SPC-based 3D printing plate and preparation method thereof

A 3D printing and plate technology, applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of long production cycle, cumbersome operation, constraints, etc., to improve wear resistance and burning resistance, 3D vision The effect is good and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An SPC-based 3D printing board, the board comprising a stone plastic (SPC) substrate layer, a color layer presented on the stone plastic (SPC) substrate layer by 3D printing, and UV covering the color layer Protective layer; the stone plastic (SPC) substrate layer includes a stone plastic (SPC) core layer and a background film layer compounded with the stone plastic (SPC) core layer; the material of the background film layer is PVC; the The background film is also embossed with wood grain texture. The color of the background film layer is white with covering properties.

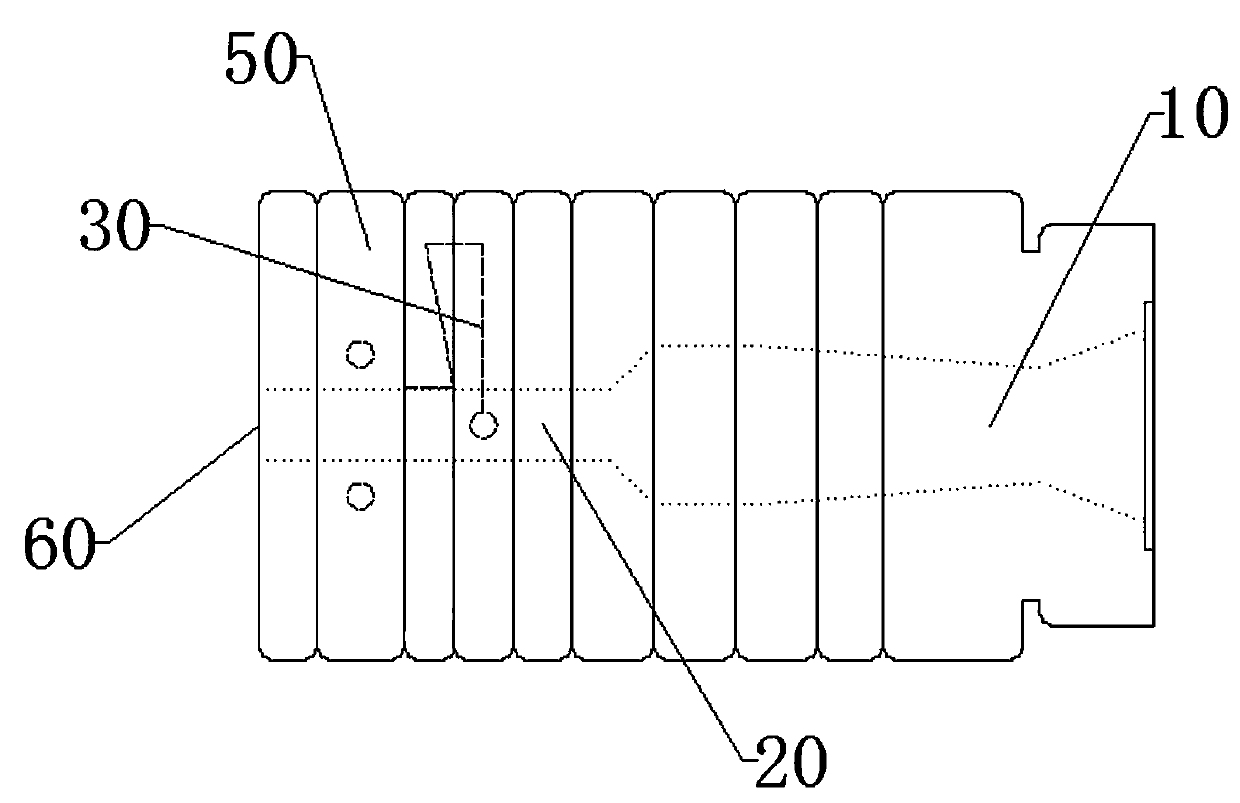

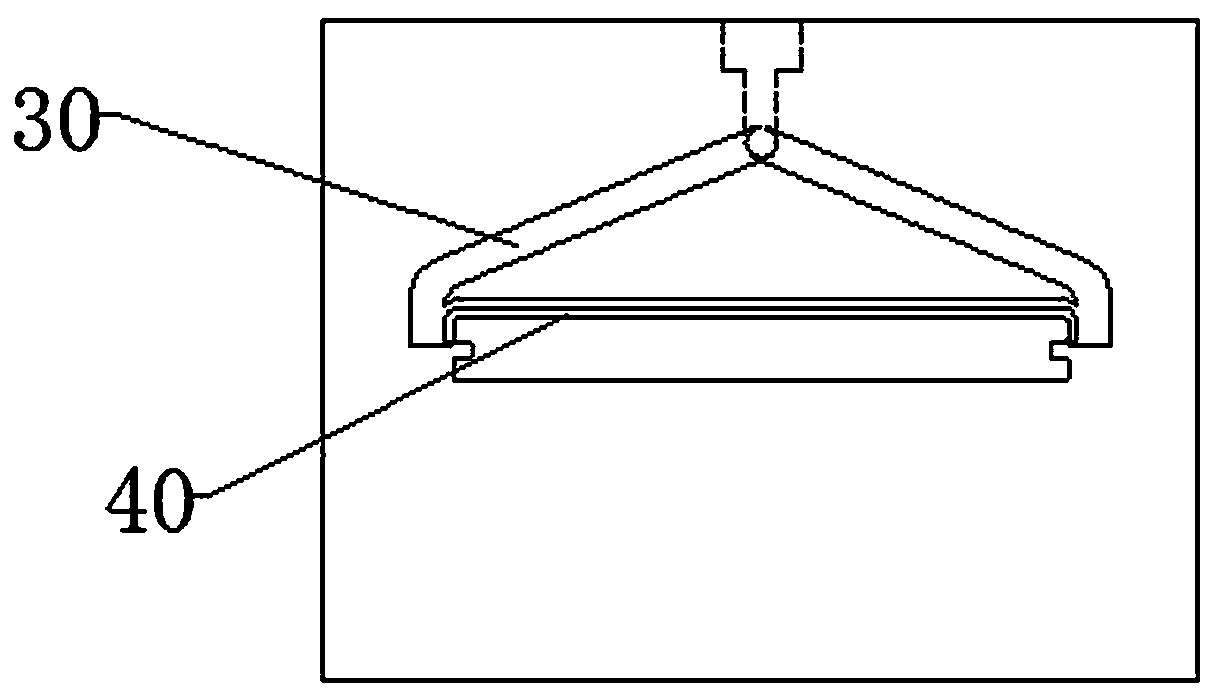

[0045] Reference figure 1 with figure 2 , A preparation method of SPC-based 3D printing plate, including the following steps:

[0046] a. Add the raw materials and additives that constitute the core layer of stone plastic (SPC) into the main extruder, and the raw materials and additives that constitute the core layer are melted through the main extruder and extruded into the main runner 10 of the mold , ...

Embodiment 2

[0052] The difference from the first embodiment is: change step b to: change the PVC film that constitutes the background film layer, through unwinding and the core layer of SPC stone plastic material obtained in step a, through on-line rolling composite, to obtain the SPC substrate The precursor structure of the layer. In this embodiment, the PVC film is a preformed film; and in the first embodiment, the PVC film is co-extruded with a core layer formed of a stone plastic (SPC) material through an extruder.

Embodiment 3

[0054] The difference from the first embodiment is: change step b to: change the PVC film that constitutes the background film layer, through unwinding and the core layer of SPC stone plastic material obtained in step a, through on-line rolling composite, to obtain the SPC substrate Floor;

[0055] Change step c to: input the SPC substrate layer obtained in step b into the pattern printing area of the 3D online printing device, and print a flat wood grain, pattern or pattern on the SPC substrate layer to obtain intermediate product one;

[0056] Change step d to: input the intermediate product 1 obtained in step c into the concave-convex effect molding area of the 3D online printing device, and print the concave-convex effect layer to obtain intermediate product two;

[0057] Change step e to: coat the second intermediate product obtained in step d with a UV primer and a UV topcoat, and light-cure them separately to form a UV protective layer.

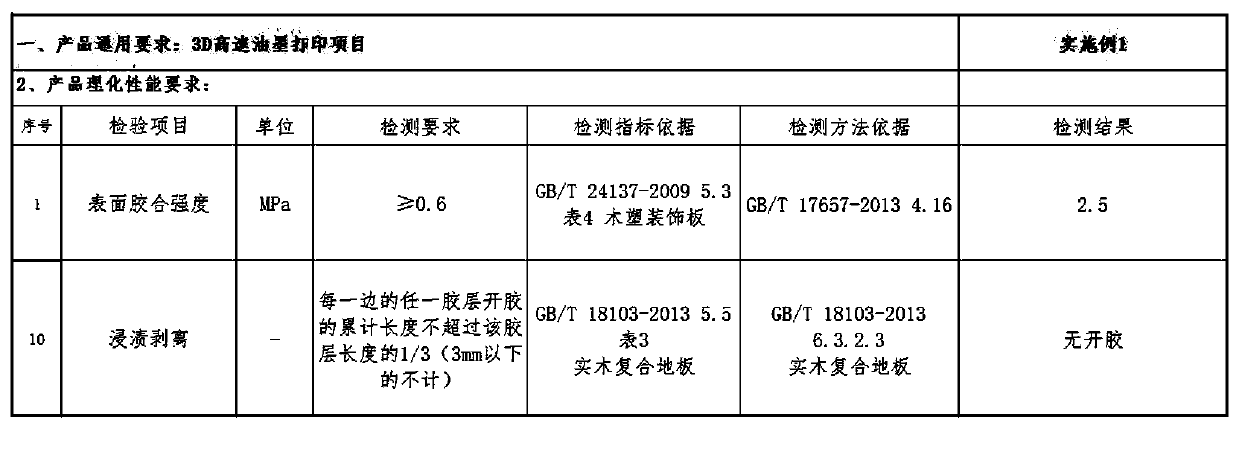

[0058] According to GB / T17657-2013 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com