Monolithic Pd catalyst for purifying industrial organic waste gas and preparation method thereof

A technology of organic waste gas and catalyst, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to prevent surface carbon deposition, improve combustion resistance, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

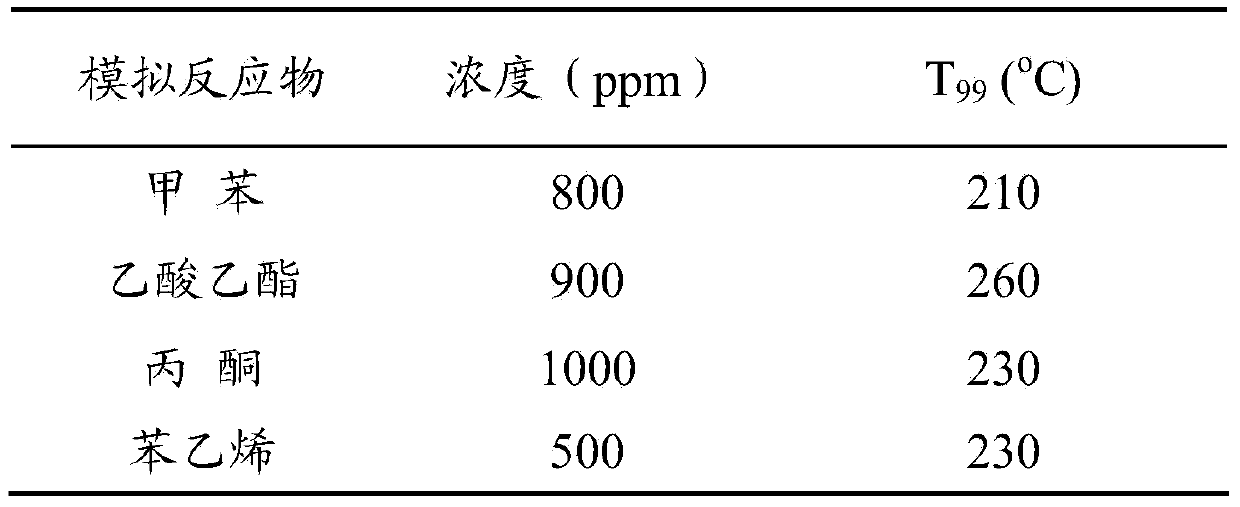

Embodiment 1

[0015] (1) The first coating: weigh 58g of cerium-zirconium solid solution, La 2 o 3 2g, Nb(OH) 5 2.67g (according to Nb 2 o 5 Calculate 2g), pseudo-boehmite binder 63.3g (38g calculated by alumina) (mass ratio is 58%: 2%: 2%: 38%), add 500ml of deionized water to dilute and ball mill for 4 hours, use Concentrated nitric acid adjusted the acidity to pH=2.5. The cordierite honeycomb ceramic carrier (200 mesh, shape 100mm*100mm*40mm) was impregnated with the above slurry, and the excess slurry in the pores of the honeycomb ceramic carrier was blown out with high-pressure gas. It was then dried at 110°C and calcined at 500°C for 4 hours. The application amount of the first coat was 20 g / L.

[0016] (2) Second coating: weigh 40g of cerium-zirconium solid solution, La 2 o 3 3g, pseudo-boehmite binder 87.5g (52.5g calculated by alumina), dehydrated alcohol 3g and H 2 PdCl 6 10 g of the solution (containing 1.5 g of Pd) (mass ratio 40%: 3%: 52.5%: 3%: 1.5%) was diluted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com