Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Tissue Embedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The technique of placing cells or tissue in a supporting medium so that thin sections can be cut using a microtome. The medium can be paraffin wax (PARAFFIN EMBEDDING) or plastics (PLASTIC EMBEDDING) such as epoxy resins.

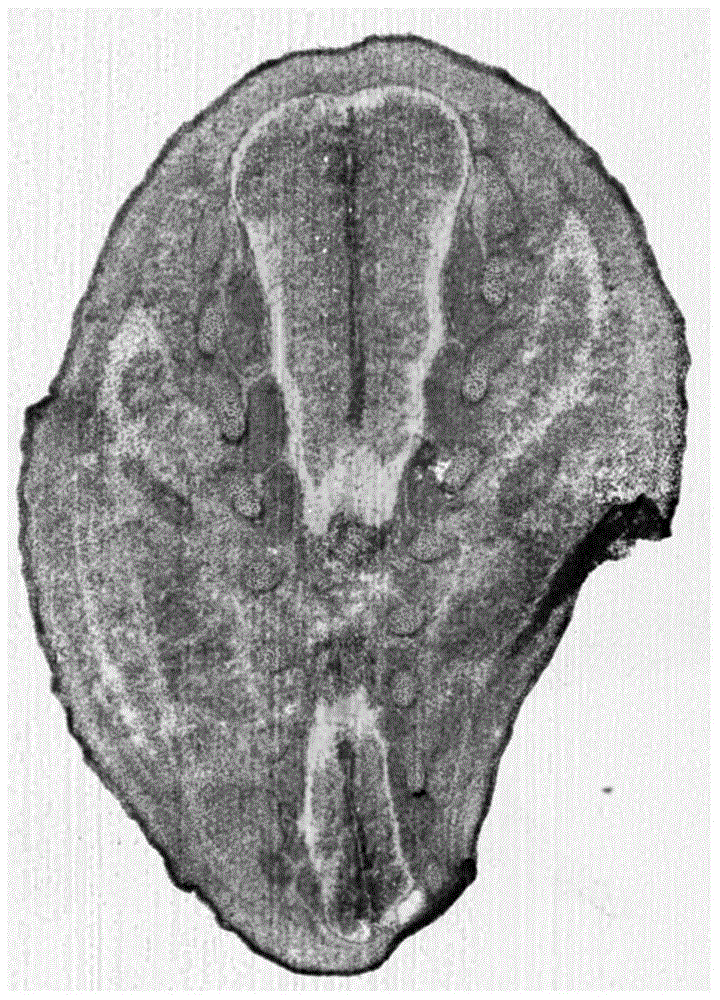

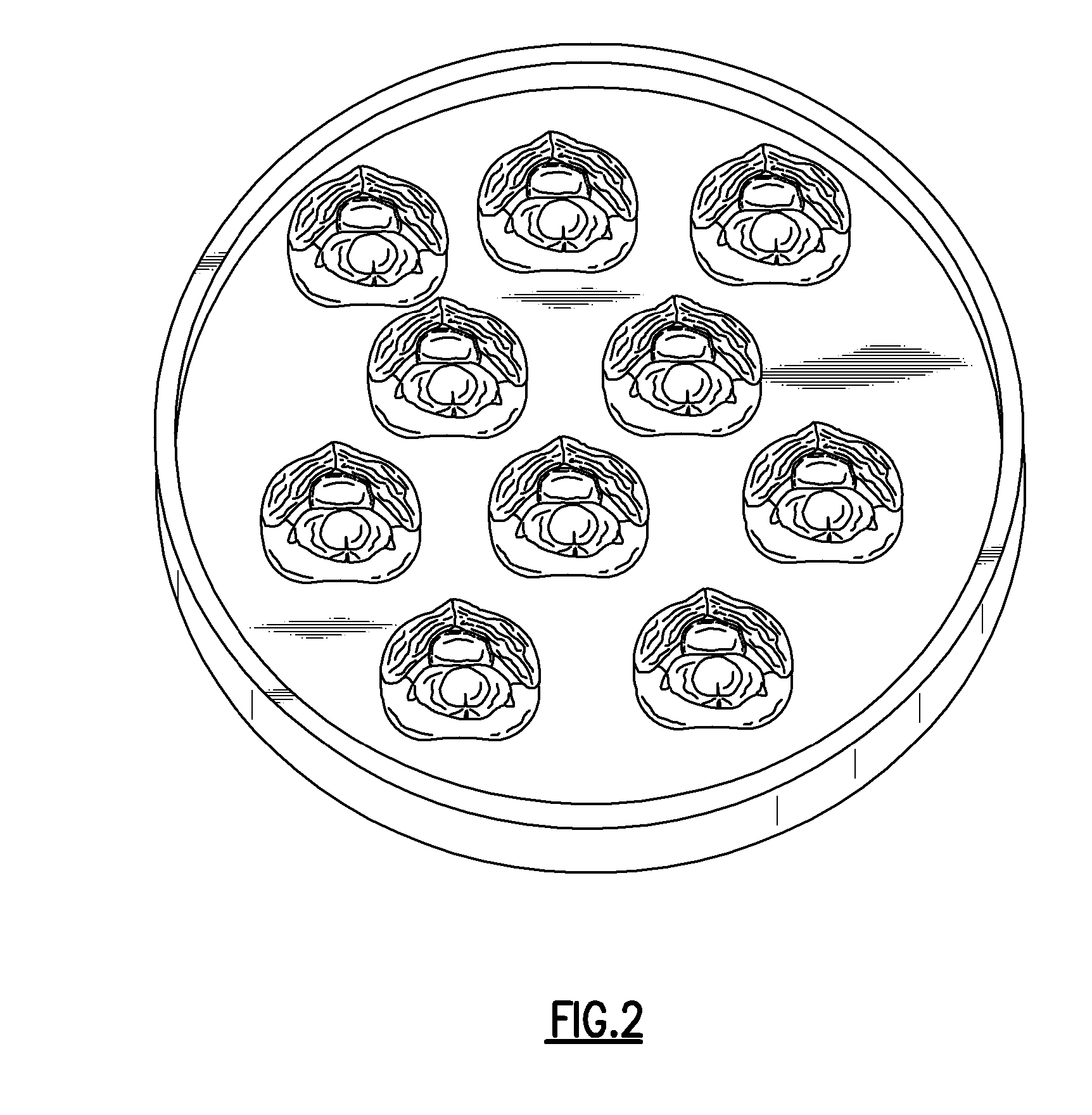

Frozen tissue microarray technology for analysis RNA, DNA, and proteins

InactiveUS6893837B2Withdrawing sample devicesPreparing sample for investigationAnalysis dnaTissue Arrays

The invention disclosed herein improves upon existing tissue microarray technology by using frozen tissues embedded in tissue embedding compound as donor samples and arraying the specimens into a recipient block comprising tissue embedding compound. Tissue is not fixed prior to embedding, and sections from the array are evaluated without fixation or post-fixed according to the appropriate methodology used to analyze a specific gene at the DNA, RNA, and / or protein levels. Unlike paraffin tissue arrays which can be problematic for immunohistochemistry and for RNA in situ hybridization analyses, the disclosed methods allow optimal evaluation by each technique and uniform fixation across the array panel. The disclosed arrays work well for DNA, RNA, and protein analyses, and have significant qualitative and quantitative advantages over existing methods.

Owner:RGT UNIV OF CALIFORNIA

Method for producing early gonad paraffin section of Chinese soft shell turtle

ActiveCN103954484AWide variety of sourcesLow costPreparing sample for investigationEmbryoPre embedding

The invention relates to a method for producing an early gonad paraffin section of Chinese soft shell turtle, which comprises the following steps: 1)fixing a sample, 2)dehydrating and transparentizing, 3)performing paraffin infiltration and embedding, 4)slicing and spreading the section, and 5)dyeing and sealing the section. The method is characterized in that the sample in the step 1) is embedded in a bean product pretreated by a stationary liquid. Compared with prior art, the method has the advantages that the bean product can be taken as a pre-embedding material for embryo stage gonad paraffin section of Chinese soft shell turtle, the source is wide, cost is low, through the pre-embedding, the embryo stage gonad can be better embedded in bean product, and subsequent tissue embedding and slicing are not influenced. The method avoids the disadvantages in a traditional method, and overcomes the disadvantages of difficult operation and observation of early gonad paraffin section of Chinese soft shell turtle; in addition, the pre-embedding gonad position is fixed and several gonad tissue can be processed at a time, so that large scale slicing and analysis are convenient to operate, and the method is especially suitable for researches by aiming at different individuals.

Owner:ZHEJIANG WANLI UNIV

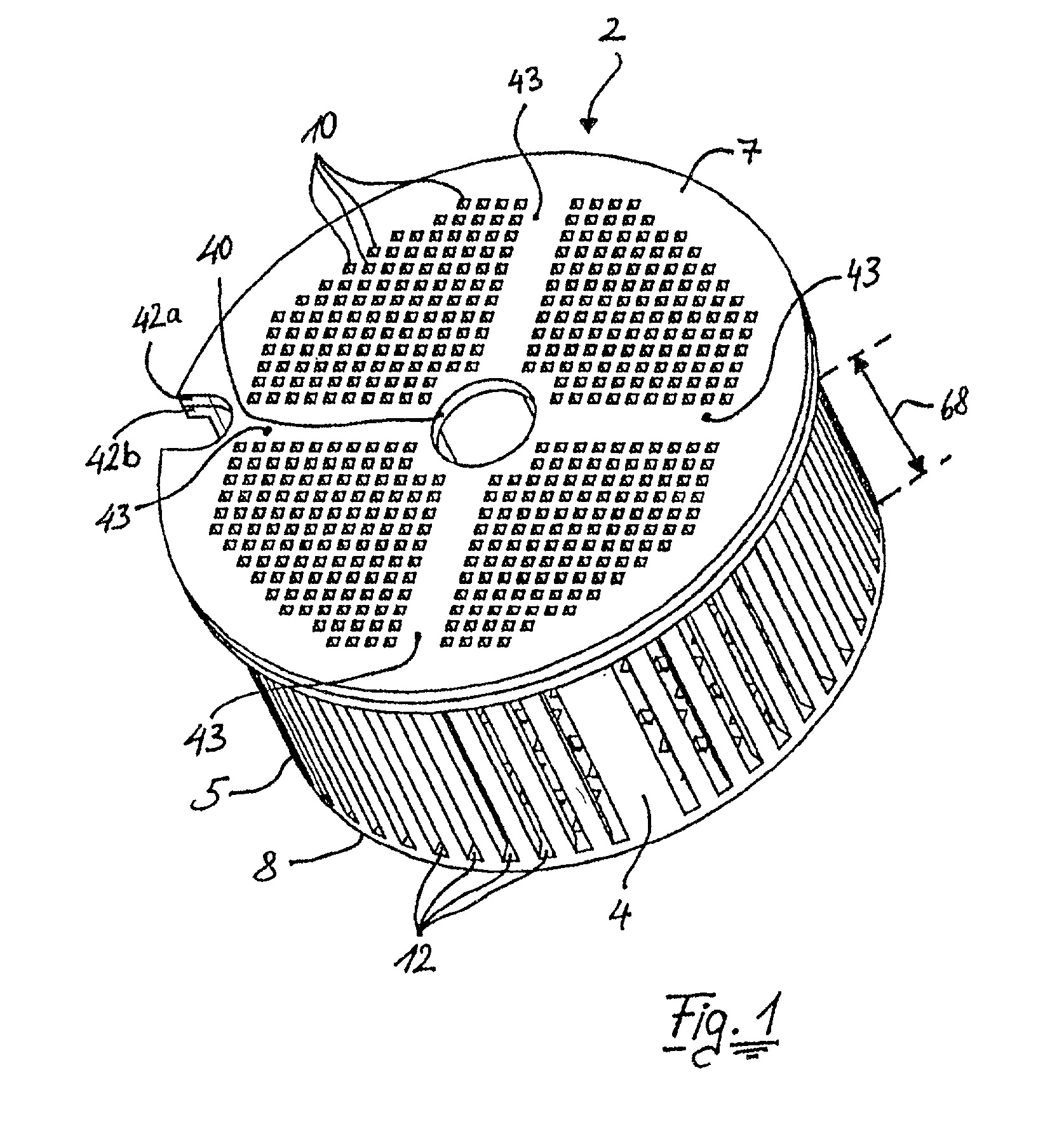

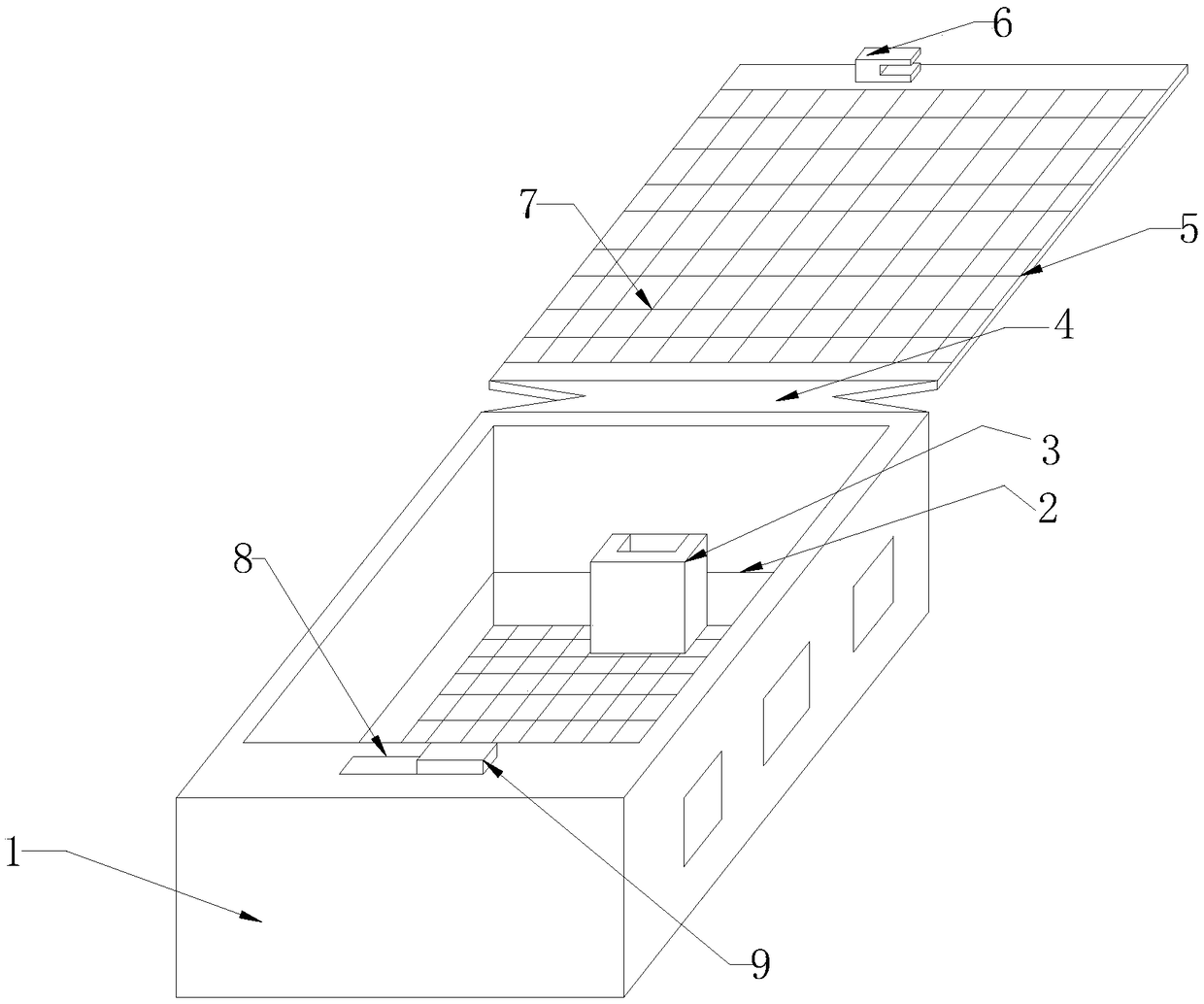

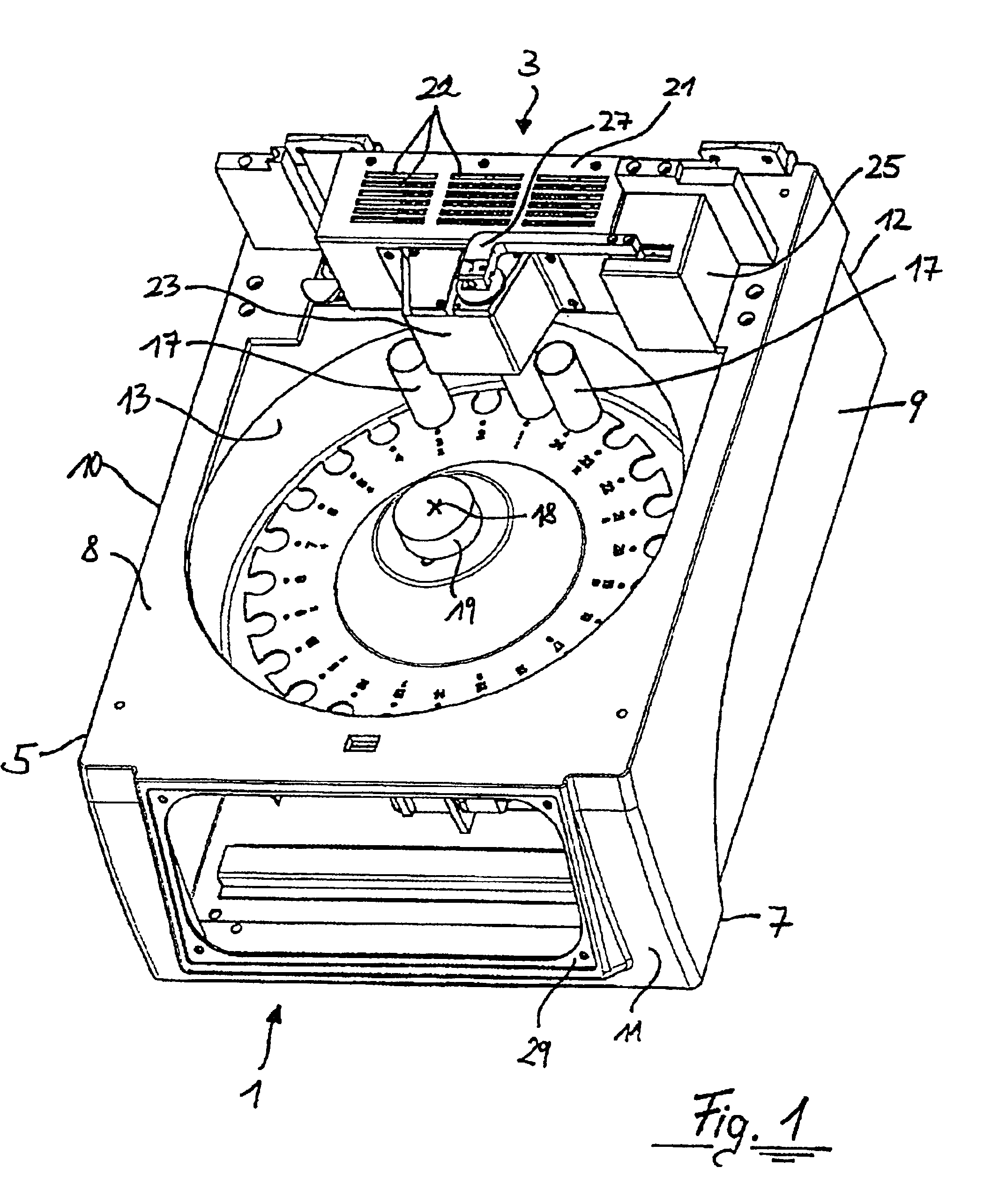

Tissue Embedding Apparatus, And Method For Operating A Tissue Embedding Apparatus

ActiveUS20100248301A1Faster and uniform embeddingReduce in quantityBioreactor/fermenter combinationsBiological substance pretreatmentsImage evaluationTissue sample

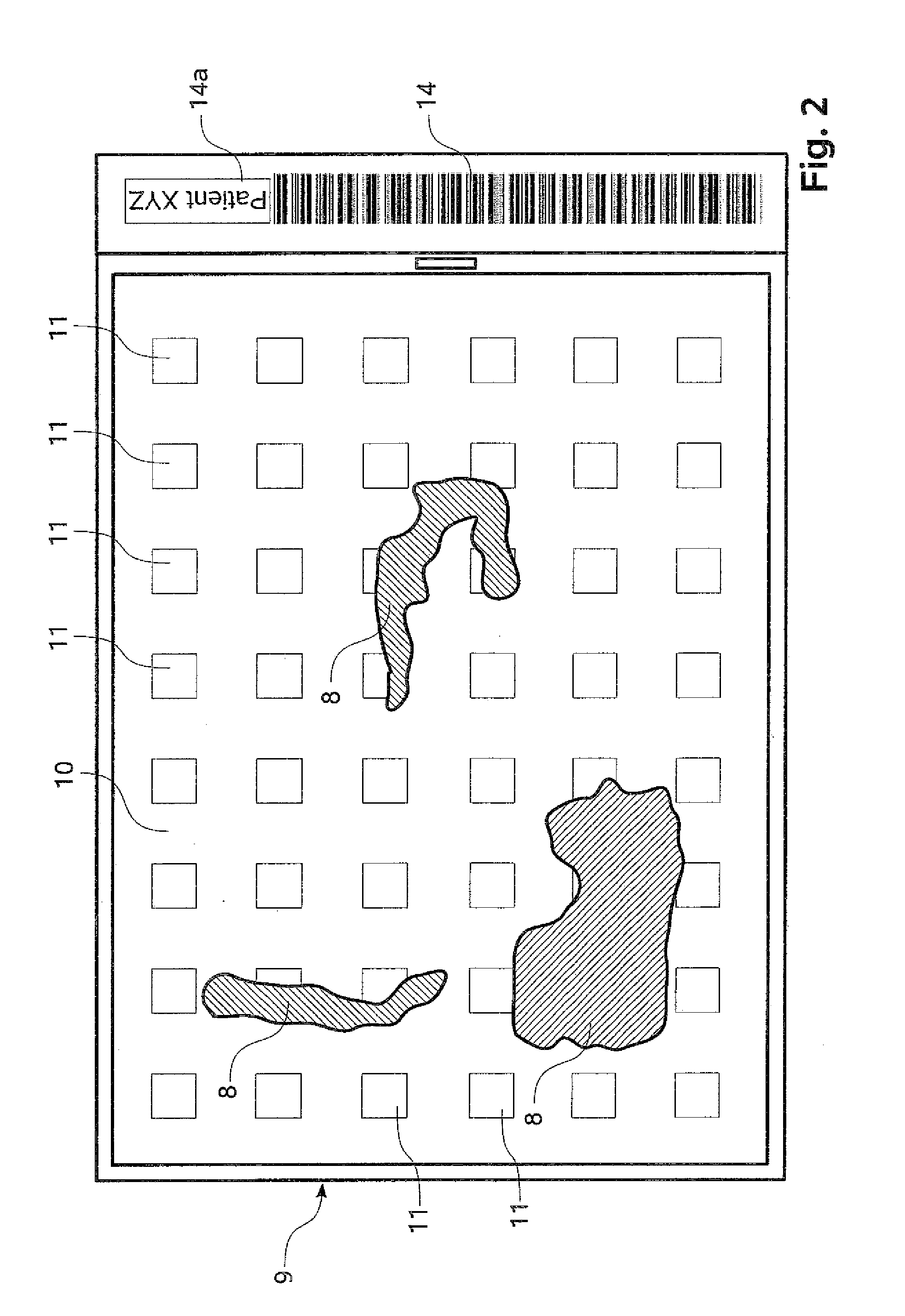

The present invention relates to a tissue embedding apparatus (1) for automatic embedding of at least one tissue sample (8). The tissue embedding apparatus (1) encompasses an input unit (2), an image acquisition unit (3), an embedding unit (4), at least one output unit (5, 6), and a control unit (7). A cassette (9) containing at least one tissue sample (8) is transferable to the input unit (2) of the tissue embedding apparatus (1). The tissue sample (8) is embeddable in an embedding medium by means of the embedding unit (4). The embedded tissue sample is outputtable with the at least one output unit (5). At least one image of the tissue sample (8) is acquirable with the image acquisition unit (3). In order for automated tissue embedding to be achievable even with the use of different cassettes, a tissue embedding apparatus (1) according to the present invention is characterized in that the image acquired of the tissue sample (8) is evaluatable, and the further processing of the tissue sample (8) in the tissue embedding apparatus (1) is definable as a function of the image evaluation.

Owner:LEICA BIOSYST NUSSLOCH

Dewaxing device of tissue embedding machine

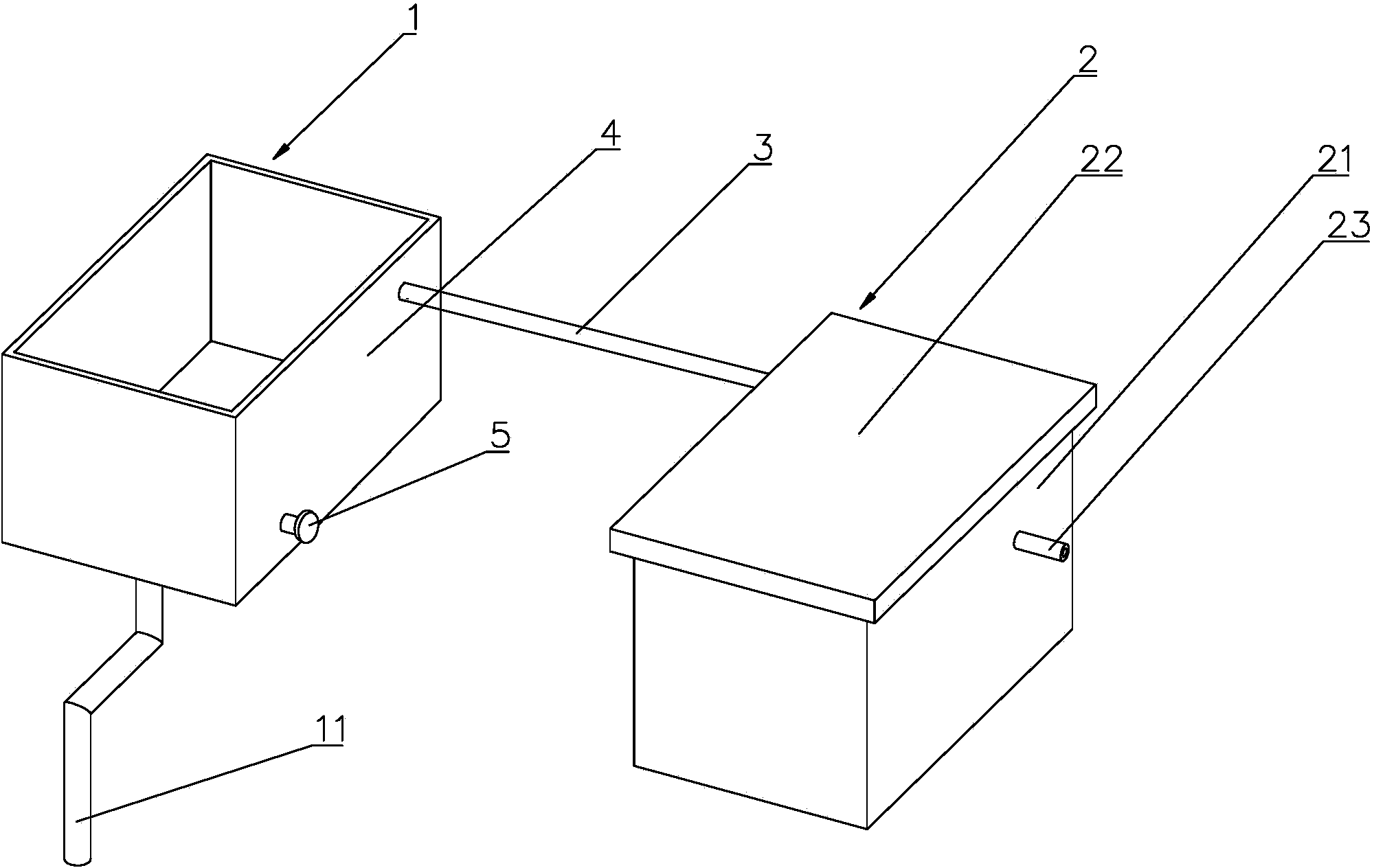

ActiveCN104324668AEnsure uninterrupted supplyPrevent cooling hardeningPreparing sample for investigationFusionParaffin waxTissue Embedding

The invention provides a dewaxing device of a tissue embedding machine; the dewaxing device is capable of continuously discharging wax, and comprises a main dewaxing cylinder and an auxiliary dewaxing cylinder, wherein the auxiliary dewaxing cylinder is provided with a first heating device; the bottom of the main dewaxing cylinder is provided with a wax outlet pipe; a wax conveying pipe is arranged between the main dewaxing cylinder and the auxiliary dewaxing cylinder; the auxiliary dewaxing cylinder is provided with a wax feeding hole and an air inlet; the auxiliary dewaxing cylinder is hermetically arranged; a second heating device is arranged at the pipe orifice of the wax outlet pipe. The dewaxing device of the tissue embedding machine has the beneficial effects that the auxiliary dewaxing cylinder can be used for providing standby wax for the main dewaxing cylinder in time, so that the liquid paraffin wax is continuously supplied without waiting; the heating device arranged at the pipe orifice of the wax outlet pipe can be used for separately heating paraffin wax at the pipe orifice, so that the paraffin wax is prevented from being cooled and hardened, the wax is smooth in flow, and wax blockage is avoided; the wax conveying pipe is controlled to convey the liquid paraffin wax by enabling the air inlet to be filled with high-pressure air, and a control valve is not arranged in the wax conveying pipe, so that wax leakage is avoided.

Owner:福建启盛实验设备科技有限公司

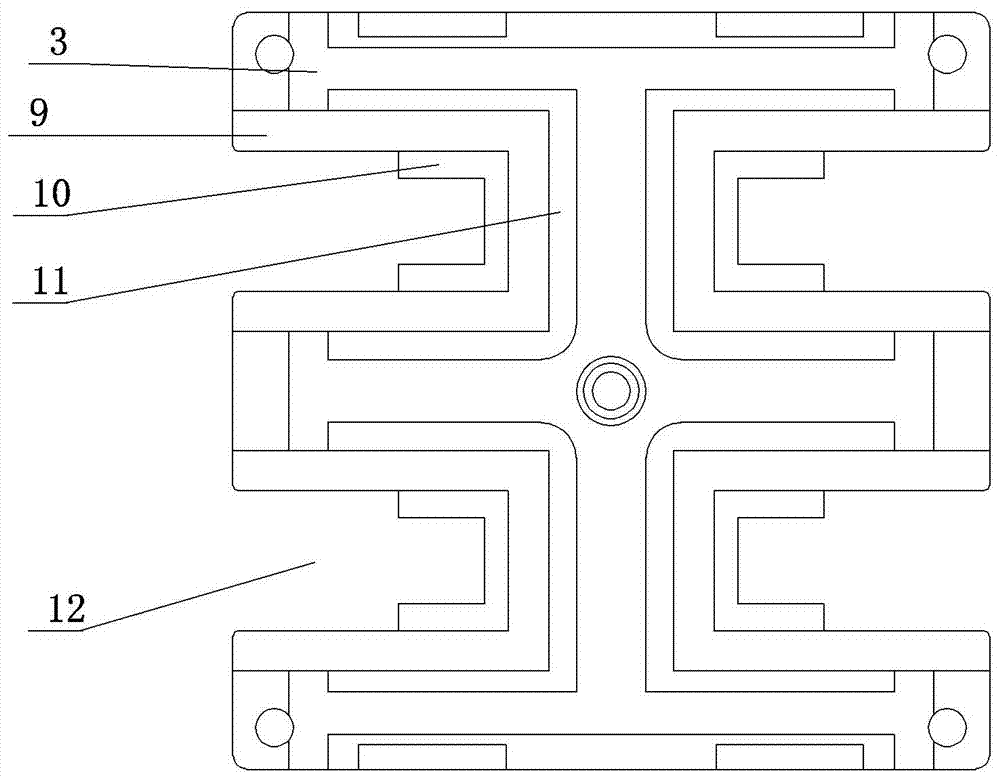

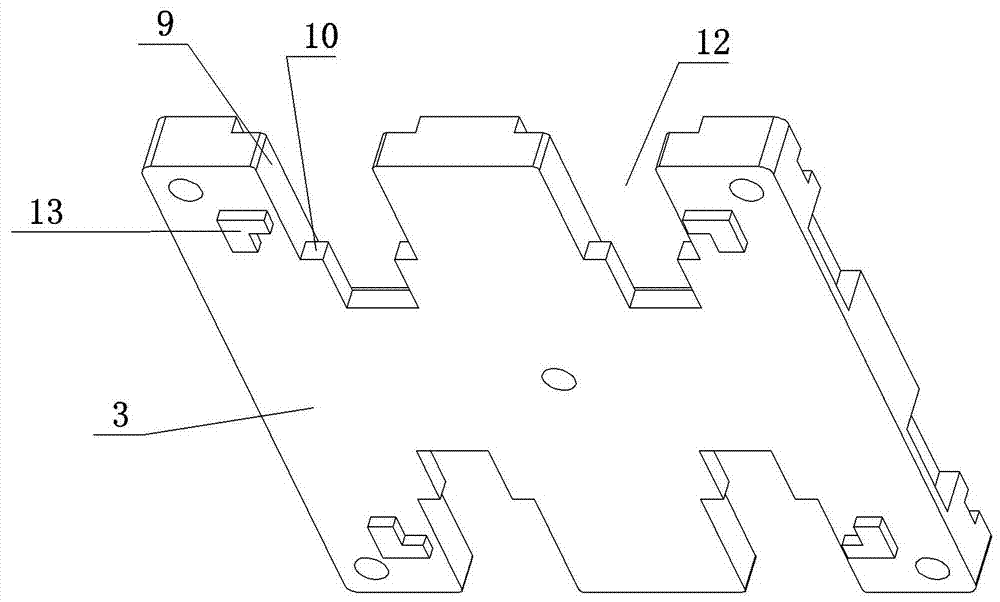

Biological tissue embedding unit, template, dehydrating and embedding dual function machine and using method

ActiveCN104777029AAvoid mistakesShorten the timePreparing sample for investigationWaxTissue Embedding

The invention provides a biological tissue embedding unit, an embedding template, an embedding tool, a dehydrating and embedding dual function machine and a using method. The biological tissue embedding unit comprises a multifunctional tissue embedding mould and a multifunctional tissue embedding box, wherein the longitudinal section of the multifunctional tissue embedding mould is in a concave structure; the opening of the concave structure is gradually reduced from top to bottom; a mould embedding positioning needle or a mould embedding positioning network or a mould embedding positioning secondary concave opening is formed at the bottom of the concave opening of the multifunctional tissue embedding mould, and a wax overflowing strip-shaped hole is formed in the mould wall of the longitudinal front end of the multifunctional tissue embedding mould; the multifunctional tissue embedding box is embedded into the multifunctional tissue embedding mould in a matched manner. The longitudinal section of the multifunctional tissue embedding box is in a trapezoidal structure, and an elastic positioning piece for compressing a biological tissue is further arranged in the multifunctional tissue embedding box. According to the invention, the errors are avoided, the medical accidents are prevented, a lot of time and labor intensity are saved, multiple embedding processes are saved and an embedding machine and a wax block refrigerator can be saved.

Owner:宁波察微生物科技有限公司

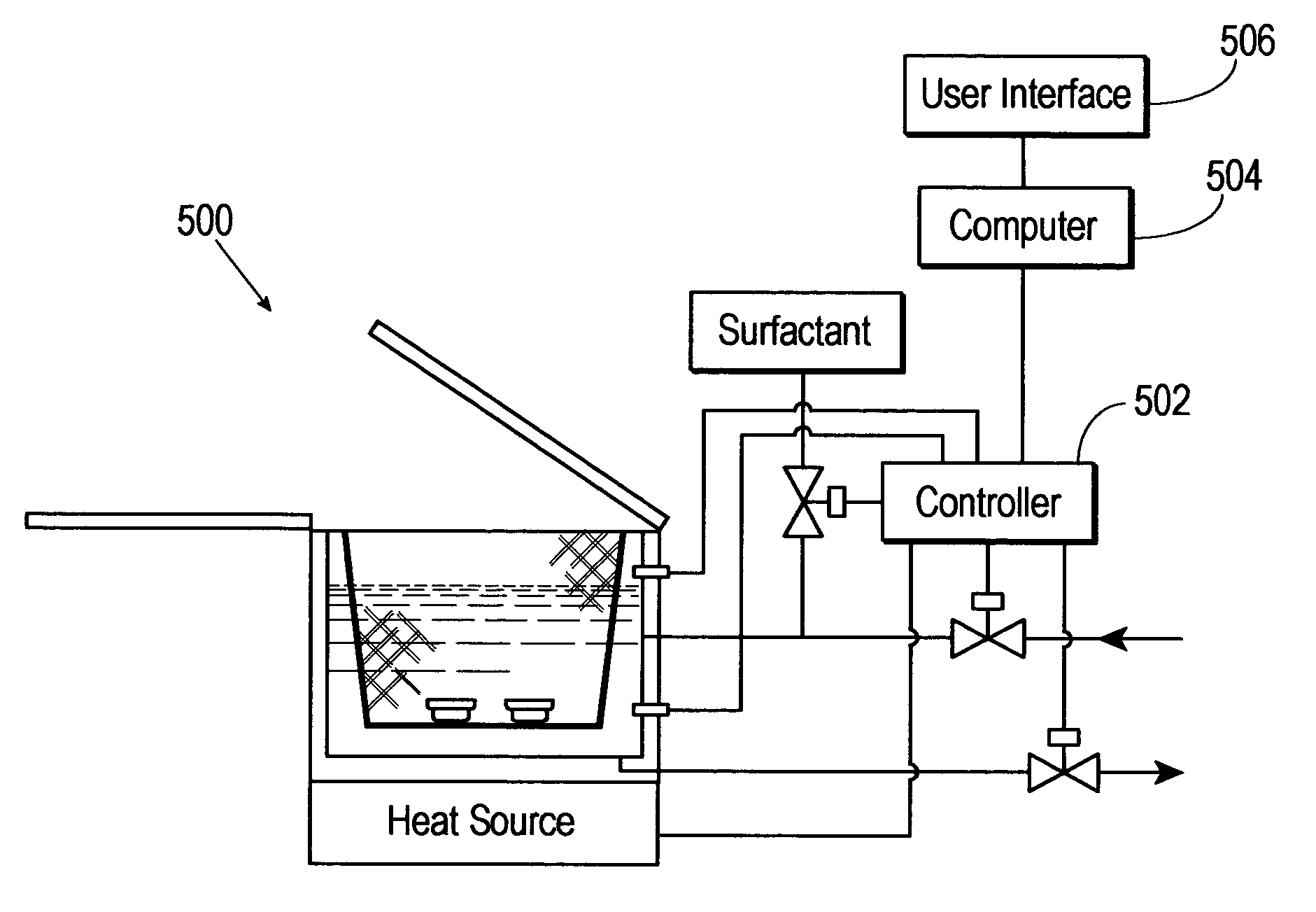

Method for cleaning tissue processing molds

The present invention is directed to a cleaning system and methods for cleaning tissue embedding molds. The cleaning system includes a cleaning vessel that holds a cleaning solution. The tissue processing molds are supported by a basket receptacle which is placed inside the cleaning vessel. Cleaning solution is supplied to the cleaning vessel through a supply line. Additional fluids are stored in a reservoir and may be mixed with the cleaning solution in the supply line. Cleaning solution drains from the cleaning vessel through a drain line. A controller controls the opening and closing of valves and the activation or deactivation of a heat source to operate a wash cycle, a rinse cycle, and a dry cycle.

Owner:HAYES STEVE

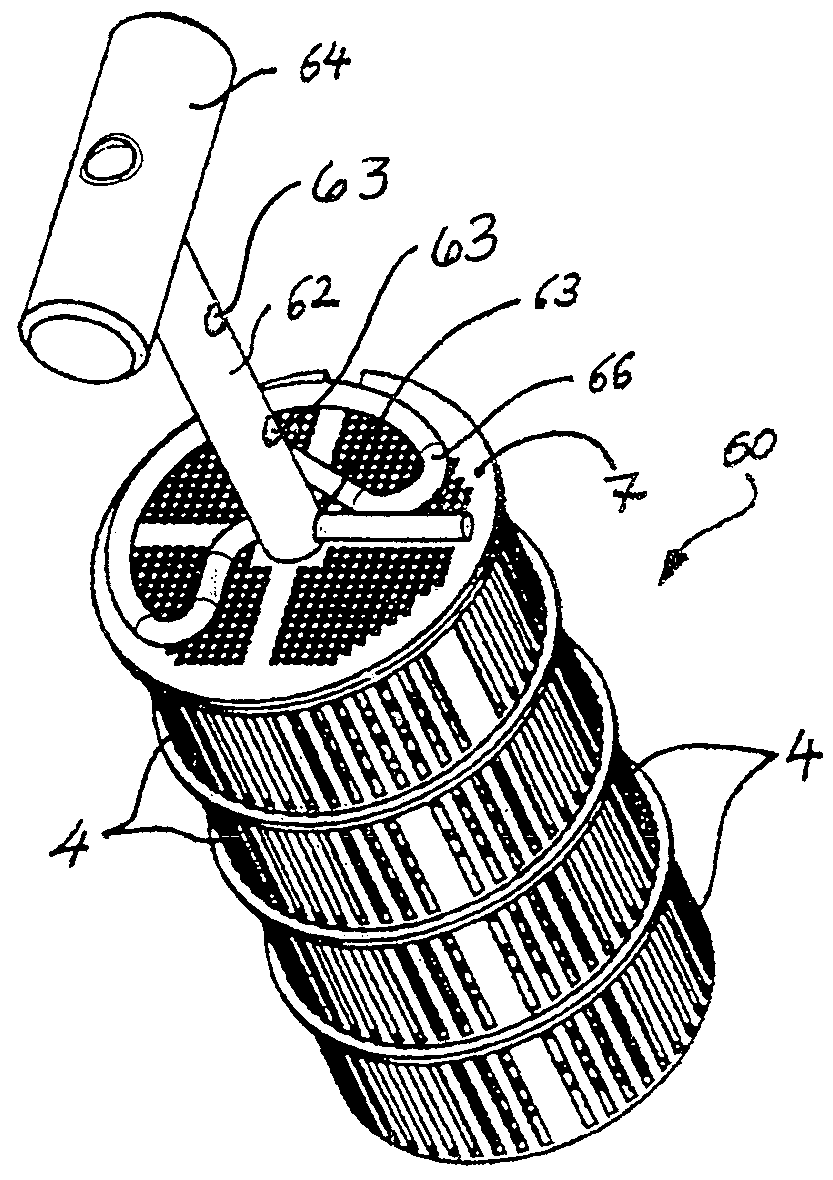

Container and apparatus for tissue processing for tissue embedding

ActiveUS7083761B2Quantity minimizationBioreactor/fermenter combinationsBiological substance pretreatmentsTissue PreparationTissue Processing

A container (2) for tissue preparation for the tissue embedding, having a base body (4), that is formed out cylindrical shaped side wall (5), a floor (6) and several bridges (50). The bridges (50) subdivide the container (2) in several sub-containers (52). The side wall (5) has a plurality of slit shaped openings (12), that extend essentially over the total height of the side wall (5).

Owner:LEICA MICROSYSTEMS GMBH

Improved frozen slicing method and applications thereof

InactiveCN104634626AEasy to operateShorten the timePreparing sample for investigationBiological macromoleculeSample preparation

The invention relates to the field of tissue sample preparation and pathogenic research, and particularly relates to an improved frozen slicing method and applications thereof. The improved frozen slicing method comprises the following steps: tissue pretreatment step, tissue embedding step, tissue freezing and sliding steps, wherein frozen tissue slices can be obtained after the slicing step, and a freezing protecting agent is adopted for soaking a tissue sample in the tissue pretreatment step. According to a tissue sample preparation method, not only can a fine tissue structure similar to a wax slice effect be obtained, but also the high quality of biological macromolecules, such as DNA, RNA and protein, can be guaranteed so as to meet the whole genome detection and analysis of the biological macromolecules. The improved frozen slicing method has the advantages of being simple, strong in universality, short in sample preparation time, wide in application prospect, and the like.

Owner:SHANGHAI JIAO TONG UNIV

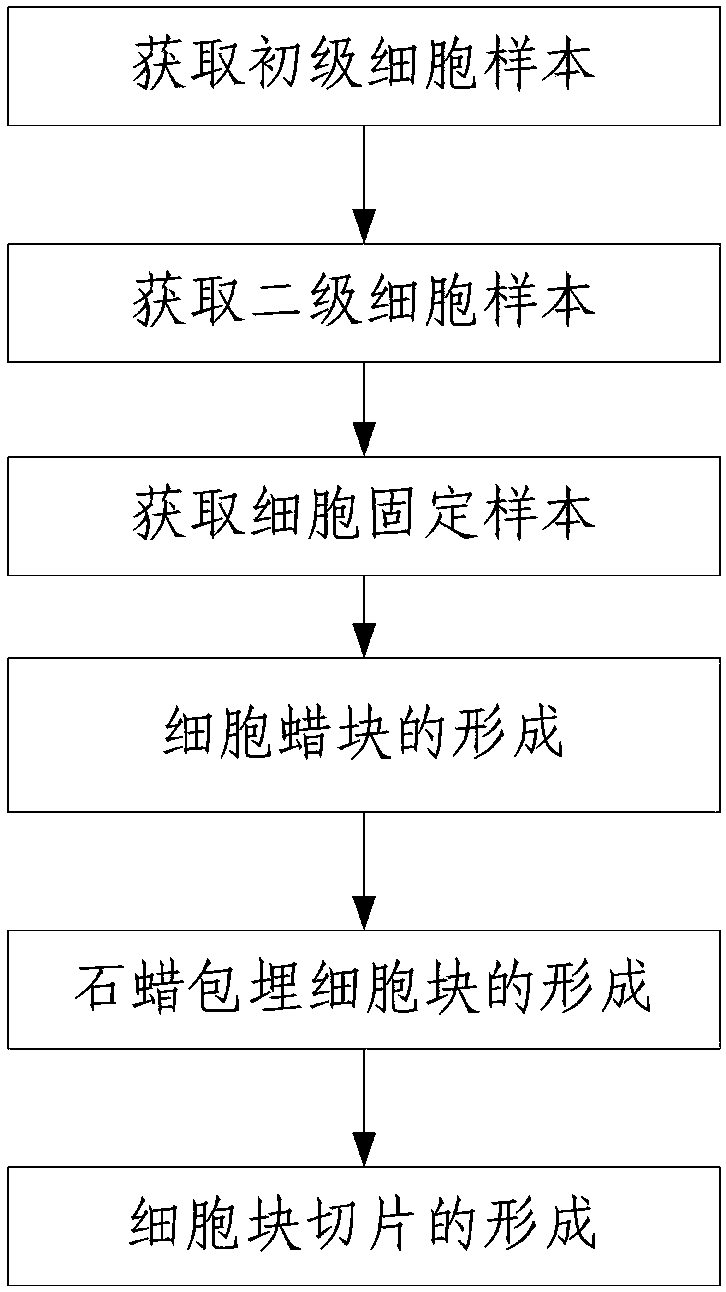

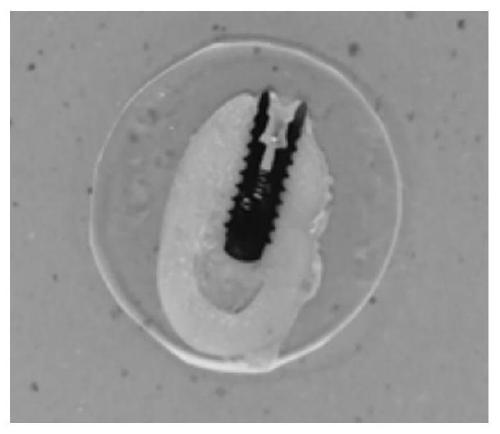

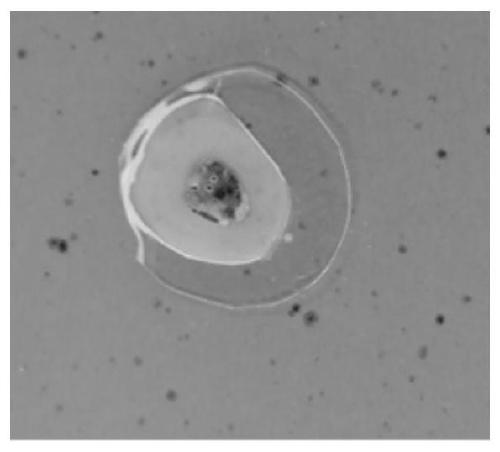

Production method of cell block paraffin section for fully presenting position of malignant cell

InactiveCN107677531AImprove accuracyAvoid the phenomenon of unreliable positioning or even disappearingPreparing sample for investigationPrimary cellBiology

The invention discloses a production method of a cell block paraffin section for fully presenting the position of a malignant cell. The method comprises the following steps: firstly, acquiring a primary cell sample and performing centrifugation sediment on the primary cell sample, so as to obtain a secondary cell sample; after the secondary cell sample is fixed, placing the secondary cell sample into a tissue dehydration box in a manner of vertical dividing from the middle for dehydration, transparentizing and waxing in sequence, so as to obtain a cell fixed sample; and vertically placing thecell fixed sampled into a tissue embedding box for embedding by taking a plane of section as a bottom surface, so as to form the section finally. Each section produced by the method can present the same cell hierarchical structure, so that the malignant cell appears at the same position of each section, a phenomenon that the malignant cell is located unreliably and even disappears in continuous sections is avoided, a comparative analysis when various antibodies are labeled in immunocytochemistry is facilitated, and cytopathology doctors can be effectively assisted to judge the source and the type of a malignant tumor, and therefore, the accuracy rate of cytopathological diagnosis is improved, a clinical application effect is good, and the practical value is high.

Owner:杨莉

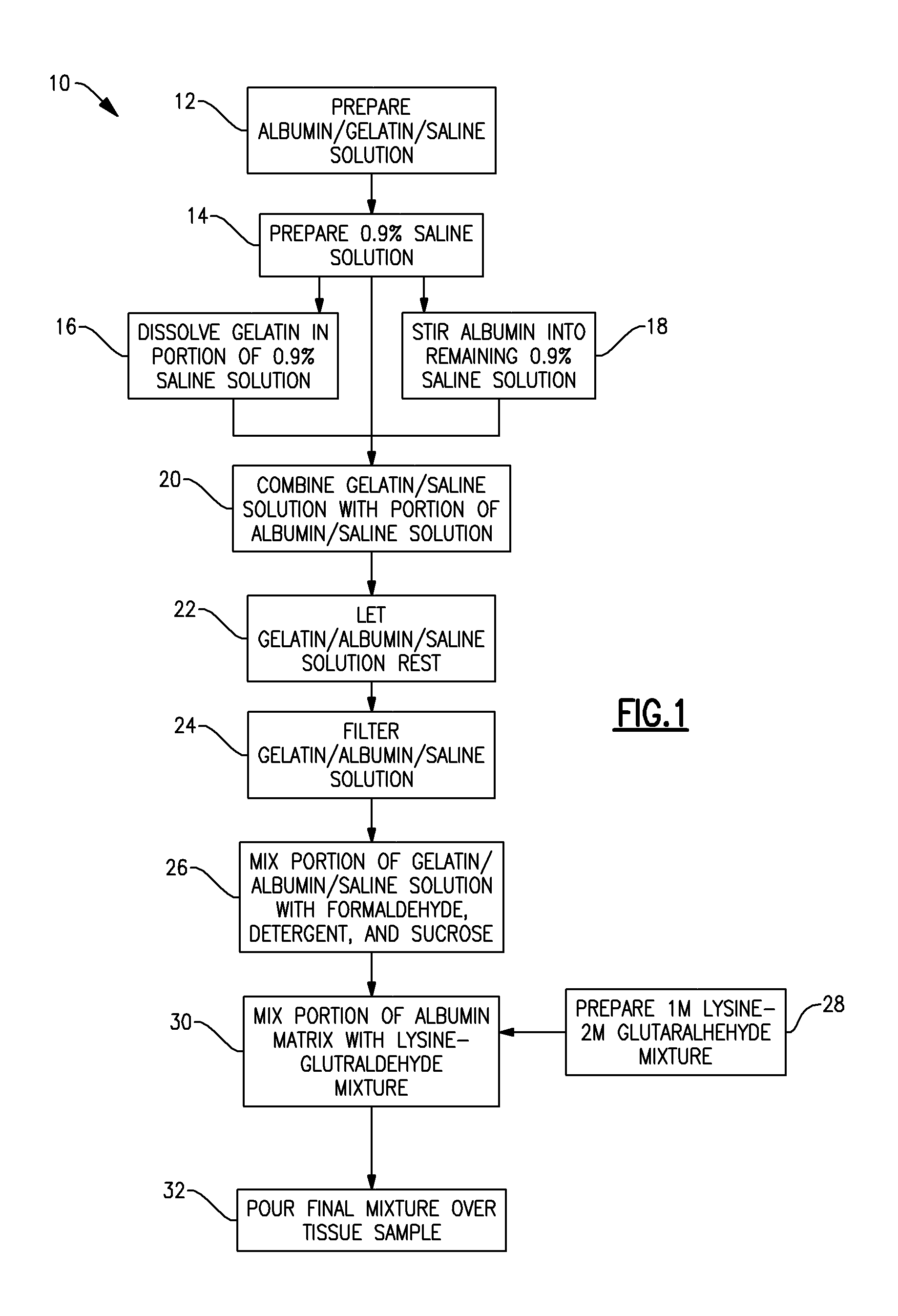

Tissue Embedding Matrix

InactiveUS20080009028A1Simple preparation processEasy to useMicrobiological testing/measurementPreparing sample for investigationSucroseTissue sample

The invention is a matrix for preparing a tissue sample made of saline, albumin, gelatin, formaldehyde, a detergent, sucrose, lysine, and glutaraldehyde. The matrix is formed by first preparing a solution of saline, albumin, and gelatin, and then mixing the solution with formaldehyde, a detergent, and sucrose. Immediately prior to fixation of the tissue, a separately prepared lysine-glutaraldehyde mixture is added. The resulting matrix will harden rapidly and may be used to fix tissue samples for histological processing. In particular, a layer of the matrix may be poured into a mold and allowed to harden to form a base. One or more tissue samples may then be pinned to the base of matrix in the mold and then covered with the matrix. Once the matrix hardens, the pins and mold may be removed, and the tissue sample or samples embedded in the matrix are ready for sectioning.

Owner:RES FOUDATION FOR MENTAL HYGIENE INC

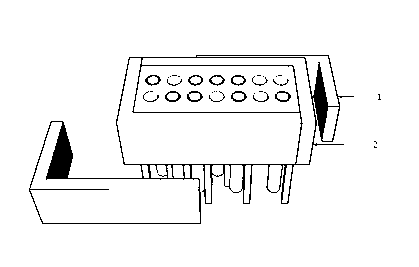

Method for making tissue chip based on one-step molding

InactiveCN102998153AUnrestricted tissue shapeMeet research needsPreparing sample for investigationFlat glassPunching

The invention provides a method for making a tissue chip based on one-step molding. The method is characterized in that the tissue chip is made through one-step molding without preparing a donor which is paraffin or an acceptor which is a paraffin tissue block. The method concretely comprises the following steps: 1, taking a mold frame, putting a tissue in the embedding tube of the mold frame in a required size and a required tangent plane, dumping paraffin for embedding, and allowing the paraffin to stand for a period of time to carry out polymerization molding of the paraffin; and 2, taking a paraffin-embedded frame, placing the mold frame having the embedding structure obtained in step 1 in the embedding frame on flat glass, dumping molten paraffin into the paraffin-embedded frame, allowing the paraffin in the porous tubes of the mold frame and the paraffin in the embedded frame to melt, and removing the embedded frame after the melting to complete the tissue embedding. According to the invention, the tissue positions and the embedding accuracy are strictly controlled, and no burrs or discontinuous cracks appear during punching, so the method has the advantages of cheapness, convenience, high efficiency, time saving and labor saving, and can be popularized to each pathology department and relevant research units.

Owner:饶莹

Application of polyethylene glycol to dyeing animal tissue section grease

InactiveCN110426259AAvoid destructionPrevent shrinkage deformationWithdrawing sample devicesPreparing sample for investigationSolubilityPolyethylene glycol

The invention belongs to the technical field of pathological tissue section making, and particularly relates to application of polyethylene glycol to dyeing animal tissue section grease. Through the excellent water solubility characteristic of the polyethylene glycol, with the polyethylene glycol as the dehydrating agent, the permeation and embedding formation of a medium are realized by means ofembedding in the dehydrating process, a formed tissue embedding block has the appearance characteristic of a paraffin block, the embedded medium can be removed by washing the tissue embedding block without processing the tissue embedding block with an organic solvent, and the problem that grease loss is caused by organic solvent processing is avoided. Tissue sections prepared by the method have the thickness of 3-5 micron, and the problem that tissue overlapping is caused by the too high thickness of the frozen sections is avoided. After the tissue sections prepared by the method are dyed by oil red O, due to the dehydration and permeation of the polyethylene glycol, most of grease drops are completely preserved in cytoplasm, the problem of displacement of grease drops in the frozen sections is avoided, and the problem that a tissue structure is not complete since ice crystals are generated in the frozen sections at a low temperature is also avoided.

Owner:武汉赛维尔生物科技有限公司

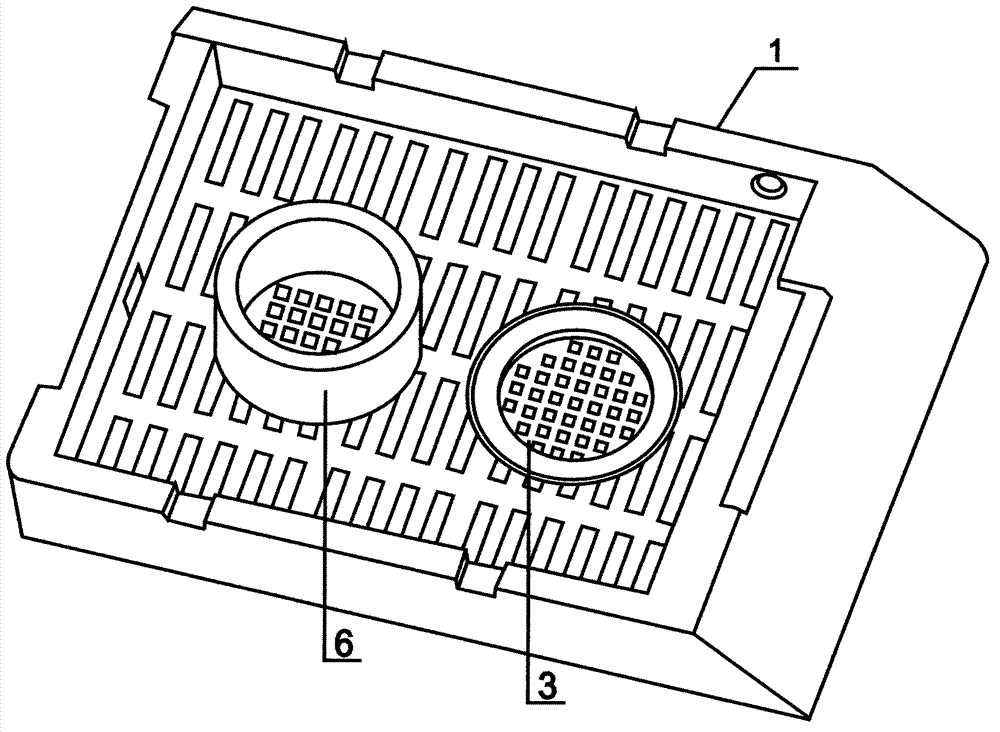

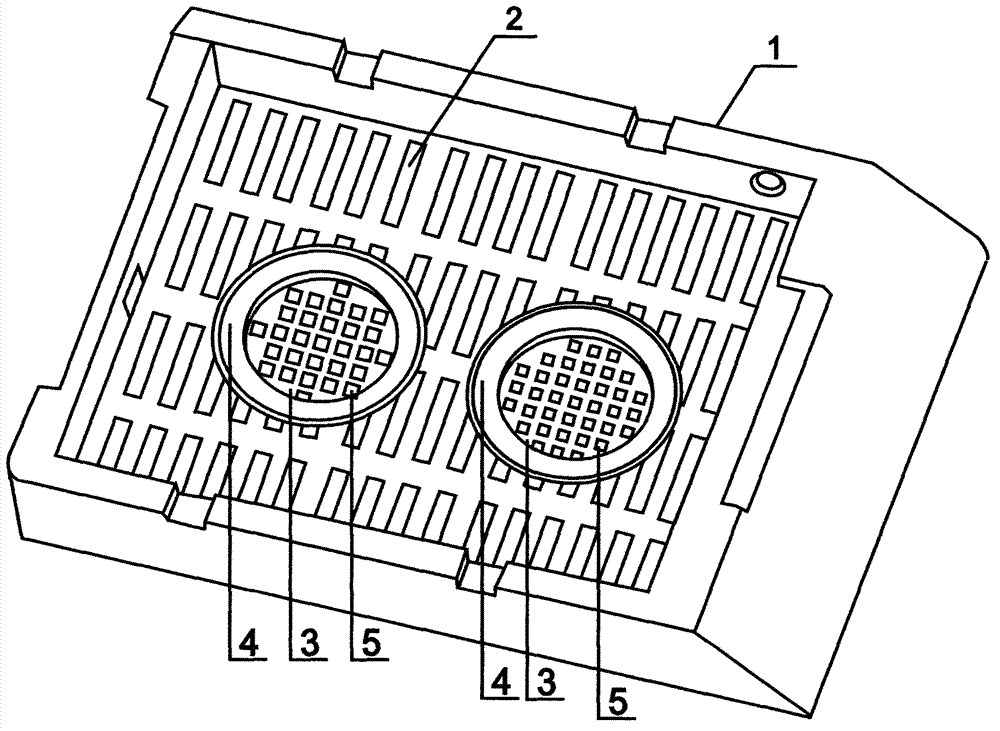

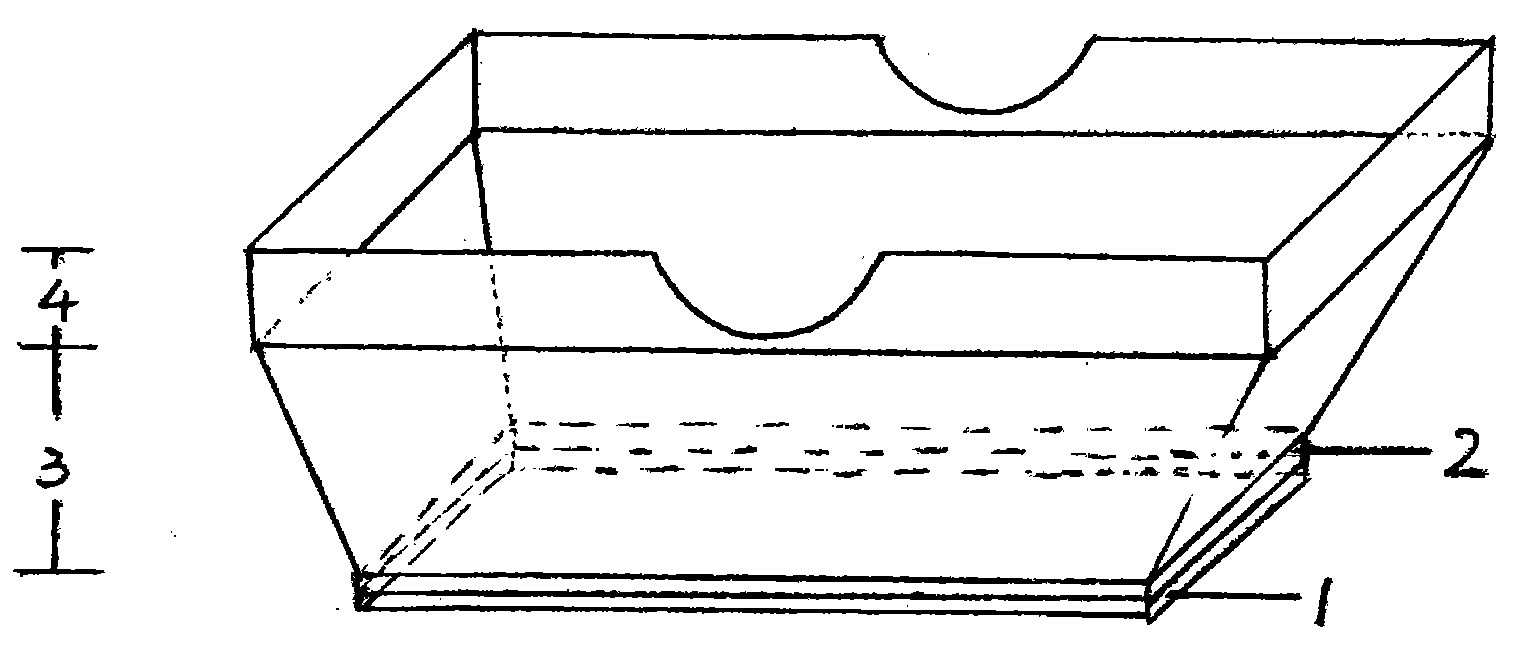

Multifunctional pathological tissue embedding box

InactiveCN103926118AHigh embedding efficiencyRealize dehydration embeddingPreparing sample for investigationParaffin oilsTissue specimen

The invention discloses a multifunctional pathological tissue embedding box, which is provided with a box body (1) for placing a tissue specimen and a box cover, wherein the box body (1) is a concave groove formed by a bottom surface and four side surfaces, the bottom surface is provided with louvers (2) and is further provided with at least two sinking wells (3), the inner diameter of each sinking well (3) is 0.5-2 cm, the depth is 0.2-1 mm, the well edge of each sinking well (3) is provided with an annular groove (4), the well bottom of the sinking well (3) is provided with a plurality of through holes (5), the distance between the through holes (5) is 0.2-1 mm, separated tissue placement chambers (6) are correspondingly arranged on the sinking wells (3), and the bottom end of the tissue placement chamber (6) is just inserted into the annular groove (4). According to the multifunctional pathological tissue embedding box, with the structure, multi-purpose-in-one-box can be achieved, dehydration embedding on conventional tissues, small tissues and gastrointestinal endoscope tissues can be achieved, the embedding efficiency of paraffin can be fundamentally improved, and the case analysis speed can be increased.

Owner:陈军

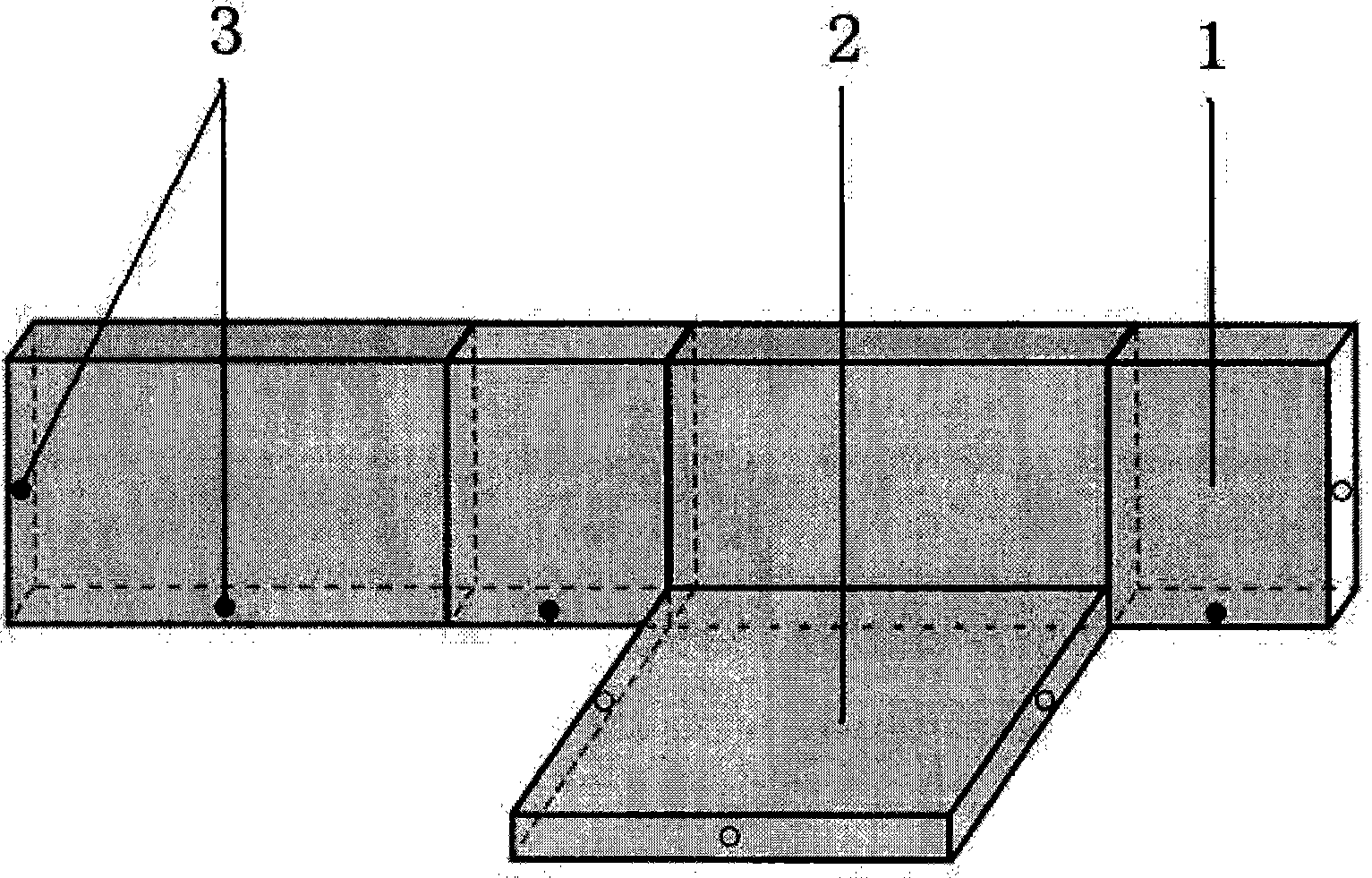

Multi-specification and multipurpose organization example embedding machine

InactiveCN101451929ASmooth peelingNo stickingWithdrawing sample devicesPreparing sample for investigationCommunicating vesselsTissue sample

This invention is frozen tissue sample section embed apparatus used for life science experiment and medical pathological tissue examination. A multi-gauge multi-use tissue sample embed apparatus is comprised of a multi-gauge embedding frame, an embedding substrate, a spherical connector. By designing tissue sample embedding apparatus with different size and gauge, problems with existing technology of difficulty on embedding tissue and embryo in different shape and size can be conveniently solved via using single case, which effectively avoid confusion among different tissue and samples. The apparatus according to this invention can conveniently and rapidly carry out high quality freezing process can be carried out on embedded tissue and embryo as a special tissue embed-freeze apparatus, especially suitable for life science, pathology and anatomy, etc., which simultaneously bring new improvement for existing tissue embedding module.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

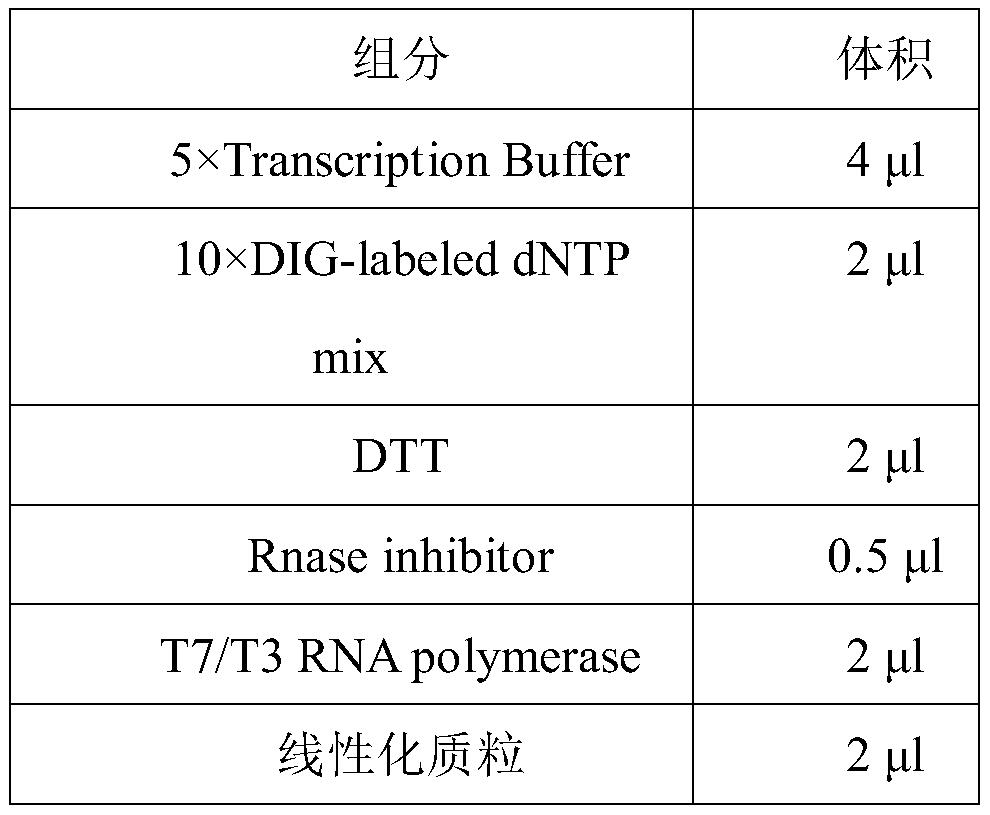

Method suitable for in-situ hybridization of cherax quadricariratus gonadal tissue mRNA paraffin section

ActiveCN109988846ARealize the display effectClear specificityMicrobiological testing/measurementClimate change adaptationBiologyNucleoplasm

The invention provides a method suitable for in-situ hybridization of a cherax quadricariratus gonadal tissue mRNA paraffin section, and belongs to the technical field of in-situ hybridization. The method comprises the steps of gonadal tissue embedding, paraffin sectioning, in-situ hybridization, and photographing and recording. The sequence of a probe used in in-situ hybridization is as shown inSEQ ID NO.3. The probe has clear specificity on tissue positioning of a dsx gene, so that the display effect on the mRNA level of the dsx gene is realized. The method for mRNA in-situ hybridization ofthe paraffin section is established in cherax quadricariratus to research expression modes of related genes in the gonad, and the expression location of the sex-related genes of the cherax quadricariratus in the gonad can be clearly described. The method avoids tissue shrinkage and cell deformation while the dewaxing effect of the paraffin section is good, so that the tissue is still kept in theoriginal position, the tissue morphology is kept complete, the enzymolysis effect can be improved, cell coloring is good, nucleoplasm is clear, and the in-situ hybridization accuracy is finally improved.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

Cell three-dimensional culture matrigel wax embedding method

The invention discloses a cell three-dimensional culture matrigel wax embedding method. The method includes steps: (1) designing and manufacturing a slide which morphologically fits an internal storage space of an embedding box; (2) cutting off a matrigel three-dimensional culture tissue from a Transwell upper chamber, and fixing in paraformaldehyde in mass percent of 4-6% for 6-24h; (3) after successful fixing, taking the matrigel three-dimensional culture tissue out of paraformaldehyde, and enabling a collagen face of the matrigel three-dimensional culture tissue to be adsorbed on the slide;(4) putting the slide which morphologically fits the internal storage space of the embedding box and adsorbs the matrigel three-dimensional culture tissue into the embedding box in which gauze is laid; (5) dewatering, transparentizing and waxing; (6) adopting a tissue slicing knife for completely scrape off the tissue adsorbed on the slide from the slide, and embedding the tissue. In an embeddingprocess, tissue curling and shedding and cell falling are avoided. Therefore, the method is suitable for popularization and utilization.

Owner:程辉

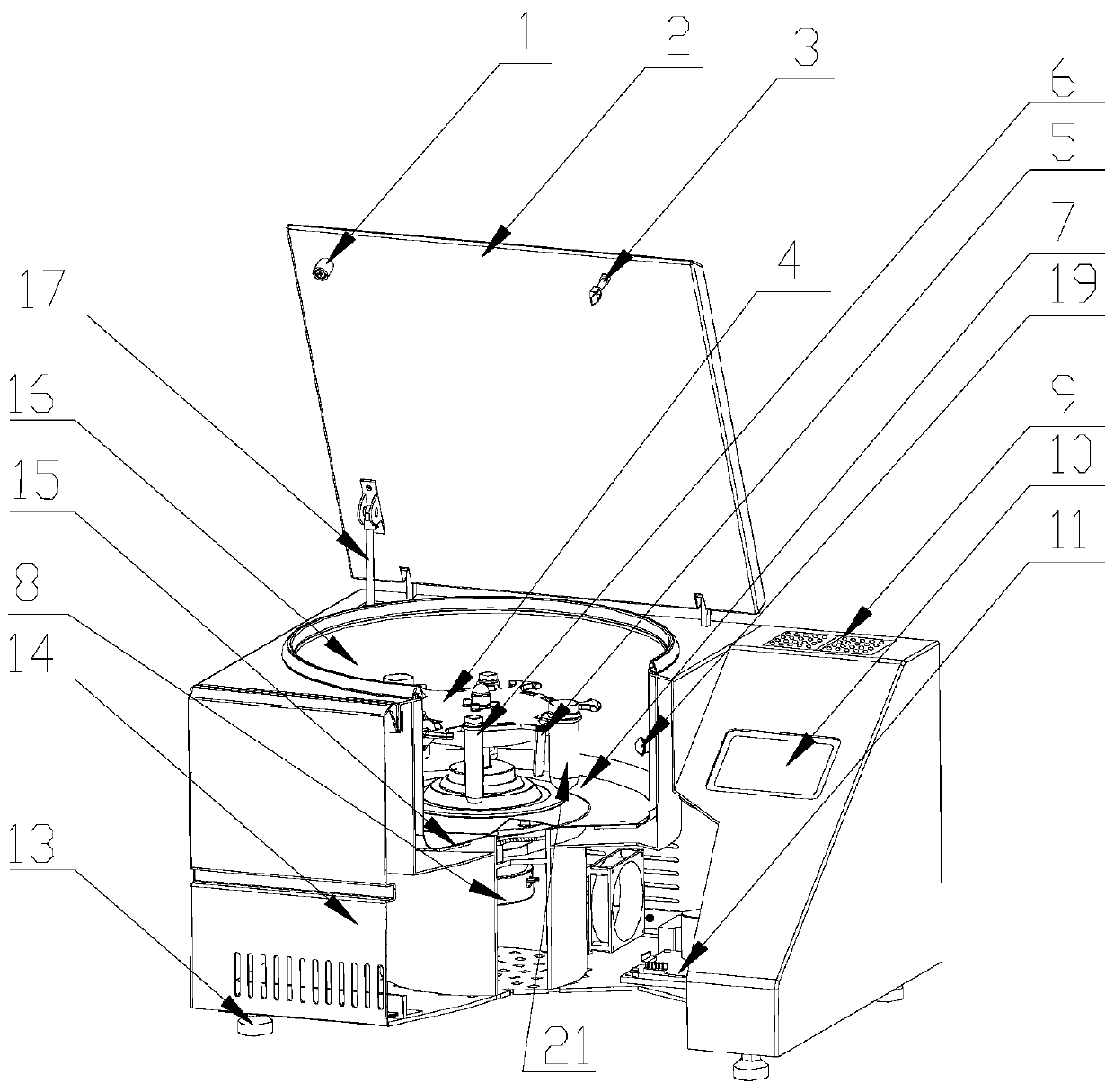

Pathological liquid-based thin-layer cell tissue embedding machine and using method thereof

ActiveCN111562165AEasy to operateSmall footprintPreparing sample for investigationCircular discTissue sample

The invention discloses a pathological liquid-based thin-layer cell tissue embedding machine and a using method thereof. The pathological liquid-based thin-layer cell tissue embedding machine comprises a centrifugal mechanism, the centrifugal mechanism comprises a rotating disc, the rotating disc comprises a disc body and a plurality of hanging plates evenly arranged on the peripheral side of thedisc body, protruding blocks matched with positioning grooves of a pod box are arranged on two sides of each hanging plate, and a plurality of through holes used for hanging cylindrical pods are formed in the edge of the disc body. The using method of the embedding machine comprises the following steps of: 1, determining a dosage threshold value of a cell tissue sample; 2, pretreating a first celltissue sample; 3, pretreating a second cell tissue sample; 4, selecting a required cell tissue sample detection type; 5, preparing a liquid-based thin-layer cell smear; and 6, preparing the cell embedding block. The problems of large instrument space occupation, high cost and the like due to the fact that various detection modes need various instruments and equipment are solved, the inspection time is saved, and popularization and application are facilitated.

Owner:XIAN MEIJIAJIA MEDICAL TECH CO LTD

Toluidine blue rapid staining method of brain tissue frozen section

InactiveCN110132690AShorten dyeing timeImprove continuityPreparing sample for investigationToluidineCylindroma

The invention relates to a toluidine blue rapid staining method of brain tissue frozen section. The method comprises the following steps: appropriately trimming the treated experimental animal brain tissue, placing on a sample holder in a required direction, embedding the tissue as a cylinder by utilizing tinfoil, dropping in OTC embedding glue, and quickly freezing in a refrigerator at -80 DEG C;taking out the frozen tissue section, and then placing in AF stationary liquid to immobilize immediately; performing washing: placing the immobilized frozen section in distilled water to wash for 5-7s; performing toluidine blue staining: placing the washed frozen section in a toluidine blue solution, which is preheated to 50-60, to stain; performing washing: placing the stained section in the distilled water, washing for 8-14s until the flooding is washed; performing dehydrating: placing the section in 80% of alcohol to dehydrate for 1min; performing color separation: placing the dehydrated section in the 95% of alcohol to perform color separation for 20-30s; performing dehydrating: quickly placing the color-separated section in the anhydrous alcohol to dehydrate for 10-20s; and performing transparency and mounting: placing the section in the xylene-alcohol mixed solution for 3-8s, and then placing in the pure xylene for 5-10s, and then performing the mounting.

Owner:HENAN UNIV OF URBAN CONSTR

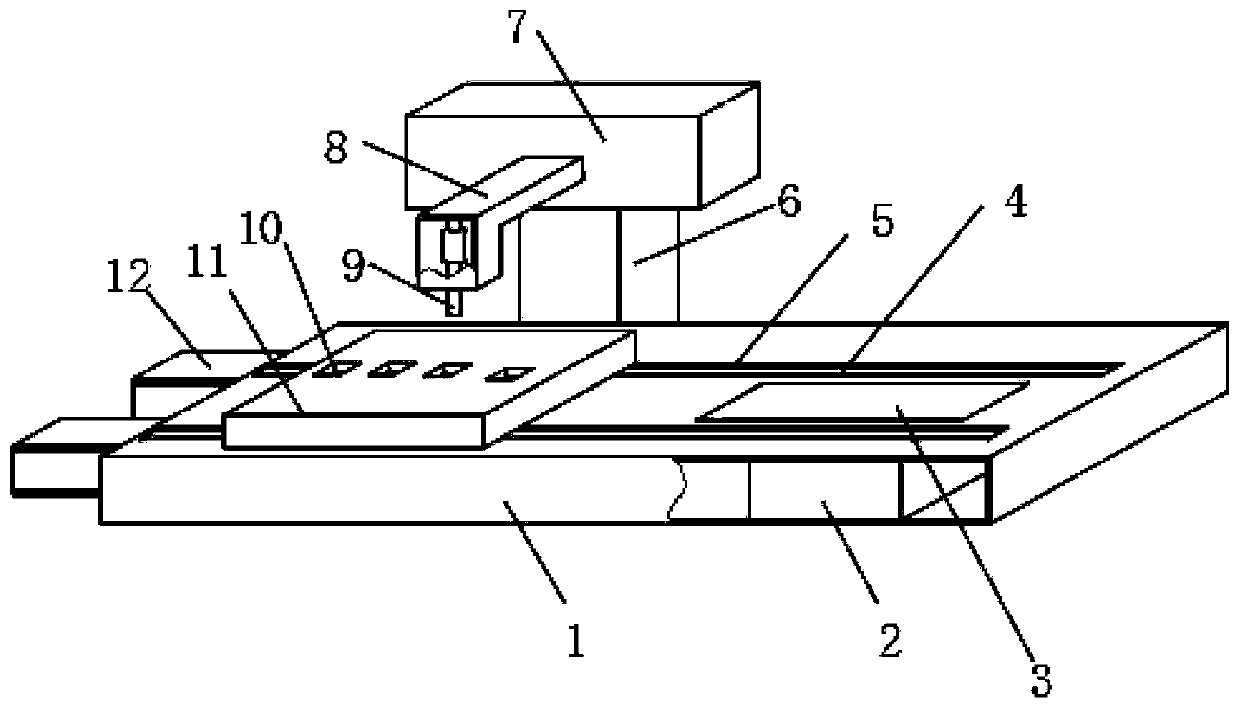

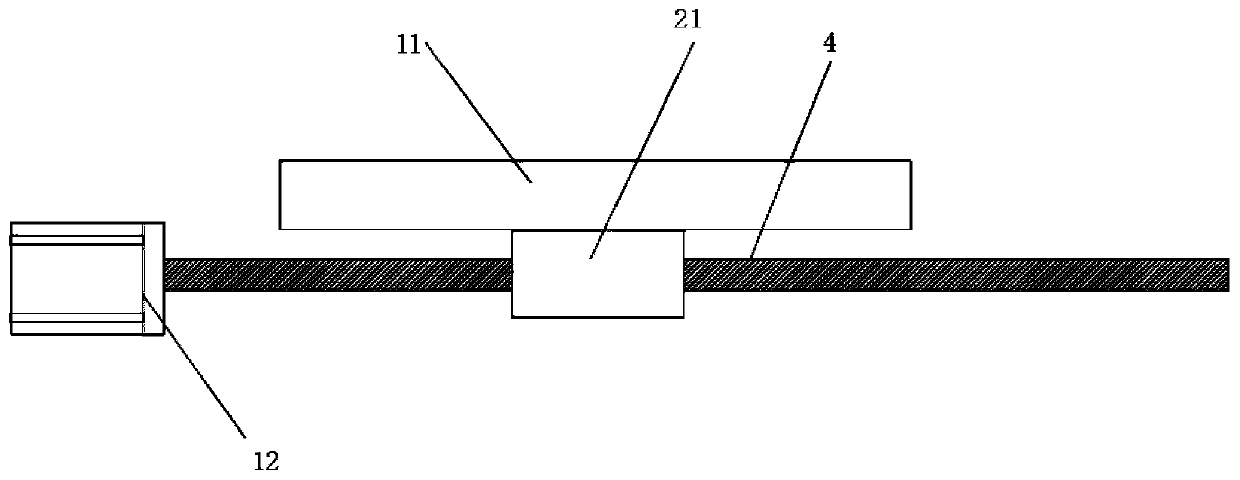

Biological tissue embedding machine

PendingCN111504755AEasy to cleanAvoid pollutionPreparing sample for investigationForeign matterStructural engineering

The invention discloses a biological tissue embedding machine. The biological tissue embedding machine comprises a base, a wax melting box and a manufacturing table; a strip-shaped groove is formed inthe upper surface of the base in the length direction; a lead screw is rotationally connected into the strip-shaped groove; a lead screw nut seat is in threaded connection with the lead screw; the manufacturing table is arranged on the upper surface of the base and fixedly welded to the lead screw nut seat; a servo motor driving the lead screw to rotate is fixed to one end, in the length direction, of the base through bolts. According to the biological tissue embedding machine of the present invention, a filter cover is arranged on a wax guide pipe for conveying wax liquid; a filter screen cover is arranged in the filter cover; the wax liquid enters the filter screen cover to be filtered; the wax liquid passing through the filter screen cover can be discharged through the wax guide pipe;impurities in the wax liquid can be filtered and collected through the filter screen cover and then discharged through a slag discharge pipe; and therefore, foreign matters are effectively prevented from polluting specimens; and the the slag discharge pipe is designed, so that the cleaning of the filter screen cover can be facilitated.

Owner:成都华银医学检验所有限公司

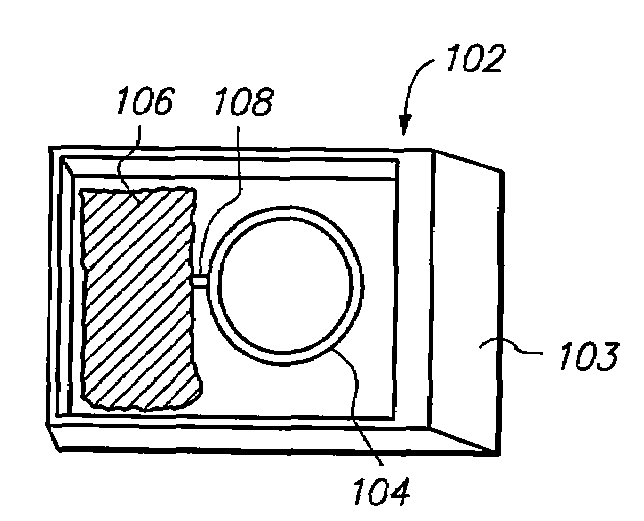

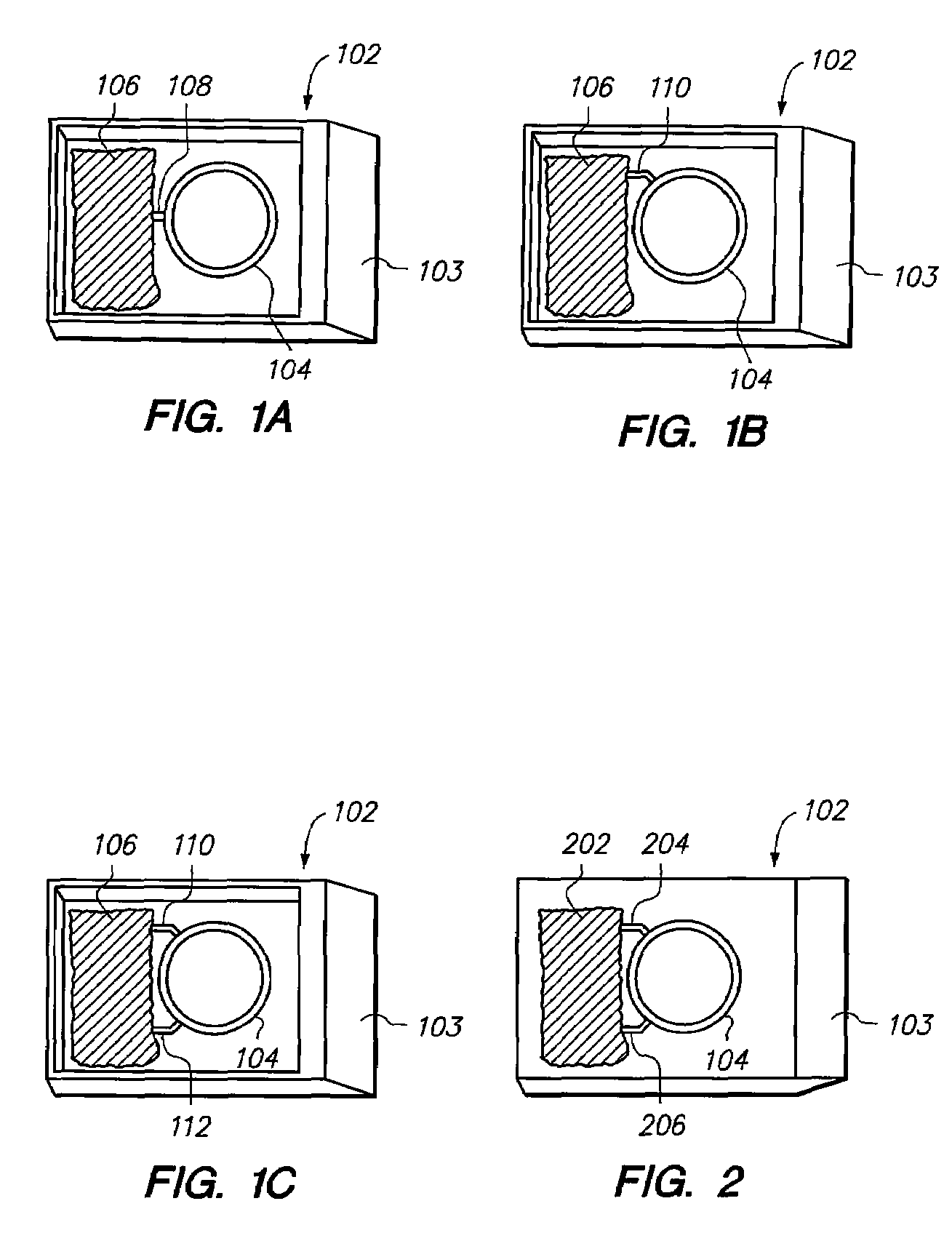

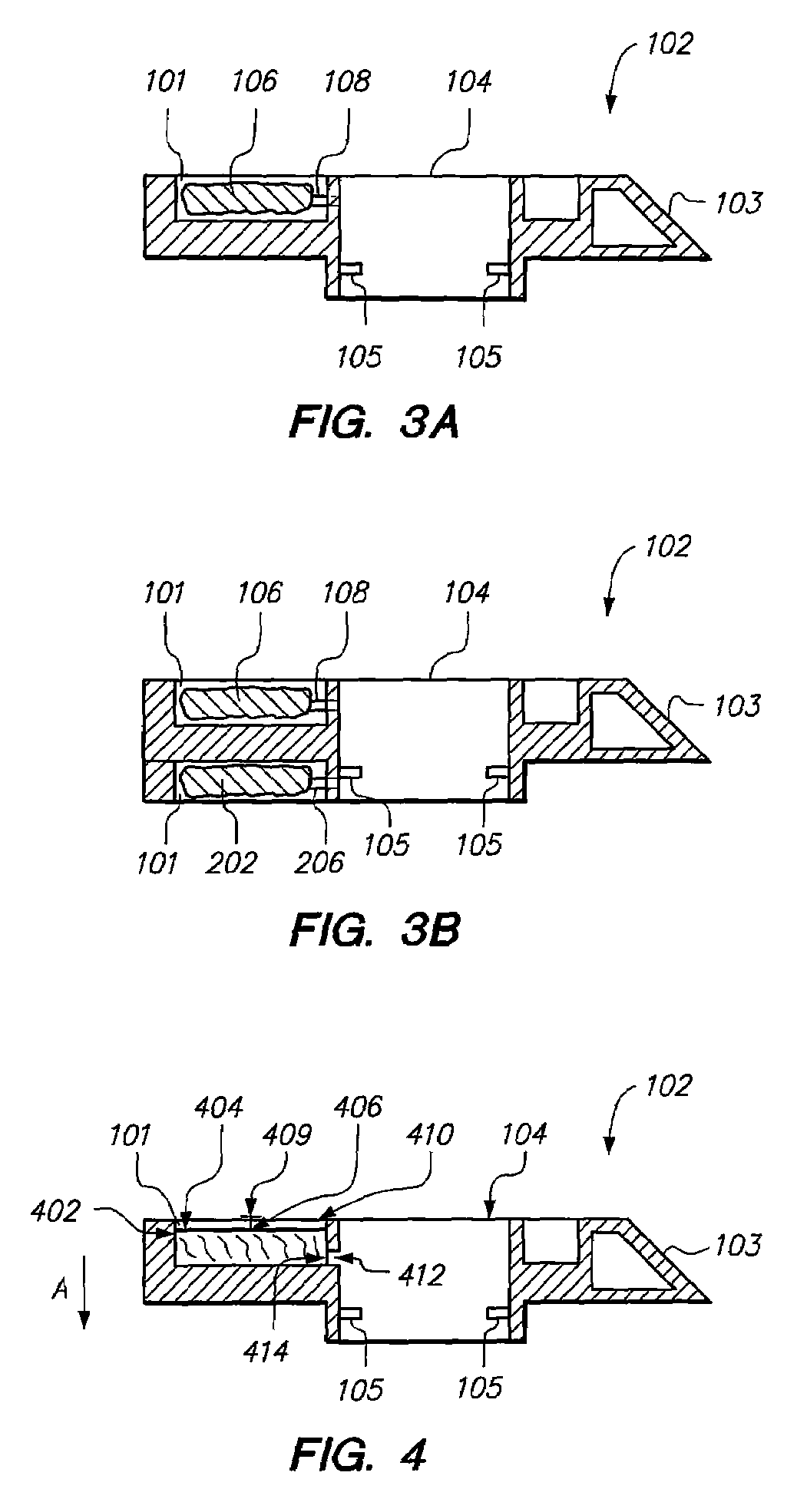

Cell block cassette device

ActiveUS7666358B2Withdrawing sample devicesPreparing sample for investigationBiomedical engineeringTissue cassette

A tissue cassette assembly includes a housing having a recess formed therein, and a compressible reservoir disposed partially or wholly inside of, or otherwise attached in fluid communication with, the housing recess, the compressible reservoir containing a tissue embedding material. The tissue cassette further includes a port disposed in the housing, the port in fluid communication with the compressible reservoir at one end and terminating in a sample cavity at another end. During operation, the compressible reservoir is compressed or squeezed to release the tissue embedding material into the sample cavity containing the biological sample.

Owner:CYTYC CORP

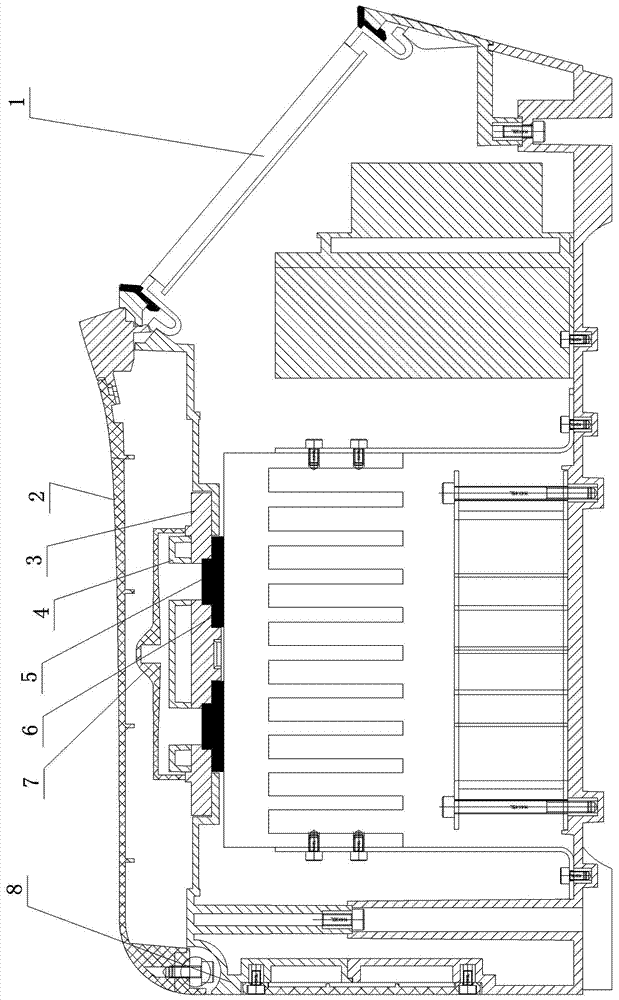

Heating and cooling device for an apparatus for tissue processing for the tissue embedding

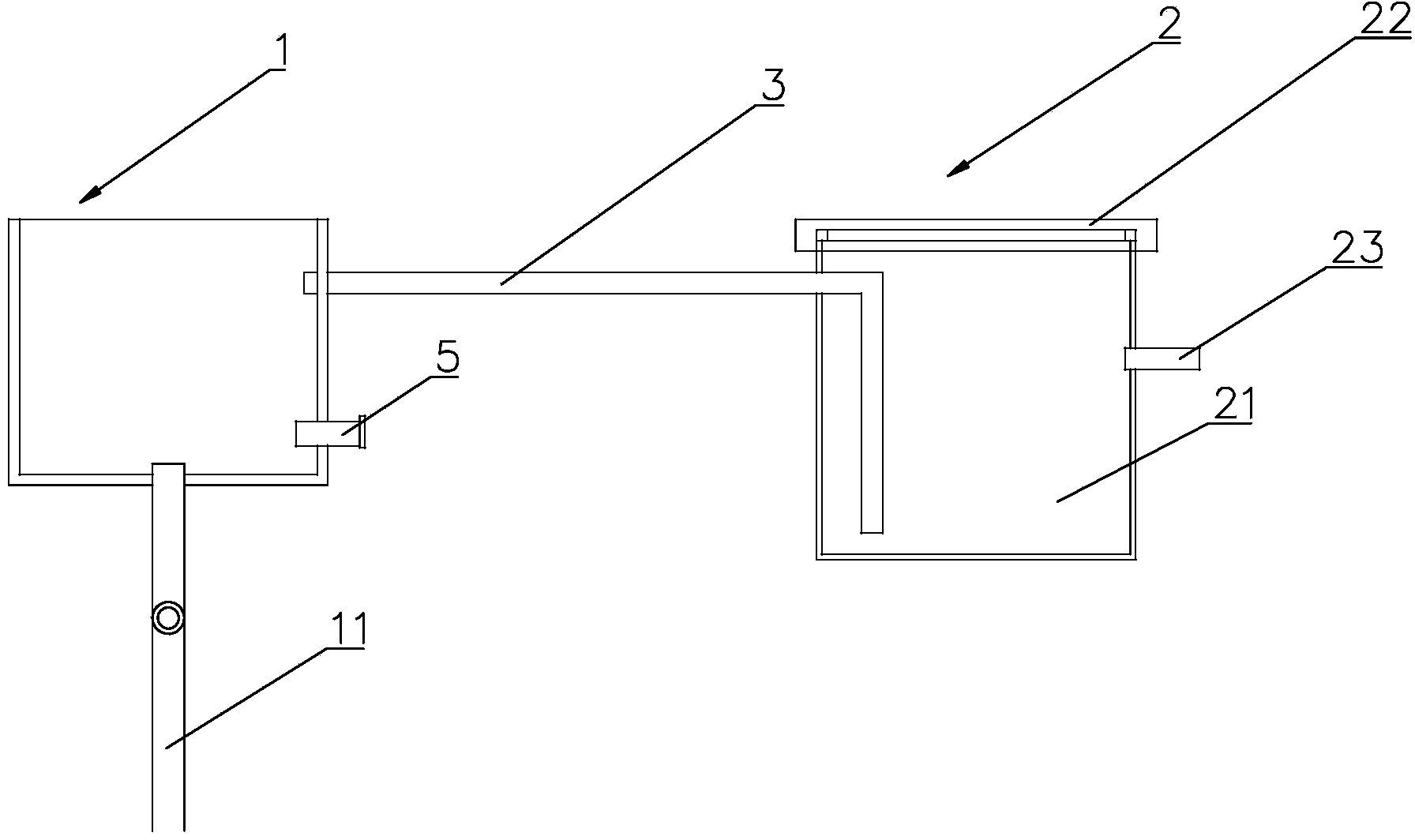

ActiveUS6939512B2Promote exchangeEasy to changeLiquid surface applicatorsHeating or cooling apparatusTissue EmbeddingTissue Preparation

A heating and cooling device (3) for an apparatus (1) for tissue preparation for the tissue embedding is disclosed. The apparatus (1) has a free space (13) for the accommodation of a transport plate (15). The apparatus (1) is surrounded by a housing (5) which defines an upper side (8) and a heating and cooling device (3) that is provided on the upper side (8) of the housing (5), and the heating and cooling device (3) has a reception (23) with at least one chamber (32) for the accommodation of at least one processing container (17). The heating and cooling device (3) is pivotable with respect to the upper side (8) of the housing (5).

Owner:LEICA MICROSYSTEMS GMBH

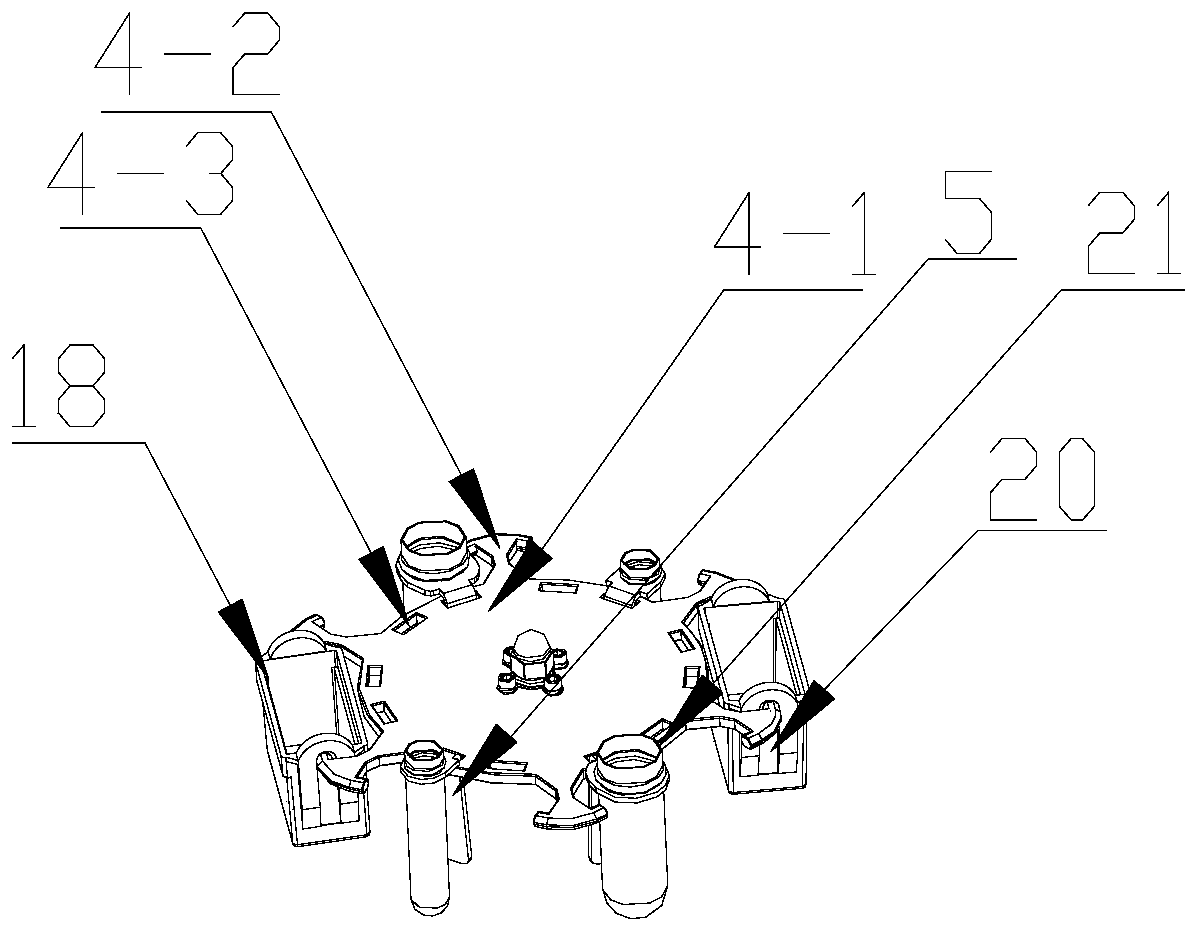

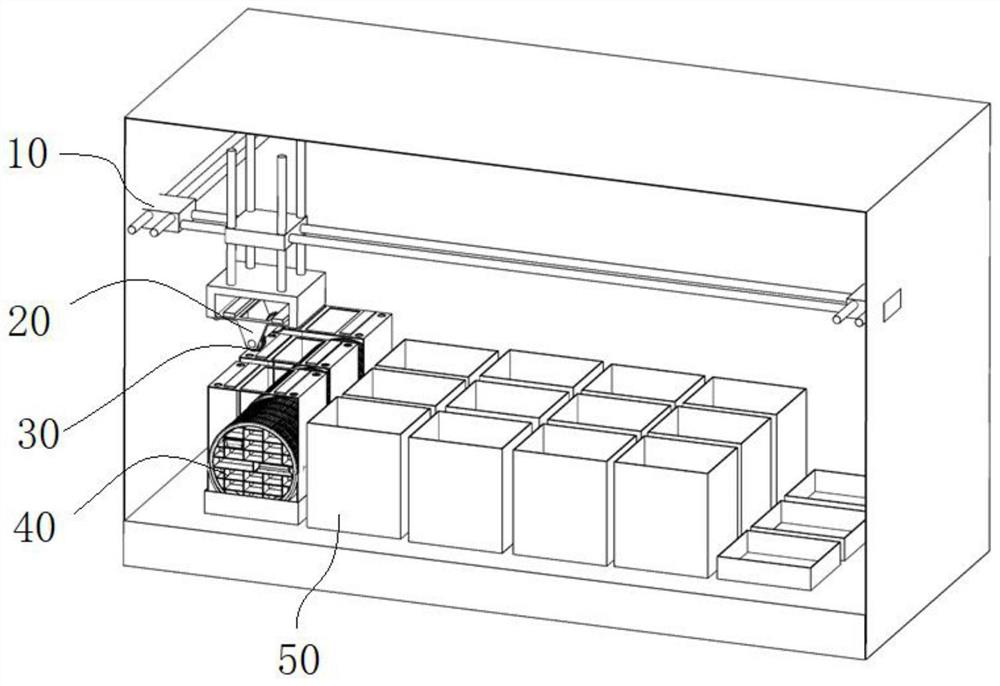

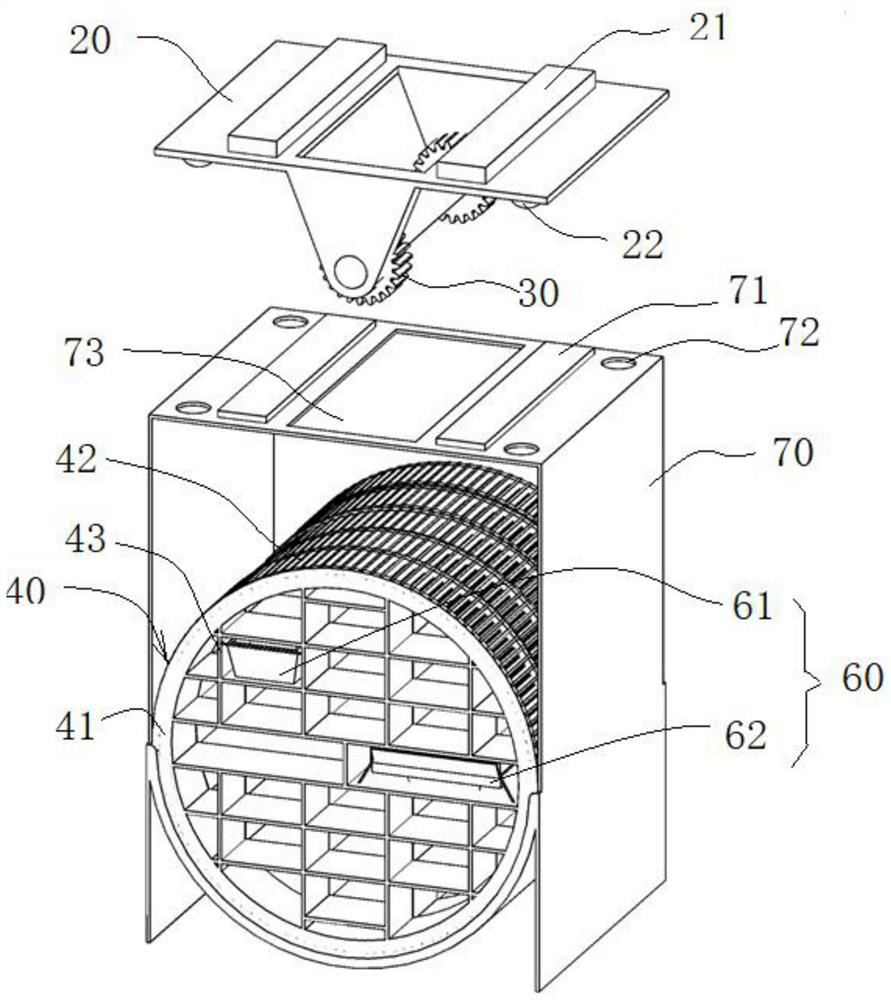

Automatic treatment device and method for tissue sample dehydration and embedding

PendingCN112098183AImprove work efficiencyPreparing sample for investigationCircular discTissue sample

The invention provides an automatic treatment device and method for tissue sample dehydration and embedding. The device comprises a three-dimensional moving device, a rotary driving device, a disc container, a multi-groove liquid changing workbench and a tissue embedding mold box assembly. The tissue embedding mold box assembly comprises an embedding mold box upper cover, an embedding mold box anda tissue positioning support located between the embedding mold box upper cover and the embedding mold box. The tissue positioning support is used for seamlessly attaching biological tissue to the bottom of the embedding mold box. The disc container is used for accommodating at least one tissue embedding mold box assembly; the multi-groove liquid changing workbench comprises at least one container containing molten embedded wax liquid. The three-dimensional moving device is used for driving the disc container to move up and down in each container; and the rotary driving device is used for driving the disc container to rotate in the container. The whole process is automatically carried out, and compared with the prior art, samples do not need to be manually transferred among several different machines, so that the working efficiency is greatly improved.

Owner:武汉泰沃科技有限责任公司

Tissue embedding solution and tissue slice preparation method

PendingCN110426254AAvoid deformationPreparing sample for investigationPlasticizerTissue slice preparation

The invention relates to tissue embedding solution and a tissue slice preparation method. The tissue embedding solution comprises resin monomers, a plasticizer, a catalyzer, an accelerator and a defoamer; according to the volume percentage of the tissue embedding solution, the resin monomers include 30-35% of a hydrophilic resin monomer, 55-60% of a first hydrophobic resin monomer and 5-10% of a second hydrophobic resin monomer; the plasticizer is 5-8% in the volume percentage of the tissue embedding solution; the concentration of the catalyzer is 0.4g / 100mL; the concentration of the accelerator is 40muL / 100mL to 50muL / 100mL; and the concentration of the defoamer is 200muL / 100mL to 400muL / 100mL. After being embedded by the tissue embedding solution, a tissue to be analyzed is sliced; and atissue slice difficult to deform can be prepared.

Owner:深圳市领先医疗服务有限公司

Tissue embedding box

The invention belongs to the technical field of pathology equipment, solves the technical problems in the prior art that an incubator and a cold table are used manually to carry out preheating, cooling and re-preheating on an embedding box, as a result, the process is tedious, manpower is consumed, the progress is affected, and skin injury of an operator is caused by the too high temperature of the preheated embedding box, and solve the problems that when being taken out, an embedding block, with residual wax remaining around, cannot be directly used for slicing, and block trimming and re-precooling are needed before slicing. The adopted technical scheme is as follows: the embedding box comprises a pressure sensing device positioned at the bottom and an automatic temperature adjusting device connected with the pressure sensing device, a tissue embedding area positioned at the middle part and a dehydration box fixing area positioned at the top. According to the technical scheme, pressure sensing is adopted to control the temperature adjustment, and the incubator or the cold table is not needed, so that space is saved; a thermal insulation material is arranged outside the embedding box, so that skin injury of the operator caused by the high temperature is avoided; the embedding block taken out can be directly used for slicing, and block trimming and re-precooling are not needed before slicing, so that time and manpower are saved, the cost is reduced, and the working efficiency is improved.

Owner:FIRST HOSPITAL AFFILIATED TO GENERAL HOSPITAL OF PLA

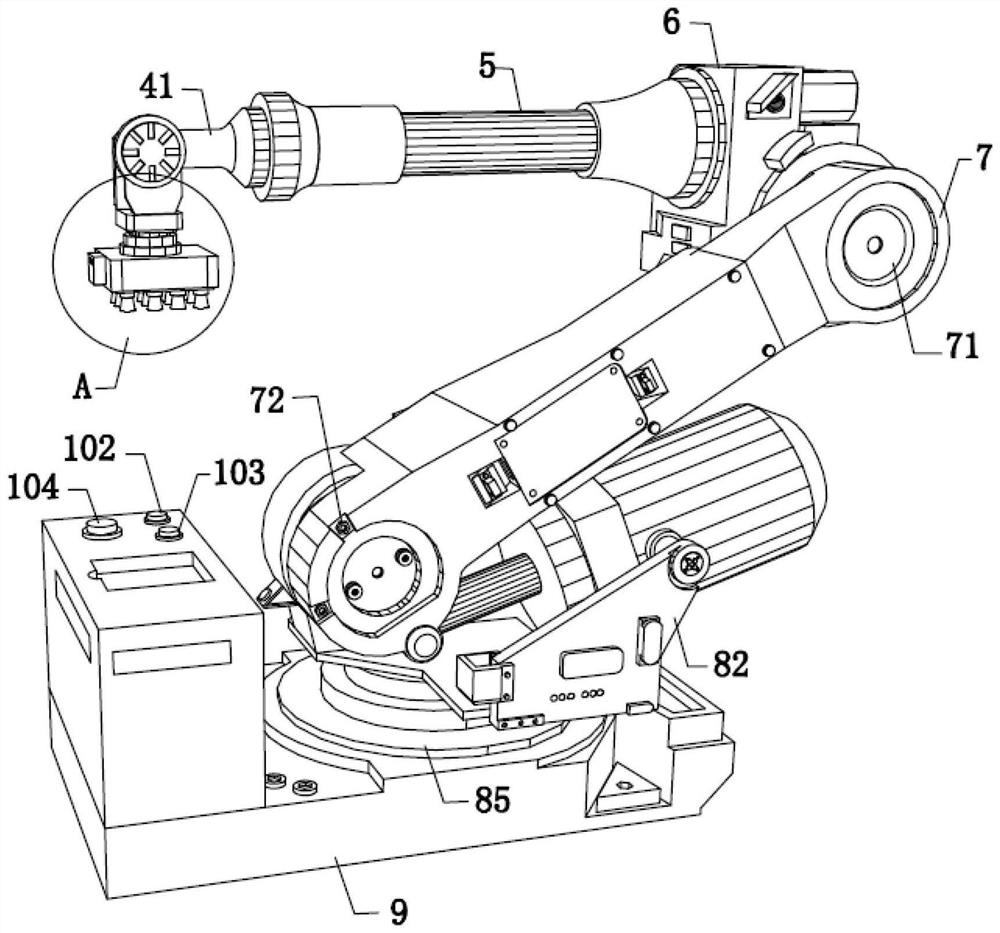

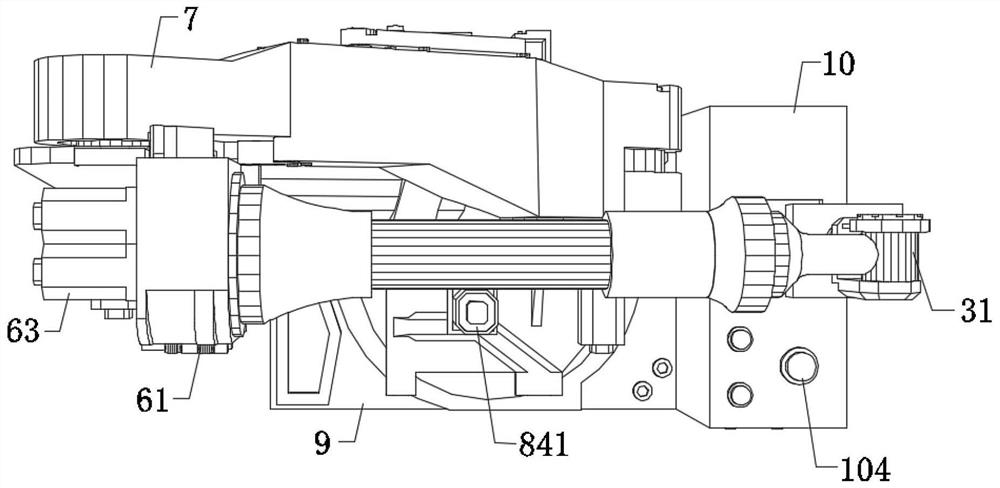

Intelligent covering device

PendingCN113264485AEasy to replaceImprove work efficiencyFlanged caps applicationCap deviceElectrical and Electronics engineering

The invention discloses an intelligent covering device which is particularly suitable for a pathological tissue embedding box. The intelligent covering device comprises an adsorption device, a sensing device, a first rotating device, a telescopic device, a mechanical arm, a driving device, a second rotating device, a chassis and an operator, the sensing device is installed on one side of the adsorption device, and the adsorption device is fixedly connected with the first rotating device; the first rotating device is connected with a revolver, one side of the revolver is connected with one end of the telescopic device, the other end of the telescopic device is connected with a fixing device, one side of the fixing device is rotationally connected with one end of the mechanical arm, the other end of the mechanical arm is connected with the driving device, and the second rotating device is arranged below the driving device; and the chassis is arranged below the second rotating device, and one side of the chassis is fixedly connected with the operator. The sensing device and the rotating devices of the intelligent covering device are matched with each other, so that a box cover of the embedding box can be aligned with the embedding box for pressing, and the accuracy is high.

Owner:赣南医学院第一附属医院

Mold for preparing wax block used for embedding pathologic tissue

ActiveCN110146366APlay the role of orientationMorphological integrityPreparing sample for investigationWaxEngineering

The invention relates to a mold for preparing a wax block used for embedding pathologic tissue. The mold comprises a frame and a mold core, wax block grooves are formed in the upper surface of the mold core, guiding holes penetrating the mold core are arranged in the bottom centers of the wax block grooves respectively, each guiding hole is internally provided with a matched and vertically penetrated push rod, horizontal top plates are fixed to the upper ends of the push rods respectively, the lower portions of the push rods are sleeved by springs respectively, and castings extending vertically and upwardly are fixed to the centers of the upper surfaces of the top plates respectively. The prepared wax block is complete in the morphological structure and provided with a central hole, relatively small or thin tissue can be placed in the hole during use, and then liquid wax is filled into the hole to embed the tissue, the hole can limit the tissue movement and prevent the tissue from inclination, thus, the orientation of the tissue is fixed, and a user can obtain an ideal position during slicing, and mechanical damage on the tissue when the orientation of the tissue is adjusted by repeatedly clamping the tissue by tweezers can be effectively avoided.

Owner:HENAN INST OF SCI & TECH

Low-temperature tissue embedding temperature control system

ActiveCN107463193AFast heatingFast coolingComputer controlTemperatue controlTemperature controlControl system

The invention provides a low-temperature tissue embedding temperature control system, and belongs to the technical field of biospecimen low-temperature tissue embedding. The low-temperature tissue embedding temperature control system is high in working efficiency, and good in use effect. The system comprises a heating and refrigerating semiconductor element and a control circuit; a control signal output end port of the control circuit is connected to a control signal input port of the heating and refrigerating semiconductor element; a detection signal input port of the control circuit is connected with a detection signal output port of a temperature sensor for detecting the temperature of the heating and refrigerating semiconductor element; the control circuit comprises a CPU, a power conversion part, a system control part, a storage, a system feedback part, a display part, a Bluetooth part and a heat dissipating control part; the control signal output port of the CPU is correspondingly connected with the control signal input port of the system control part and the control signal input port of the heat dissipating control part.

Owner:苏州碳卡智造科技有限公司

Temperature control system for cryogenic tissue embedding

InactiveUS20190063798A1Operation efficiency is highEasy to useComputer controlTemperatue controlTemperature controlControl system

A temperature control system for cryogenic tissue embedding belongs to the technical field of cryogenic tissue embedding of biological samples, which in particular relates to a temperature control system for cryogenic tissue embedding. The present invention provides a temperature control system for cryogenic tissue embedding with high operation efficiency and good use effects. The present invention comprises a heating and cooling semiconductor element and a control circuit. A control signal output port of the control circuit is connected to a control signal input port of the heating and cooling semiconductor element, and a detection signal input port of the control circuit is connected to a detection signal output port of a temperature sensor that detects the temperature of the heating and cooling semiconductor element. The control circuit comprises a CPU, a power conversion part, a system control part, a memory, a system feedback part, a display part, a Bluetooth part, and a heat-dissipation control part. A control signal output port of the CPU is connected to a control signal input port of the system control part and a control signal input port of the heat-dissipation control part, respectively.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

Wax melting device for tissue embedding machine

ActiveCN104324668BEnsure uninterrupted supplyPrevent cooling hardeningPreparing sample for investigationFusionParaffin waxPulp and paper industry

Owner:福建启盛实验设备科技有限公司

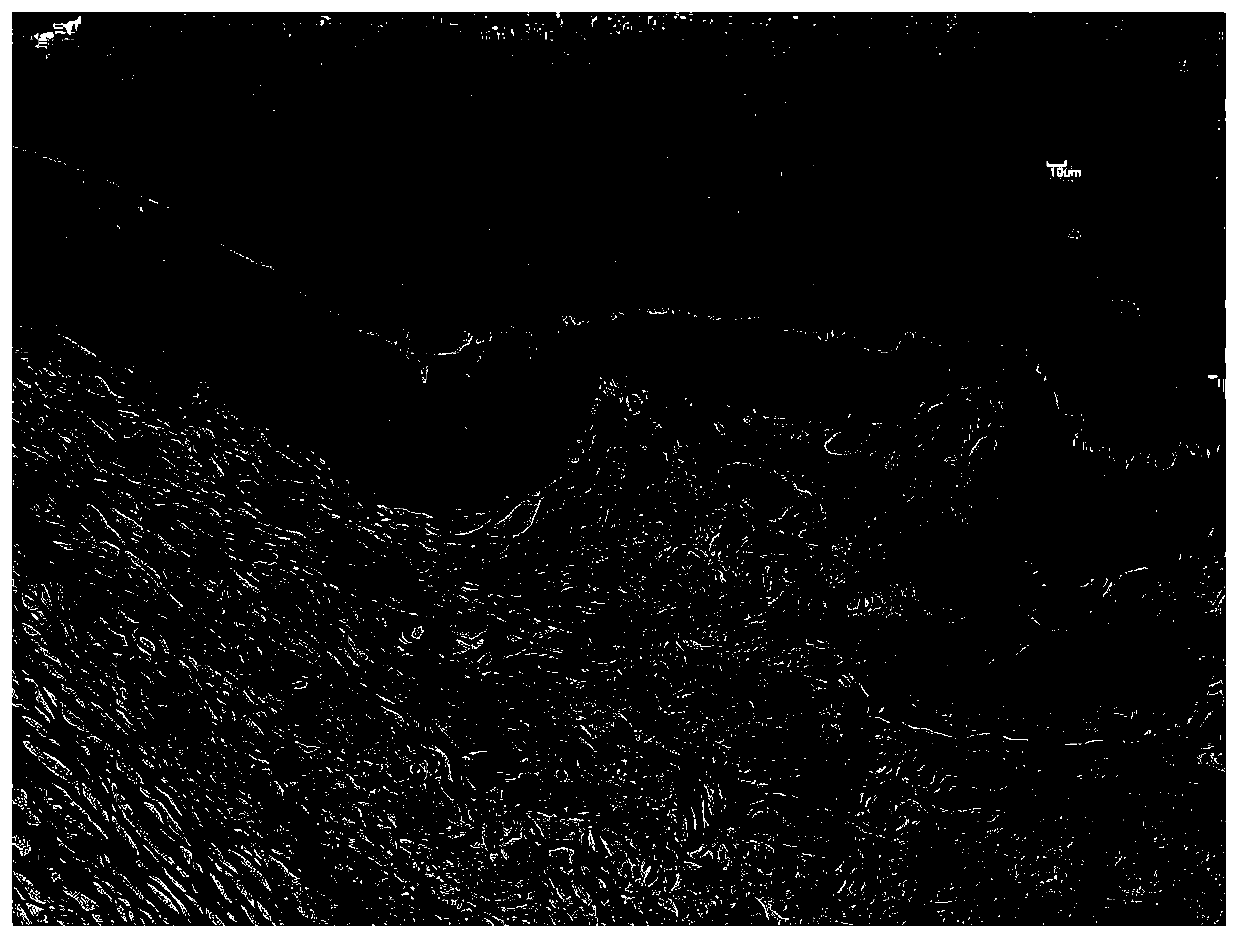

Application of three-dimensional printing technology in establishment of three-dimensional structure digital model in vitro of corneal limbal tissues

ActiveCN109859304ASolve the shortcomings of difficult alignmentSimple counterpointIncreasing energy efficiency3D modellingDimensional modelingDigitization

The invention belongs to the technical field of corneal anatomy, and particularly discloses an application of a three-dimensional printing technology in corneal limbal tissue in-vitro three-dimensional modeling, and the method of the application comprises the steps of specimen fixation, tissue embedding and slicing, HE staining, image acquisition, digitization and three-dimensional reconstructionto obtain a three-dimensional structure digitized model of corneal limbal tissue. The reconstructed corneal limbal three-dimensional stereogram can display the microstructure of the human corneal limbal tissue, and therefore it is indicated that the method for conducting three-dimensional digital reconstruction by collecting the high-definition microscopic tissue image obtained after slice dyeingis feasible. The method combines the advantages that adjacent tissue images are easy to align under the low-power lens and tissue images under the high-power lens are clearer, is simple and practical,and can also be used for microstructure three-dimensional reconstruction of other tissues.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com