Method for improving filtering performance of dry spray booth

A technology of filtration performance and spray booth, applied in separation methods, chemical instruments and methods, spray devices, etc., can solve problems such as affecting production efficiency, high maintenance costs, and difficulty in cleaning and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

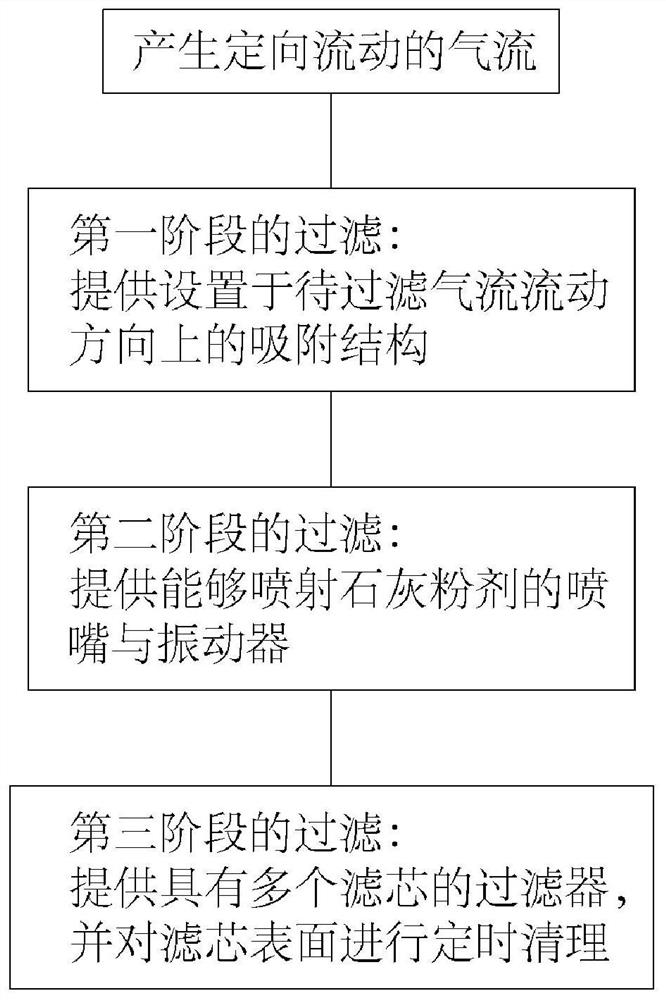

[0048] A method of improving the filtration performance of dry spray booths, such as figure 1 As shown, it is used to filter the paint particles generated by the spray booth in the dry spray booth, and the methods include:

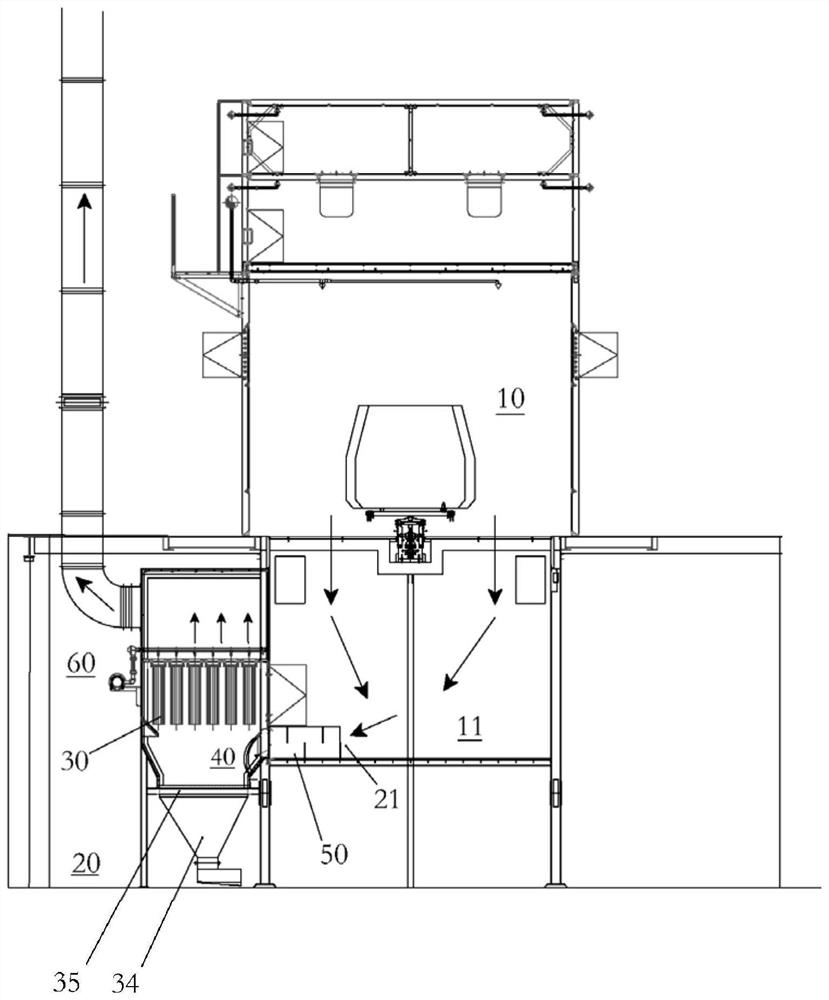

[0049] Generate directional flow airflow: install a circulating fan to form a negative pressure area at the windward port 21 of the filter chamber 20, that is, the pressure difference between the spray booth 10 and the filter chamber 20, forming a windward flow from the paint spray booth 10 to the filter chamber 20 A stream of directional flow of paint particles containing paint particles to be filtered at port 21;

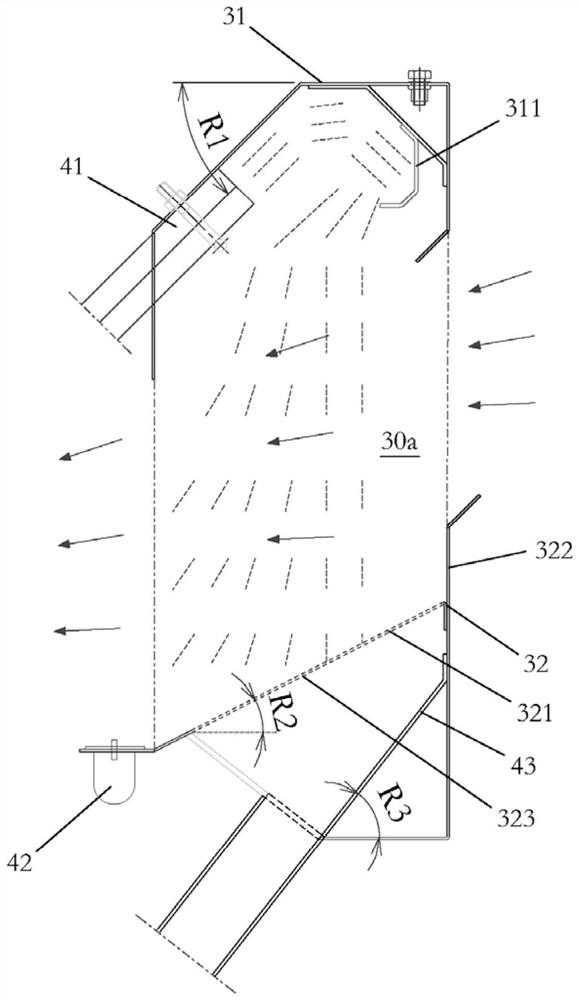

[0050] Filtration in the first stage: providing an adsorption structure 50 arranged in the flow direction of the airflow to be filtered;

[0051] Wherein the adsorption structure 50 provides an air inlet 511, an air outlet 512, at least one adsorption baffle 52 for direct contact with the airflow to be filtered containing paint particles, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com