Flue gas demercuration, desulfurization and denitration adsorbent and preparation method thereof

A desulfurization, denitrification, and adsorbent technology, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of high economic cost and low adsorption efficiency, and achieve simple production process, high efficiency, and realization of reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

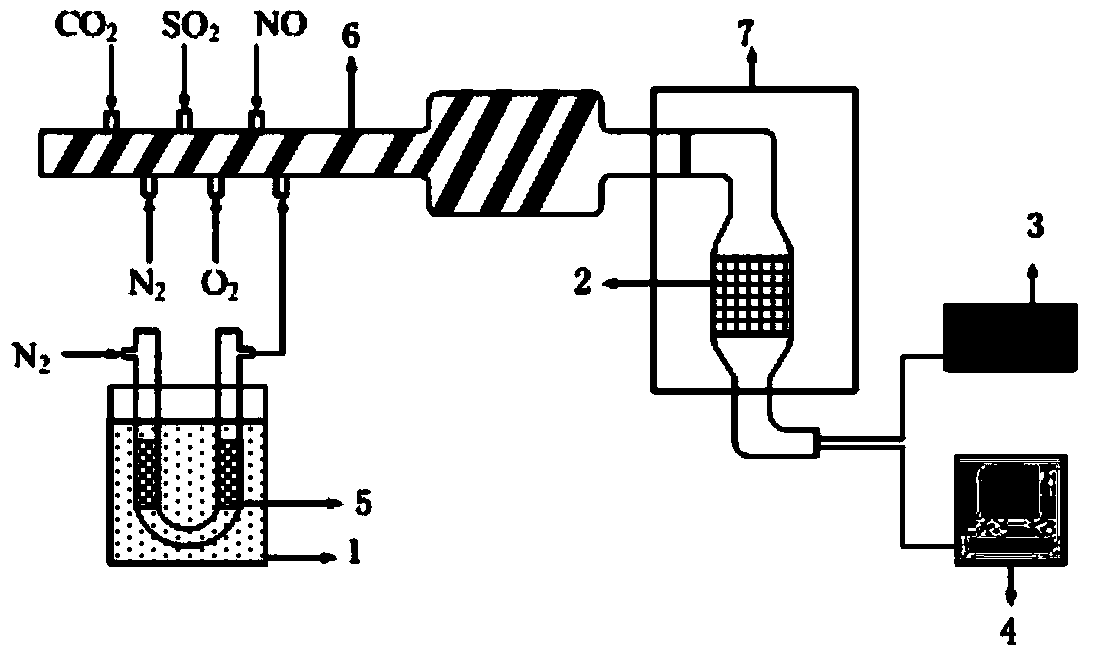

Image

Examples

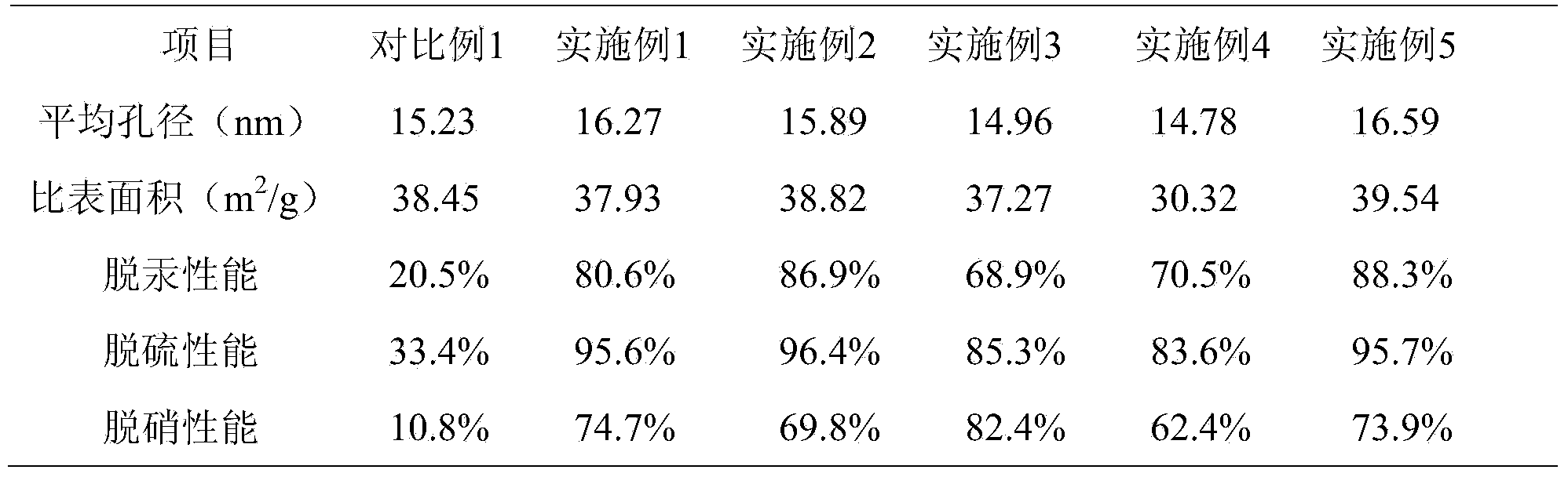

Embodiment 1

[0028] Step 1. Put the red mud raw material in a ventilated place to dry naturally for 36 hours, transfer the dried red mud to a muffle furnace at 400°C for 3.5 hours, and then crush it after cooling and pass through a 150-mesh sieve;

[0029] Step 2. Add 0.25mol / L hydrochloric acid solution and the red mud obtained in step 1 to the reactor at a liquid-solid ratio of 20mL / g and place it in a constant temperature bath at 80°C for 3 hours, then mix the red mud-hydrochloric acid solution at 9000r / g Min centrifuge for 30min, use filter paper to filter out the red mud;

[0030] Step 3, washing the red mud obtained in step 2 in clean water, and then filtering, and repeating this 2 times;

[0031] Step 4. Put the red mud obtained in Step 3 in a drying oven and keep it at 105°C for 18 hours;

[0032] Step five, weigh 1.33gMn(NO 3 ) 2 and 1.74gNH 4 VO 3 , dissolved in 50mL deionized water, placed in a constant temperature bath at 80°C and stirred at a constant speed to obtain a mi...

Embodiment 2

[0036] Step 1. Put the red mud raw material in a ventilated place to dry naturally for 36 hours, transfer the dried red mud to a muffle furnace at 400°C for 3.5 hours, and then crush it after cooling and pass through a 150-mesh sieve;

[0037] Step 2. Add 0.25mol / L hydrochloric acid solution and the red mud obtained in step 1 to the reactor at a liquid-solid ratio of 20mL / g and place it in a constant temperature bath at 80°C for 3 hours, then mix the red mud-hydrochloric acid solution at 9000r / g Min centrifuge for 30min, use filter paper to filter out the red mud;

[0038]Step 3, washing the red mud obtained in step 2 in clean water, and then filtering, and repeating this 2 times;

[0039] Step 4. Put the red mud obtained in Step 3 in a drying oven and keep it at 105°C for 18 hours;

[0040] Step five, weigh 2.06g Mn(NO 3 ) 2 and 1.32g NH 4 VO 3 , dissolved in 50mL of deionized water, placed in a constant temperature bath at 80°C and stirred at a constant speed to obtain ...

Embodiment 3

[0044] Step 1. Put the red mud raw material in a ventilated place to dry naturally for 36 hours, transfer the dried red mud to a muffle furnace at 400°C for 3.5 hours, and then crush it after cooling and pass through a 150-mesh sieve;

[0045] Step 2. Add 0.25mol / L hydrochloric acid solution and the red mud obtained in step 1 to the reactor at a liquid-solid ratio of 20mL / g and place it in a constant temperature bath at 80°C for 3 hours, then mix the red mud-hydrochloric acid solution at 9000r / g Min centrifuge for 30min, use filter paper to filter out the red mud;

[0046] Step 3, washing the red mud obtained in step 2 in clean water, and then filtering, and repeating this 2 times;

[0047] Step 4. Put the red mud obtained in Step 3 in a drying oven and keep it at 105°C for 18 hours;

[0048] Step five, weigh 1.79g Mn(NO 3 ) 2 and 2.08 g of NH 4 VO 3 , dissolved in 30mL of deionized water, placed in a constant temperature bath at 80°C and stirred at a constant speed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com