Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Play a role in strengthening the support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

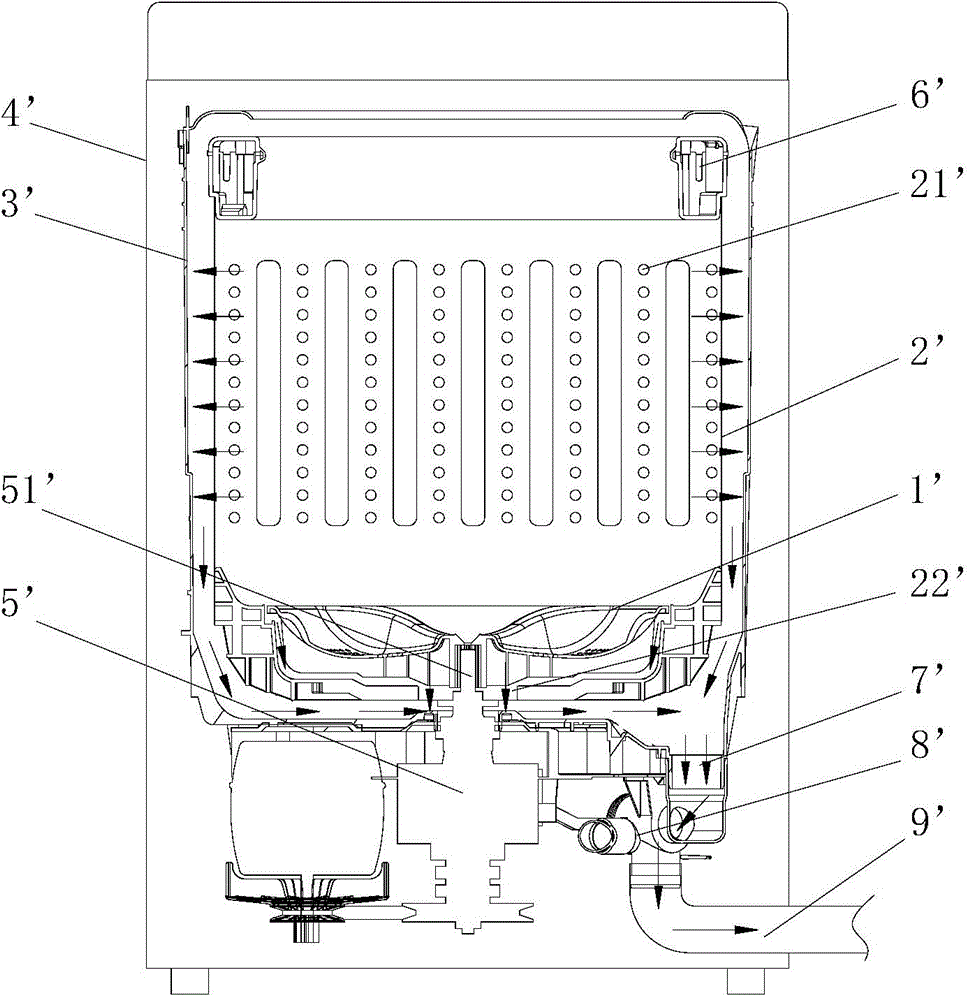

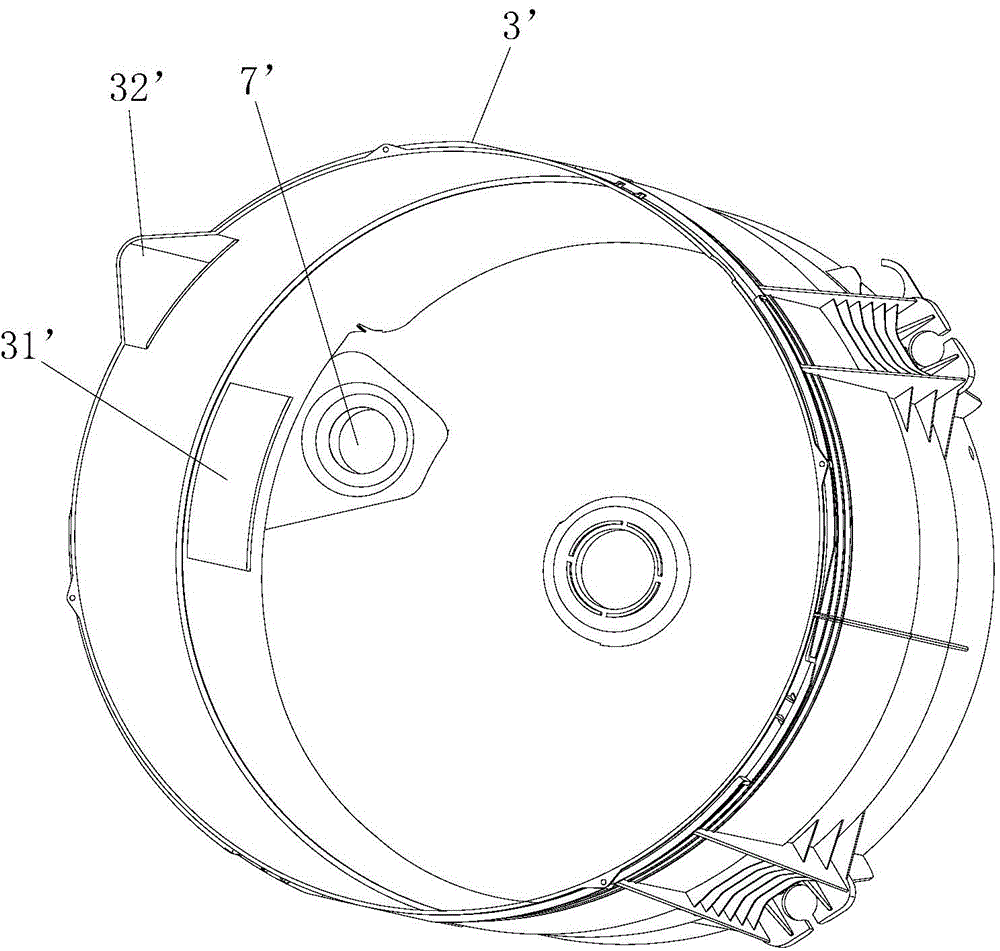

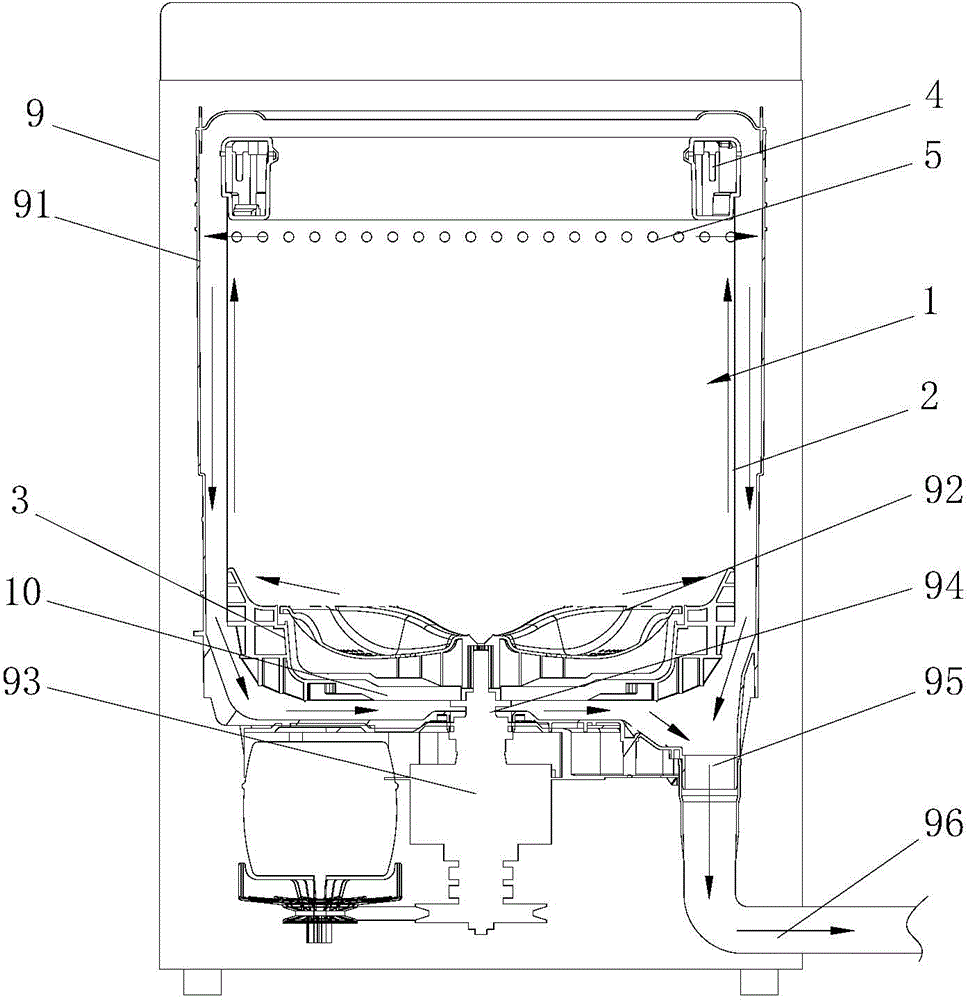

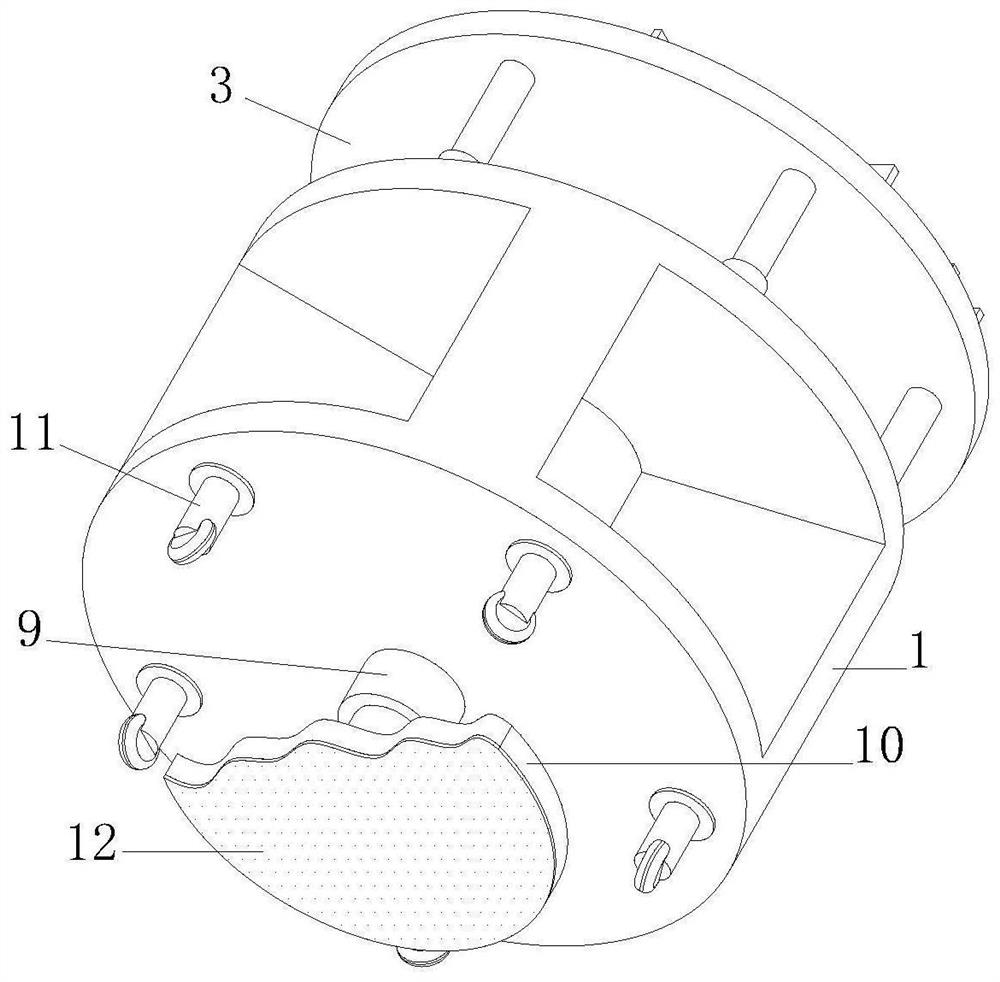

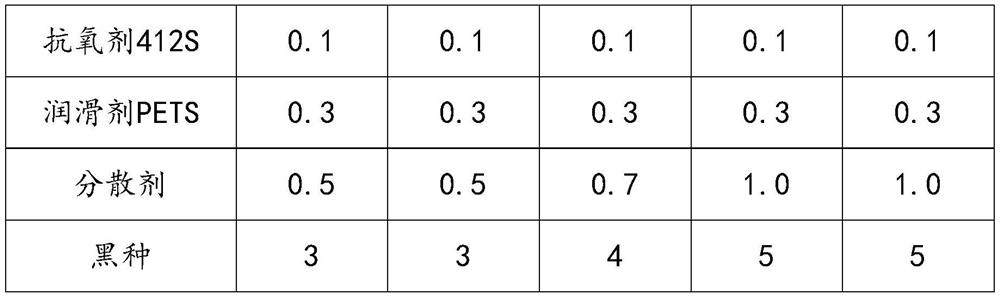

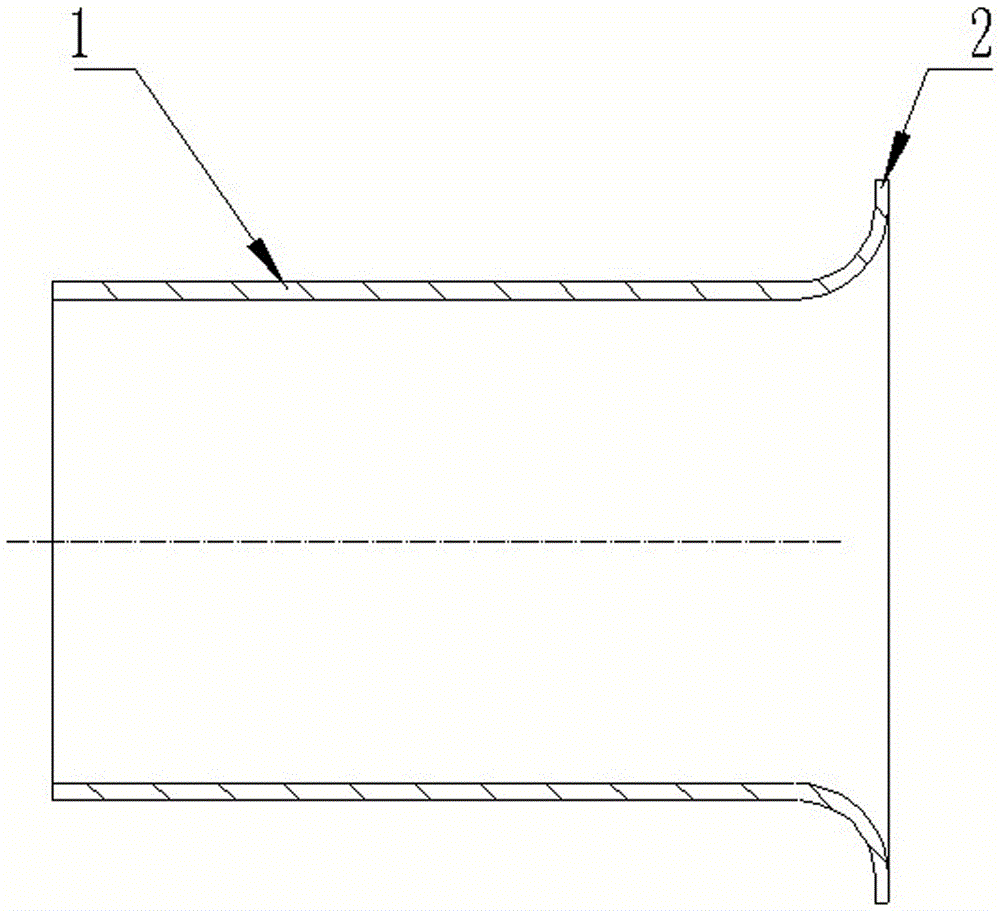

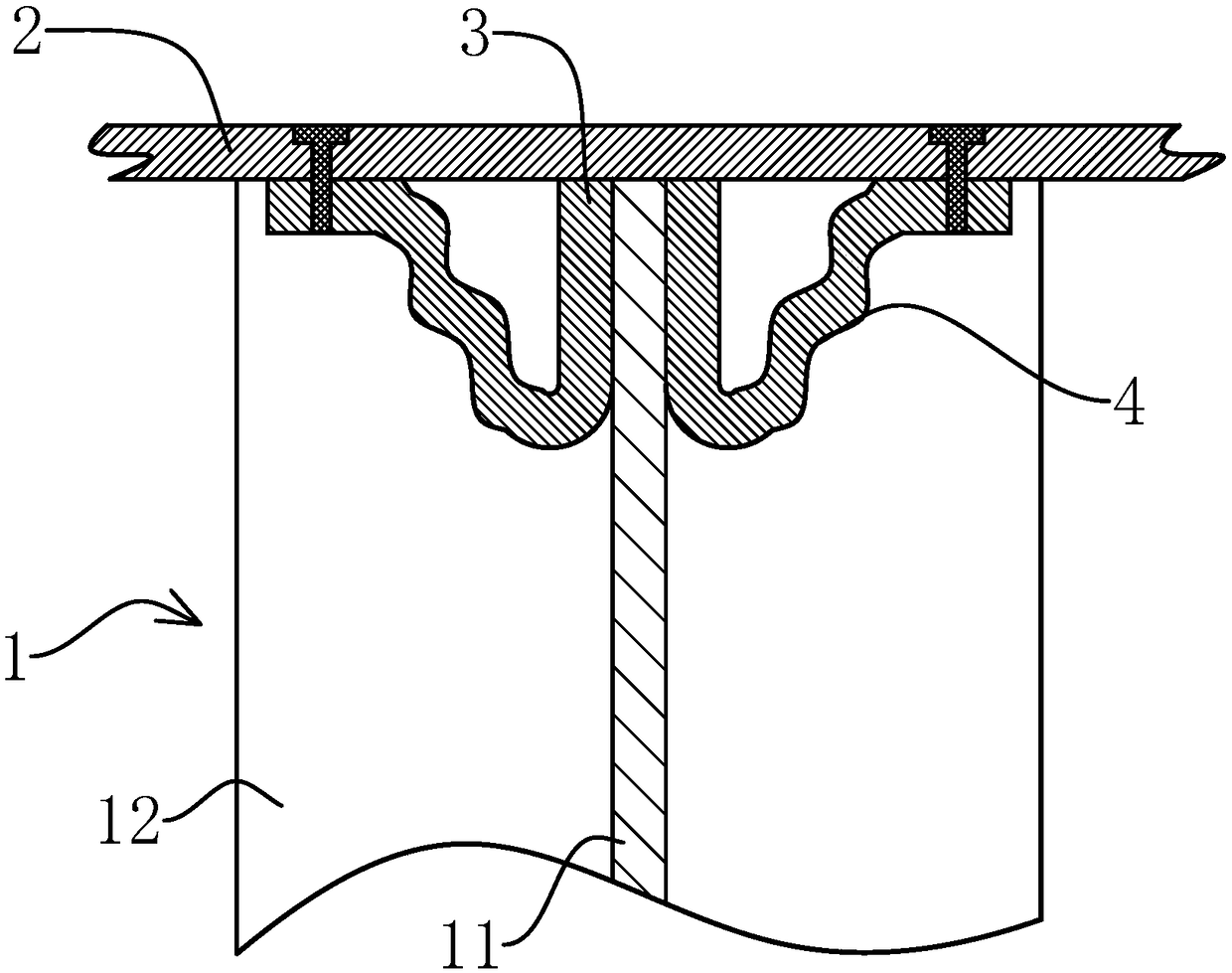

Washing machine inner barrel

PendingCN105624976AHygienic useEnvironmental protectionOther washing machinesTextiles and paperEngineeringWater holding

The invention discloses a washing machine inner barrel. The washing machine inner barrel comprises a barrel body, an inner barrel bottom arranged on the lower part of the barrel body, and a balancing ring arranged on the upper opening of the barrel body. The upper part of the inner barrel is provided with a water outlet, a water holding structure is arranged under the water outlet, and the barrel body is in seal connection with the inner barrel bottom. Specifically, the barrel body and the inner barrel bottom form an integral injection moulding structure; or the barrel body is provided with a loop of profiled part along the circumference, the profiled part is matched with the upper end face of the circumferential wall of the inner barrel bottom to form a blocking and supporting structure, a sealing ring is arranged between the profiled part and the inner barrel bottom, and end face seal is formed; or a sealing ring or a seal cartridge is arranged between the circumferential wall of the inner barrel bottom and the lower part of the barrel body, the inner wall of the seal cartridge is provided with at least two loops of convex ribs, and each loop of convex rib is correspondingly arranged in a mounting groove which is arranged in the external surface of the circumferential wall of the inner barrel bottom in the circumferential direction; or the lower part of the barrel body sleeves the outer surface of the circumferential wall of the inner barrel bottom, the lower edge of the barrel body is bent inwards to form a bound edge, the bound edge is connected with the inner barrel bottom, and the bound edge is inside provided with a sealing ring. The washing machine inner barrel is simple in structure and good in sealing effect, and can be installed conveniently, stably and firmly.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

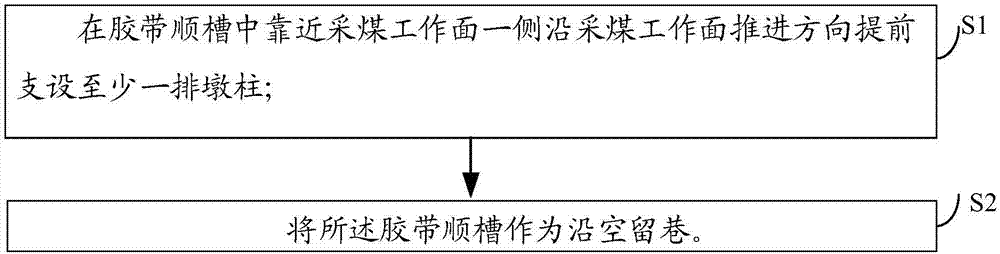

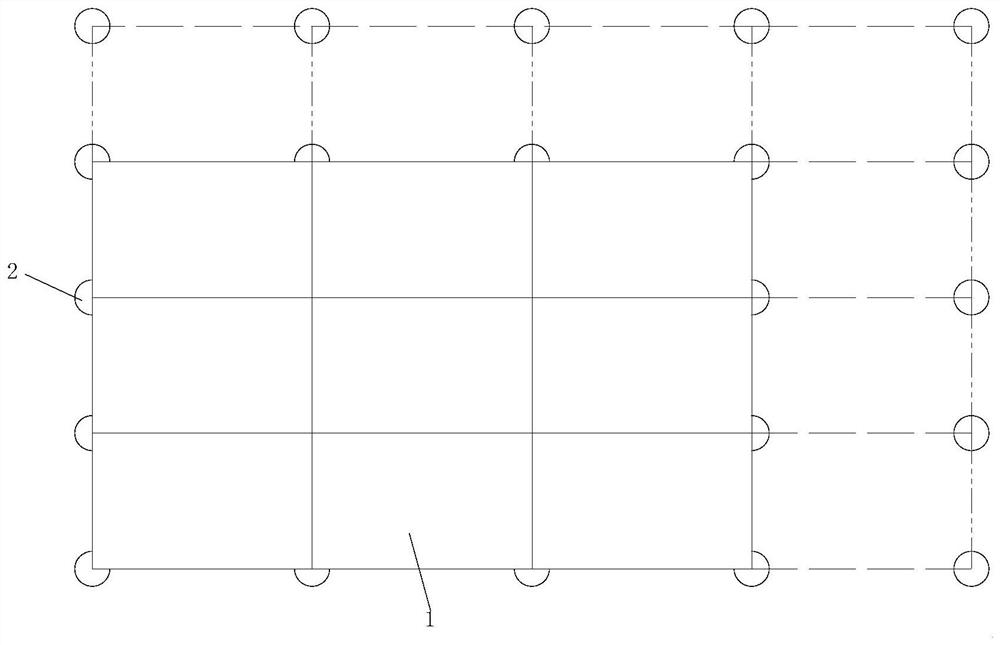

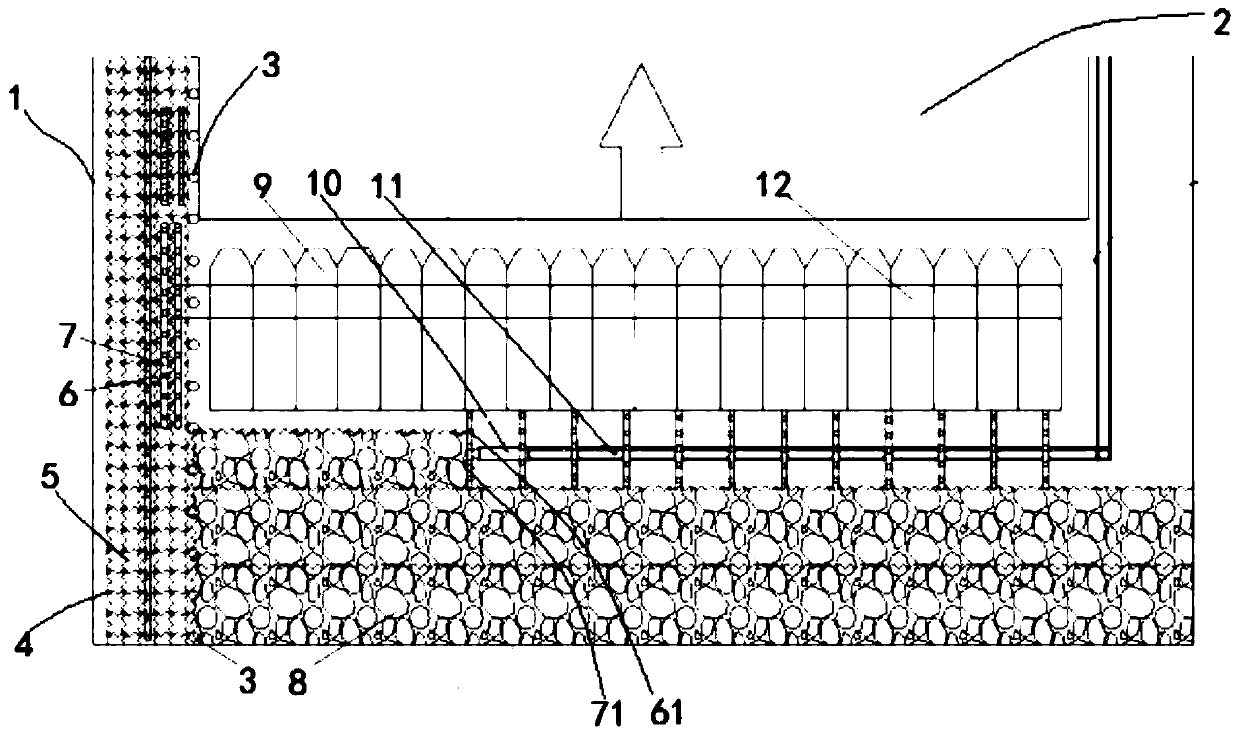

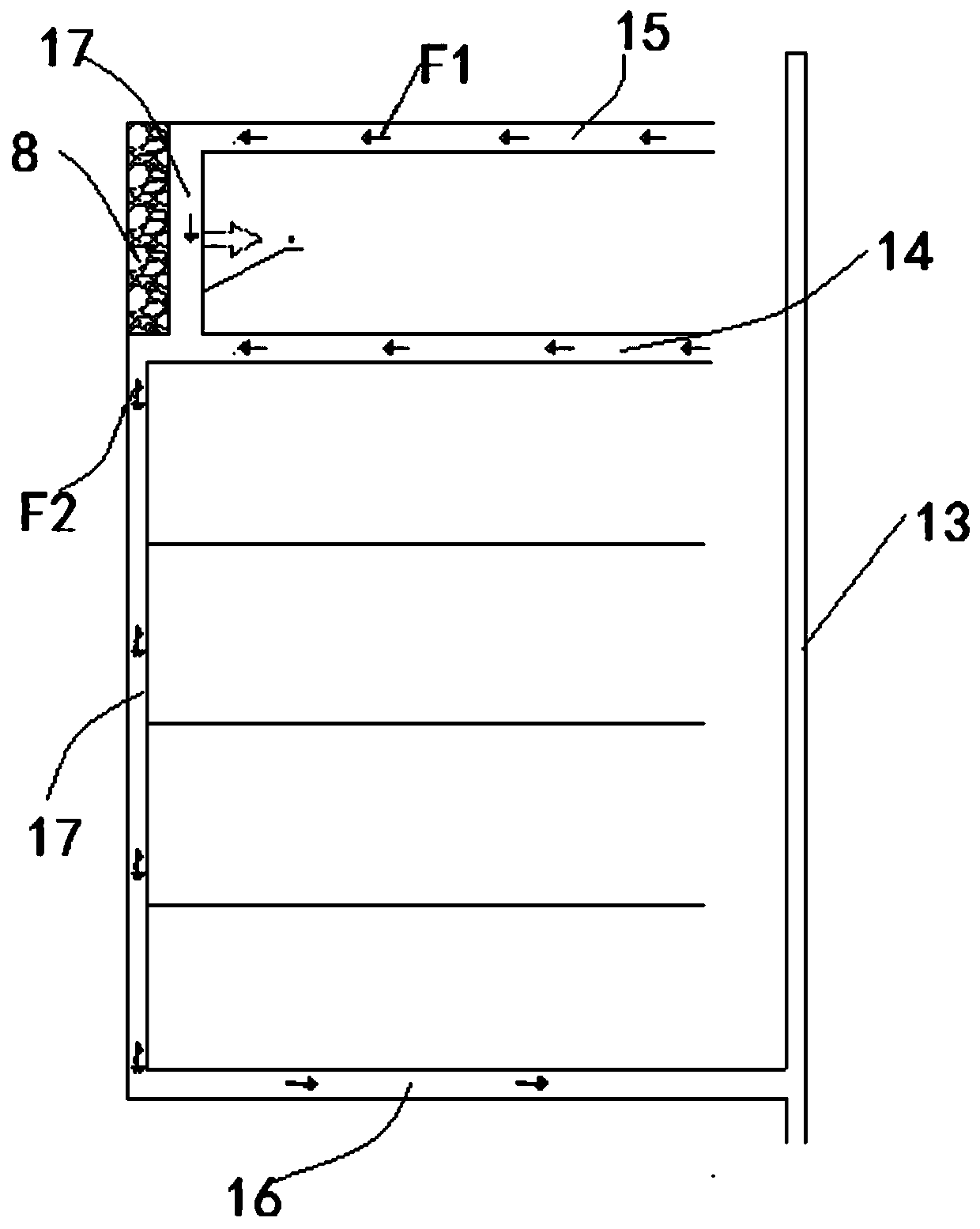

Gob-side entry retaining method without influence on coal mining procedure

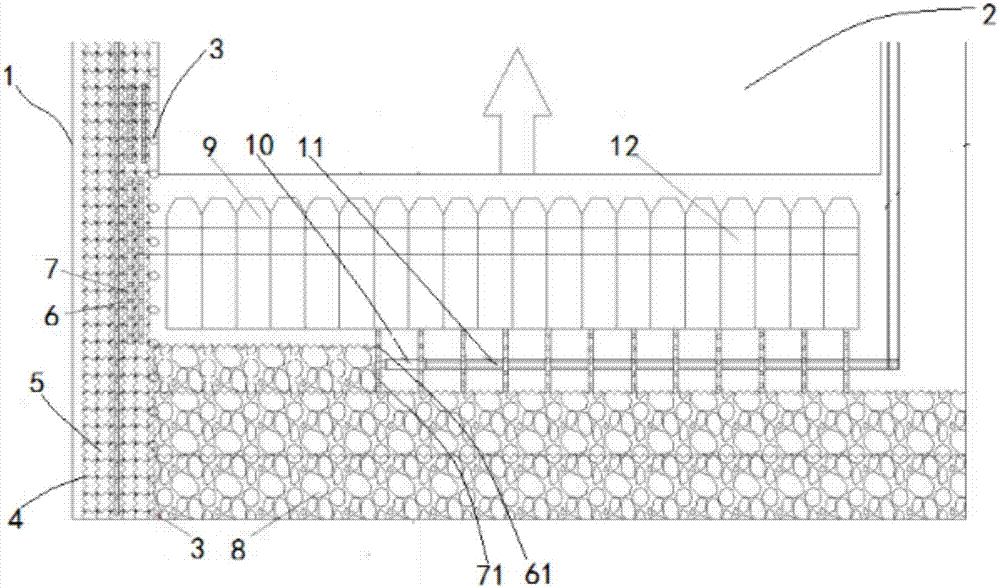

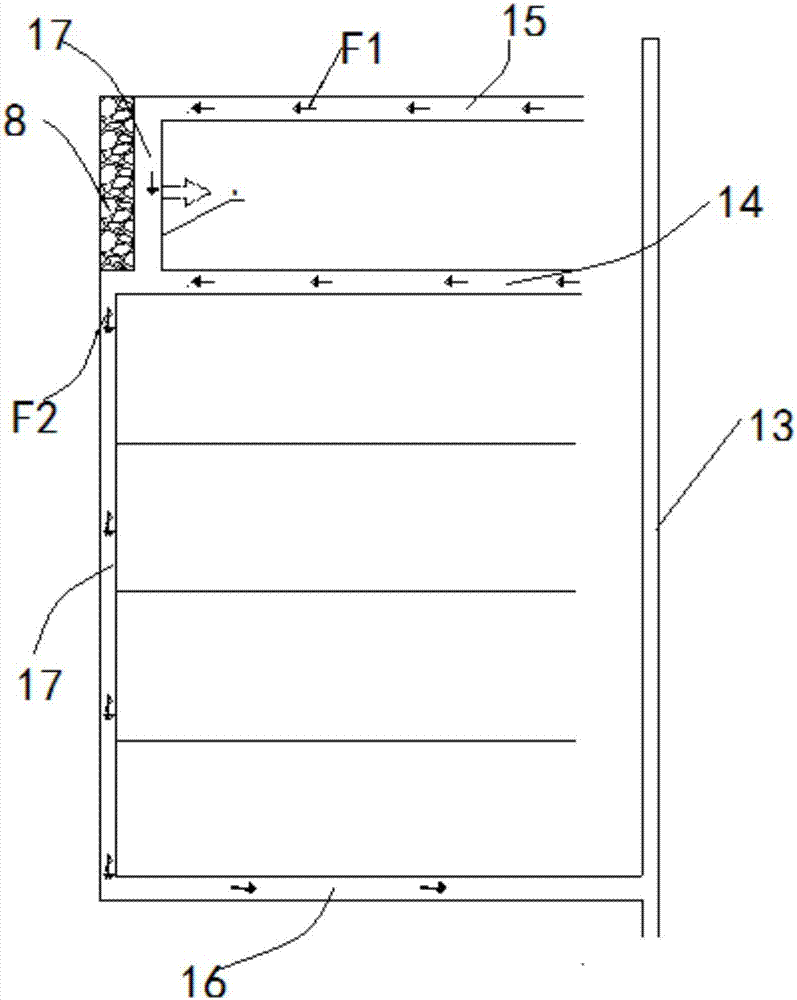

ActiveCN107882566AAvoid interferenceEasy to pushUnderground miningSurface miningEngineeringCoal mining

In one embodiment, the invention discloses a gob-side entry retaining method without influence on coal mining procedure, relating to the technical field of coal mining. The method can effectively avoid interference on the coal mining procedure of stope surface. The method includes a step of arranging at least one row of pillars in advance along the advance direction of the coal working surface atone side being closed to the coal working surface in a belt crossheading, which serves as gob-side entry retaining. The method is suitable for roadway and tunnel engineering and coal mining.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Remained small coal pillar comprehensive mechanized coal mining supporting structure and construction method

PendingCN107905807APrevent intrusionAvoid roof fall accidentsUnderground chambersUnderground miningEngineeringCoal pillar

The invention discloses a remained small coal pillar comprehensive mechanized coal mining supporting structure and a construction method. The remained small coal pillar comprehensive mechanized coal mining supporting structure and the construction method comprises a narrow coal pillar arranged between a current stope working face and an adjacent stope working face, one side of the narrow coal pillar is provided with a filling body, and the adjacent stope working face is also provided with a roof presplitting cutting line; the construction method of the remained small coal pillar comprehensivemechanized coal mining comprises the following steps that before the coal mining, an air return way, a haulage gate, and an auxiliary haulage gate are constructed; the roof presplitting cutting line of the current stope working face is constructed in the auxiliary haulage gate; then the filling body is constructed synchronously with a head coal mining. The remained small coal pillar comprehensivemechanized coal mining supporting structure and the construction method solves the problems of gangue darting into a lane in a worked out section, roof bolting accident of the auxiliary transport chute, and the leakage of the narrow coal pillar in the current stope working face; and the mining influence to the auxiliary transport chute caused by the stope working face is weakened, cost of maintenance of the lane is reduced, and recovery coefficient of coal resource is enhanced; and the remained small coal pillar comprehensive mechanized coal mining supporting structure and the construction method can be applied to most geological mining conditions and has a great significance to promote and achieve safe and efficient mining of coal mine.

Owner:SHAANXI COAL & CHEM TECH INST

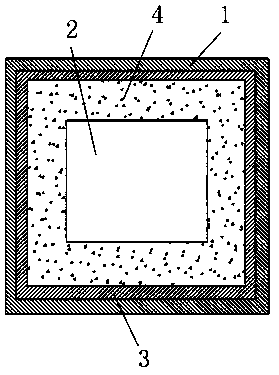

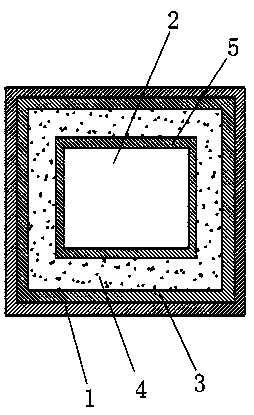

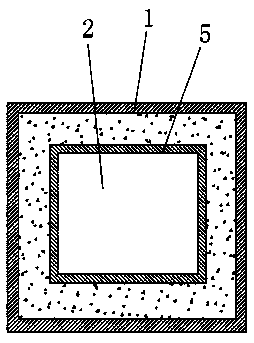

Structure of fire-proof explosion-proof type new energy vehicle battery

InactiveCN109256502AImprove securityEnsure safetyBattery isolationSurgical veterinaryPtru catalystNew energy

The invention discloses a structure of a fire-proof explosion-proof type new energy vehicle battery, comprising a sealed shell and a battery body arranged in the sealed shell. A fire-proof material filling cavity is arranged between the sealed shell and the battery body, and the fire-proof material filling cavity is filled with a dry powder extinguishing agent. A fire-proof plate is fixed on the inner surface of the sealed shell, and a filling cavity of the fire-proof material is arranged between the fire-proof plate and the battery body. The sealing shell material sequentially comprises a metal layer from the inside to the outside, polypropylene plastic layer, ceramic silicone rubber layer, wherein the ceramicized silicone rubber layer is formed in an amount of parts by weight of the ceramic silicone rubber layer, It is prepared from the following raw materials: 100 parts of silicone rubber, 40-80 parts of porcelain filler, 5-20 parts of flux, 0. 2-1.5 parts of platinum catalyst, 2-8parts of hydroxyl silicone oil and 2-4 part of vulcanizing agent, wherein that porcelain filler is a mixture of aluminum silicate fiber and acicular wollastonite, wherein the mass ratio of aluminum silicate fiber to acicular wollastonite is 15-25:30-40.

Owner:IANGSU COLLEGE OF ENG & TECH

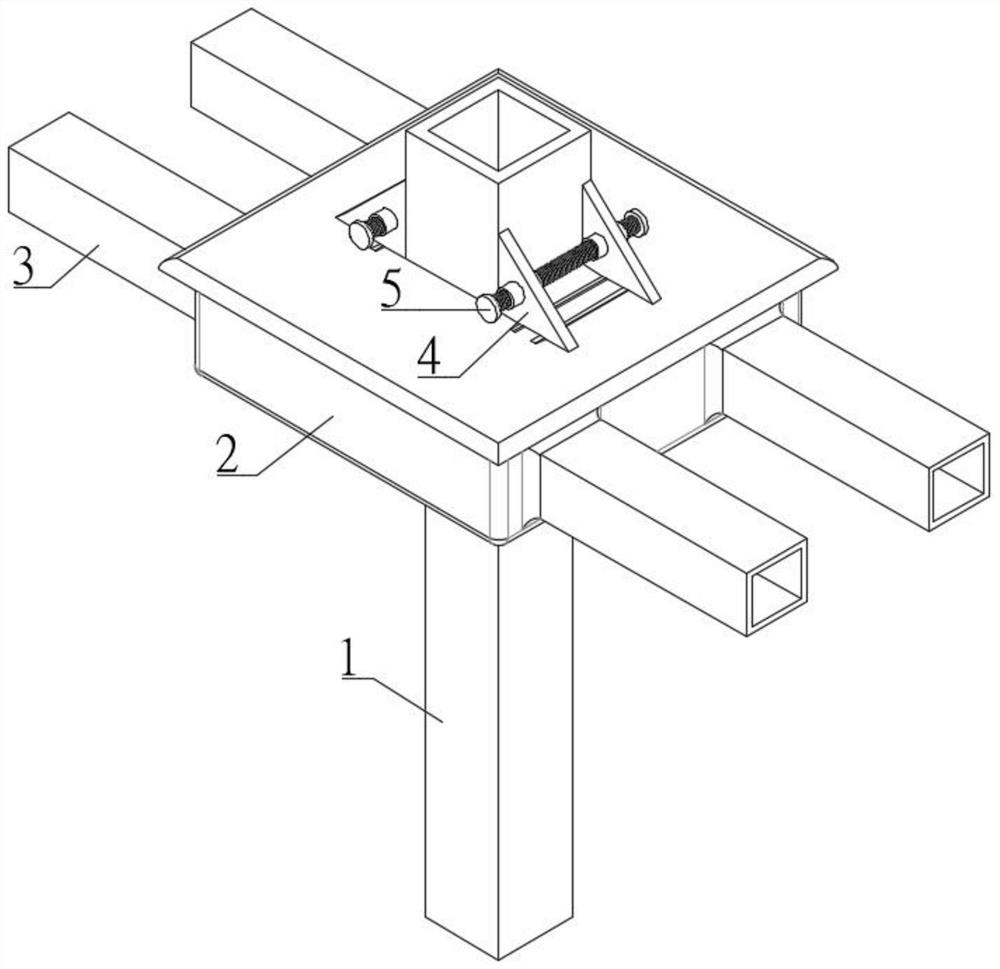

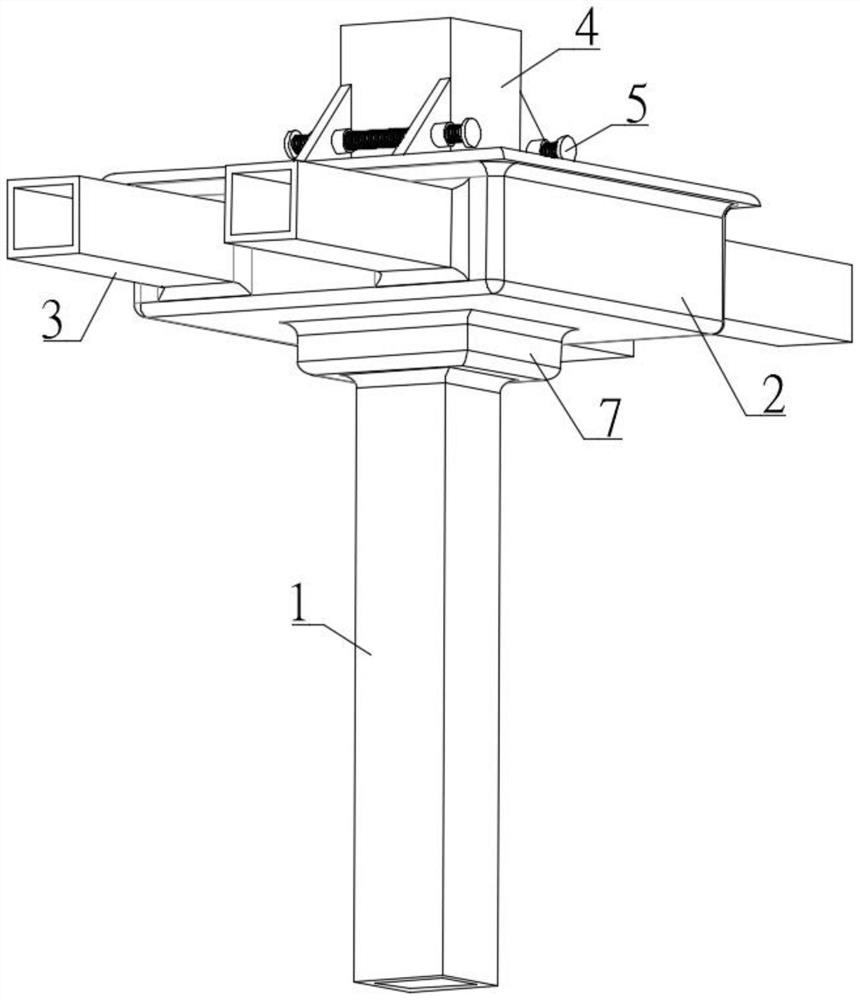

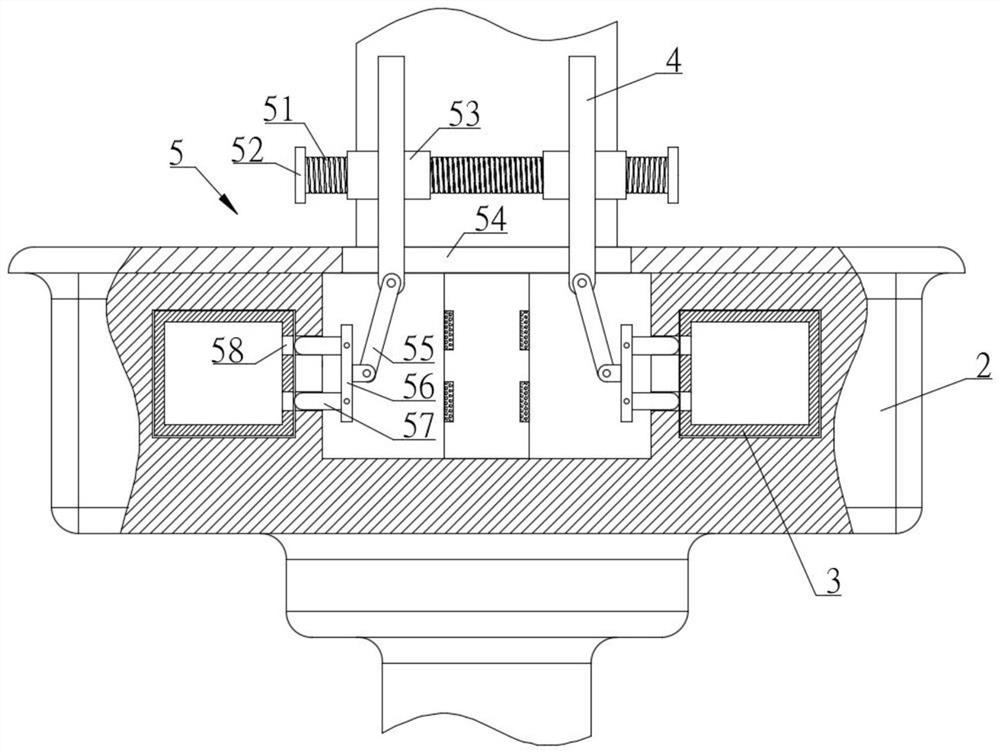

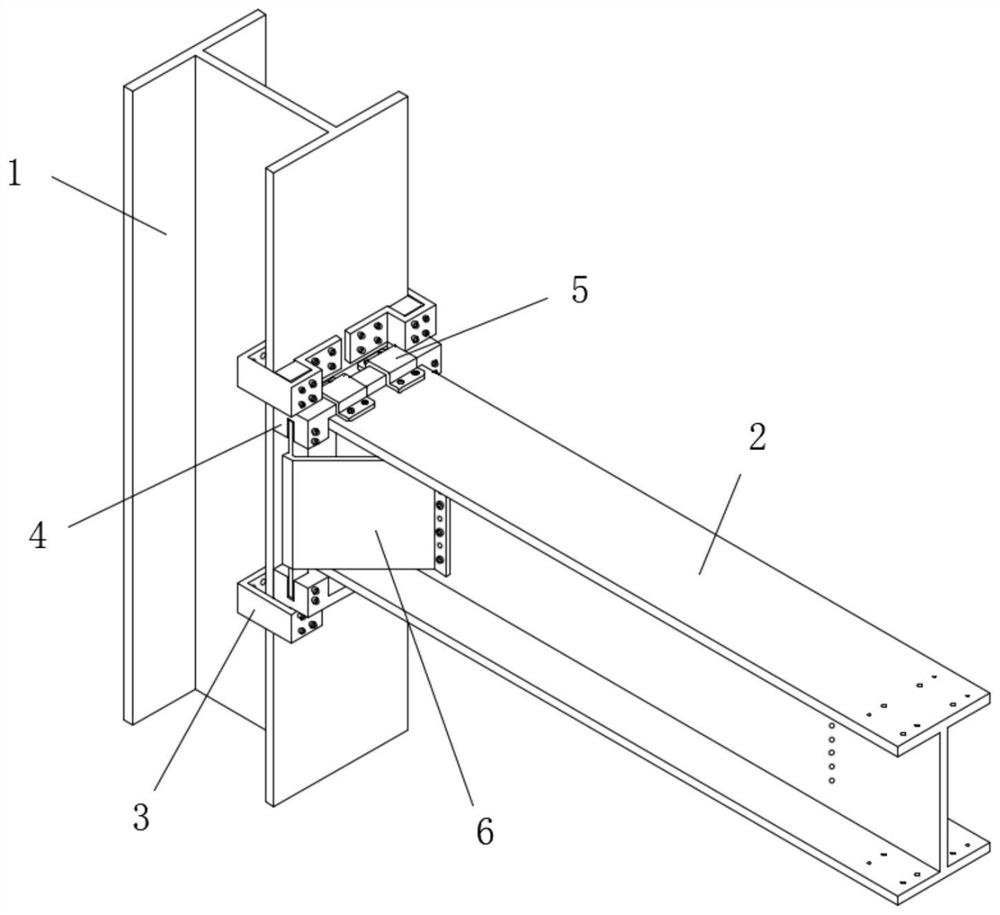

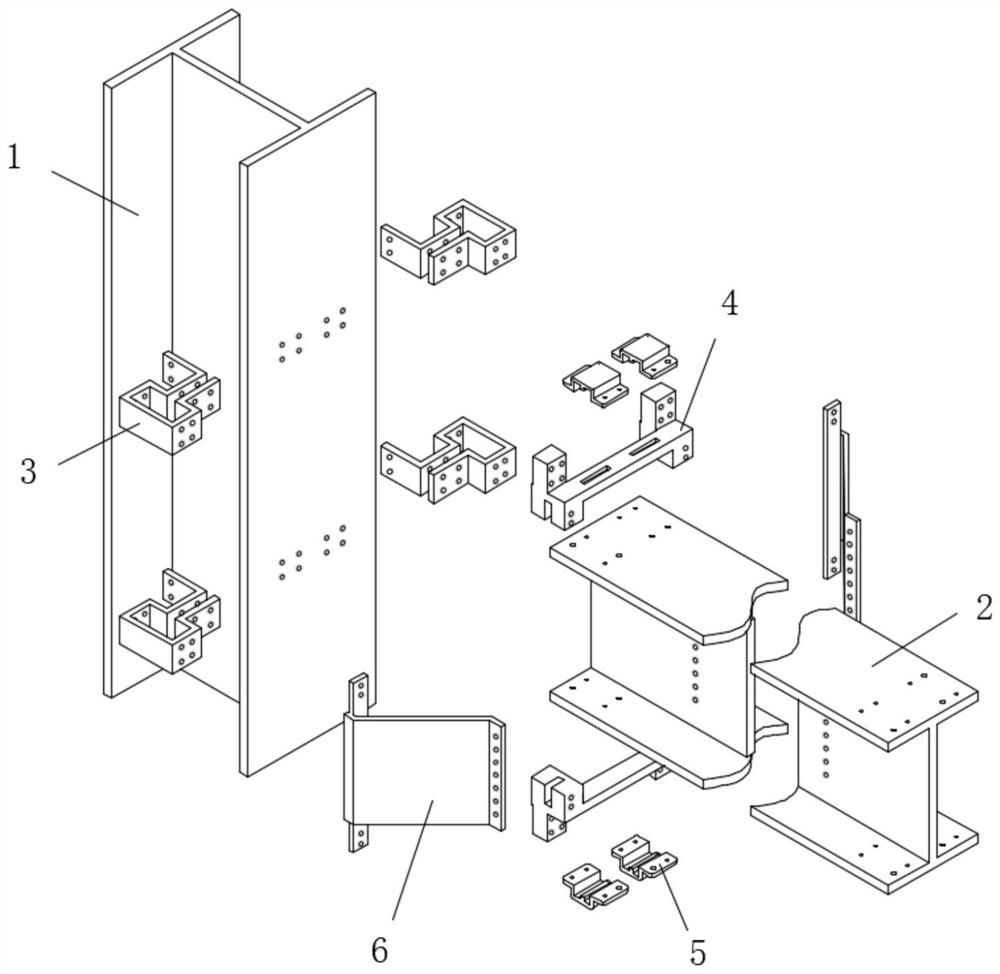

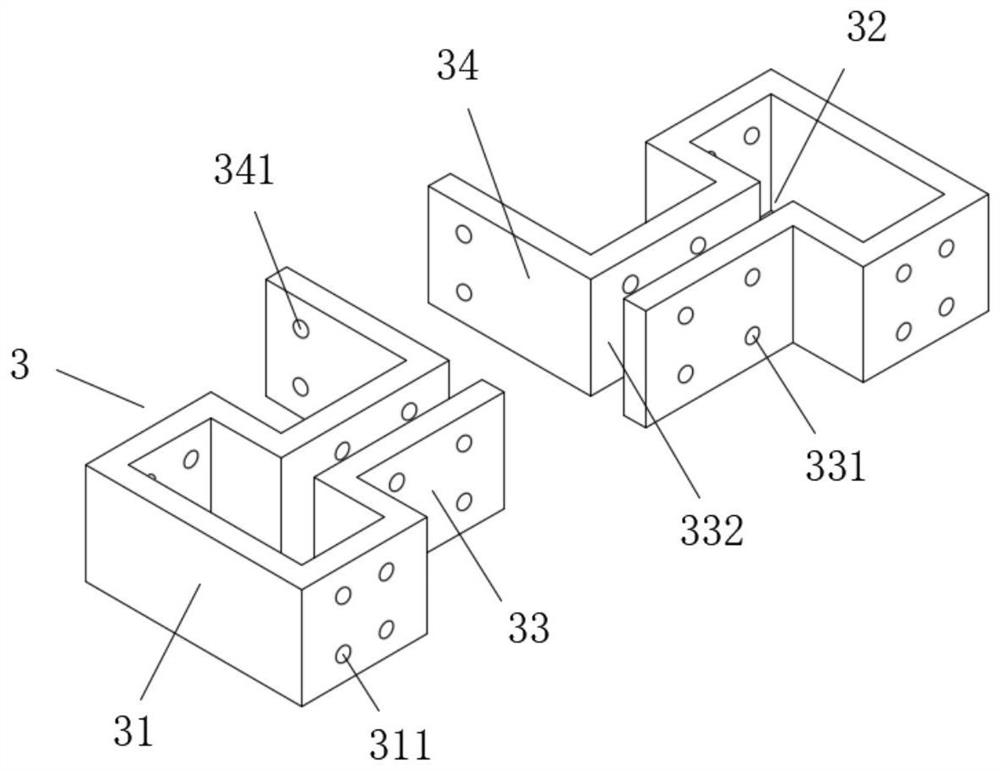

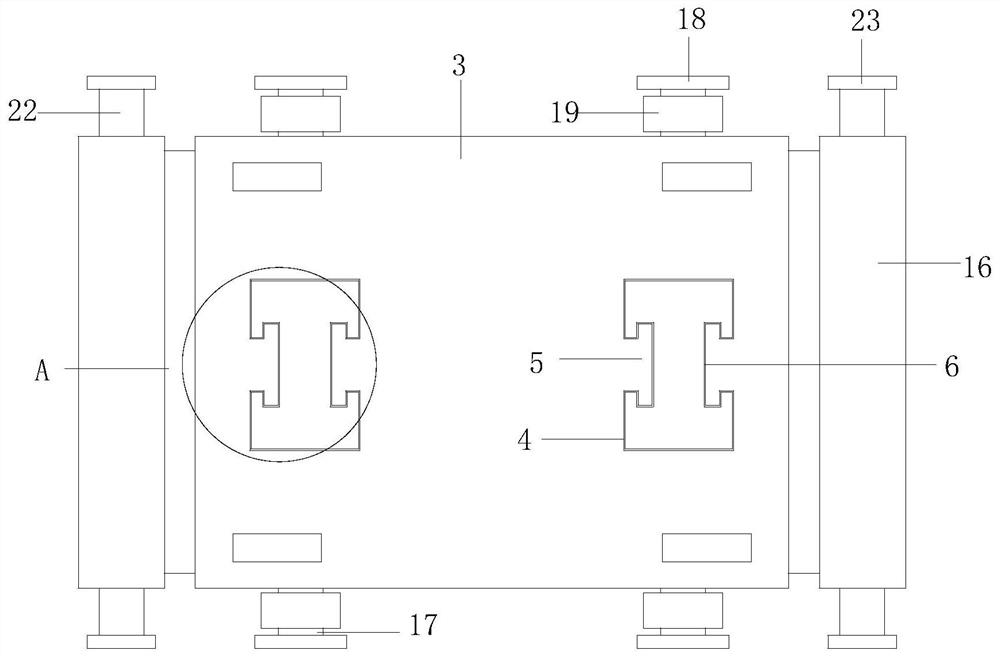

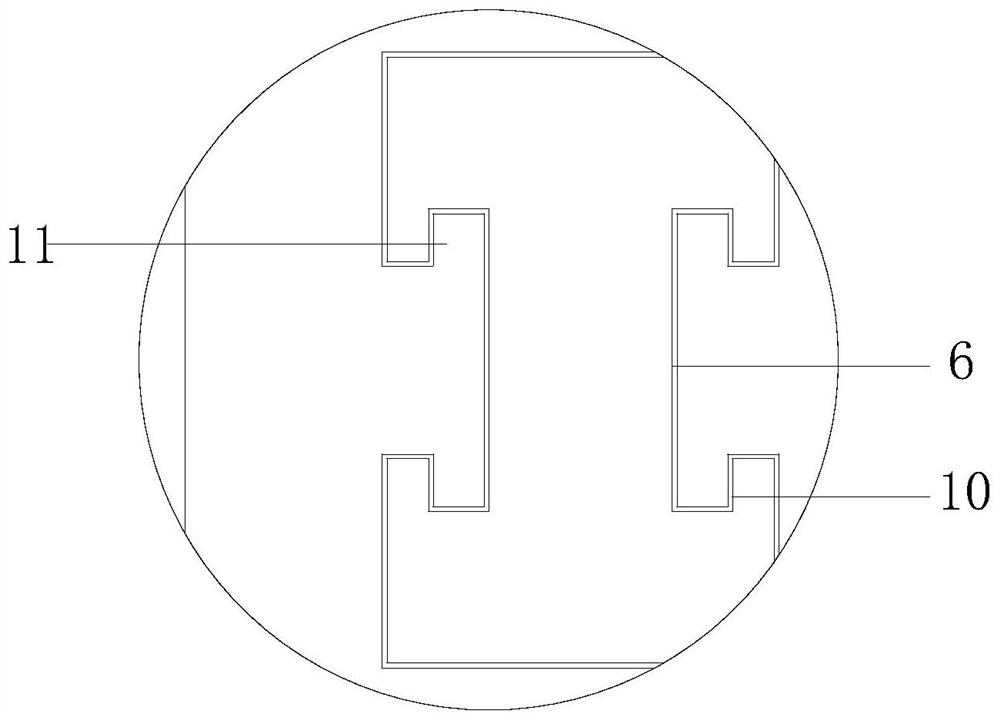

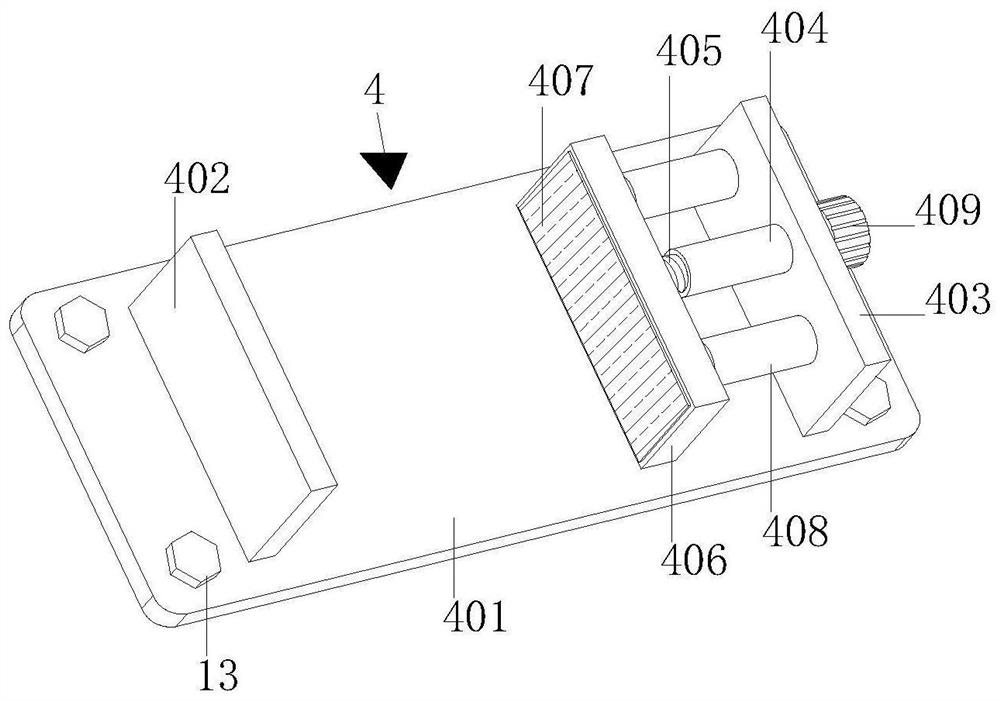

Fabricated building beam column steel structure connecting piece and construction method thereof

PendingCN114541581AGood installation consistencyPlay a role in strengthening the supportBuilding material handlingFire proofingWrenchBeam column

The invention discloses an assembly type building beam column steel structure connecting piece and a construction method thereof.The assembly type building beam column steel structure connecting piece comprises a steel structure connecting piece body, the steel structure connecting piece body is arranged at the joint of a supporting beam and a cross beam, and the steel structure connecting piece body is used for supporting connection of the supporting beam and the cross beam; the sliding supporting angle steel is slidably arranged at the top end of the steel structure connecting piece, and the right-angle edges on the two sides of the sliding supporting angle steel abut against the supporting beam and the steel structure connecting piece correspondingly. The cross beam locking assembly is arranged in the sliding supporting angle steel and connected with the sliding supporting angle steel. By arranging the cross beam locking assembly, a double-thread screw is rotated through a wrench, the double-thread screw drives nuts on the two sides to move away from each other when rotating, and when the nuts move away from each other, connecting plates on the two sides are pushed to move through connecting rods on the two sides till inserting rods are inserted into inserting holes of a cross beam; and a plurality of cross beams can be installed and fixed through one input end, and the installation consistency is good.

Owner:安徽一品小院建筑科技有限公司

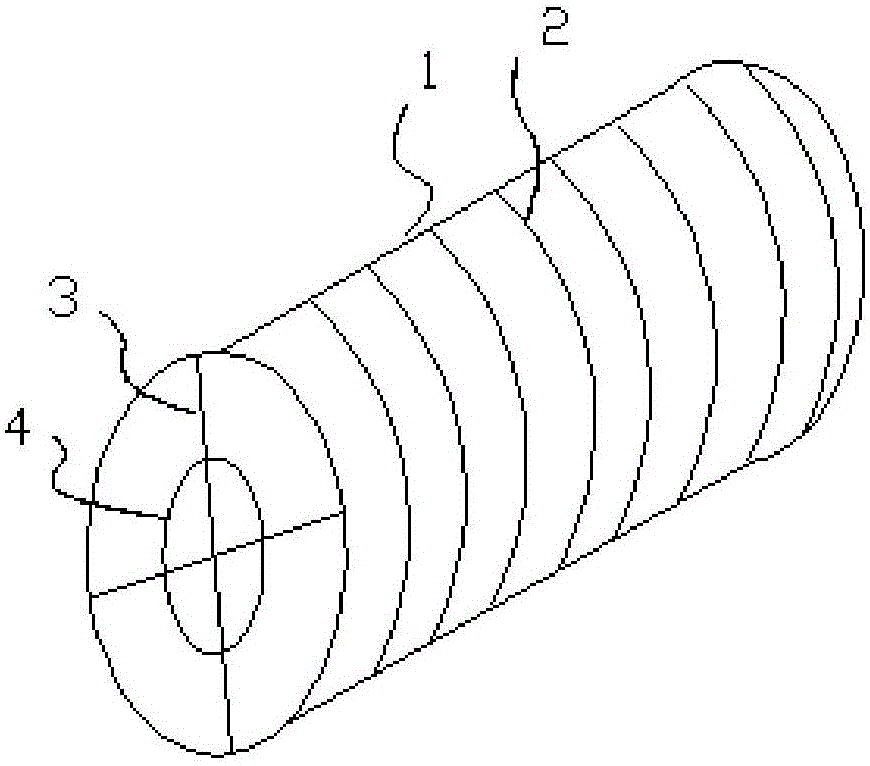

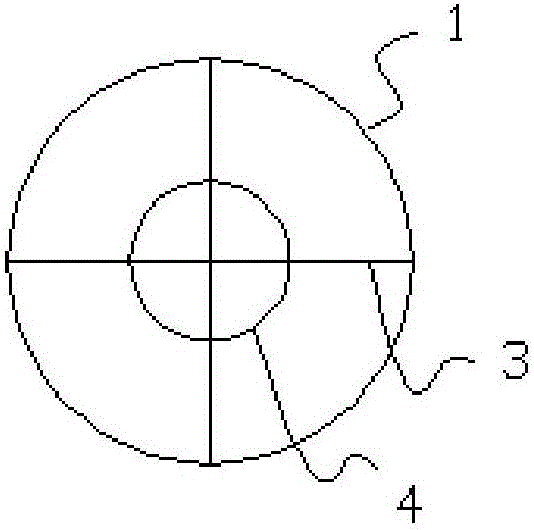

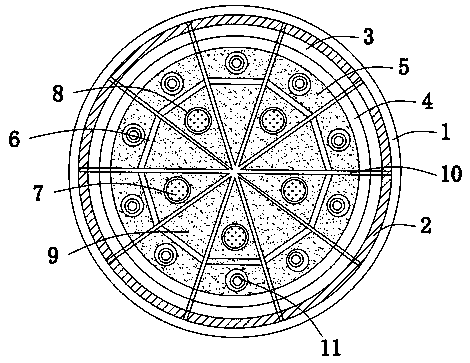

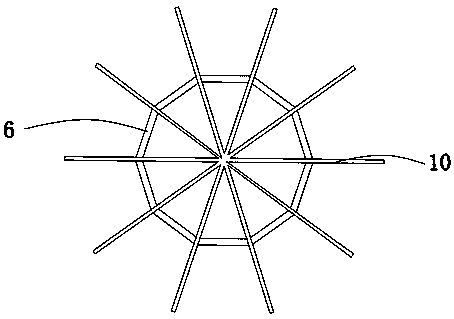

Negative pressure wind pipe

InactiveCN105890132APlay a supporting roleAvoid bendingDucting arrangementsLighting and heating apparatusEngineeringTextile

The invention relates to a negative pressure wind pipe. Through the adoption of the wind pipe, the problem that under the negative pressure state, bending and shrinking are easy to occur can be effectively solved. The negative pressure wind pipe structurally comprises a cylinder body made of a textile fabric, wherein a bracket is spirally and fixedly arranged on the outer surface of the cylinder body in the axial direction; reinforcing brackets are arranged on the inner surface of the cylinder body in a crossed manner, and stiffening rings are arranged on the reinforcing brackets. The negative pressure weaving wind pipe disclosed by the invention is simple to operate, convenient to use, and suitable for varied places.

Owner:JIANGSU GOLD IRON MAN AUTOMATION TECH

Convenient-to-assemble steel structure beam-column connecting joint

InactiveCN113323145AImprove connection strengthIncrease the bearing rangeBuilding constructionsSteel columnsEngineering

The invention relates to a convenient-to-assemble steel structure beam-column connecting joint. The convenient-to-assemble steel structure beam-column connecting joint comprises an H-shaped steel column and an H-shaped steel beam which are connected with each other, four sets of supporting mechanisms are symmetrically connected to flange plates on one side of the H-shaped steel column in a rectangular shape, and two sets of connecting mechanisms are symmetrically connected to the sides, away from each other, of two flange plates of the H-shaped steel beam. The two sets of connecting mechanisms are correspondingly connected with the two sets of supporting mechanisms located on the same horizontal direction in a limiting mode, the two sets of connecting mechanisms are connected with the flange plates on one side of the H-shaped steel beam through two connecting pieces, and the same reinforcing mechanism is arranged between the two sides of a web of the H-shaped steel beam and the two sets of supporting mechanisms located on the same vertical direction. The structure is compact, the whole joint connecting structures are matched and borne mutually, the defect that bearing is carried only through bolts traditionally is overcome, the whole joint connecting mode is simple and rapid, firmness is good, limitation in actual application is greatly reduced, and the development space of steel structure buildings is wider.

Owner:温州凯胜瑞恒科技有限公司

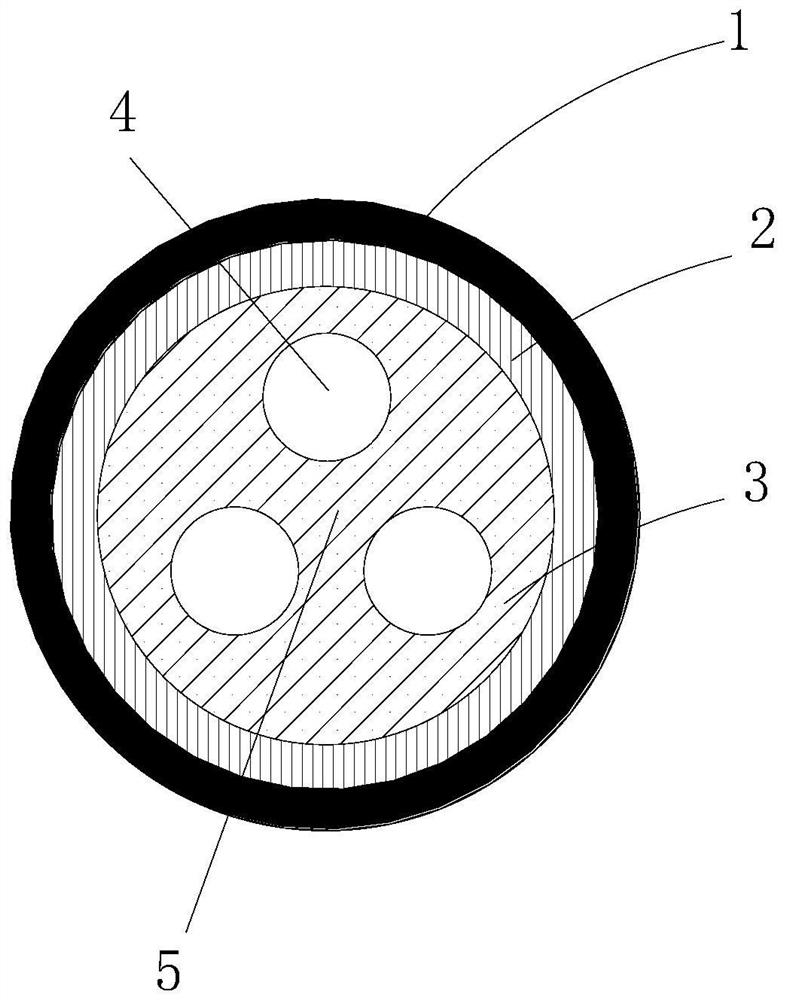

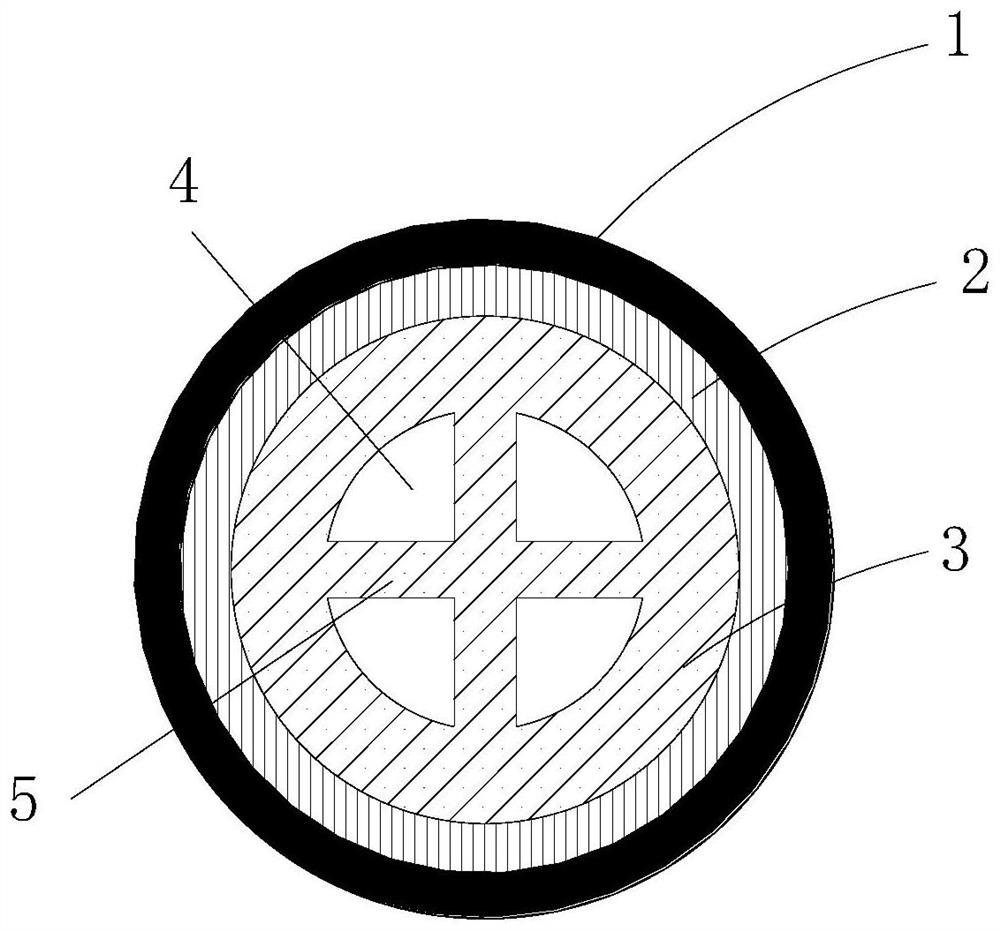

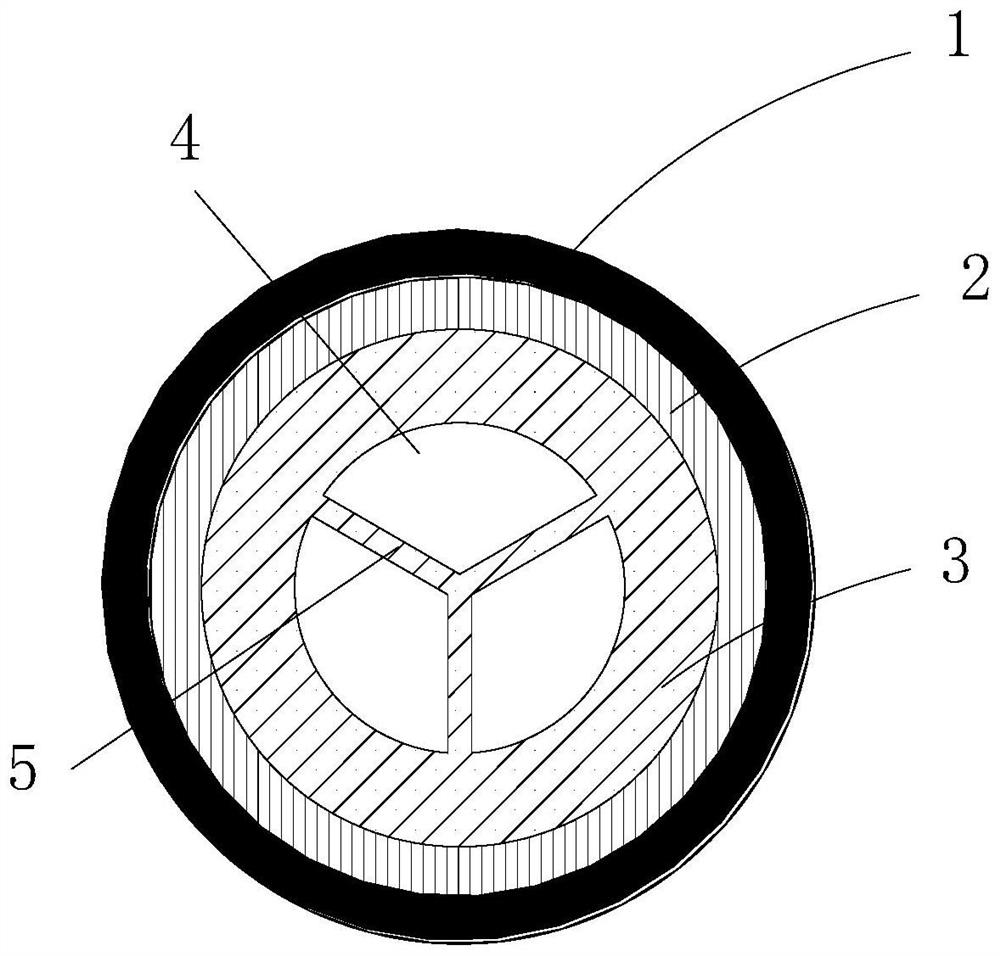

A safe and environment-friendly low-voltage power control composite cable

InactiveCN109065249APlay a role in strengthening the supportNot easy to damagePower cables with screens/conductive layersInsulated cablesFirst FillFilled cable

A safe and environment-friendly low-voltage power control composite cable includes a composite cable body, the composite cable body comprises an outer sheath, a armor layer, a shield layer, a first reinforcement layer, a first fill layer, a first support bar, a cable core, an insulating layer, a second fill layer, a second support bar, and a fill cable, At that same time, the composite cable bodyis halogen-free, Low-smoke, high-flame retardancy, and achieves safe, green and environment-friendly safety design requirements, A second support rod is arranged in an umbrella shape, A second supportrod, through the cooperation of the armor layer and the first support bar, plays a role of reinforcing support to the composite cable body so that external gravity doe not compress the cable core andfill the cable, each group of cable core and fill cable has its own independent space, no displacement and friction are generated, the service life of the cable core and fill cable is prolonged, andthe composite cable body is not easily damaged and more safe and reliable when used.

Owner:安徽扬子线缆有限公司

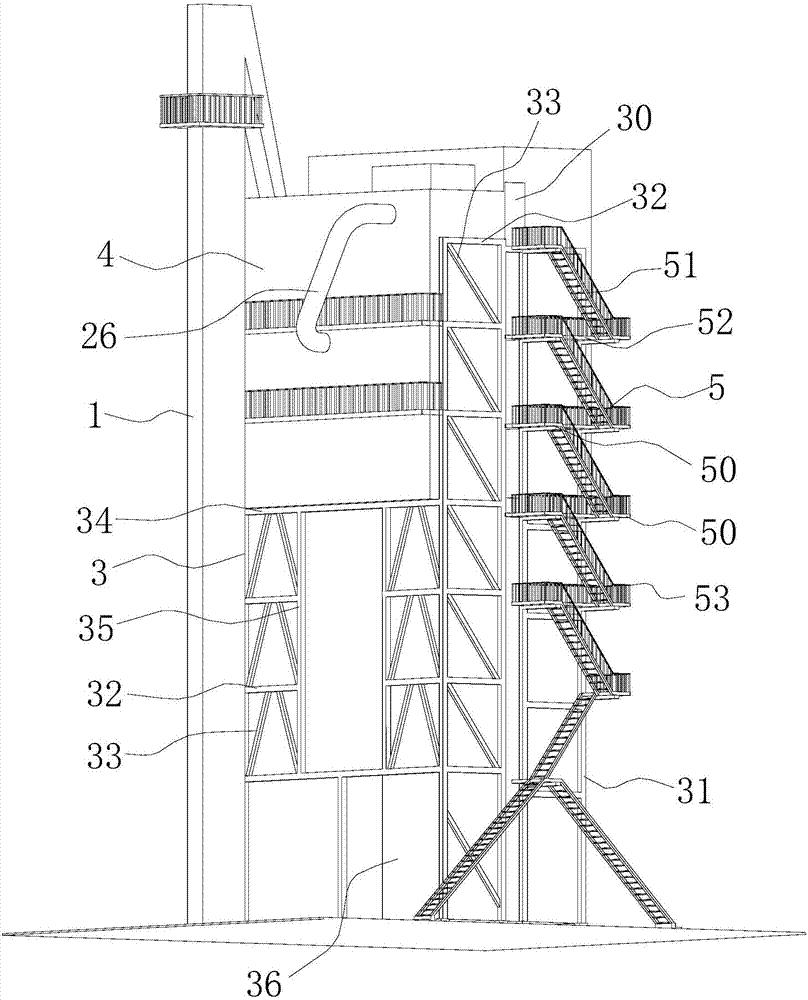

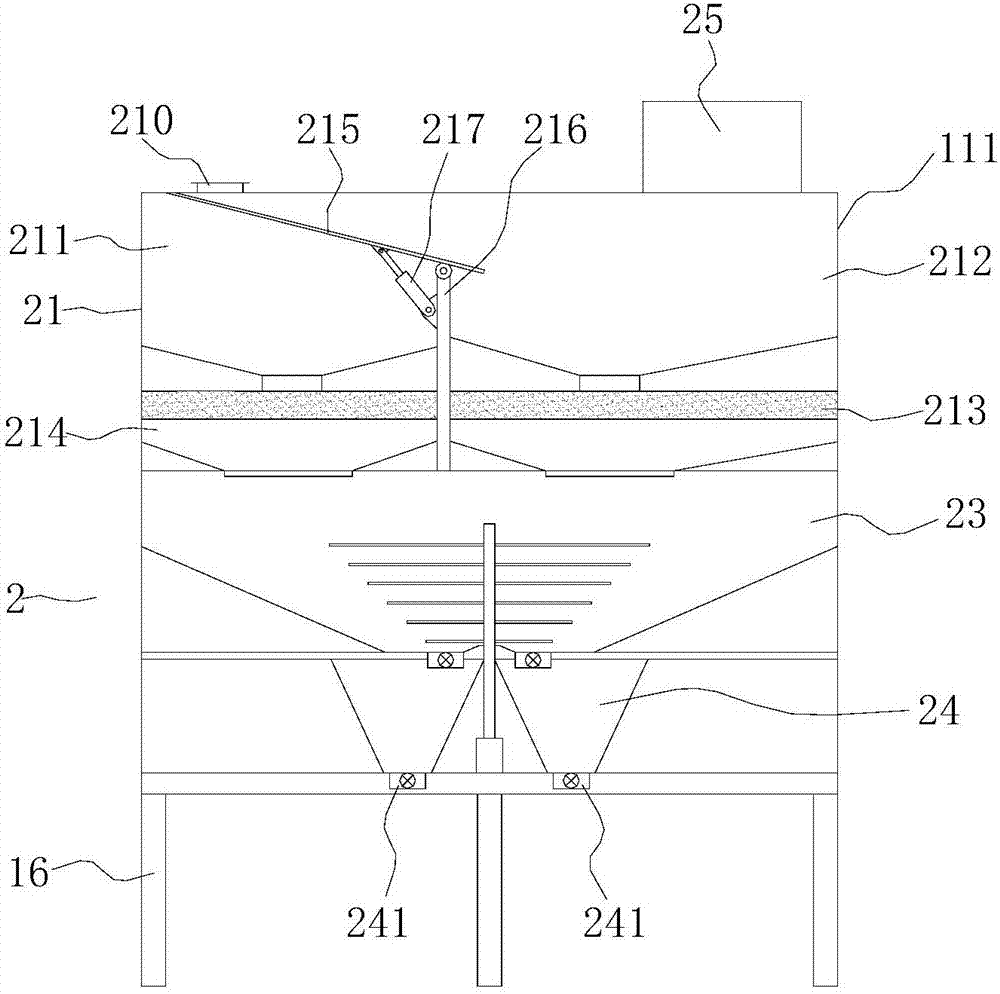

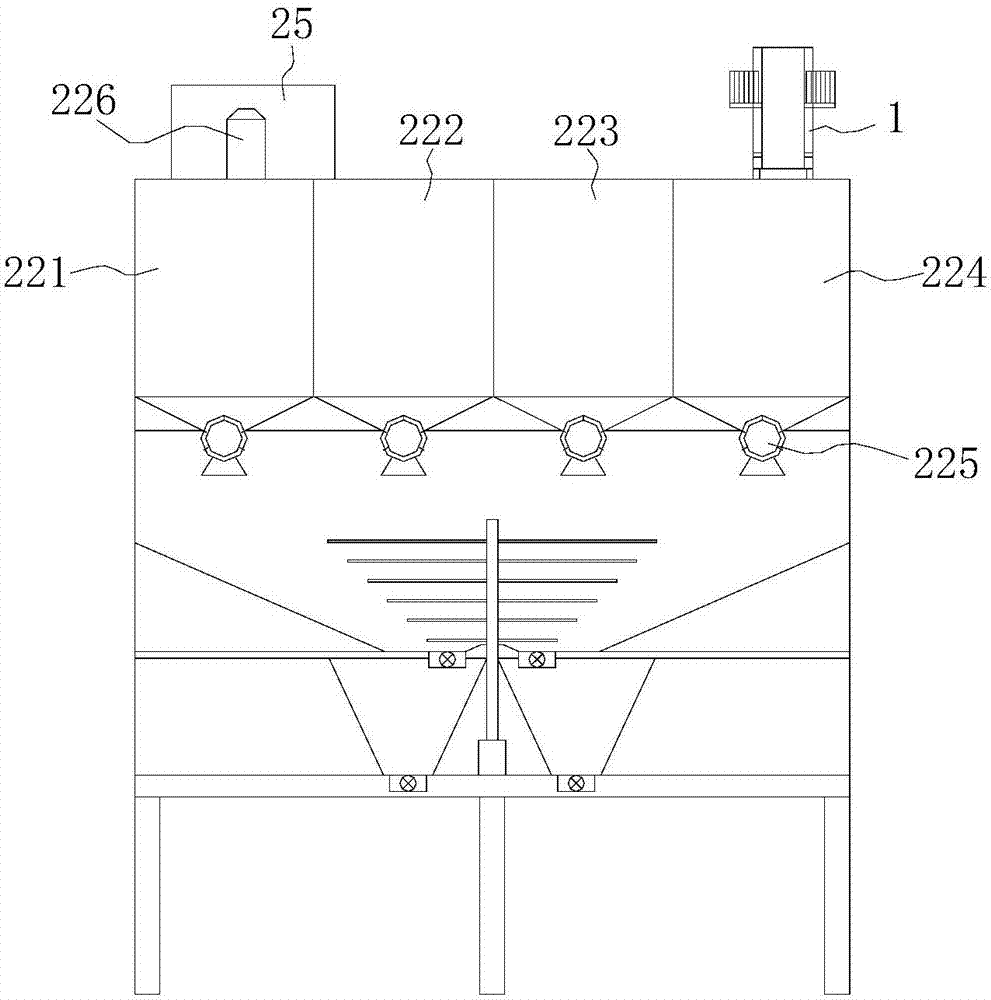

Recycled asphalt mixture mixing station with long service life

PendingCN106868986AExtended service lifeReasonable structureRoads maintainenceInterior spaceCorrosion

The invention discloses a recycled asphalt mixture mixing station with a long service life, which comprises an elevator, a mixing station, a peripheral stand, a shielding panel, and a crawling ladder; the mixing station is disposed in an internal space formed by the peripheral stand and the shielding panel; the shielding panel is spliced and fixed on an inner wall of the peripheral stand; the crawling ladder is fixedly welded on a right side of the peripheral stand; the mixing station is of a multi-stage structure; a front side of an upper layer is a hot material screening region, a rear side of the upper layer is a loading region, a middle layer is a stirring layer, and a lower layer is a recycled stock bin; the elevator is disposed beside the peripheral stand, is vertical upwards from the ground to be connected to a feed port in the hot material screening region; and a burner bin connected to the hot material screening region is disposed at the top of the mixing station. The station provided by the invention is easy to maintain; an integrally structural design achieves recycling and using of old asphalt mixture, saves energy and reduces materials; the peripheral stand and the shielding panel not only can reinforce support, but also can prevent the mixing station from corrosion, thereby facilitating prolonging the service life.

Owner:浙江昊业建设发展有限公司

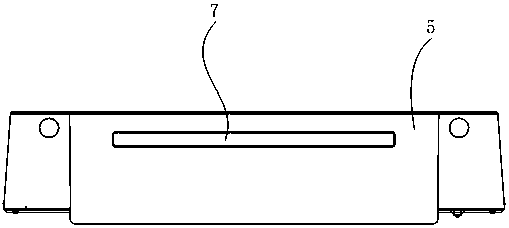

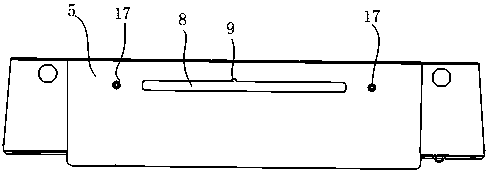

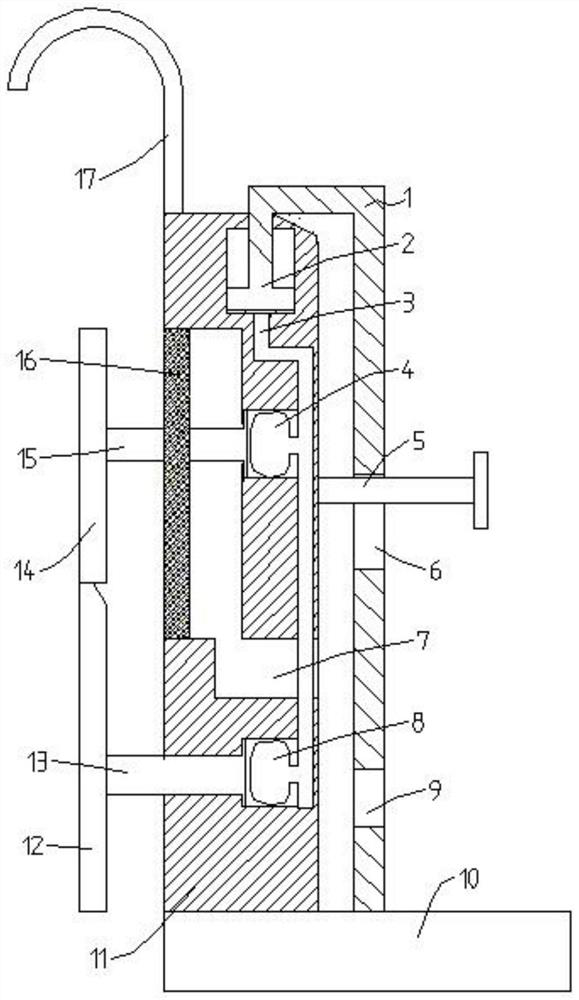

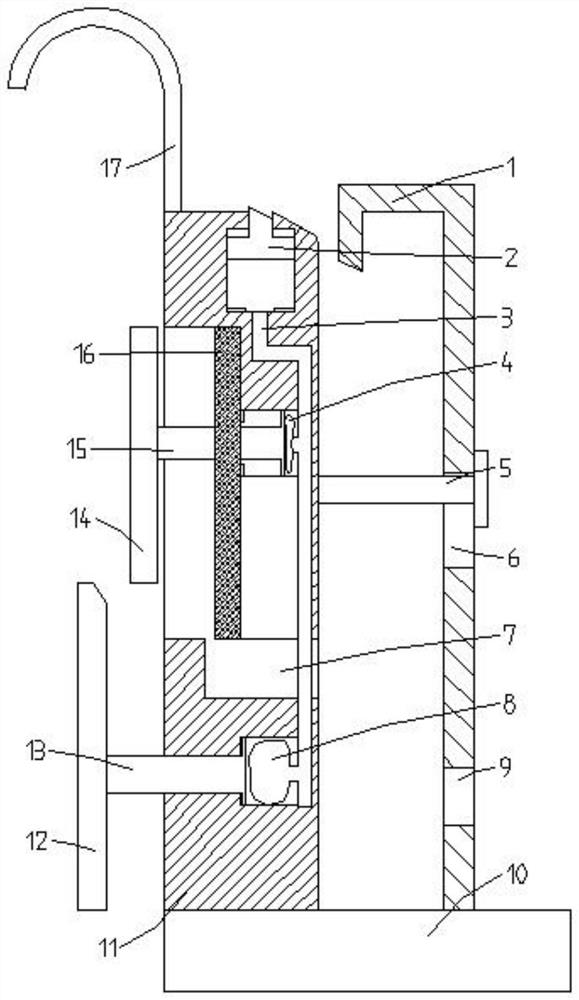

Air flue cover plate and refrigerator

InactiveCN108458538AAvoid frostAvoid condensationLighting and heating apparatusCooling fluid circulationAgricultural engineering

The invention discloses an air flue cover plate and a refrigerator. The air flue cover plate comprises a front cover plate and an upper cover plate connected with the front cover plate, wherein a front air outlet is formed in the surface of the front cover plate; and side air outlets are formed in two sides of the front cover plate. The air flue cover plate is characterized in that an opening is formed in the upper cover plate; an air guiding strip is arranged on the opening; and the opening and the air guiding strip form an upper air outlet. According to the air flue cover plate provided by the invention, an existing air flue cover plate structure is improved, so that the problems of frost formation and condensation of the air flue cover plate are solved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Hydraulic engineering flood prevention device and using method thereof

The invention provides a water conservancy project flood prevention device and a using method thereof. The water conservancy project flood prevention device comprises a water retaining mechanism and a force unloading mechanism. The force unloading mechanism comprises a base, the base is connected with a force unloading wall, the force unloading wall is provided with an upper movable plate and a lower movable plate, the force unloading wall is provided with a sliding cavity, and a sealing plate is slidably connected into the sliding cavity; the upper movable plate is connected with an upper movable rod, and the upper movable rod is connected with the sealing plate; the unloading wall is further provided with a first sliding hole. One end of the upper movable rod penetrates through the sliding cavity and enters the first sliding hole; an upper air bag is mounted in the first sliding hole; the unloading wall is also provided with a drainage hole; a second sliding hole is formed below the sliding cavity, and a lower air bag is arranged in the second sliding hole; the lower movable plate is connected with a lower movable rod, and the other end of the lower movable rod enters the second sliding hole. An air path is arranged in the unloading wall, and the upper air bag and the lower air bag are connected with the air path; a third sliding hole is formed in the top of the unloading wall, and a lifting block is slidably connected into the third sliding hole. The lifting block is in linkage connection with a stabilizing assembly. The device is good in stability and capable of effectively weakening impact force of water flow.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

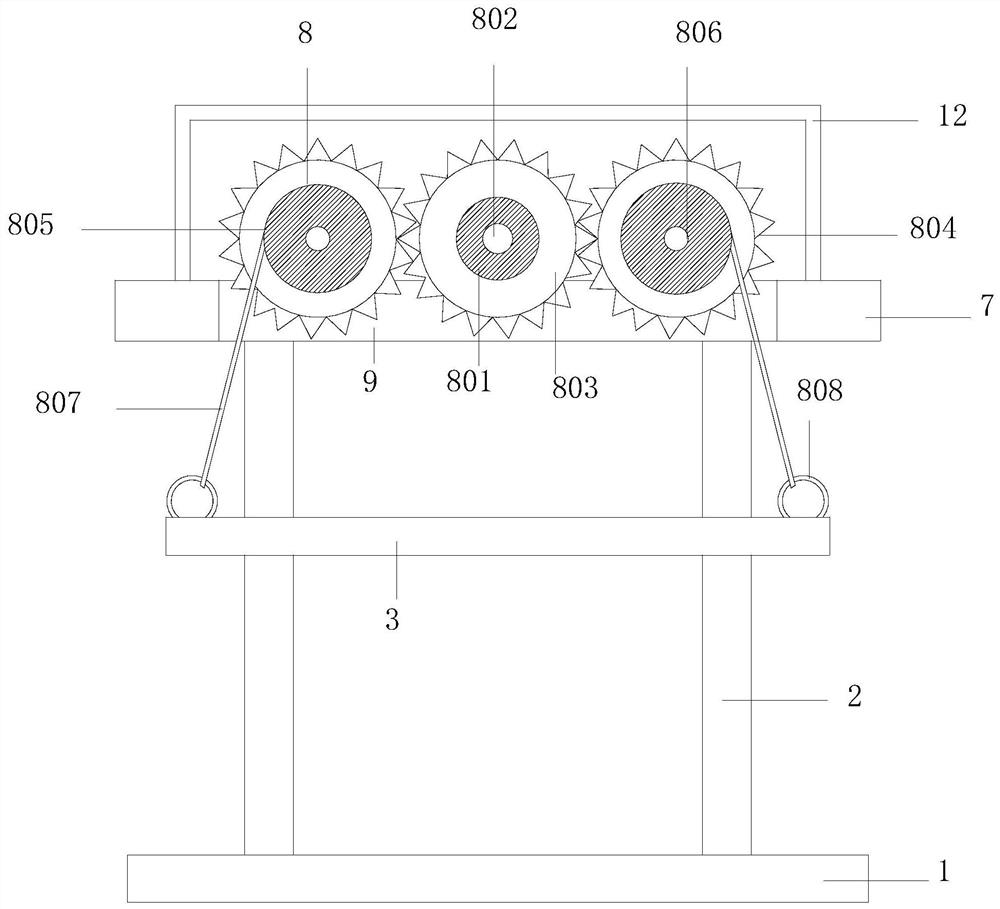

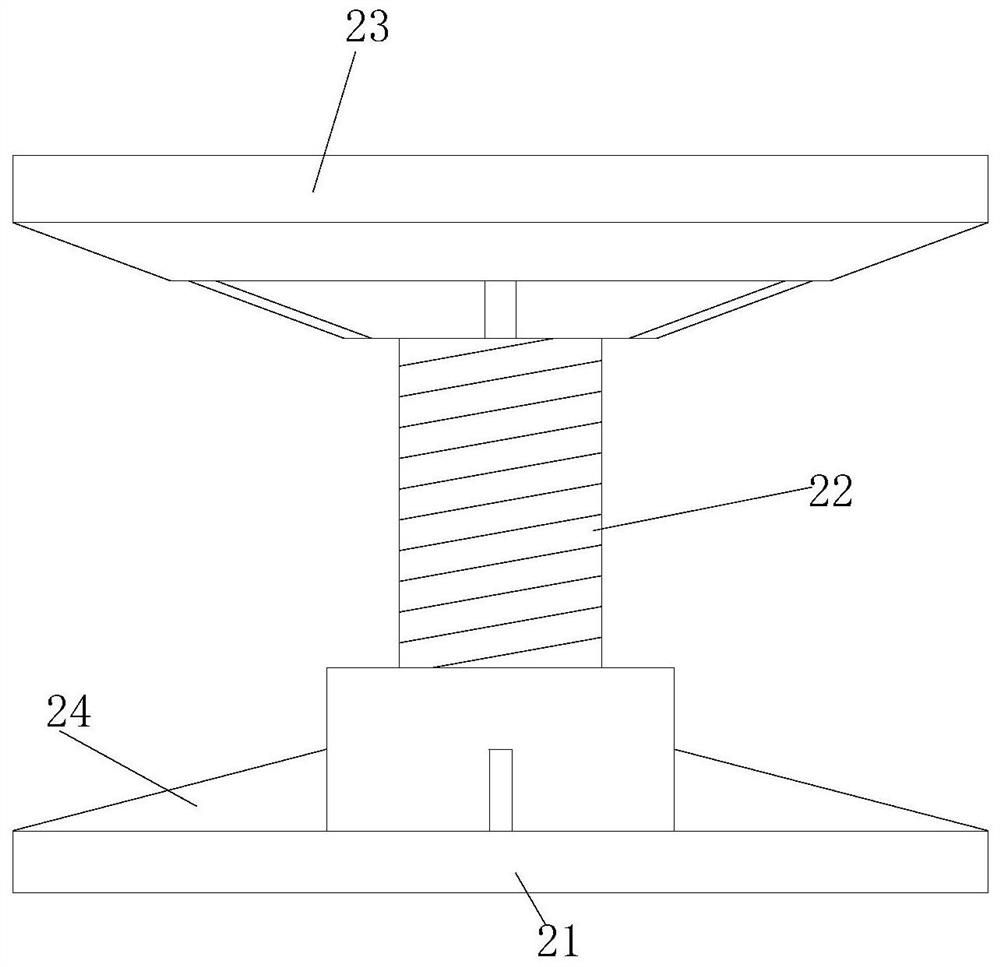

Height-adjustable stable engineering building construction frame

InactiveCN112049393ARealize lifting functionGuaranteed stabilityScaffold accessoriesGear wheelArchitectural engineering

The invention belongs to the technical field of engineering building equipment, and particularly discloses a height-adjustable stable engineering building construction frame. The height-adjustable stable engineering building construction frame comprises a base, guide rods and a lifting assembly; the guide rods are vertically fixed to the two sides of the surface of the base, a sliding plate is arranged between the two guide rods, square holes matched with the guide rods are symmetrically formed in the surface of the sliding plate, protrusions are arranged on the two sides of the inner walls ofthe square holes in an outward extending mode, and grooves are formed in the positions, corresponding to the protrusions, of the surfaces of the guide rods; a top plate is arranged at the top ends ofthe two guide rods, and the lifting assembly is arranged on the surface of the top plate; the lifting assembly comprises a driving motor, a first gear and a second gear; and the driving motor is fixed to the middle of the surface of the top plate, and the output end of the driving motor is fixedly connected with a rotating shaft. Through the effect of the lifting assembly and the sliding plate, the sliding plate can stably slide on the guide rods to realize the height-adjustable purpose, and the stability of the sliding plate can be guaranteed through meshing of the first gear and the secondgear.

Owner:浙江富成建设集团有限公司

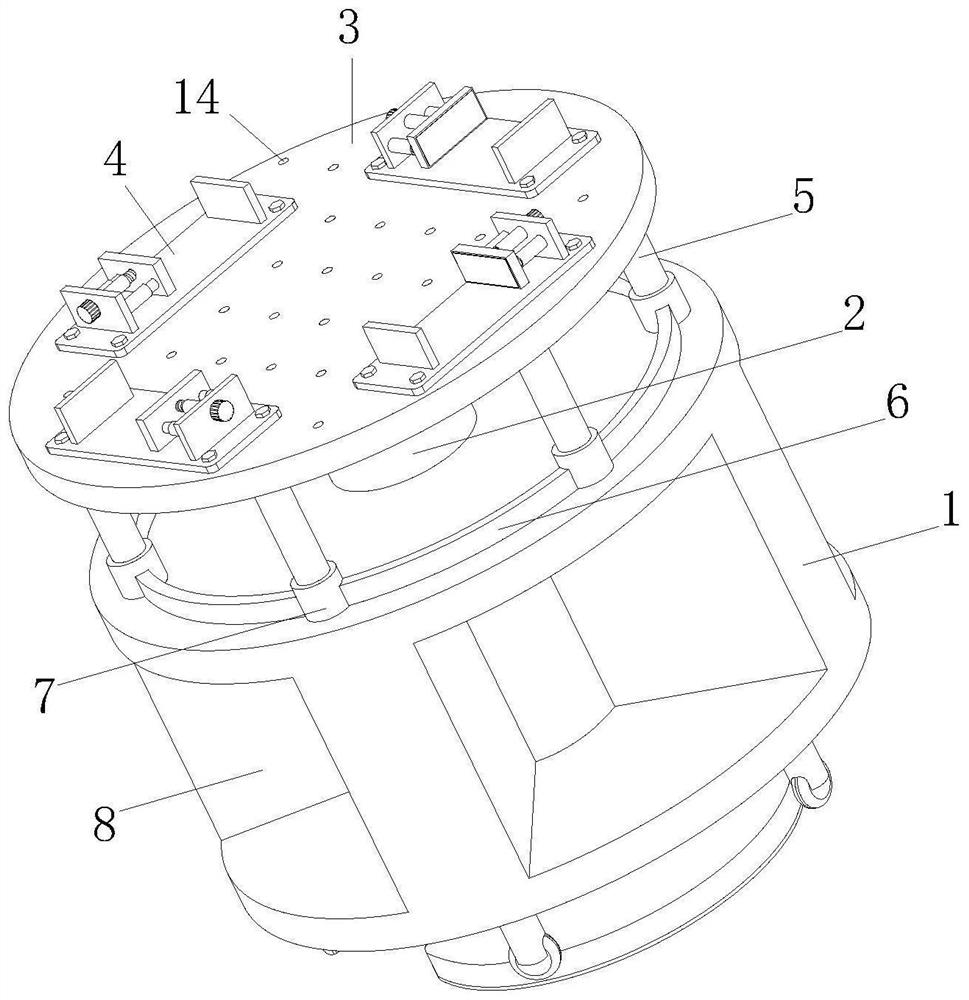

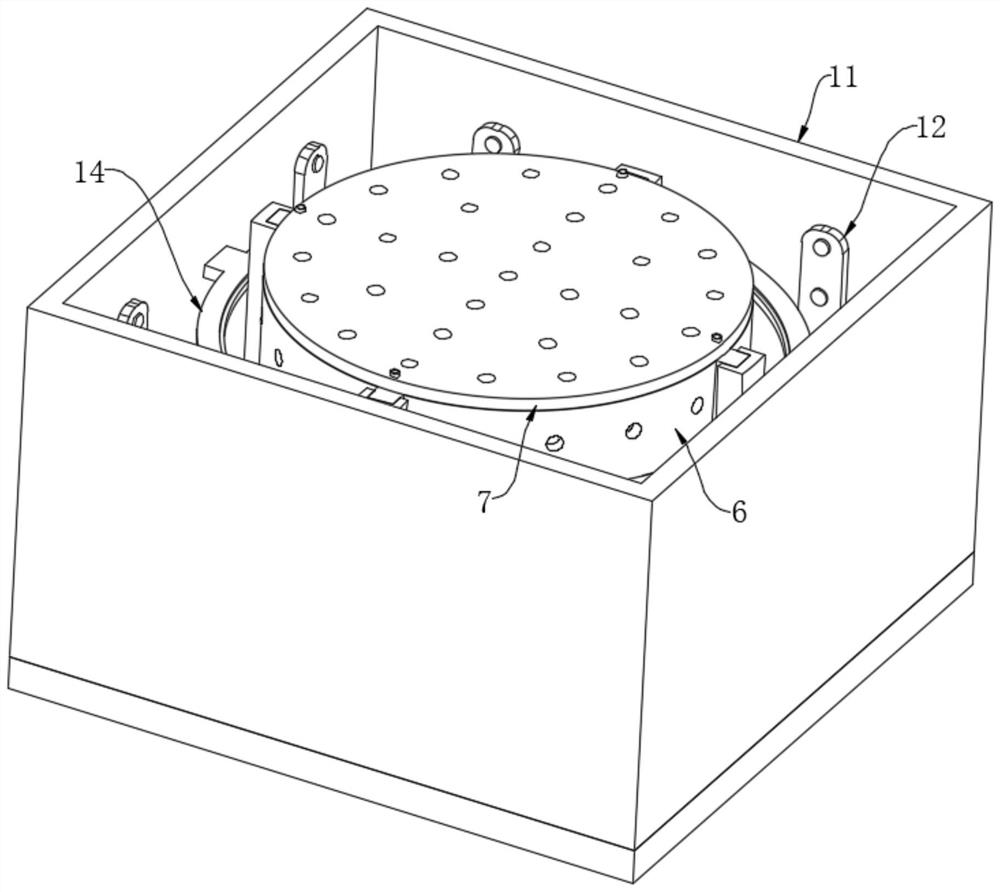

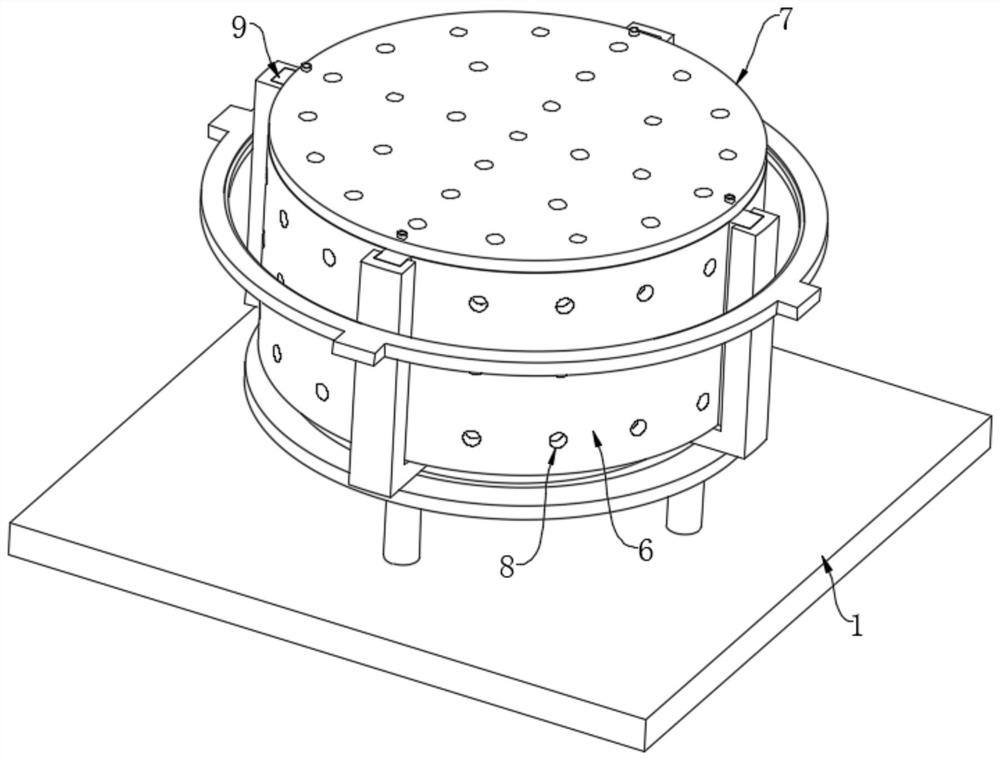

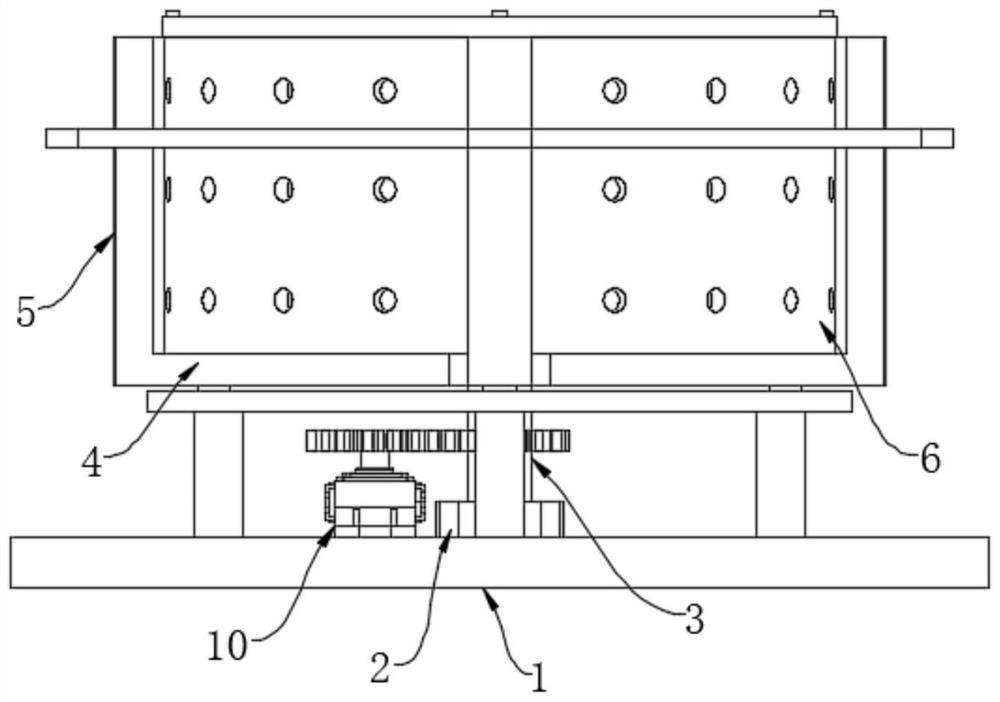

Horizontal rotary table driven by ultrasonic motor

InactiveCN113510670APlay a role in strengthening the supportGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesWork holdersElectric machineryEngineering

The invention discloses a horizontal rotary table driven by an ultrasonic motor. The horizontal rotary table comprises a shell, an ultrasonic motor body is fixedly mounted at the top of the shell, a top plate is fixedly connected to the output end of the ultrasonic motor body, a connecting rod is fixedly connected to the bottom of the top plate, a sliding block is fixedly connected to one end of the connecting rod, an annular sliding rail is fixedly connected to the top of the shell, the inner wall of the sliding block is slidably connected with the annular sliding rail, a clamping device is arranged at the top of the top plate, moving wheels are rotationally connected to the bottom of the shell through bearings, and an electric air cylinder is fixedly connected to the bottom of the shell. Through cooperation of the connecting rod, the annular sliding rail and the sliding block, the supporting effect on the top plate can be enhanced, meanwhile, the top plate can be limited, the top plate is more stable in the running process, the bearing effect and running stability of the horizontal rotary table are effectively improved, and use is more facilitated.

Owner:苏州浩智博智能科技有限公司

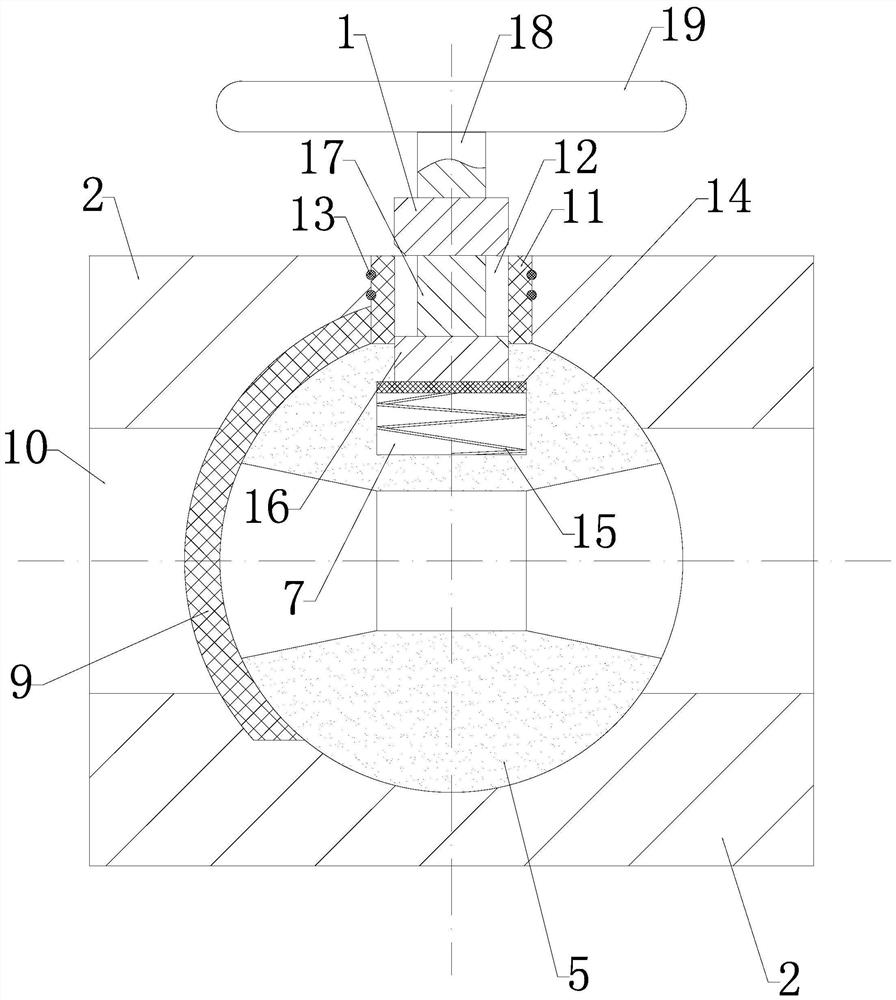

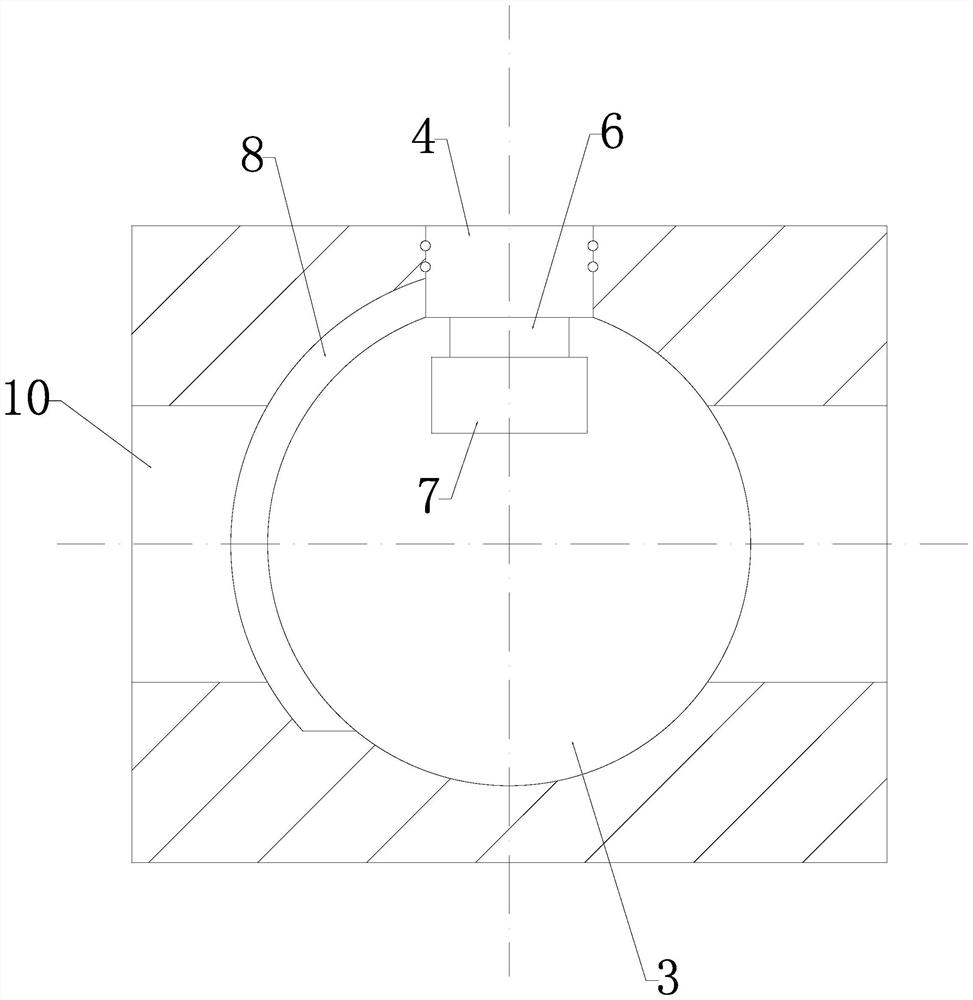

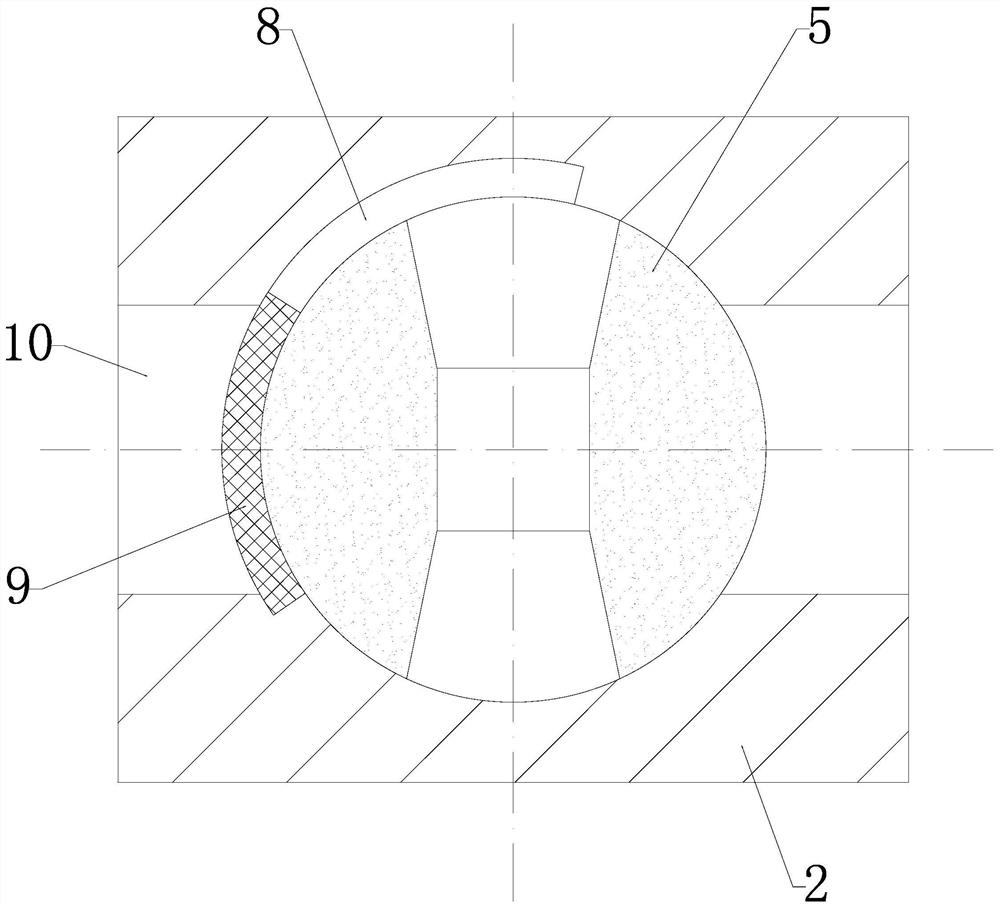

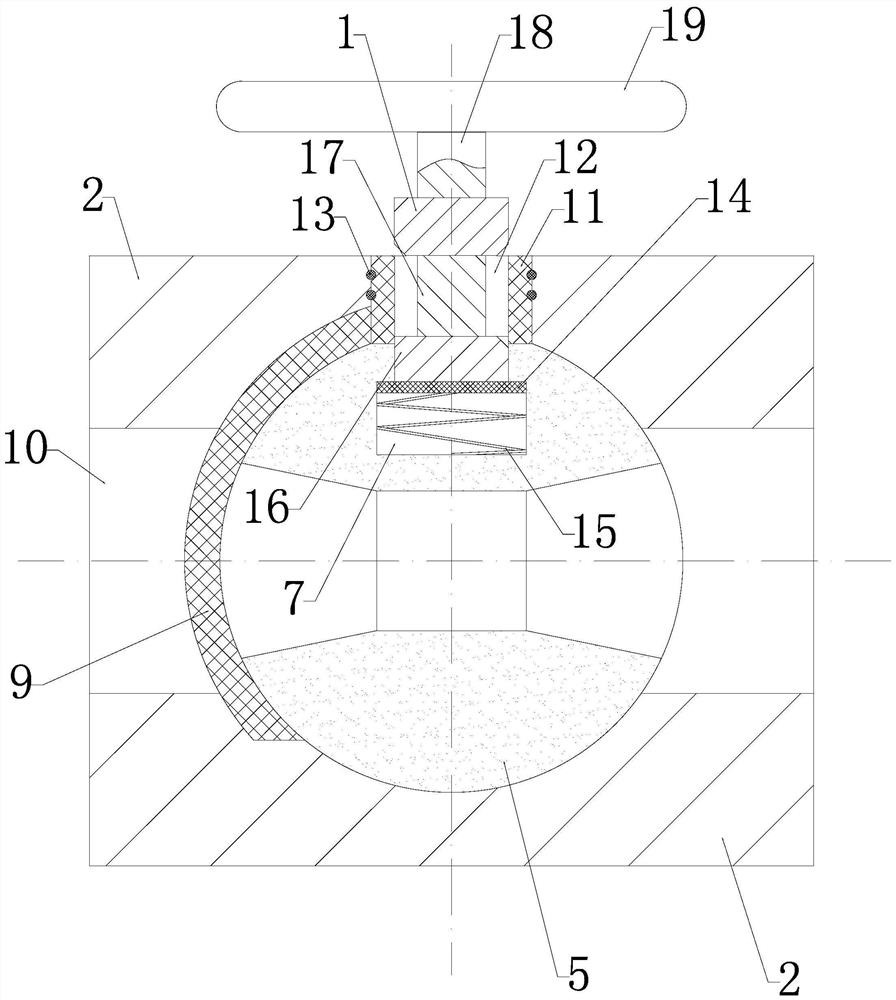

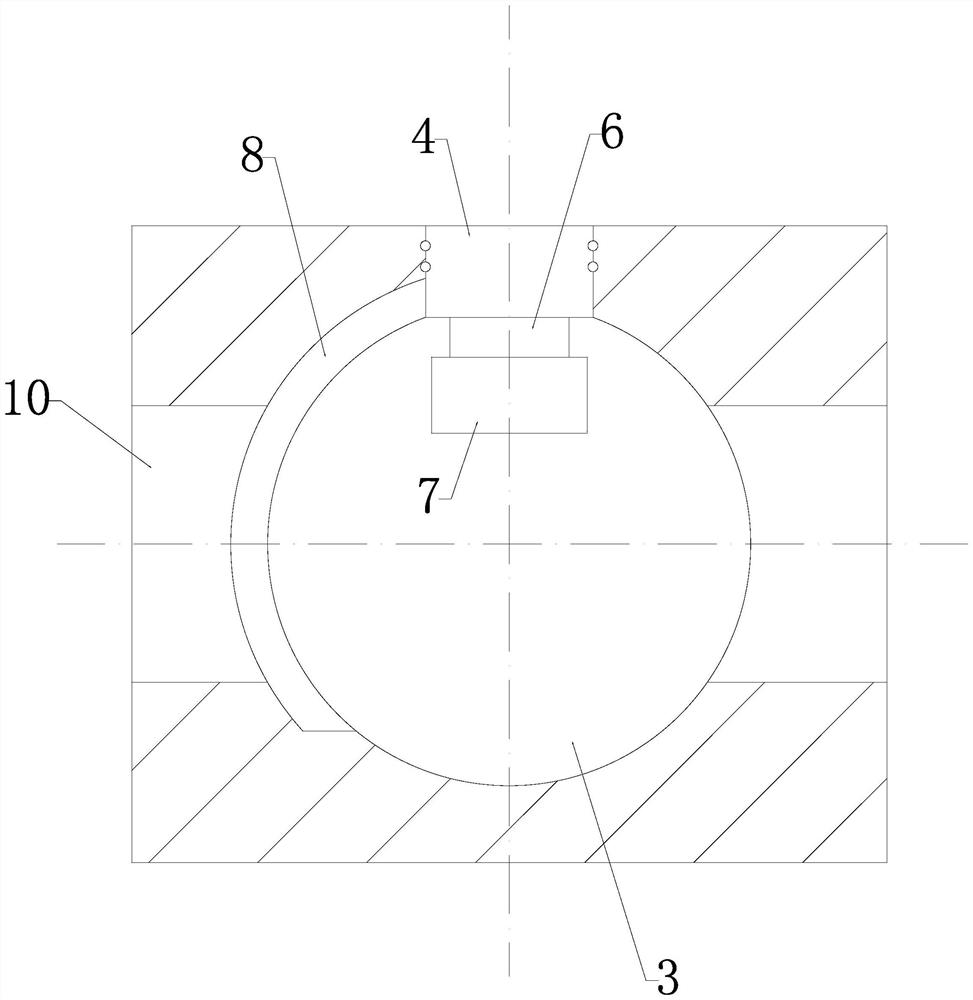

Plastic valve and processing and manufacturing method thereof

The invention relates to the technical field of valve manufacturing, in particular to a plastic valve and a processing and manufacturing method thereof. The plastic valve comprises a valve body, wherein a main valve cavity is formed in the middle of the valve body, and two sides of the main valve cavity are communicated and matched with conveying pipelines to be mounted on two sides; an insertinground cavity communicating with the main valve cavity is formed in the portion, at the top of the main valve cavity, of the valve body, a main ball valve assembly and an auxiliary valve assembly are mounted in the main valve cavity, and the main ball valve assembly is used for achieving intercepting sealing in the normal pressure state. The main ball valve assembly and the auxiliary valve assemblyare matched to achieve intercepting sealing in a high pressure state. According to the plastic valve, by adopting the structure of the main valve element and the auxiliary valve element, double-effect sealing in the high-pressure state can be achieved through adjustment of the main valve element and the auxiliary valve element, so that the sealing effect is good, the overall structure is small, the main valve element and the auxiliary valve element are tightly matched, and therefore, the more effective sealing and intercepting effect is achieved.

Owner:SHANXIAN XINGYUAN PLASTIC VALVE CO LTD

Overhead mounted waterless spliced floor tile and preparation and mounting method thereof

InactiveCN113356516APlay a role in strengthening the supportEasy to fixFalse floorsEngineeringStructural engineering

The invention discloses an overhead mounted waterless spliced floor tile. The overhead mounted waterless spliced floor tile comprises a tile body and a leveling support leg, wherein the leveling support leg comprises a base and a panel, nuts are respectively fixed in the base and the panel, and a stud is in threaded connection between the two nuts. The invention further discloses a preparation method of the overhead mounted waterless spliced floor tile. The preparation method comprises the following steps of (S1) forming side grooves in the side surfaces of a reinforcing bottom plate; and (S2) after the reinforcing bottom plate and a tile plate are bonded through a bonding layer, applying external force to press the reinforcing bottom plate and the tile plate so as to form a tile body. The invention further discloses a mounting method of the overhead mounted waterless spliced floor tile. According to the overhead mounted waterless spliced floor tile and the preparation and mounting method, the reinforcing bottom plate is bonded to the bottom surface of the fragile tile plate so as to reinforce and support the tile plate, the side grooves are formed in the side surfaces of the reinforcing bottom plate on the basis, compared with a preparation method that the side grooves are formed in the fragile tile plate, the machining is simple, two tile bodies are fixed firmly through splicing of splicing strips and the side grooves, and the stability is high.

Owner:上海品宅装饰科技有限公司

Fingerprint module and electronic equipment

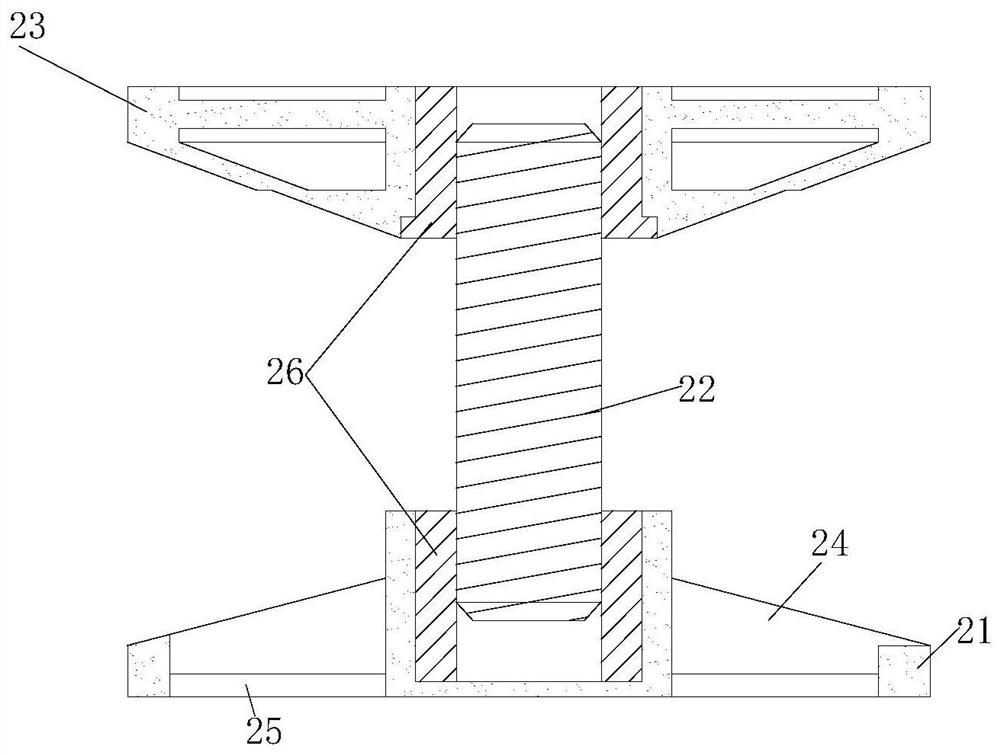

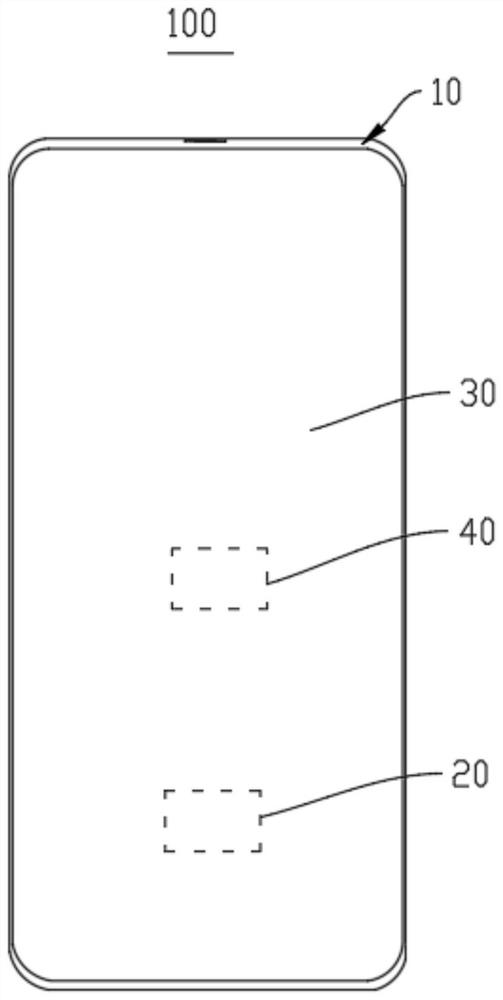

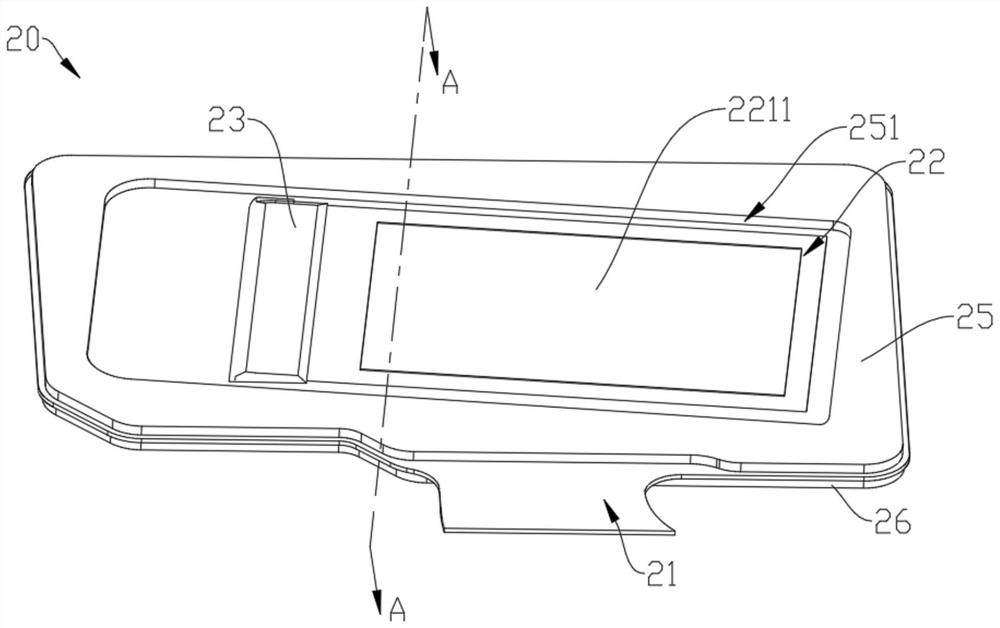

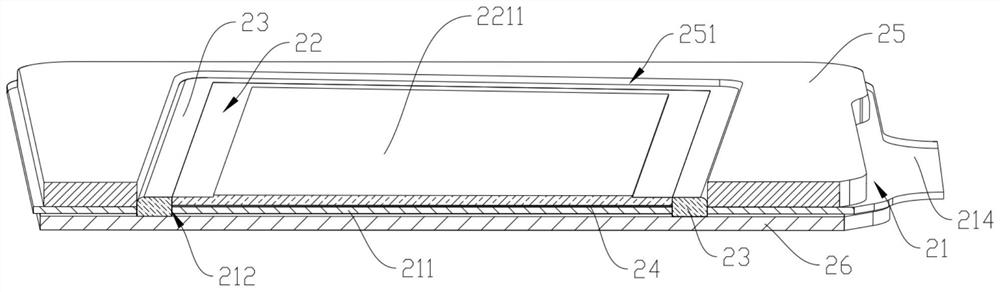

InactiveCN113068304APlay a role in strengthening the supportImprove stabilityAcquiring/reconising fingerprints/palmprintsPrinted circuit non-printed electric components associationComputer hardwareEngineering

The invention provides a fingerprint module and electronic equipment. The fingerprint module comprises a circuit board, a colloid and a sensing chip, the circuit board is provided with a chip mounting area and an accommodating part arranged around the chip mounting area, the sensing chip is arranged in the chip mounting area, and the colloid is arranged in the accommodating part and is connected with the periphery of the sensing chip. The fingerprint module provided by the invention avoids the problems of complex structure and high production cost of the existing fingerprint module.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

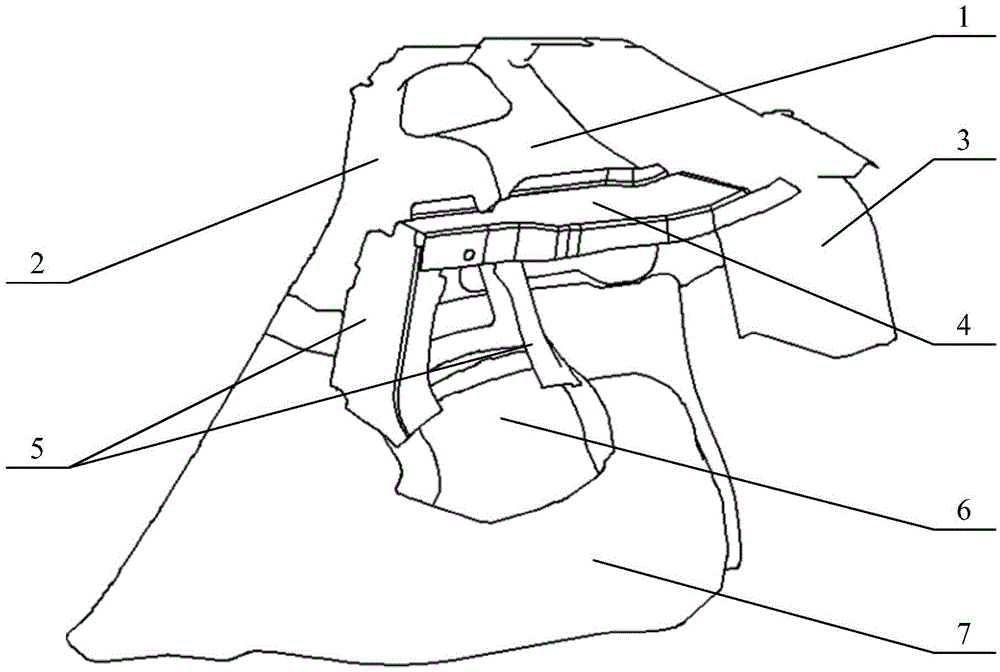

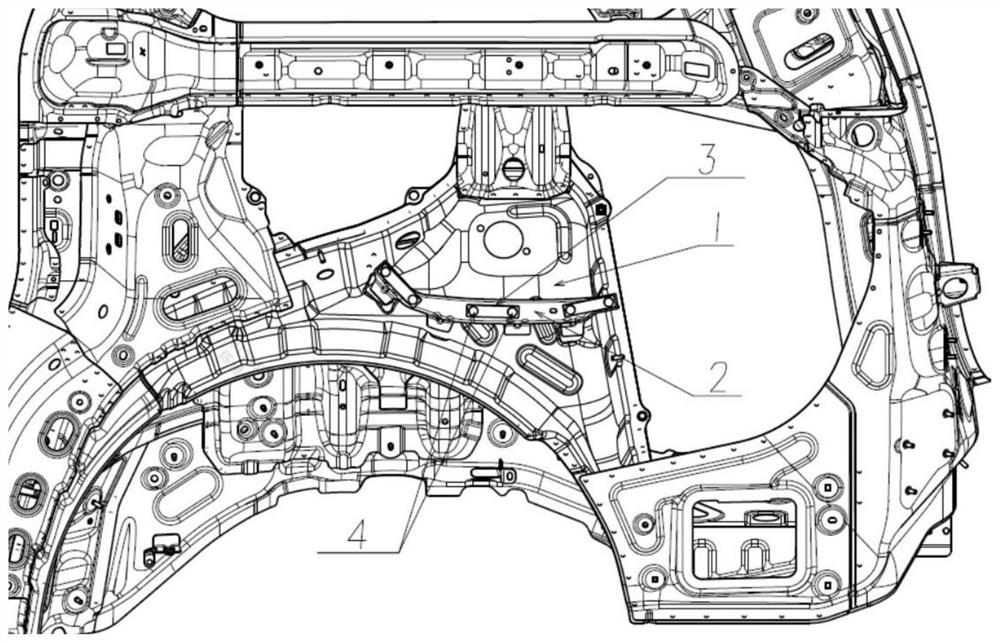

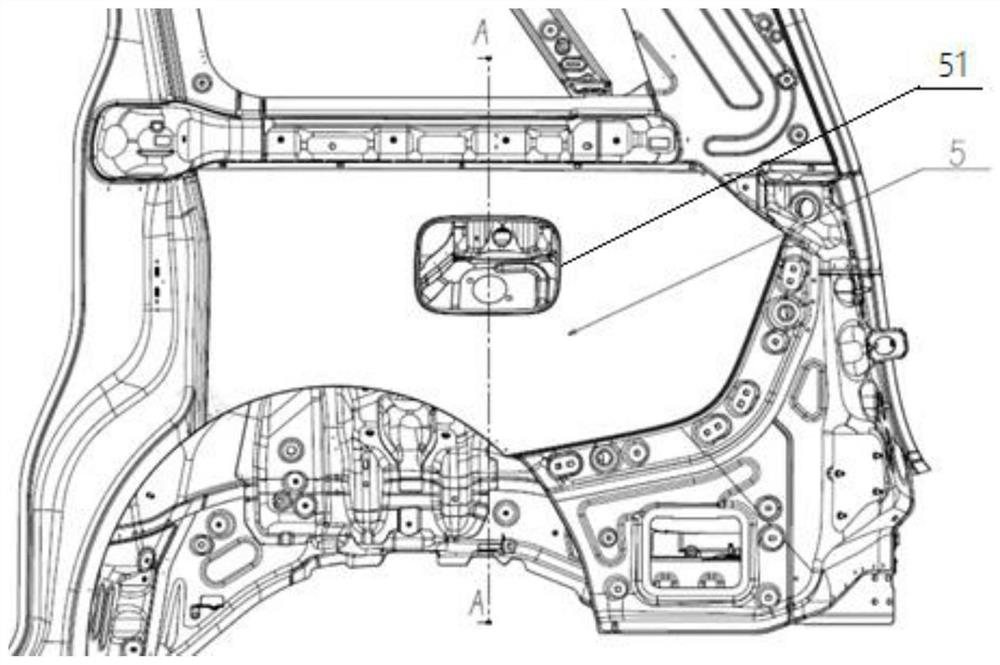

Side wall back structure of automobile and automobile

InactiveCN104554453AIncrease stiffnessIncrease the amount of vibration isolationSuperstructure subunitsBack structureEngineering physics

The invention provides a side wall back structure of an automobile and the automobile. The side wall back structure comprises a column C inner plate, and a column D inner plate, wherein the column C inner plate is horizontally connected with the head side of a back side window inner plate, the column D inner plate is horizontally connected with the tail side of the back side window inner plate, and a back coiler mounting plate is simultaneously connected with the column C inner plate and the column D inner plate. The side wall back structure of the automobile and the automobile can solve the problem of poor control noise and vibration control effect in the automobile because of smaller rigidity of the mounting point of the back damper in the side wall back structure of the automobile in the prior art.

Owner:GREAT WALL MOTOR CO LTD

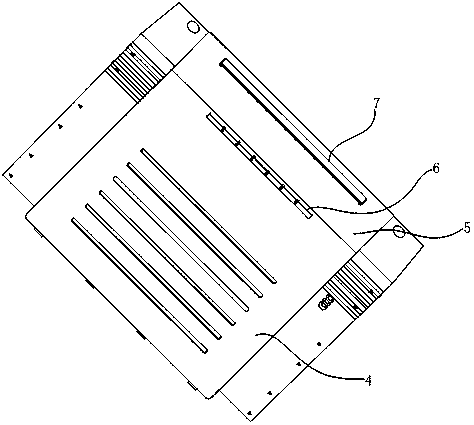

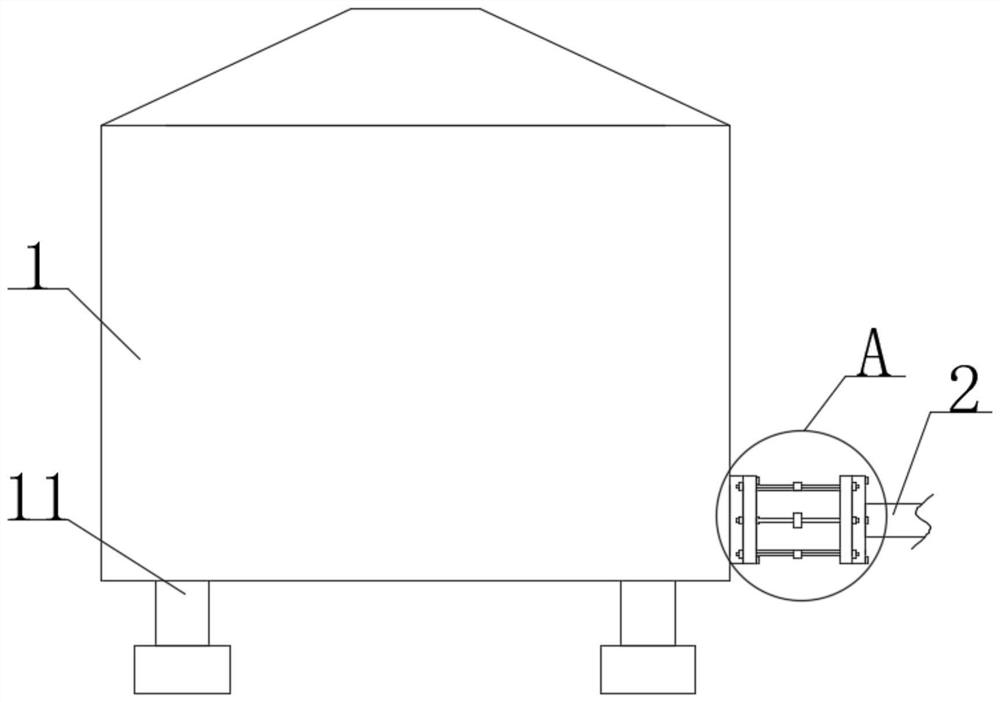

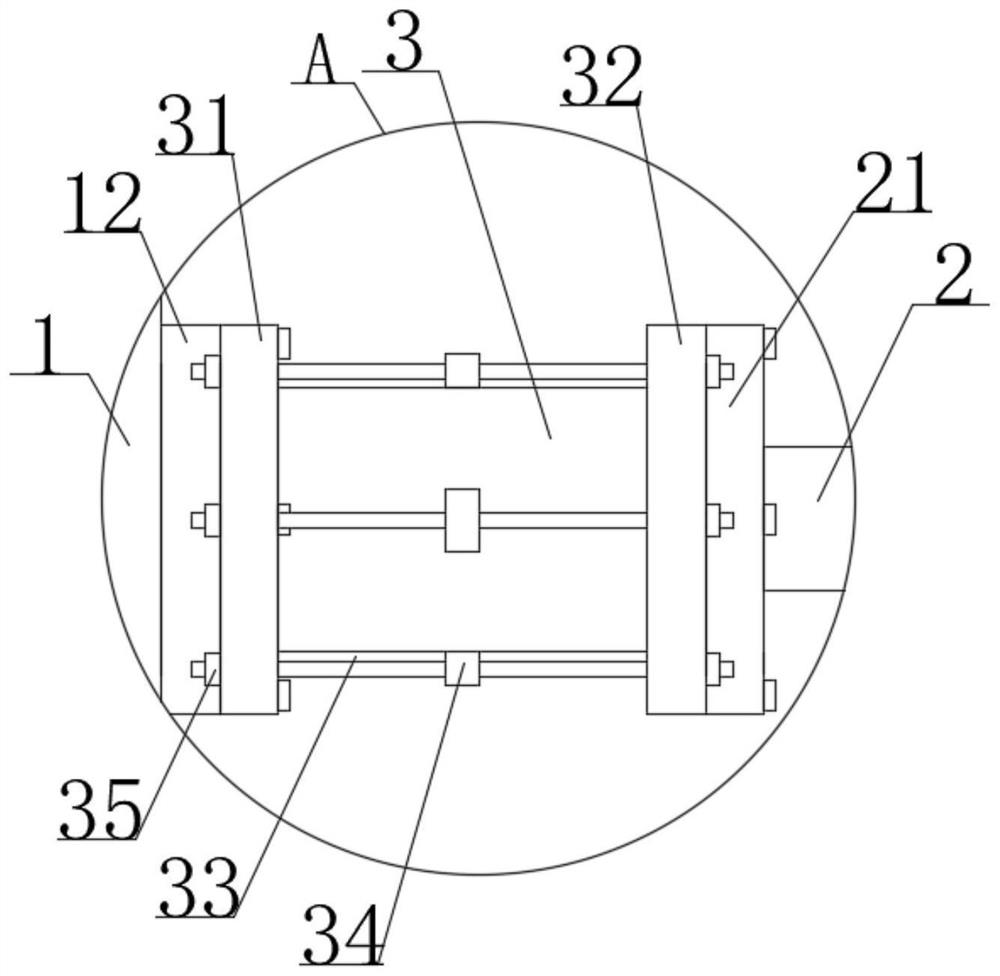

Bead dispersing and drying process and device for polystyrene production

PendingCN114136063ADry thoroughlyEvenly heatedGranular material dryingDrying chambers/containersComposite materialPolystyrene particle

The invention relates to the field of polystyrene processing technologies, and discloses a bead dispersing and drying technology and device for polystyrene production, the bead dispersing and drying device comprises a supporting plate and an outer frame of a rectangular structure, the top end of the supporting plate is provided with a bearing seat, the bearing seat is connected with a rotating shaft located in the vertical direction, the top end of the rotating shaft is fixedly connected with a cross, and the cross is fixedly connected with the outer frame. Vertical rods located in the vertical direction are fixed to the four corners of the top end of the cross, the four vertical rods and the cross are matched to form a containing frame, a charging barrel is arranged in the containing frame, a cover plate is installed at the top end of the charging barrel, and a plurality of air holes with the diameter smaller than that of polystyrene particles are formed in the cover plate and the charging barrel in a penetrating mode. And a clamping mechanism for clamping the charging barrel is arranged between the charging barrel and the placing frame. The polystyrene particles in the charging barrel can be heated by the heater on the outer frame while rotating, and the polystyrene particles can be heated more uniformly due to the continuous rolling of the polystyrene particles, so that the polystyrene can be dried more thoroughly.

Owner:江苏中信国安新材料有限公司

Double-bed gasification furnace using universal expansion joint to connect furnace bottom air inlet pipe and circulating fluidized bed

InactiveCN114437832AAvoid spillingPrevent leakageGranular/pulverulent flues gasificationFluidized bedMechanical engineering

The invention discloses a double-bed gasification furnace using a universal expansion joint to connect a furnace bottom air inlet pipe and a circulating fluidized bed, the double-bed gasification furnace comprises a gasification furnace, an air inlet pipe and the universal expansion joint, one side of the gasification furnace is provided with an opening, and one side of the opening is hermetically connected with the universal expansion joint; a one-way expansion joint for connecting the gasification furnace and the air inlet pipe is replaced by the universal expansion joint, that is, the fixed furnace bottom air inlet pipe and the vibrating circulating fluidized bed double-bed gasification furnace body are connected through the universal expansion joint, so that cracking caused by overlarge amplitude can be avoided, gas leakage accidents are avoided, potential safety hazards are eliminated, and the service life of the gasification furnace is prolonged. Shutdown and production halt caused by gas leakage accidents are prevented, the production efficiency is improved, and the loss of funds and production capacity is reduced; and by arranging the reinforcing ribs and the reinforcing plates, the universal expansion joint can be reinforced and supported, the universal expansion joint is protected, and gas leakage can be further prevented.

Owner:SHANDONG PHARMA GLASS

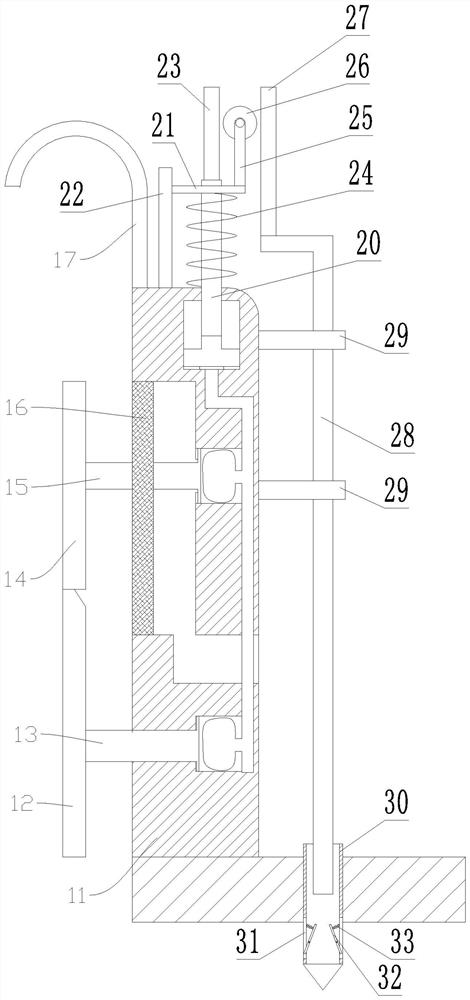

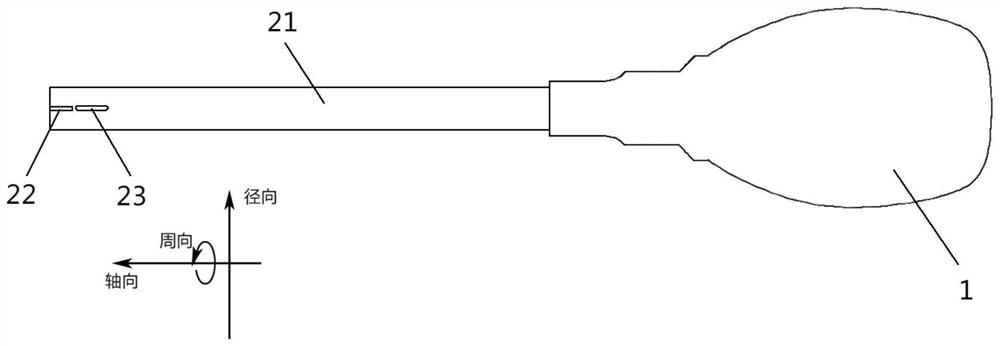

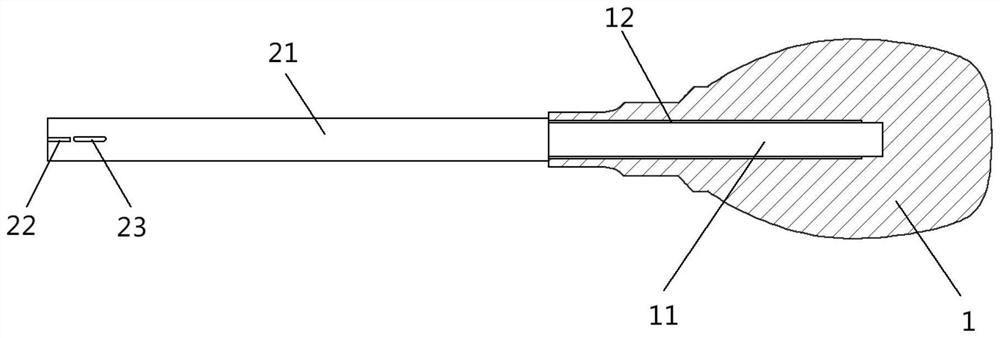

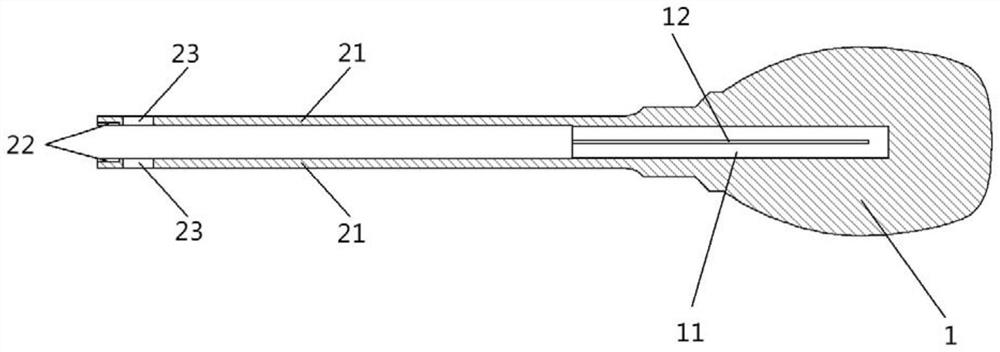

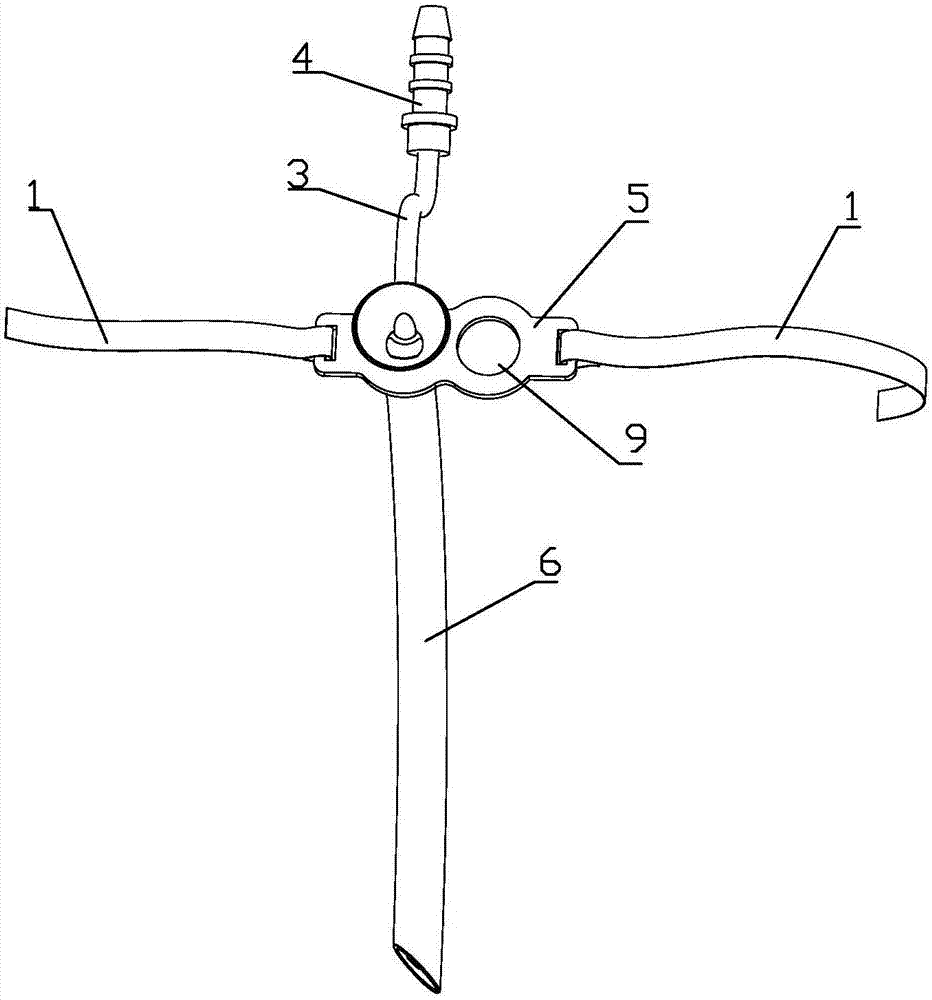

Opening awl with positioning needle assembly for field spinal surgery

PendingCN114469246AReasonable structureSimple and efficient operationBone drill guidesSpinal operationEngineering

The open-circuit cone comprises a holding handle and an open-circuit assembly which are connected through a supporting assembly, a strength supporting assembly is installed in the holding handle, the supporting assembly comprises a pair of supporting rods, a steering limiting groove and a rotating sliding groove are formed in the top ends of the supporting rods, and the open-circuit assembly comprises a cone head. A pair of rotary supporting rods is arranged in the middle of the rotary base, the rotary supporting rods can drive the rotary base to move along the rotary sliding groove and rotate between the pair of supporting rods with the rotary supporting rods as axes, and a positioning needle containing bin used for containing a positioning needle assembly is further formed in the bottom of the rotary base. The positioning needle assembly comprises a first positioning needle and a second positioning needle which are different in connecting body and different in needle body penetrating depth through the needle handle, the structure is reasonable, operation is easy and convenient, the mouth gag, the opening awl and the positioning needle placing device are integrated, the device is suitable for field spine surgery, personnel and time cost is saved, and the success rate of the surgery is increased.

Owner:AIR FORCE MEDICAL UNIV

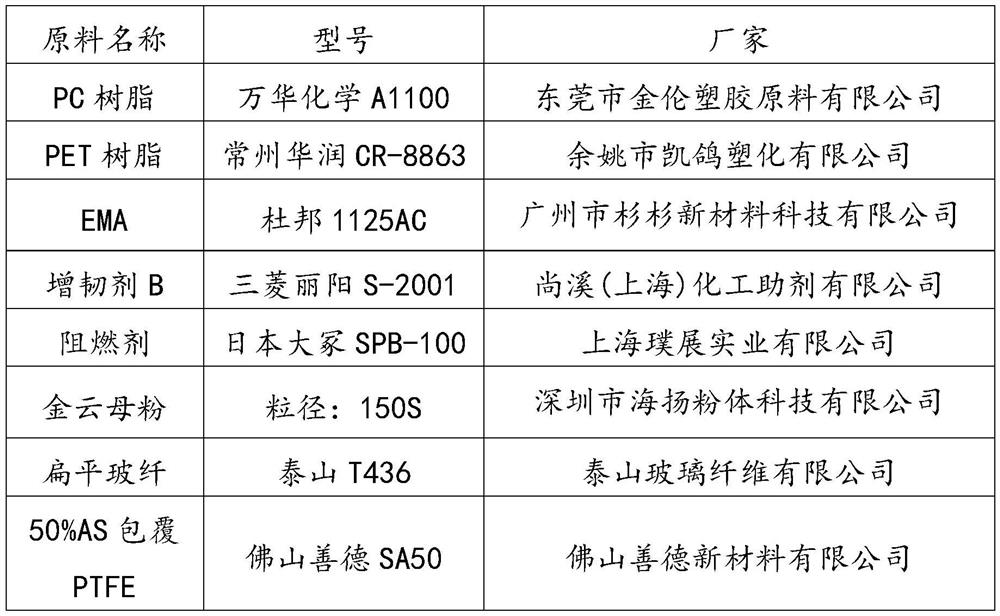

Halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate composite material and preparation method thereof

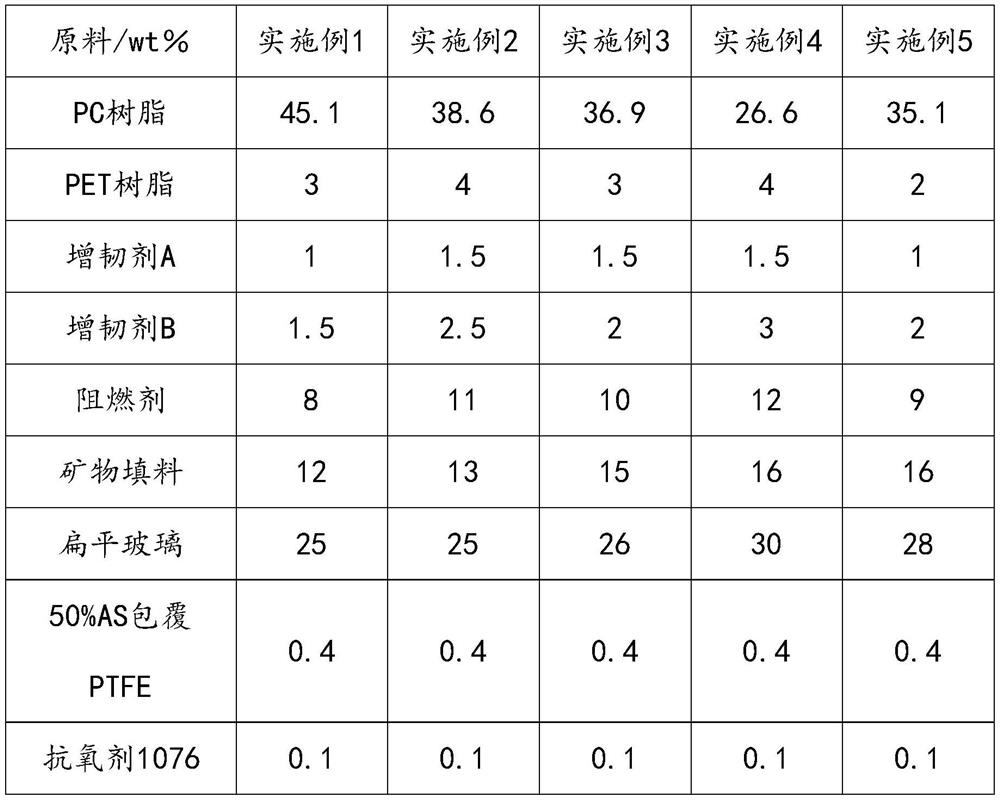

ActiveCN113292838ASolve warpingSolve the problem of large expansion rate at high and low temperaturesGlass fiberPolymer science

The invention relates to the field of polycarbonate resin composite materials, and discloses a halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate composite material and a preparation method thereof. The halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate material is prepared from the following components in percentage by mass: 25.9 to 46.5 percent of PC (polycarbonate) resin, 2 to 4 percent of PET (Polyethylene terephthalate) resin, 8 to 12 percent of a flame retardant, 1 to 1.5 percent of a flexibilizer A, 1.5 to 3 percent of a flexibilizer B, 12 to 16 percent of a mineral filler, 25 to 30 percent of glass fibers, 0.2 to 0.5 percent of an anti-dripping agent, 0.1 to 0.3 percent of a main antioxidant, 0.1 to 0.3 percent of an auxiliary antioxidant, 0.1 to 0.5 percent of a lubricant, 0.5 to 1 percent of a dispersing agent and 3 to 5 percent of a black seed. The linear expansion coefficient of the material can be reduced, warpage deformation of the material can be prevented, meanwhile, the problems of thin-wall flame retardance and toughness balance of the material are solved, the preparation method is simple in process and high in efficiency, the production cost can be greatly saved, and industrial production is easy.

Owner:GUANGDONG JUSHI CHEM CO LTD

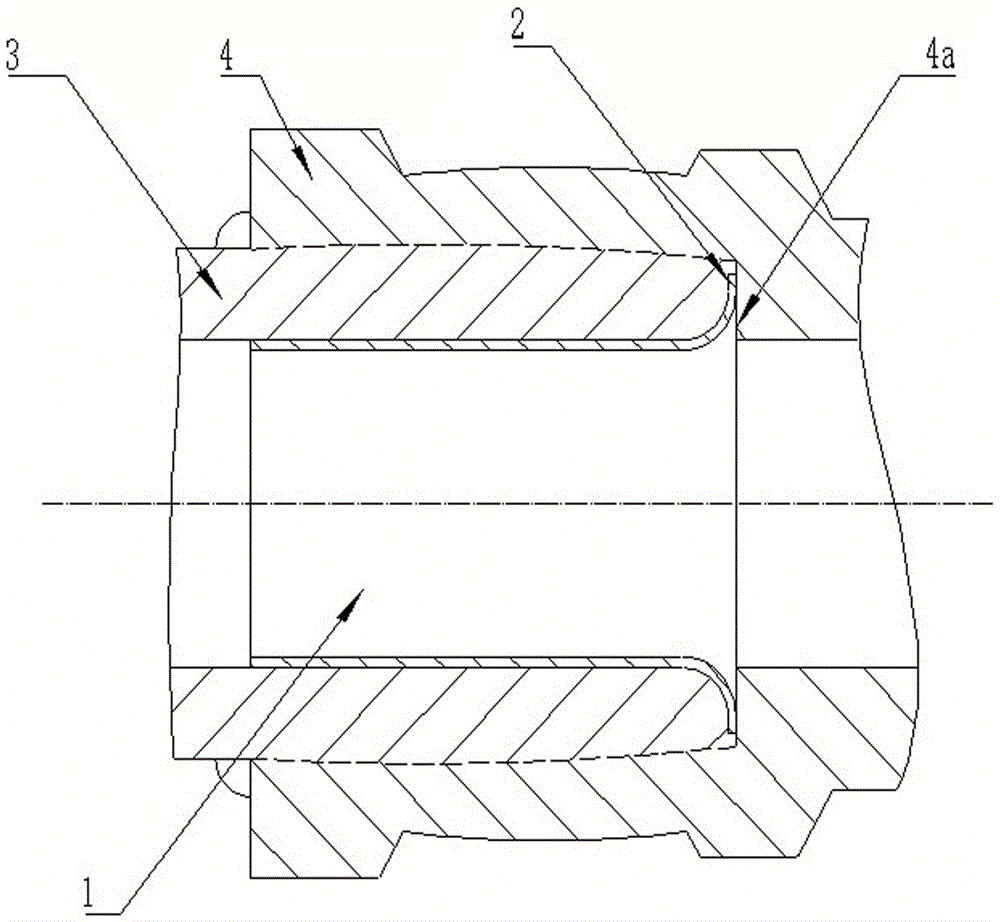

Plastic tube welding protection opening

InactiveCN105479734APlay a role in strengthening the supportAvoid lossNon-disconnectible pipe-jointsWater flowCornice

The invention discloses a plastic tube welding protection opening. The plastic tube welding protection opening is of a structure which is integrally formed by a tubular lining ring and a horn-shaped cornice. The tube wall of the tubular lining ring is very thin, and the outer diameter of the tube wall of the tubular lining ring is equal to the inner diameter of a round limiting ridge or slightly smaller than the inner diameter of a plastic tube inserting opening. The outer diameter of the horn-shaped cornice is slightly smaller than the outer diameter of the plastic tube inserting opening. According to the plastic tube welding protection opening, before construction, the plastic tube welding protection opening is embedded into the plastic tube inserting opening to be welded and tightly attached to the inner wall and the opening edge of the plastic tube inserting opening, the the outer wall of the plastic tube inserting opening is subjected to hot melting, the inner wall of the plastic tube inserting opening is slightly softened and then inserted into a tube fitting bell mouth which is obtained after hot melting, and welding is completed. When a hot melting device is drawn away, molten materials can be protected against losses and retention, the plastic tube inserting opening can also be prevented from deforming and silting and reducing towards the interior of a tube in the inserting connecting process, the closed molten materials can bear extrusion and are matched for correcting skew and eliminating gaps, and the purposes of meshing of concave and convex staggered faces and dense melting and combining are achieved. According to the plastic tube welding protection opening, operation errors which are hard to avoid can be positively utilized, and the welding effect is improved; the operation error range can be reasonably widened, and work efficiency is improved; and a primary-standard-wall-thickness tube can be used for replacing a super-standard-wall-thickness tube, the cost is reduced, and water flow is increased.

Owner:刘纯风

Hollow fiber membrane yarn structure, composite filter element assembly and water purifying device

PendingCN114392650APlay a role in strengthening the supportPlay a supporting roleReverse osmosisWater/sewage treatment bu osmosis/dialysisYarnComposite filter

The invention provides a hollow fiber membrane yarn structure, a composite filter element assembly and a water purifying device.The hollow fiber membrane yarn structure comprises a separation layer, a middle supporting layer and a supporting base layer, the separation layer is of a hollow cylindrical structure, the middle supporting layer is arranged in an inner cavity of the separation layer in a penetrating mode, and the supporting base layer is arranged on the inner periphery of the middle supporting layer in a penetrating mode; a solid supporting part is arranged in the center of the inner circumference of the supporting base layer, the inner circumference of the supporting base layer is further provided with at least two hollow cavities extending in the axis direction of the separation layer, the solid supporting part is located between the at least two hollow cavities, the separation layer can filter impurities, and the middle supporting layer and the supporting base layer can both allow fluid to penetrate through. The separation layer is reinforced and supported through the middle supporting layer, the compression strength of the membrane filaments is improved, the problem of filament breakage can be effectively solved, and the integrated design can reduce the production cost and facilitate assembly.

Owner:GREE ELECTRIC APPLIANCES INC

A gob-side entry retaining method that does not affect the coal mining process

ActiveCN107882566BAvoid interferenceEasy to pushUnderground miningSurface miningEngineeringTunnel engineering

In one embodiment, the invention discloses a gob-side entry retaining method without influence on coal mining procedure, relating to the technical field of coal mining. The method can effectively avoid interference on the coal mining procedure of stope surface. The method includes a step of arranging at least one row of pillars in advance along the advance direction of the coal working surface atone side being closed to the coal working surface in a belt crossheading, which serves as gob-side entry retaining. The method is suitable for roadway and tunnel engineering and coal mining.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

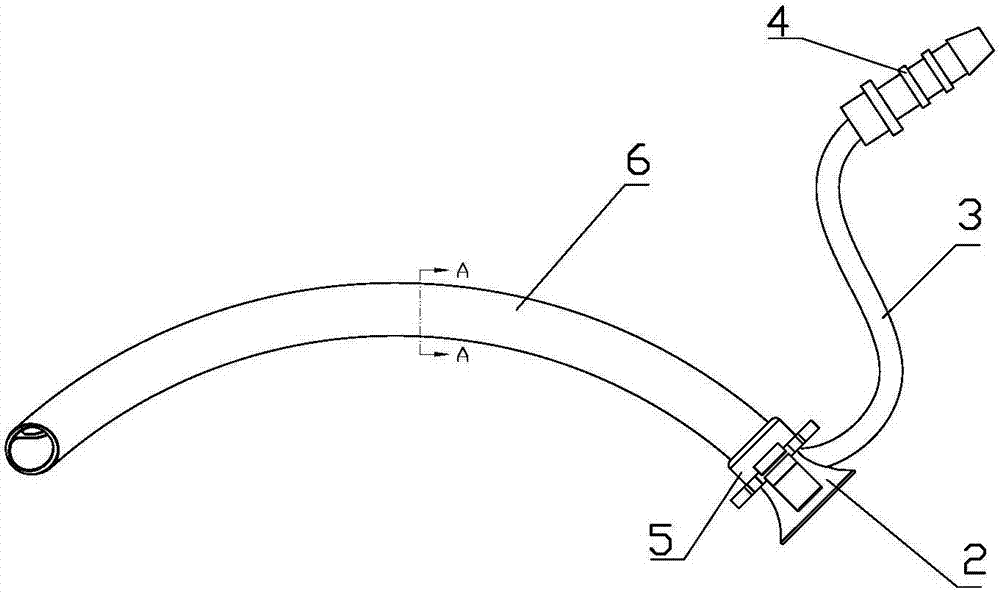

Deep oxygen supply type nasopharyngeal airway

PendingCN107050607AAvoid damagePlay a role in strengthening the supportTracheal tubesMedical devicesNasopharyngeal airwayEngineering

The invention relates to a deep oxygen supply type nasopharyngeal airway, and belongs to the technical field of medical instruments. The deep oxygen supply type nasopharyngeal airway comprises a main ventilation pipe and an extension pipe. A main ventilation chamber and a side chamber are arranged in the main ventilation pipe. A bell mouth is formed in the tail end of the main ventilation pipe. The outer wall of the lower end of the bell mouth is sleeved with a rotatable fixing wing. The fixing wing is provided with a through hole, and straps are arranged on the two side edges of the fixing wing. An oxygen source connector communicates with one end of the extension pipe, and the other end of the extension pipe communicates with the tail end of the side chamber. The deep oxygen supply type nasopharyngeal airway has a respiratory tract obstruction eliminating function and a deep oxygen supply function, and by adding the fixing wing, the problem that the deep oxygen supply type nasopharyngeal airway is hard to fix in clinical use is solved.

Owner:浙江海圣医疗器械股份有限公司

Stable type steel connecting structure

InactiveCN108204047AImprove connection strengthPlay a role in strengthening the supportBuilding constructionsUltimate tensile strengthMaterials science

The invention provides a stable type steel connecting structure, and belongs to the field of steel structures. The stable type steel connecting structure solves the problem of the low strength of an existing steel connecting structure. The stable type steel connecting structure comprises I-shaped steel, a fixed steel plate and two connecting steel plates, and the two connecting steel plates are parallel to each other and are perpendicularly fixed to one side of the fixed steel plate; the I-shaped steel comprises a web and wing plates connected to the two sides of the web, and the two connecting steel plates are clamped on the two sides of the wing plates; the stable type steel connecting structure further comprises reinforcing steel plates, the reinforcing steel plates and the connecting steel plates are of an integrated structure, the edges, away from the fixed steel plate, of the connecting steel plates are connected with one edges of the reinforcing steel plates, the other edges ofthe reinforcing steel plates and the fixed steel plate are fixed, and the reinforcing steel plates and the connecting steel plates are arranged at intervals; and a triangular cavity is formed by enclosing of the reinforcing steel plates, the connecting steel plates and the fixed steel plate. The stable type steel connecting structure utilizes the connecting steel plates to clamp the web, and meanwhile, the reinforcing steel plates are utilized for reinforcing, so that the connecting strength of the fixed steel plate and the I-shaped steel is improved.

Owner:XINCHANG SICHUANG DESIGN CONSULTING CO LTD

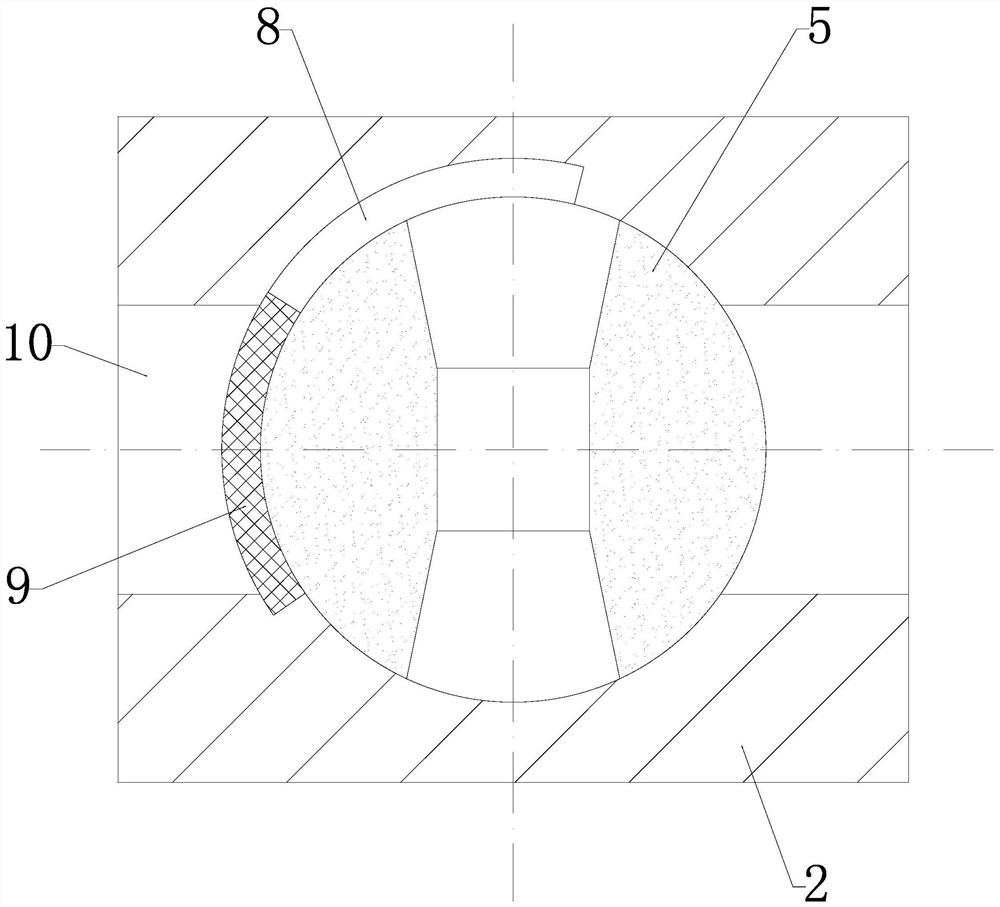

A kind of plastic valve and its processing and manufacturing method

ActiveCN112361013BFit closelyImprove sealingSpindle sealingsPlug valvesCircular cavityIndustrial engineering

The invention relates to the technical field of valve manufacturing, in particular to a plastic valve and its manufacturing method, comprising a valve body, a main valve cavity is arranged in the middle of the valve body, both sides of the main valve cavity are connected with both sides The delivery pipelines to be installed are connected and matched, and a plug-in round cavity connected with it is provided on the valve body at the top of the main valve cavity, and a main ball valve assembly and a sub-valve are installed in the main valve cavity. Assemblies, the main ball valve assembly is used to realize the cut-off seal under normal pressure, the main ball valve assembly cooperates with the auxiliary disc valve assembly to realize the cut-off seal under high pressure state, the plastic valve adopts the structure of the main and auxiliary valve cores, The double-effect sealing under high pressure can be realized through the adjustment of the two valves, the sealing effect is good, the overall structure is compact, and the main and auxiliary valve cores are closely matched to achieve a more effective sealing and intercepting effect.

Owner:SHANXIAN XINGYUAN PLASTIC VALVE CO LTD

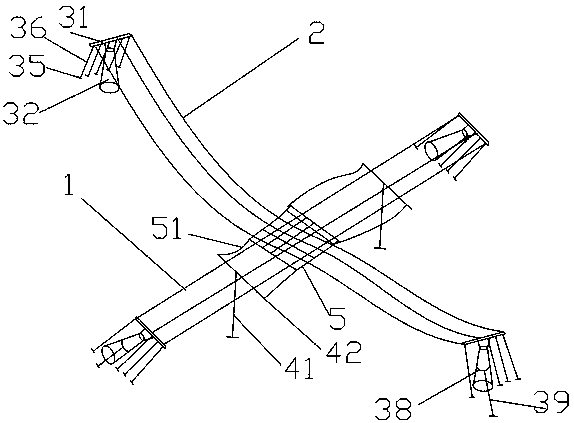

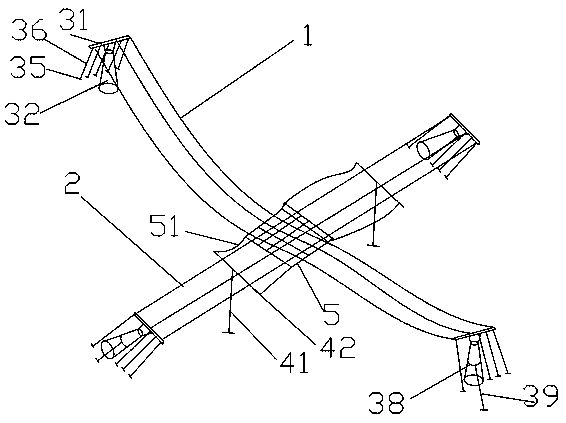

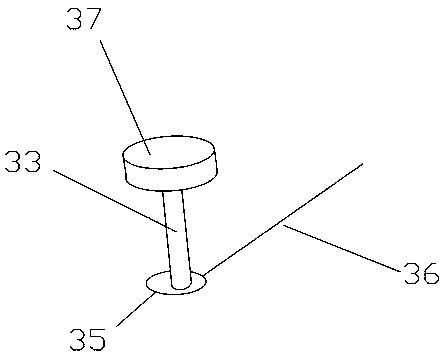

Crossed stringing device and stringing method thereof

InactiveCN110401164AStable supportEasy wiringSpatial arrangements/dispositions of cablesEngineeringSupport plane

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

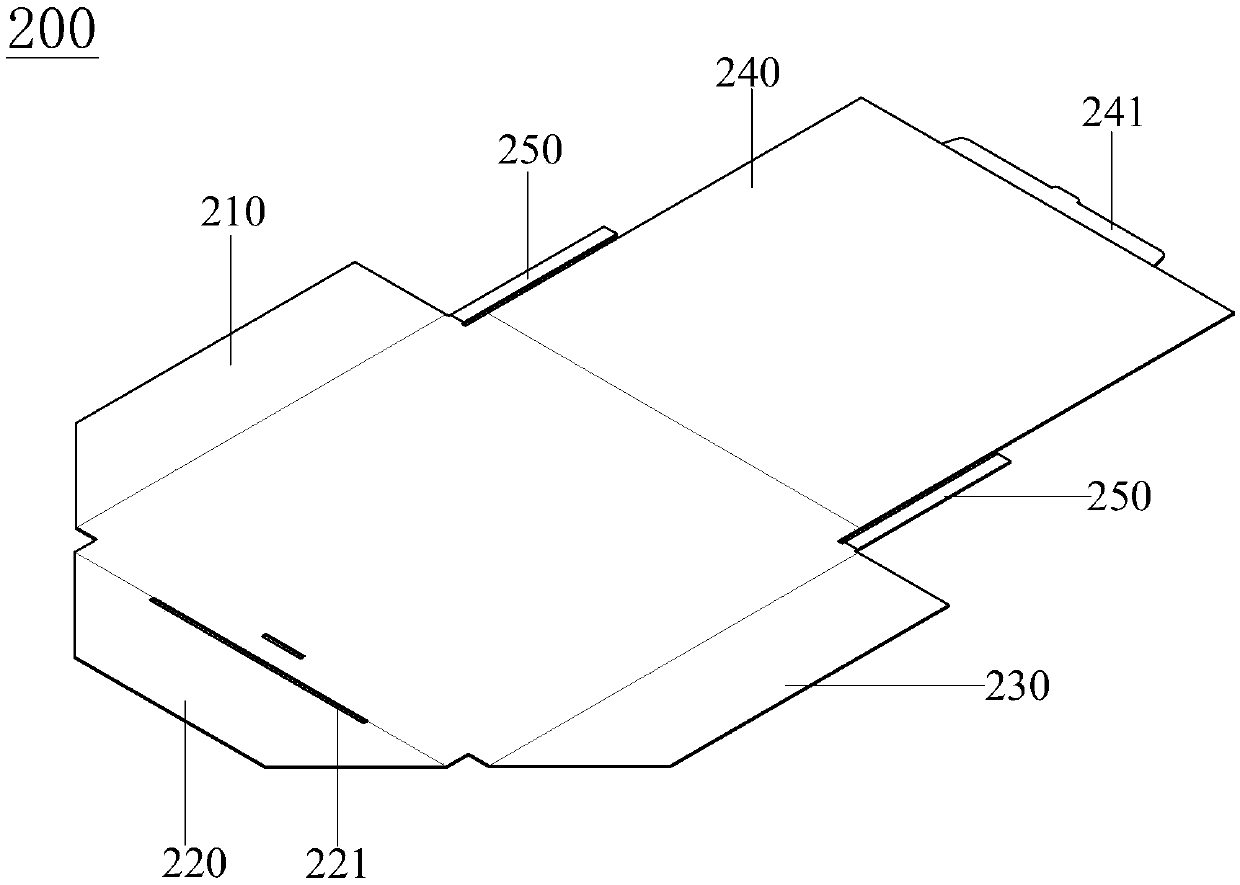

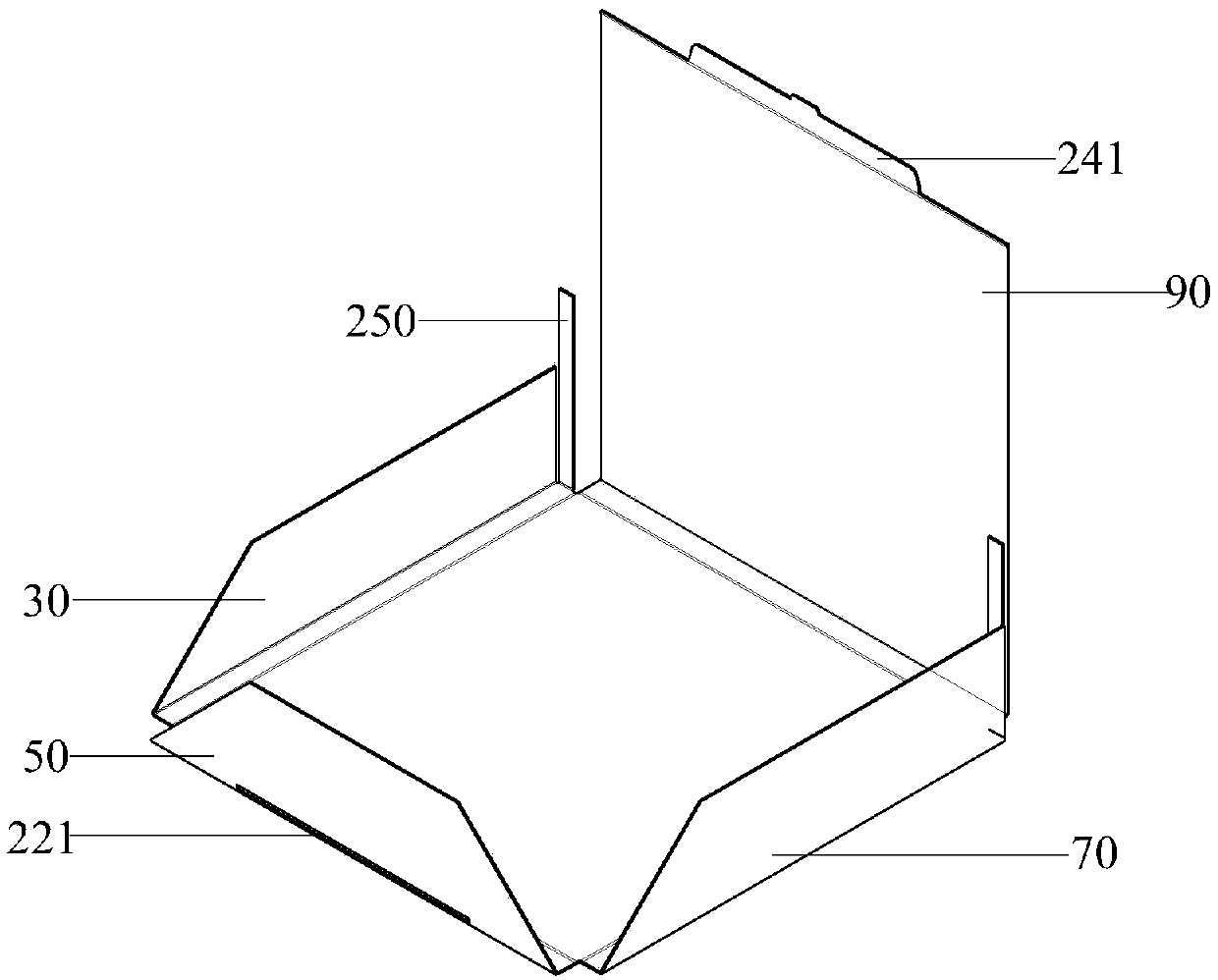

Integral molded packaging box, molding die and molding method for molding the packaging box

ActiveCN105620848BAchieving a snap-fit closureSimple processRigid containersEngineeringFront cover

The invention discloses an integrally formed packing box and a forming mould and method for forming the packing box. The packing box comprises a bottom plate, a left side plate, a left cover plate, a front side plate, a front cover plate, a right side plate, a right cover plate, a rear side plate and a top cover; the packing box is formed by a piece of paper though bending and fastening; the paper comprises a first folding sheet, a second folding sheet, a fourth folding sheet, a fourth folding sheet and a fifth folding sheet, which are integrally connected; an insertion tongue is arranged at the free end of the fourth folding sheet and a socket which is matched with the insertion tongue is arranged on the second folding sheet; the first folding sheet is bent to form the left side plate and the left cover plate; the second folding sheet is bent to form the front side plate and the front cover plate; the third folding sheet is bent to form the right side plate and the right cover plate; the fourth folding sheet is bent to form the rear side plate and the top cover; the left side plate, the front side plate, the right side plate and the rear side plate are connected to form the bottom plate; and the fifth folding sheet is bent to be clamped between the bottom plate and the top cover. The whole packing box is simple in structure, convenient to process, safe, environment-friendly and low in cost.

Owner:DONGGUAN WORLD PRECISION MACHINERY

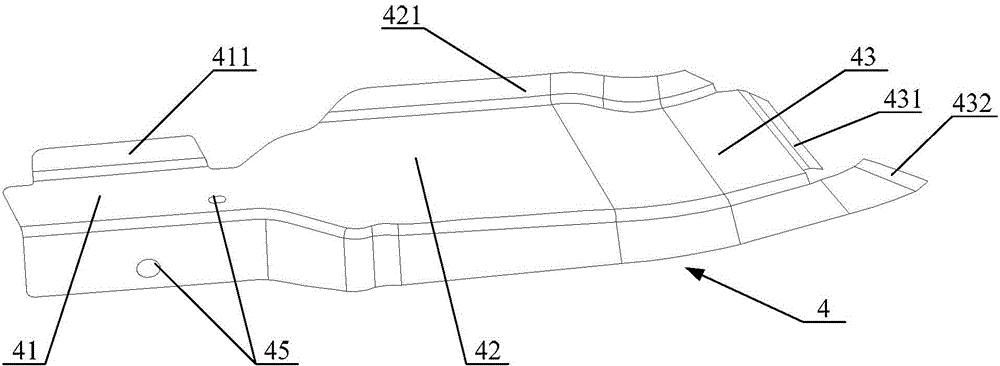

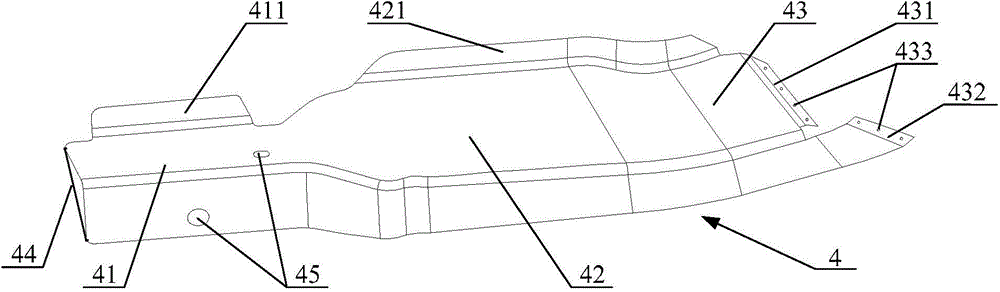

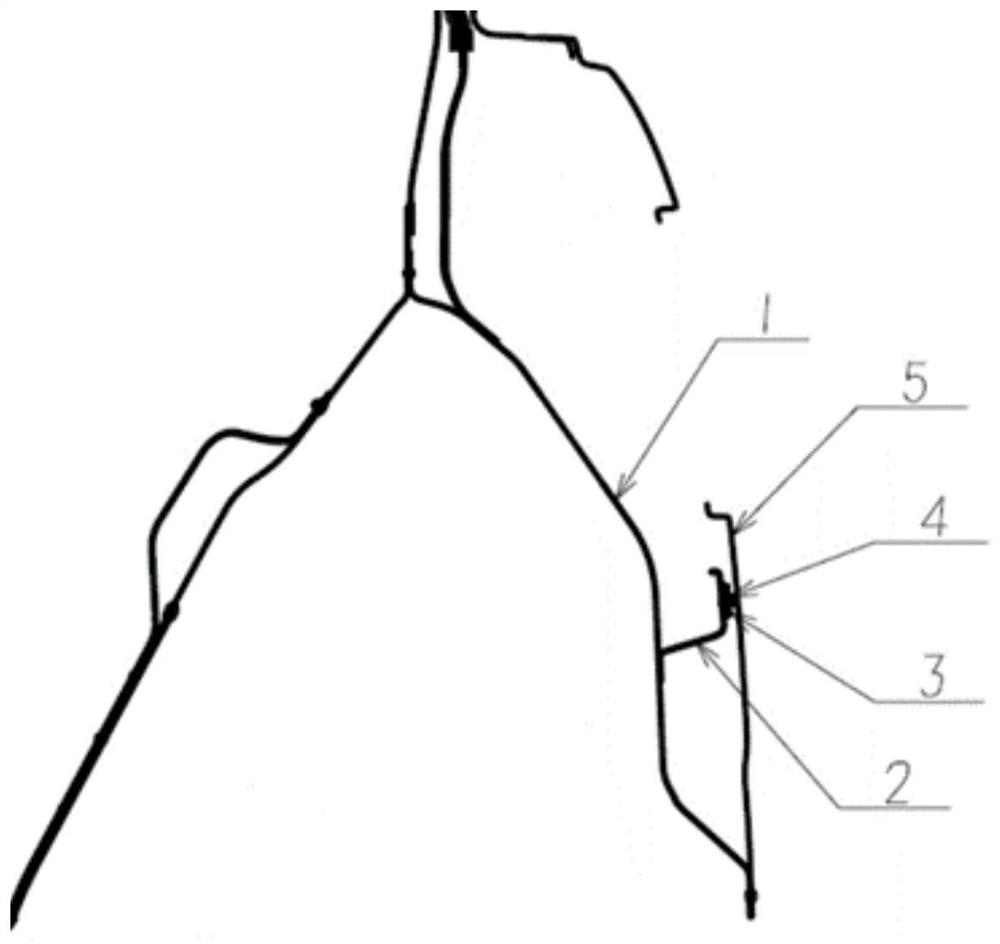

Electric automobile side wall outer plate supporting assembly structure and automobile

PendingCN114715286APlay a role in strengthening the supportSimple structureSuperstructure subunitsSuperstructure connectionsFuel tankStructural engineering

The invention relates to an electric automobile side wall outer plate supporting assembly structure and an automobile. The electric automobile side wall outer plate supporting assembly structure comprises a rear wheel cover outer plate; a side outer panel; the side wall outer plate supporting plate is supported between the rear wheel cover outer plate and the side wall outer plate and comprises a first supporting plate, a second supporting plate and a third supporting plate, the second supporting plate is fixed to the rear wheel cover outer plate, and the second supporting plate and the first supporting plate are arranged in a spaced mode; the third supporting plate is connected with the first supporting plate and the second supporting plate; the first supporting plate, the second supporting plate and the third supporting plate form a Z shape. As the bottom of the supporting plate is fixed with the rear wheel cover outer plate and the top of the supporting plate is connected with the side wall outer plate, the supporting plate can effectively play a role in reinforcing and supporting the area with insufficient rigidity around the fuel tank opening cover; due to the fact that the overall characteristic of the side wall outer plate supporting plate is Z-shaped, the side wall outer plate supporting plate can better support the side wall outer plate, and the supporting plate is simpler in structure, light in weight, low in cost and better in effect.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com