Dewaxing device of tissue embedding machine

An embedding machine and wax melting technology, applied in the field of medical devices, can solve the problems of damage to the filter screen, failure to reach paraffin, decline in embedding quality, etc., and achieve the effects of preventing cooling and hardening, avoiding wax leakage, and smoothing the flow of wax.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

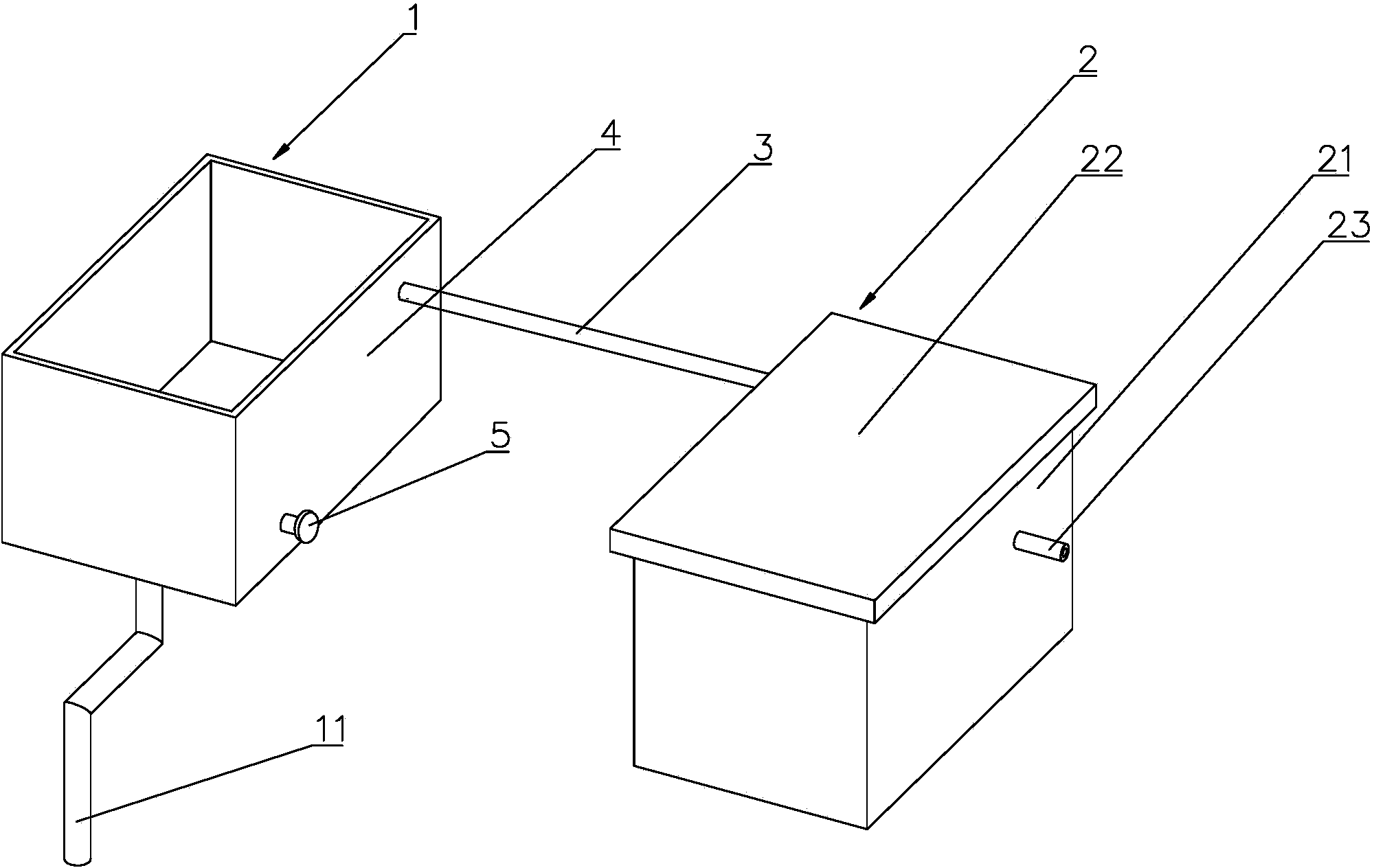

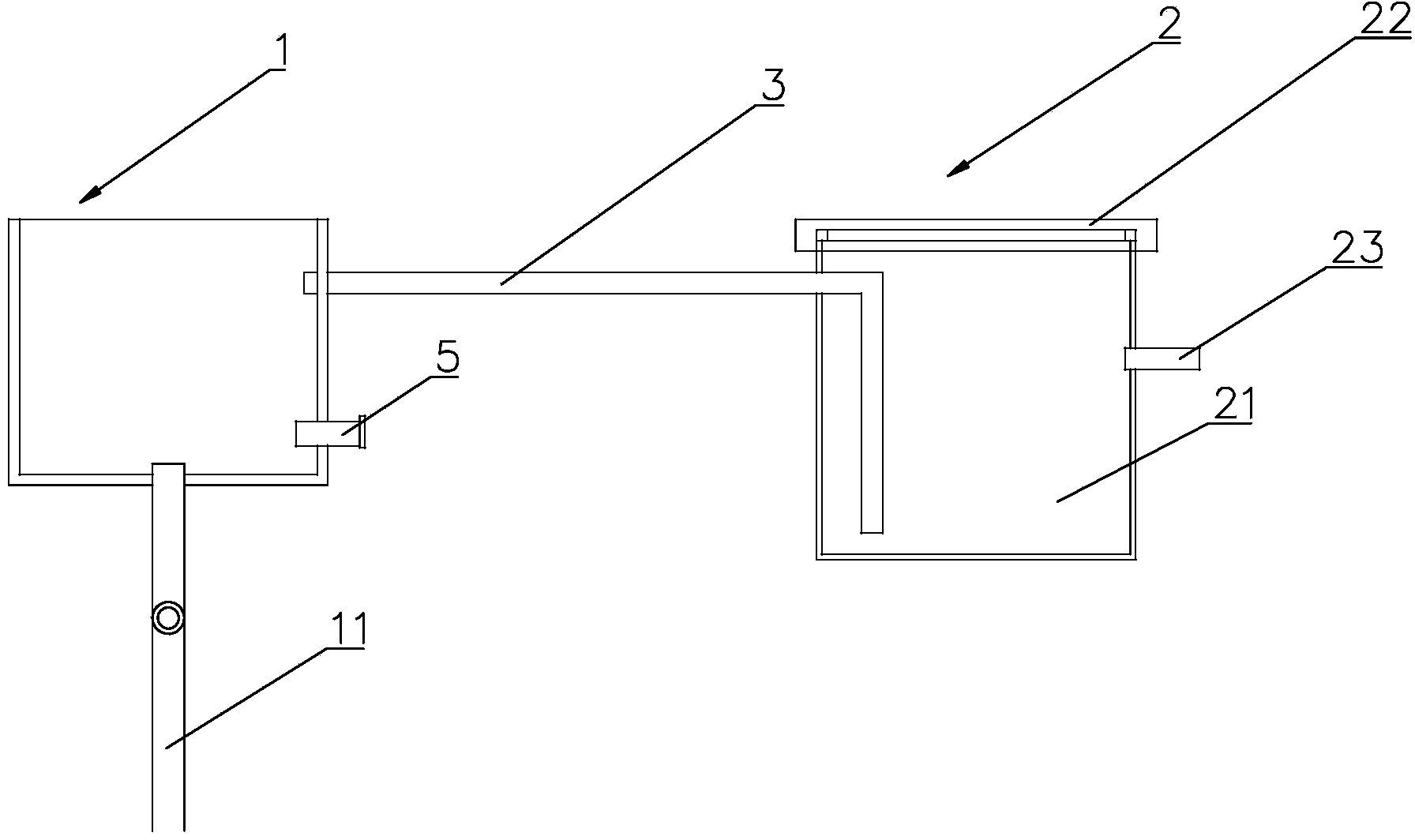

[0034] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is: a tissue embedding machine wax melting device, comprising a main wax melting tank 1 and an auxiliary wax melting tank 2, the auxiliary wax melting tank 2 is provided with a first heating device, and the main melting wax tank A wax outlet pipe 11 is provided at the bottom of the wax cylinder 1, a wax delivery pipe 3 is provided between the main wax melting cylinder 1 and the auxiliary wax melting cylinder 2, the auxiliary wax melting cylinder 2 is provided with a wax filling port, and the auxiliary melting wax cylinder 2 is provided with a wax feeding port. The wax cylinder 2 is sealed, the upper part of the side wall of the auxiliary wax melting cylinder 2 is provided with an air inlet 23, and the mouth of the wax outlet pipe 11 is provided with a second heating device. The first heating device is connected with a first temperature control device. The wax delivery pipe 3 is arranged on ...

Embodiment 2

[0035] Please refer to figure 1 and figure 2, Embodiment 2 of the present invention is: a kind of wax melting device of tissue embedding machine, comprises main wax melting cylinder 1 and auxiliary wax melting cylinder 2, and described auxiliary wax melting cylinder 2 is provided with first heating device, and described main melting wax cylinder A wax outlet pipe 11 is provided at the bottom of the wax cylinder 1, a wax delivery pipe 3 is provided between the main wax melting cylinder 1 and the auxiliary wax melting cylinder 2, the auxiliary wax melting cylinder 2 is sealed, and the auxiliary wax melting cylinder 2 The upper part of the side wall is provided with an air inlet 23, and the nozzle of the wax outlet pipe 11 is provided with a second heating device. The wax delivery pipe 3 is arranged on the upper part of the main wax melting cylinder 1 and the auxiliary wax melting cylinder 2. The wax delivery pipe 3 is located at one end of the auxiliary wax melting cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com