Device for filtering gas flow

A technology for gas flow and filtration components, applied in membrane filters, dispersed particle filtration, transportation and packaging, etc., can solve the problem of inability to export filtration auxiliary substances, and achieve the effect of improving filtration effect, avoiding downtime and improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

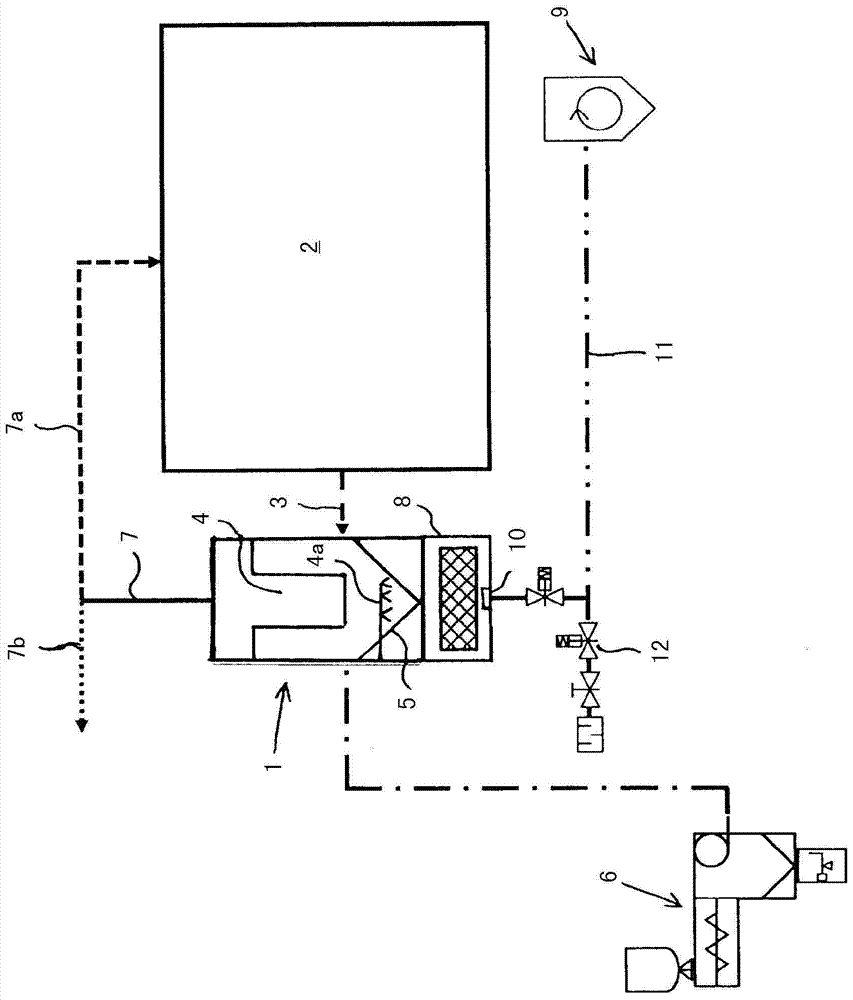

[0036] figure 1 A device 1 for filtering a gas flow is shown schematically, which is used in the present case for air cleaning in a paint spray booth 2 of a wet painting plant for painting motor vehicle parts.

[0037]A feed gas stream with cohesive paint particles, referred to below as particles, is supplied from the spray booth 2 to the device 1 . The device 1 includes a filter assembly 4 with one or more filters, which can be designed in particular as compact filters.

[0038] In order to prevent the filter surface from sticking, a container 5 arranged below the filter assembly 4 with an auxiliary filter substance is arranged in the device 1, wherein the auxiliary filter substance consists in the present case of lime powder or clay sand composition. The auxiliary filter substance in the container 5 can be rolled up by means of a nozzle assembly 4 a and then accumulate on the filter surface of the filter assembly 4 , thereby preventing particles to be filtered from causing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com