Overhead mounted waterless spliced floor tile and preparation and mounting method thereof

An installation method and a technology of floor tiles, which are applied to local access floors, floors, buildings, etc., can solve the problems of floor tiles such as fragile materials, weak load-bearing capacity, and weak splicing, and achieve uniform flatness and thickness. Simple, fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

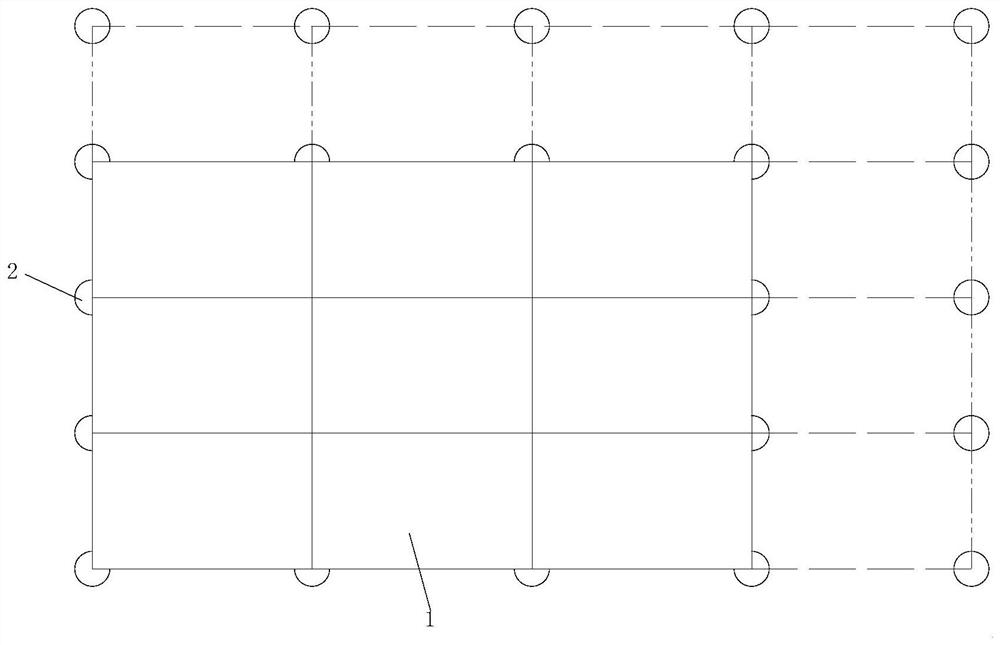

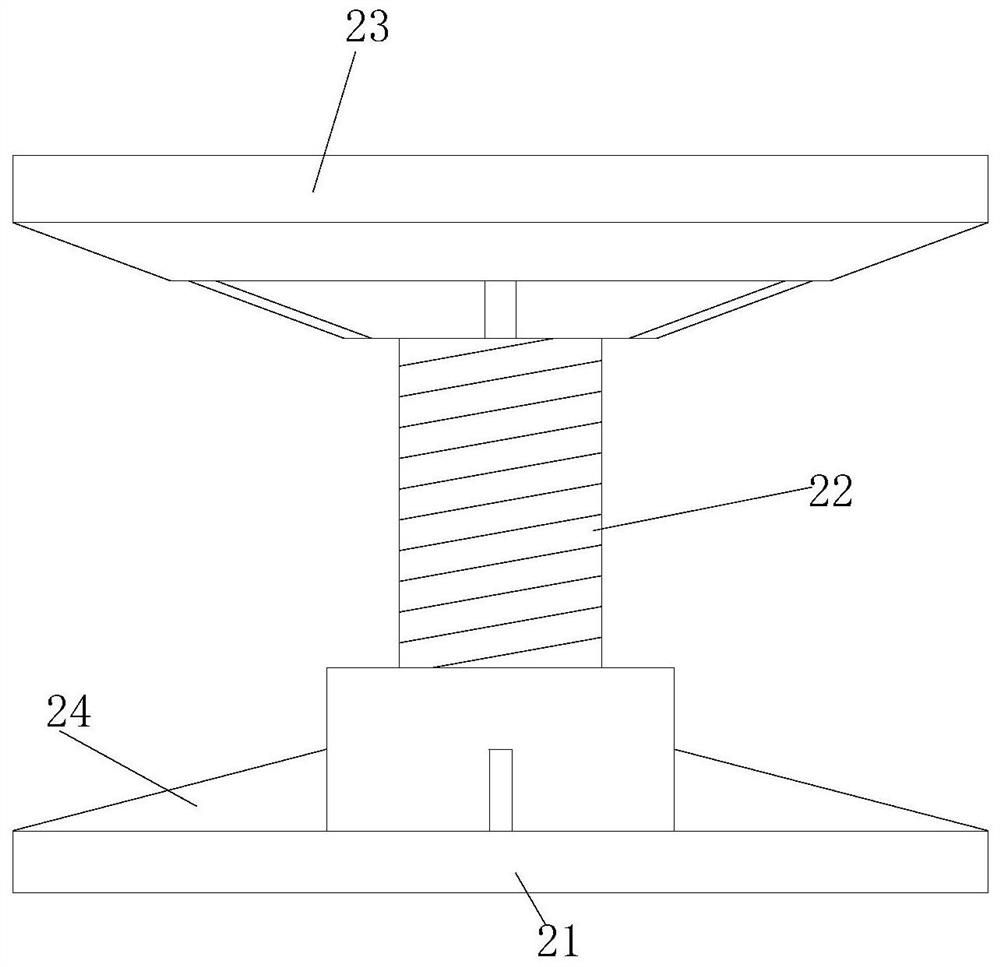

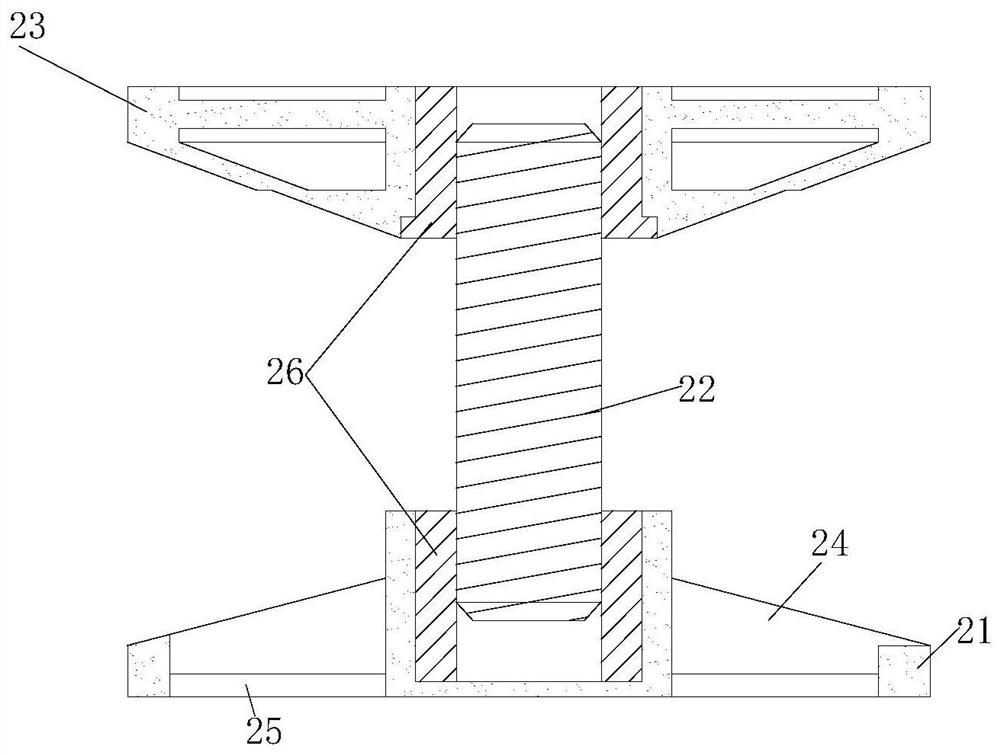

[0034] Embodiment one, refer to Figure 4 , the two sides of the reinforced bottom plate 11 are provided with side grooves 14, and the other two sides of the reinforced bottom plate 11 are respectively integrally formed with splicing strips 3, and the splicing strips 3 of two adjacent reinforced bottom plates 11 are mutually connected with the side grooves 14. Splicing, the end sections of the side groove 14 and the splicing strip 3 are semicircular, and the semicircular end plays a guiding role, which facilitates the butt joint of the side groove 14 and the splicing strip 3, and improves the construction efficiency. In the embodiment, the splicing strip 3 is directly arranged on the side of the reinforced bottom plate 11 and the side groove 14 of the reinforcing plate 24 away from the splicing strip 3 forms a male and female groove structure to realize splicing.

Embodiment 2

[0035] Embodiment two, refer to Figure 5 , the four sides of the reinforced bottom plate 11 are provided with side grooves 14, and the side grooves 14 of two adjacent reinforced bottom plates 11 are spliced by splicing strips 3. In this embodiment, the splicing strips 3 are processed separately, and directly in the reinforcement The four sides of the base plate 11 are directly provided with side grooves 14, which can also facilitate the assembly between adjacent reinforced base plates 11, wherein the splicing strip 3 can be T-shaped, and directly form a reserved seam through the splicing strip 3.

[0036] A method for preparing an overhead-installed waterless mosaic floor tile, comprising the steps of:

[0037] S1, opening side grooves 14 on the side of the reinforced bottom plate 11;

[0038] S2, apply an external force to form the brick body 1 after bonding the reinforced bottom plate 11 and the brick plate 13 through the adhesive layer 12;

[0039] S3, the surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com