Structure of fire-proof explosion-proof type new energy vehicle battery

A new energy vehicle and storage battery technology, which is applied in the direction of fire prevention equipment, structural parts, battery pack parts, etc., can solve the problems that affect the burning resistance of ceramic silicone rubber, low compactness, oxygen penetration, etc., and achieve direct and effective fire extinguishing. The effect of low cost and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

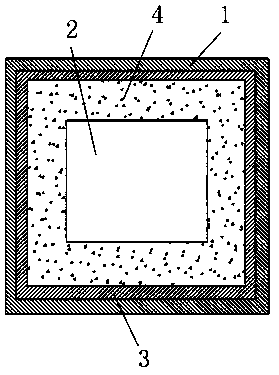

[0029] A battery with a fireproof function includes a sealed casing 1 and a battery body 2 arranged in the sealed casing. A fireproof material filling cavity 4 is arranged between the sealed casing 1 and the battery body 2. A fireproof board 3 is fixedly arranged on the inner surface of the sealed casing 1, and the fireproof material filling cavity 4 is arranged between the fireproof board 3 and the battery body 2.

[0030] The fireproof material filling cavity 4 is filled with dry powder fire extinguishing agent. The dry powder fire extinguishing agent is sodium bicarbonate, sodium chloride or potassium chloride dry powder fire extinguishing agent. The sealed enclosure 1 includes a lower shell 11 and an upper shell cover 12 that are sealed but connected. Both the lower shell 11 and the upper shell cover 12 are provided with a fireproof material filling cavity 4, and the upper shell cover 12 is provided with a communication The wire tubes 13 on the upper and lower sides of the c...

Embodiment 2

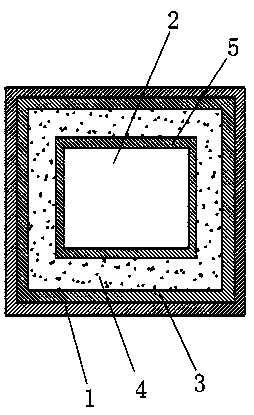

[0039] A thermally conductive partition plate 5 fixedly connected to the fireproof board 3 is provided between the fireproof filling cavity 4 and the battery body 2, and the thermally conductive partition plate 5 forms a battery inner positioning shell, and the battery body is placed in the battery The surface of the thermally conductive partition plate 5 facing the battery body 2 is attached to the surface of the battery body 2 inside the casing. A metal plate can be used for the thermally conductive separator, which not only ensures the thermal conductivity but also increases the strength of the battery.

[0040] The material of the sealing shell 1 includes a metal layer, a polypropylene plastic layer, and a ceramicized silicone rubber layer in order from the inside to the outside, wherein the ceramicized silicone rubber layer is calculated in parts by weight and is made of the following raw materials: silicon 100 parts of rubber, 80 parts of porcelain filler, 20 parts of flux,...

Embodiment 3

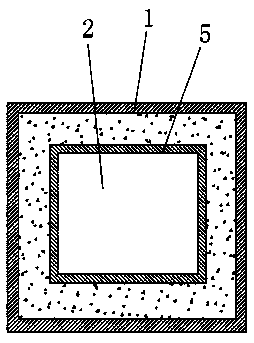

[0047] The difference from the above embodiment is that the dry powder fire extinguishing agent is sodium bicarbonate dry powder fire extinguishing agent, and the battery body 2 is a lithium battery body.

[0048] The material of the sealing shell 1 includes a metal layer, a polypropylene plastic layer, and a ceramicized silicone rubber layer in order from the inside to the outside, wherein the ceramicized silicone rubber layer is calculated in parts by weight and is made of the following raw materials: silicon 100 parts of rubber, 60 parts of porcelain filler, 15 parts of flux, 0.5 part of platinum catalyst, 6 parts of hydroxy silicone oil, 3 parts of vulcanizing agent. Among them, the porcelain filler is a mixture of aluminum silicate fiber and acicular wollastonite. The mass ratio of aluminum silicate fiber and acicular wollastonite is 20:35.

[0049] The metal layer is made of nickel-plated carbon steel.

[0050] The polypropylene plastic layer is made of carbon fiber reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com