica tape; drying is carried out, and the semi-finished micatape is placed into an oven for drying; and winding is carried out after cooling, the wound mica tape blank is divided and cut into a band shape and is wound through a dividing and cutting machine, and the high-strength heat-resisting mica tape is obtained. According to the high-strength heat-resisting mica tape production technology, the mica tape manufactured by adopting the technology has highstrength and high combustion performance, has better humidity resistance at the same time, and can be in humid environments for a long time and cannot be corroded and go bad.

Owner:平江县惠源云母制品有限公司

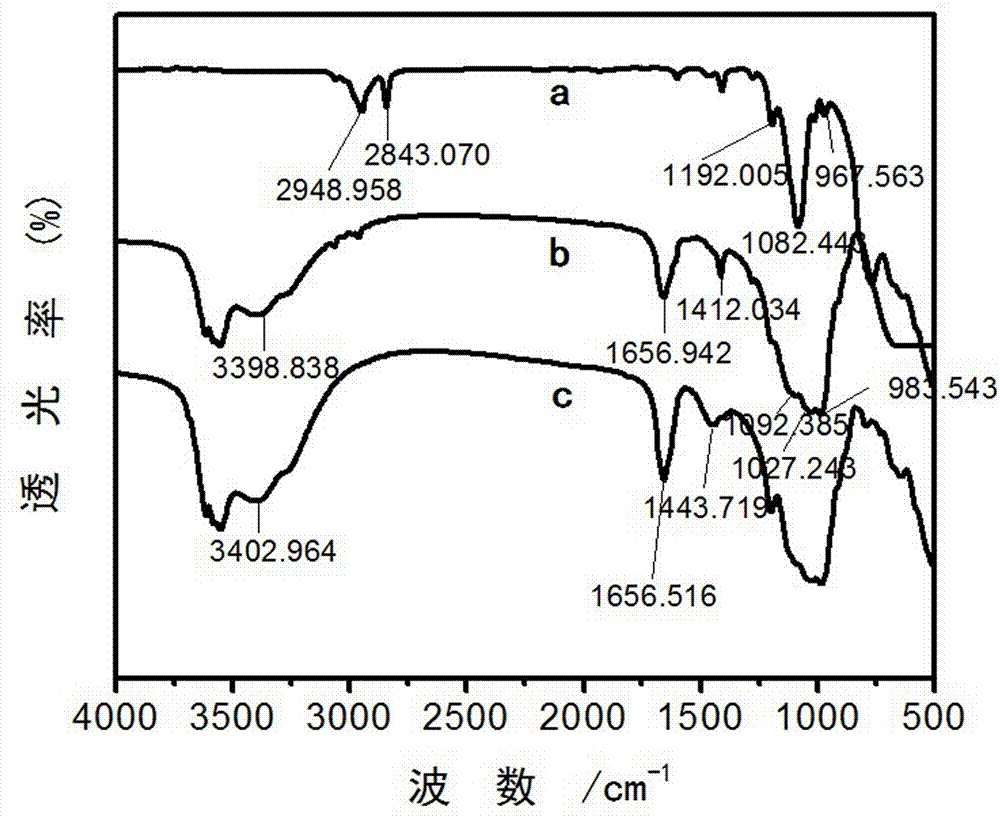

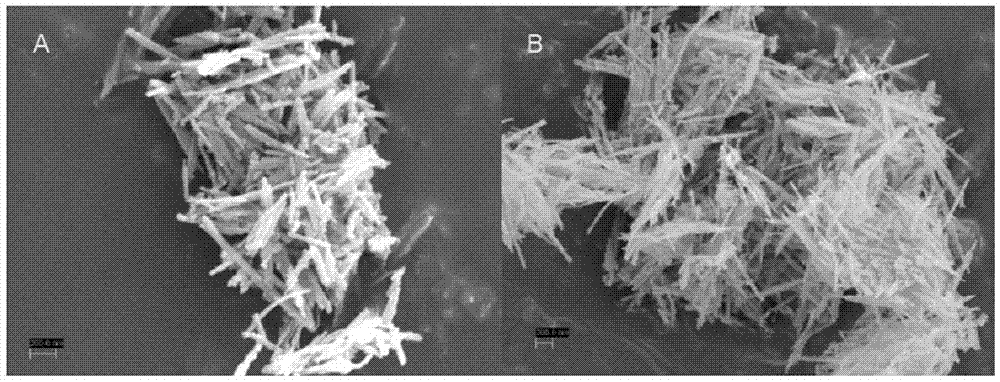

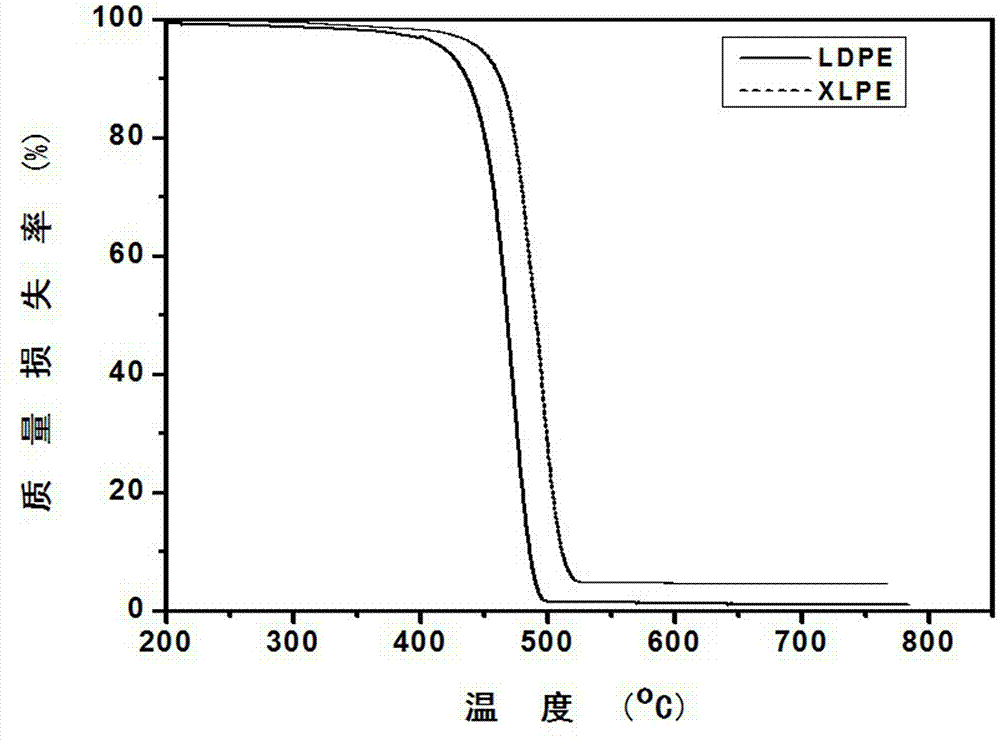

Palygorskite silane crosslinking agent preparation method and application of palygorskite silane crosslinking agent in low-density polyethylene crosslinking

The invention provides a palygorskite silane crosslinking agent preparation method and belongs to the field of high polymer materials. The method includes: dispersing activated palygorskite in an ethyl alcohol-water mixed solution, ultrasonic dispersing, adding an acidulated silane crosslinking agent, stirring, centrifuging, drying, conducting soxhlet extraction in a xylene solution, drying and grinding to obtain the palygorskite stem grafting silane crosslinking agent. Infrared absorption spectrum and scanning electron microscope analysis shows that the silane crosslinking agent is grafted on the surface of palygorskite clay, and a part of activated crosslinking group is reserved. Compared with vinyl trimethoxy silane of a common crosslinking agent of density polyethylene, under the condition of the same adding quantity and same processing technology, the palygorskite silane crosslinking agent is applied to crosslinking of the low-density polyethylene, and the mechanical property and gel content of the low-density polyethylene are improved. Meanwhile, combustion performance and thermal stability of a low-density polyethylene material are improved, the cost of the low-density polyethylene material is reduced, and the palygorskite silane crosslinking agent preparation method and the application have good application prospects.

Owner:兰州众邦电线电缆集团有限公司

High-temperature-resistant flame-retardant conveying belt

InactiveCN104650469AExtended service lifeImprove high temperature resistanceConveyorsEngineeringTriallyl isocyanurate

The invention provides a high-temperature-resistant flame-retardant conveying belt, belonging to the technical field of conveying belts and solving the problems of poor high-temperature-resistant effect and burning-resistant effect and the like of the traditional structure. The working surface coverage glue of the conveying belt is prepared from the following raw materials in parts by weight: 0-100 parts of ethylene-propylene diene copolymer, 0-100 parts of reclaimed ethylene-propylene diene copolymer, 1-15 parts of zinc oxide, 1-3 parts of stearic acid, 2-10 parts of dicumyl peroxide, 0-3 parts of triallyl isocyanurate, 1-10 parts of magnesium oxide, 1-3 parts of anti-aging agents MB, 1-3 parts of anti-aging agents RD, 1-15 parts of solar oil 2280, 1-10 parts of phenolic resin BN-1, 0-50 parts of carbon black N220 / N330, 0-50 parts of carbon black N660, 0-20 parts of white carbon black, 0-50 parts of silicon-aluminum carbon black / pottery clay / kaolin, 0-20 parts of composite flame retardants, 0-20 parts of ammonium polyphosphate and 0-10 parts of high-temperature stabilizers. The high-temperature-resistant flame-retardant conveying belt provided by the invention has the advantages of enhancing the high-temperature-resistant effect and burning-resistant effect, greatly prolonging the service life of a belt, greatly reducing the production cost, and the like.

Owner:ZHEJIANG SANJIA RUBBER BELT

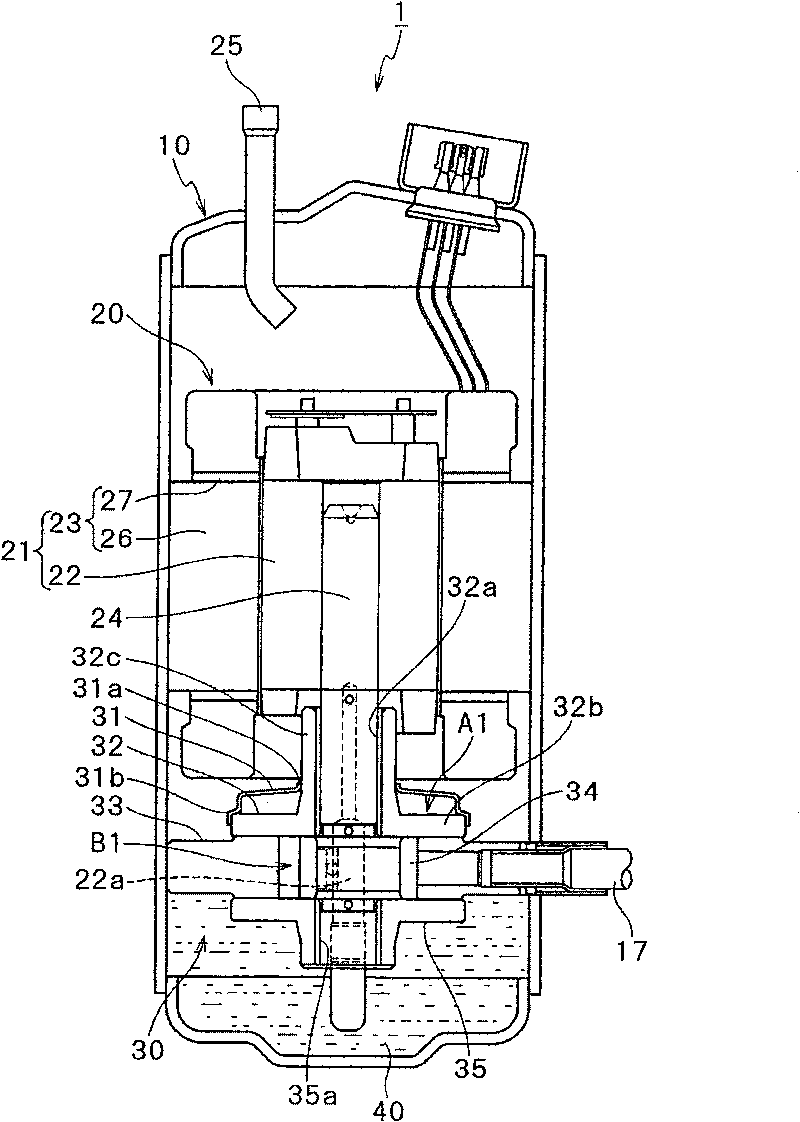

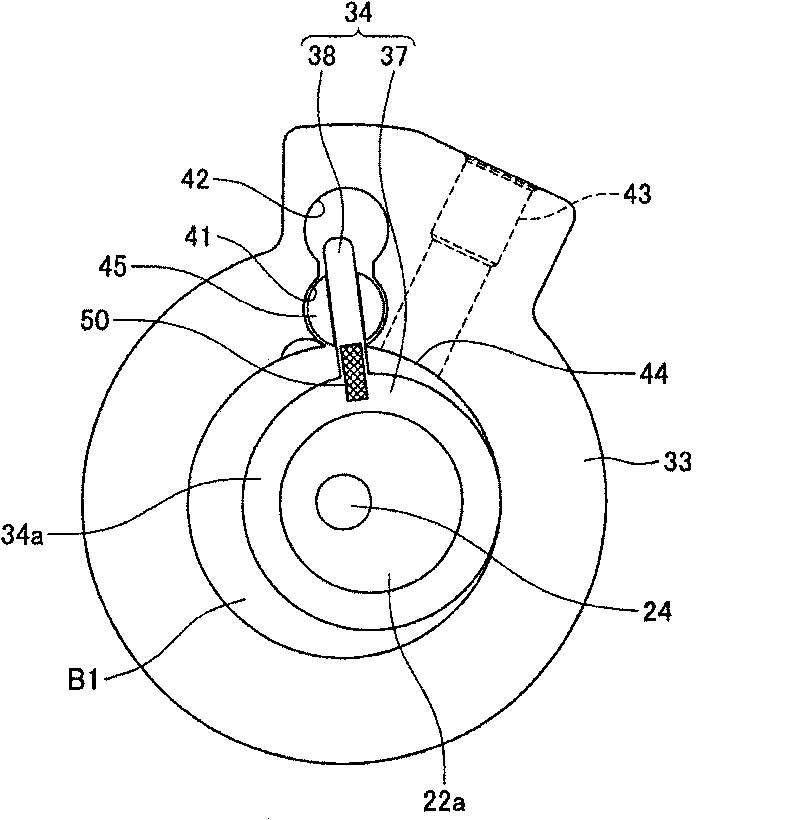

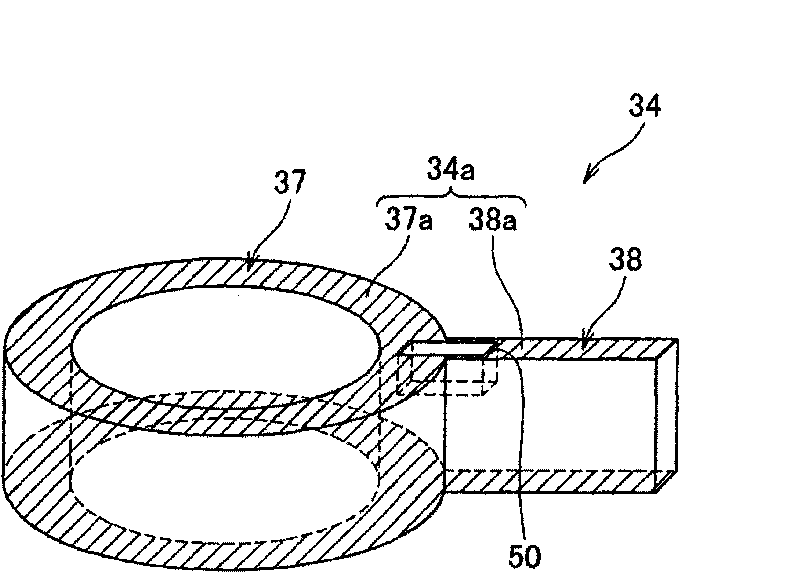

Rotary compressor

ActiveCN101725531AImprove COPInhibition of performance degradationRotary piston pumpsRotary piston liquid enginesHigh pressure chamberEngineering

The invention provides a rotary compressor capable of improving piston end face burn endurance and increasing COP. The rotary compressor (1) comprises a cylinder (33) disposed between a front sealing head and a rear sealing head; a piston (34) is disposed inside the cylinder chamber (B1) of the cylinder (33); the piston (34) has a ring shaped roller (37); and a blade (38) extended from the outer circumferential surface of the roller (37) in a holding hole (41); the roller (37) and the blade (38) divides the cylinder chamber (B1) into a high pressure chamber and a low pressure chamber; and a concave portion (50) is formed on the upper surface (34a) of the piston (34).

Owner:DAIKIN IND LTD

Monolithic Pd catalyst for purifying industrial organic waste gas and preparation method thereof

InactiveCN103240083BImprove oxidation capacityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumHeat stability

The invention relates to a monolithic Pd catalyst for catalytic purification of industrial organic waste gas and a preparation method thereof. The catalyst comprises a cerium-zirconium solid solution, La2O3, Nb2O5, Al2O3, noble metal Pd and a cordierite-honeycomb ceramic supporter. The preparation method comprises the following step: coating the cerium-zirconium solid solution, La2O3, Nb2O5, a pseudo-boehmite binding agent and the noble metal Pd on the surface of the cordierite-honeycomb ceramic supporter in twice, wherein the total mass of the cerium-zirconium solid solution, La2O3, Nb2O5 and Al2O3 coated for each liter of catalyst is 40g; and the loading amount of Pd contained in each liter of catalyst is 0.3g. The catalyst can prevent surface carbon deposition, and has satisfactory burning resistance and heat stability.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

High-temperature-resistant conveyor belt cover rubber for cement plant and preparation process thereof

InactiveCN111100387AImprove high temperature resistanceGood regeneration performancePolymer scienceVulcanization

The invention discloses high-temperature-resistant conveyor belt cover rubber for a cement plant and a preparation process thereof. The invention belongs to the technical field of conveying belts, andthe conveyor belt cover rubber comprises, by mass, 88-93 parts of ethylene propylene diene monomer, 8-12 parts of chloroprene rubber, 8-10 parts of high-temperature-resistant resin, 6-8 parts of softener, 30-40 parts of carbon black, 4-5 parts of nano zinc oxide, 1-2 parts of stearic acid, 10-20 parts of high-temperature-resistant filler, 5-7 parts of vulcanizing agent, 2-3 parts of accelerant, 3-4 parts of anti-aging agent and 2-3 parts of antioxidant. The preparation process comprises the following steps: gluing the ethylene-propylene-diene monomer and the neoprene, mixing into master batch, controlling the temperature to be 60-75 DEG C, then adding the high-temperature-resistant resin, the zinc oxide, the stearic acid, the accelerant, the anti-aging agent, the thermal oxidant, the carbon black, the softener and the high-temperature-resistant filler step by step, mixing, controlling the mixing temperature to be less than 120 DEG C, and finally controlling temperature to 90 DEG C formolding vulcanization. The prepared cover rubber can be used for a long time at the temperature of 180 DEG C, and has excellent high temperature resistance and reproducibility.

Owner:HEBEI JIUZHOU RUBBER BELTS

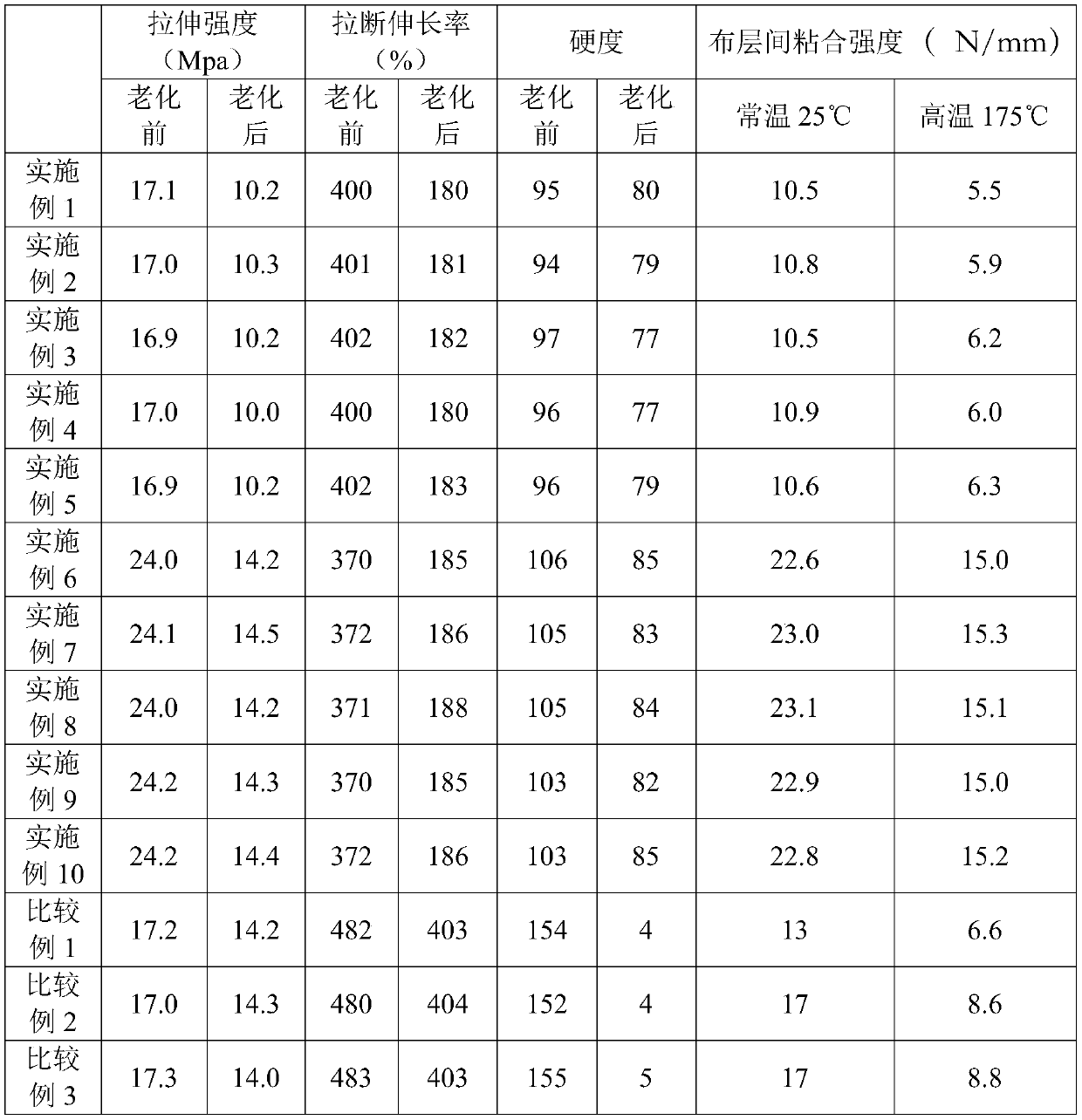

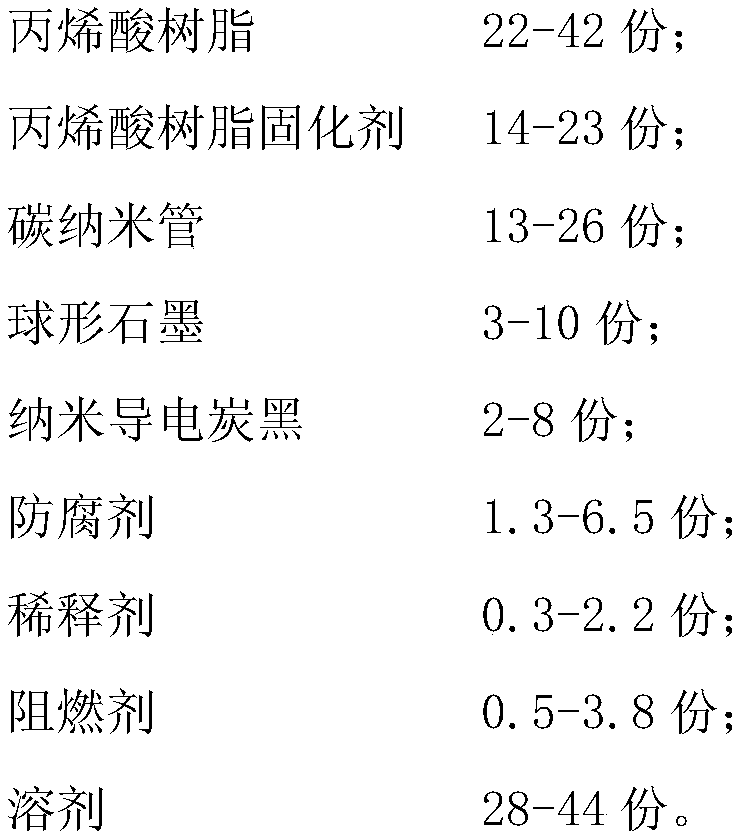

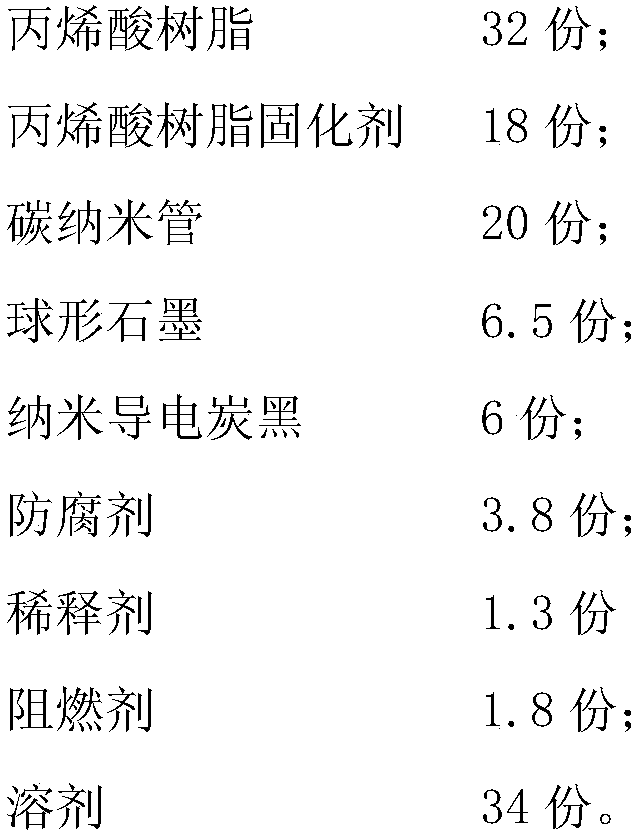

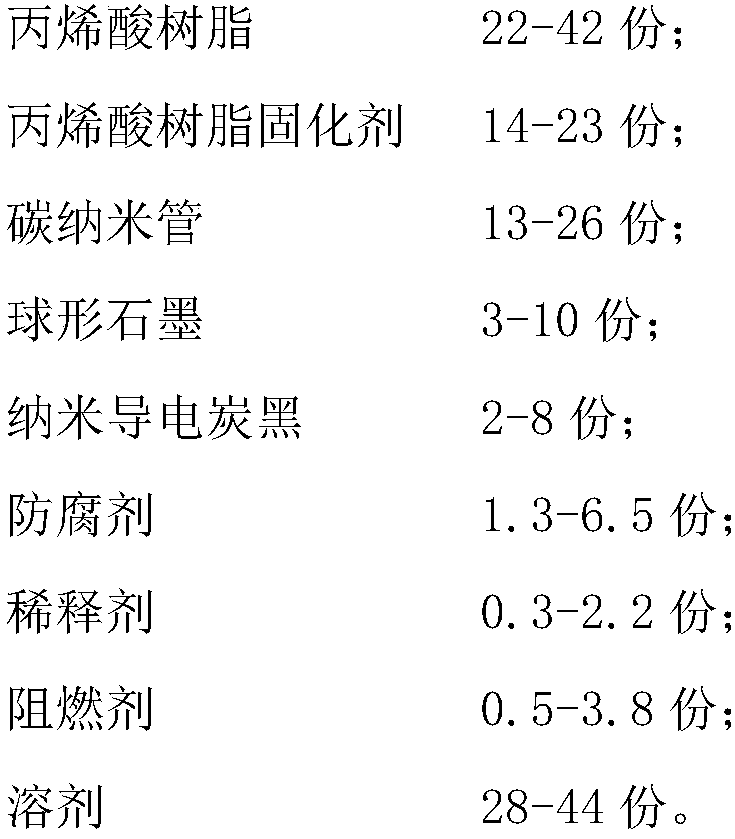

Conductive anticorrosion coating and preparation method thereof

InactiveCN108250870AImprove corrosion resistanceGood construction technologyFireproof paintsAnti-corrosive paintsAcrylic resinCarbon nanotube

The invention discloses a conductive anticorrosion coating and a preparation method thereof. The coating is mainly prepared from acrylic resin, an acrylic resin curing agent, a carbon nanotube, spherical graphite, nanometer conductive carbon black, an anticorrosion agent, a diluent, a flame retardant and a solvent. The conductive anticorrosion coating adopts a spraying or brushing mode to preparea conductive and anticorrosion coating layer on the surface of a well-treated workpiece, and can be widely applied to metal structural pieces such as grounding grid devices in the power industry and oil storage devices in the petrochemical industry, achieves the functions of electricity conduction, static electricity conduction and corrosion resistance, and meets the field service requirement. Thepreparation technology of the coating is simple, and industrialized production can be achieved easily.

Owner:尚福平

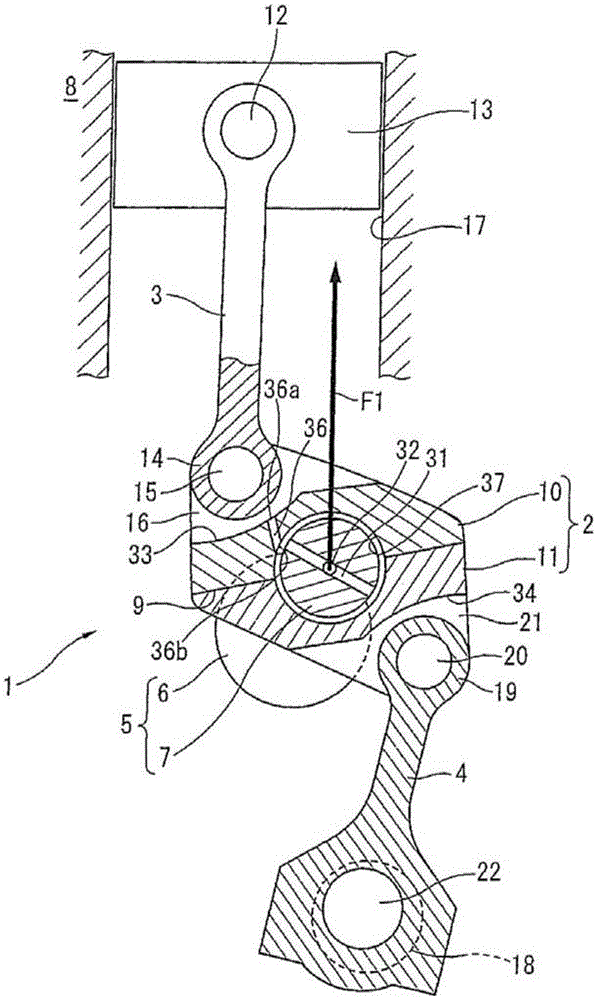

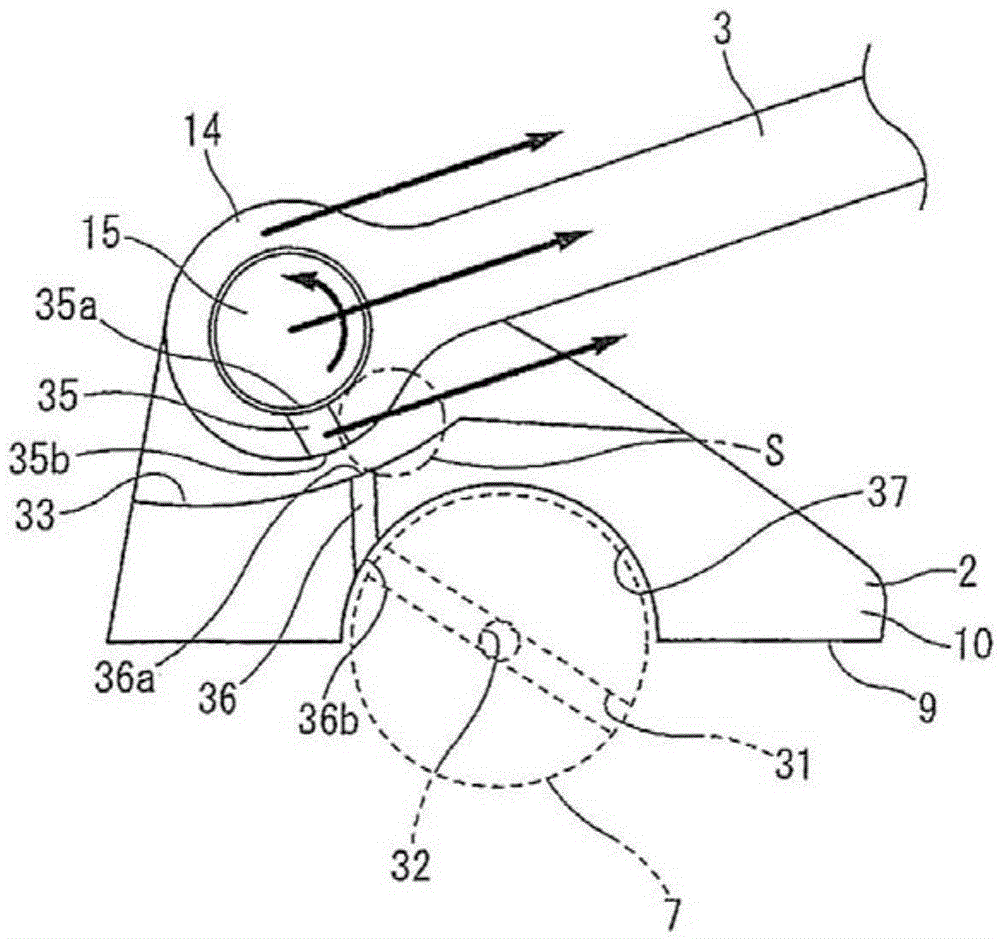

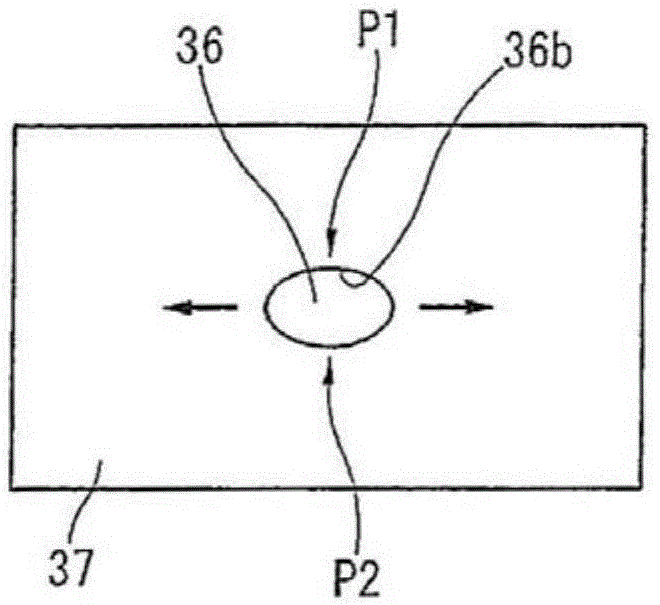

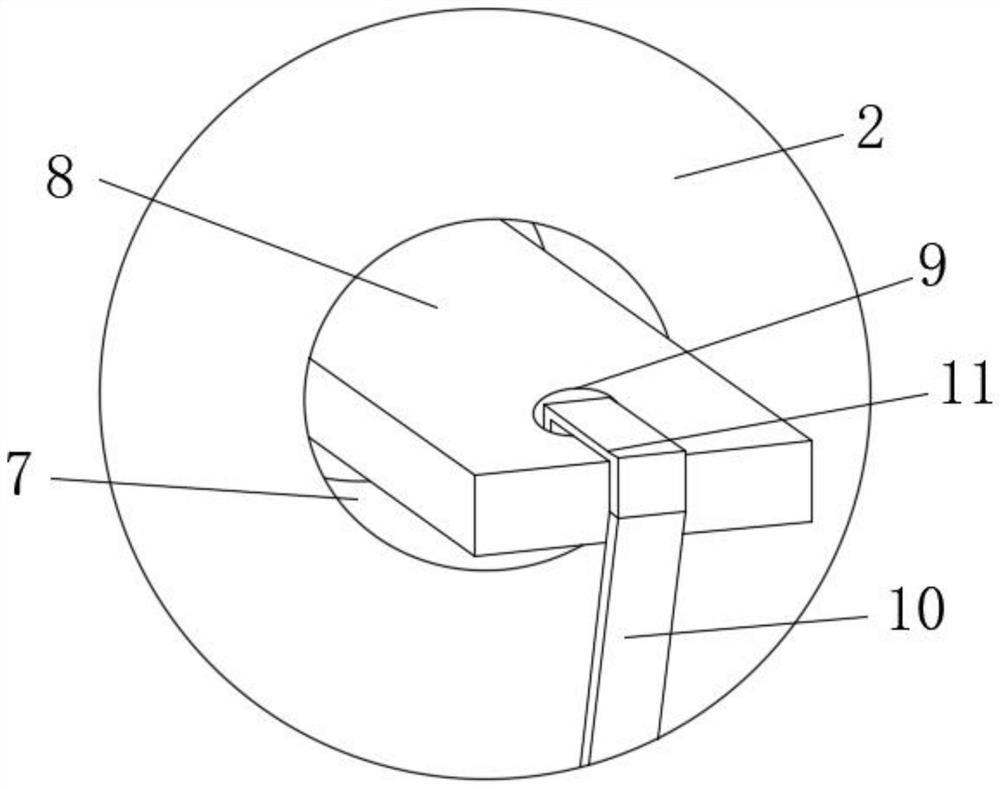

Double-link piston crank mechanism for internal combustion engine

ActiveCN105579684AImprove resistance to burningCrankshaftsConnecting rodsInternal combustion engineBearing surface

The opening (35a) on one end side of a pin-boss oil passage (35) opens to the inner-circumferential surface of a pin boss part (14) of an upper link (3), while the opening (35b) on the other end side thereof opens to the outer-circumferential surface of the pin boss part (14) of the upper link (3). A lower-link oil passage (36) has an opening (36a) on one end side thereof which opens to a lower-link (2) pin-boss-facing surface (33) facing the outer-circumferential surface of the pin boss part (14) of the upper link (3), and an opening (36b) on the other end side thereof which opens to a crank-pin-bearing surface (37). The lower-link oil passage (36) is formed so as to point, when at a prescribed crank angle, to an end edge on one end side of the upper link (3), among the end edges of the other-end-side opening (35b) of the pin-boss oil passage (35).

Owner:NISSAN MOTOR CO LTD

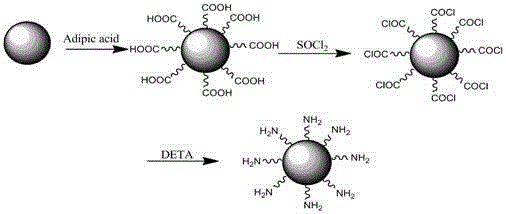

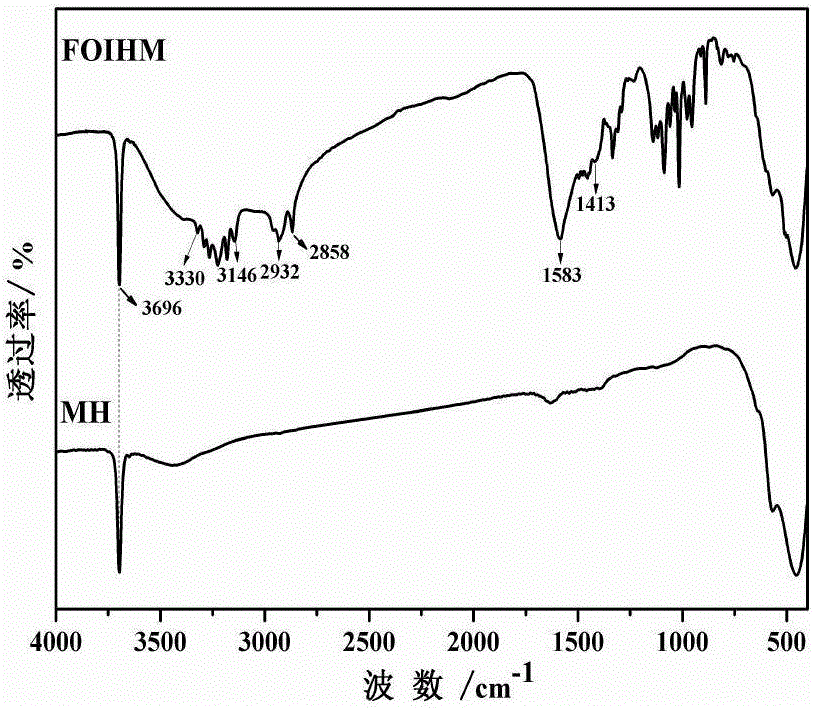

Functional curing agent and method for preparing bisphenol A type epoxy resin thereof

The invention relates to the technical field of material science, in particular to a functional curing agent and a method for preparing bisphenol A type epoxy resin thereof. Magnesium hydroxide and adipic acid are added into a flask, added into absolute ethyl alcohol to react for 6 h at 80 DEG C and then washed through absolute ethyl alcohol; 5-10 g of the product in the step A is added into the flask, and thionyl chloride is added; 5-10 g of the product in the step B is added into the flask, 100-300 ml of analytically pure dimethyl formamide (DMF) is added into each gram of product in the step B, the analytically pure DMF is utilized for washing, DMF is removed through drying in a vacuum drying oven at 90 DEG C, and the curing agent FOIHM is obtained. The functional curing agent is a hybrid functional material and has the advantages of being easy to prepare and low in cost, and the epoxy resin curing capability of the prepared curing agent is much better than that of a commercially available curing agent at the same grade. The adding of magnesium hydroxide also potentially improves combustion resistance of the composite material.

Owner:NORTHWEST NORMAL UNIVERSITY

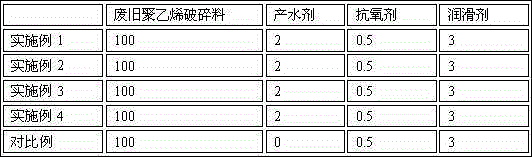

Regenerative polyethylene plastic where novel cross-linking agents are added and preparation method thereof

The invention discloses regenerative polyethylene plastic where novel cross-linking agents are added and a preparation method thereof and relates to a high polymer material and a preparation method thereof. A moderately-crosslinked modification technological means is adopted, and the regenerative polyethylene plastic where novel cross-linking agents are added is prepared. Due to the fact that palygorskite clay crosslinking agents are added, silane crosslinking agents are decomposed under a certain temperature to generate free radicals, macromolecules of the regenerative polyethylene plastic are triggered to have a chemical crosslinking reaction, chemical bonds are formed between macromolecular chains, a net-shaped structure is formed, and therefore strength, rigidity, tenacity and heat resistance of the final product are all excellent. The formula of the prepared composite crosslinking agents is applied to crosslinking of waste polyethylene, not only are the mechanical property and the gel content of the waste polyethylene improved, but also combustion resistance and heat stability of waste polyethylene materials are improved, cost of low-density polyethylene materials is reduced, and therefore good application prospects are achieved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

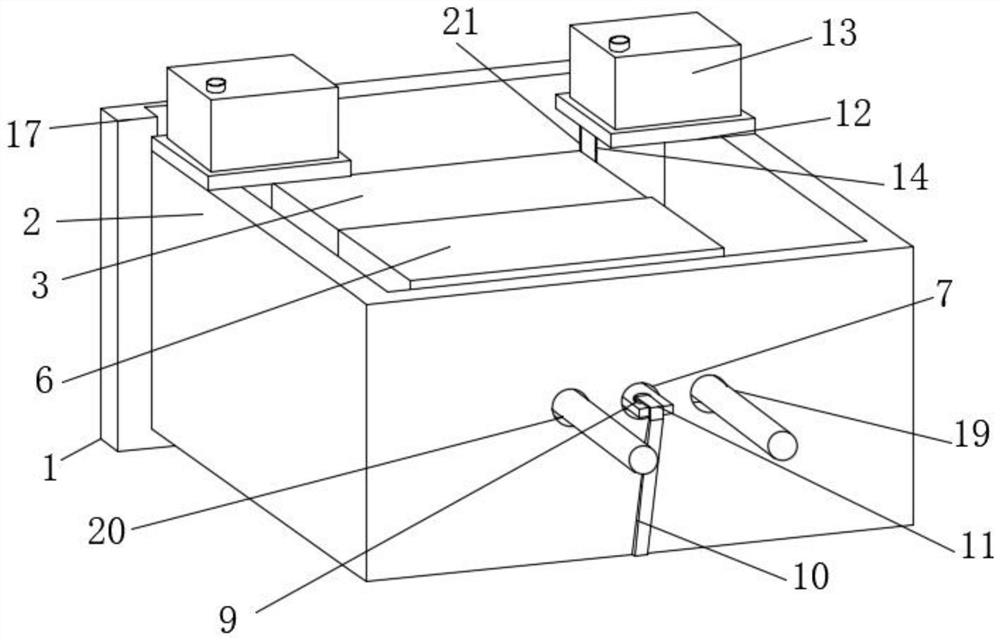

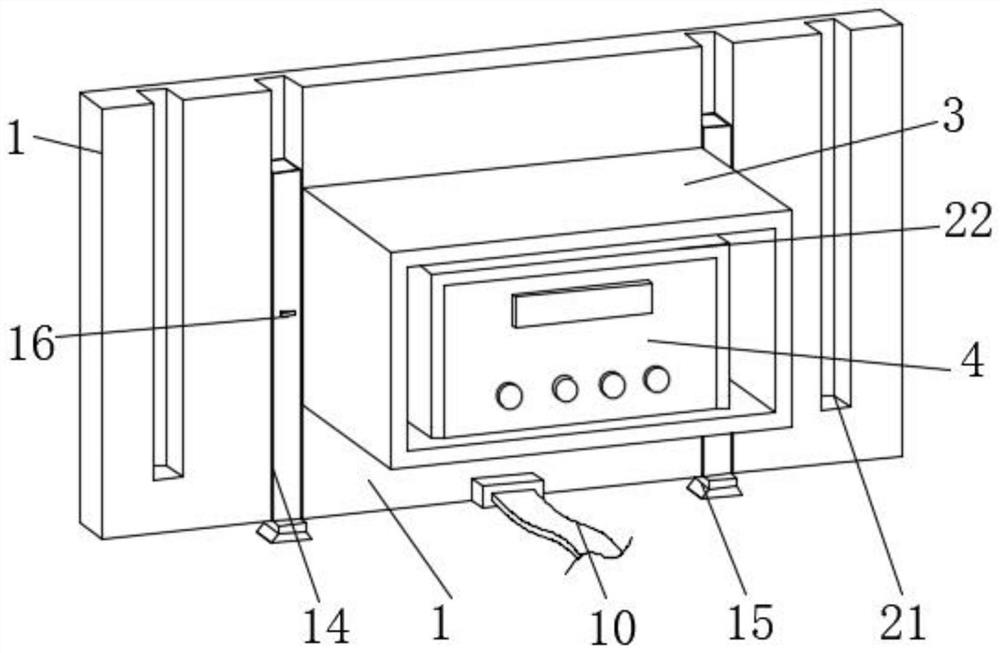

Three-phase multifunctional electric power instrument with anti-burning performance

ActiveCN112394211AEasy to removeSolving problems that cannot protect themselvesTime integral measurementWater storage tankEngineering

The invention discloses a three-phase multifunctional electric power instrument with anti-burning performance, which belongs to the technical field of electric power instruments and comprises a fixedplate, a mounting plate is slidably connected to the front surface of the fixed plate, a rock wool protective shell is fixedly connected to the front surface of the fixed plate, and an electric powerinstrument body is fixedly mounted in the rock wool protective shell. Two reset springs are fixedly connected to the back face of the mounting plate, a fireproof cover is fixedly connected to one endof the back face between the two reset springs, and the fireproof cover is located on the front face of the electric power instrument body. According to the invention, the reset springs push the fireproof cover to the rock wool protective shell until the fireproof cover completely covers the electric power instrument body, the fireproof cover touches the valve on the water conveying pipe, coolingwater in the water storage tank falls into the water conveying pipe when the valve is opened, and the water conveying pipe sprays the cooling water out of the nozzle to extinguish fire. The problem that the conventional power meter cannot be self-protected in case of a fire is solved.

Owner:苏州大鑫新能源科技有限公司

Manufacturing method of fireproof insulation board

InactiveCN106337507AThermal insulationImprove flame retardant performanceHeat proofingFire proofingFiberCellulose

The invention discloses a manufacturing method of a fireproof insulation board. The manufacturing method of the fireproof insulation board is characterized in that a plurality of holes are punched in a polystyrene foam board; 2) a fireproof insulation pouring material is prefabricated, wherein the fireproof insulation pouring material is prepared from the following components in parts by weight: 100-200 parts of Portland cement, 10-20 parts of fluorite slag powder, 10-20 parts of superfine slag powder, 40-60 parts of cinder aggregate, 40-50 parts of aluminum oxygen chamotte, 20-30 parts of asbestos fiber, 5-10 parts of calcined diatomite, 5-10 parts of simethicone, 2-4 parts of liquid paraffin, 2-4 parts of aluminium hydroxide, 2-4 parts of asbestos fiber, 3-5 parts of cellulose ether and 2-3 parts of brucite powder; 3) the prefabricated pouring material is added in the holes, the holes are sealed by a fireproof sealant after adding the pouring material, and the product is dried. According to the manufacturing method of the fireproof insulation board, the anti-burning property of the insulation board is greatly improved, the smoke volume and the smoke toxin produced by the polystyrene foam board are greatly reduced, and the fireproof insulation board further has an excellent thermal insulation effect and a waterproof property.

Owner:ANSHAN NORTHEAST CONSTR ARCHITECTURAL ENG

Colour register craftwork door and its preparation method

InactiveCN1557614AImprove craftsmanshipImprove the grade of useWood working apparatusFiberHigh density

The top colored artistic door consists of integrated wood material, sound insulating material, high density fiber board, dust and smoke blocking tape and made through the technological process including drying in kiln, cutting into board, combining, hot pressing, edge sealing and milling to shape. The present invention features the gamma ray decolorizing, covering with enamel lacquer, PU color lacquer in surface decoration, etc. Compared with available technology, the present invention has greatly raised decoration level, greatly raised corrosion resistance, yellowing resistance, burning resistance, ultraviolet resistance and wear resistance of door, and the low air polluting index.

Owner:昆明红塔木业有限公司

Press forming die, and method of manufacturing press forming die protection film

ActiveCN103476963AManage surface statesHigh resistance to burningShaping toolsVacuum evaporation coatingTectorial membraneEngineering

Owner:CAMUS CO LTD +1

Burning resistant conveyor belt

The invention provides a burning resistant conveyor belt. The burning resistant conveyor belt is prepared from the raw materials of 55-65 parts of natural rubber, 5-15 parts of butadiene rubber, 25-35parts of styrene butadiene rubber, 2-4 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 4-6 parts of an antiager, 50-60 parts of super wear-resistant carbon black, 25-35 parts of a carbon formingagent, 1-3 parts of sulfur and 2-3 parts of an accelerant. Through the mixing use of the natural rubber, the butadiene rubber and the styrene butadiene rubber, and the addition of the carbon forming agent, the burning resistant performance of conveyor belt products is greatly improved, and under the harsh working conditions of steel plants, power plants and the like, the requirements of instantaneous and short-term use can be met.

Owner:WUHU JITUO RUBBER TECH

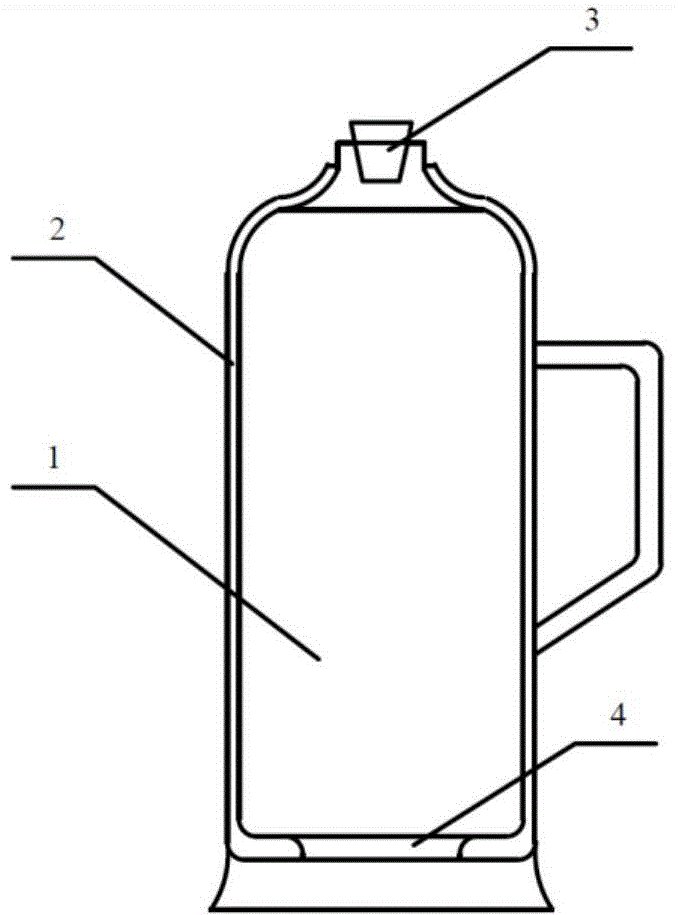

High-heat-resistance thermos

InactiveCN104927210AGood compatibilityImprove resistance to burningNon-pressured vesselsImino compound preparationCoumaronesParaffin oils

The invention discloses a high-heat-resistance thermos. The high-heat-resistance thermos comprises an inner container, a casing, a thermos plug and a rubber base, wherein the inner container is located in the casing, the rubber base is used for fixing the inner container and is made from a heat-resistant ethylene propylene terpolymer rubber material, and the heat-resistant ethylene propylene terpolymer rubber material contains the raw materials, i.e., ethylene propylene terpolymer rubber, acrylate rubber, cis-4,1-polyisoprene rubber, brominated butyl rubber, zinc methacrylate, high abrasion furnace black, modified nano silicon dioxide, polyester staple fibers, benzoyl peroxide, N,N'-metaphenyl bismaleimide, sulfur, stearic acid, zinc oxide, coumarone resin, paraffin oil, cobalt boroacylate, an anti-aging agent and a silane coupling agent. The high-heat-resistance thermos disclosed by the invention is good in heat resistance, excellent in ageing resistance and long in service life and is not liable to an aging phenomenon.

Owner:蚌埠市耀得保温容器有限公司

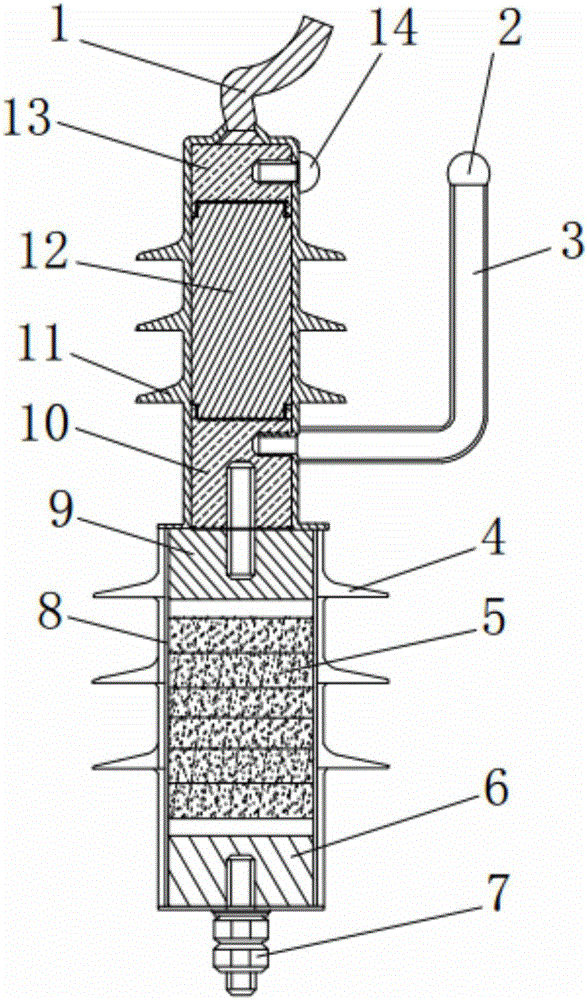

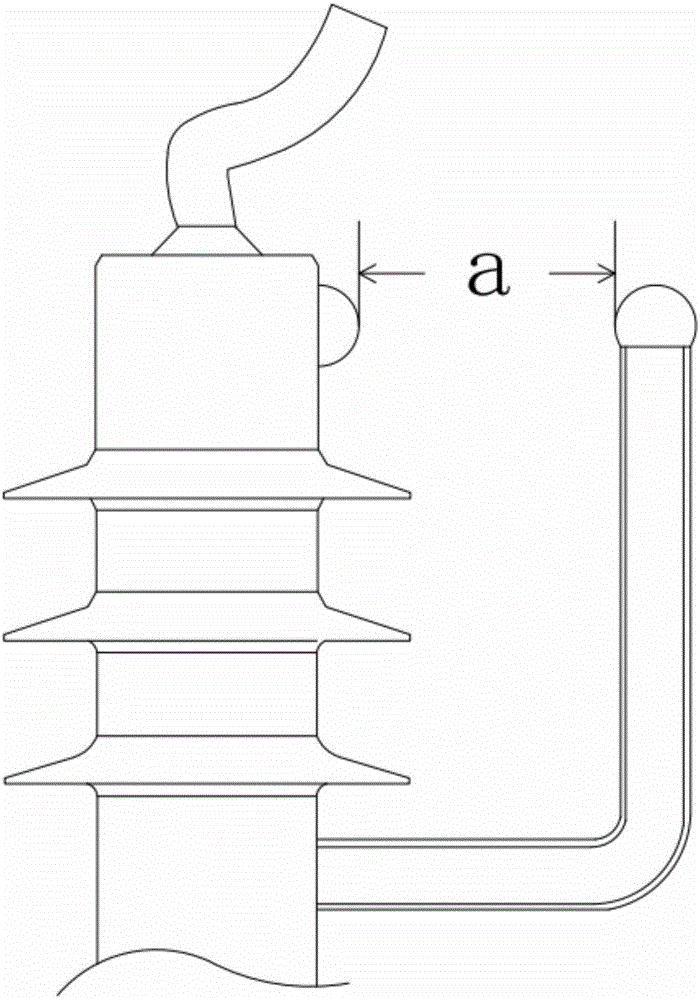

High-voltage external series gap anti-thunder combination device

ActiveCN106848841AAvoid destructionSolve the convenienceSpark gap detailsOvervoltage arrestors using spark gapsAgricultural engineeringEngineering

The invention discloses a high-voltage external series gap anti-thunder combination device. The anti-thunder combination device comprises two parts of a discharge gap component arranged at the upper portion and a zinc oxide valve plate component arranged at the lower portion, and the discharge gap component is connected to the zinc oxide valve plate component through a stud; the high-voltage external series gap anti-thunder combination device prevents a 10 kV high-voltage wire from being damaged by thunder, improves convenience of construction and installation and stability of equipment operation, and improves the equipment operation parameter; horizontal discharging is maintain in a gap, and line short circuit caused by rainwater or freezing during together vertical discharging; a quality stainless steel metal electrode is adopted to replace a traditional aluminum electrode to enhance firing-resistance capability, and the service life is prolonged; a new technology is adopted to manufacture a zinc oxide valve plate so that the conduction capacity can be big.

Owner:SHENZHEN SEP INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com