High-temperature-resistant conveyor belt cover rubber for cement plant and preparation process thereof

A technology of high temperature resistance and conveyor belt, applied in the field of conveyor belt, can solve the problems of shortened life of conveyor belt and reduced adhesive strength, and achieve the effect of improving hot tear strength, preventing foaming, and eliminating ruffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

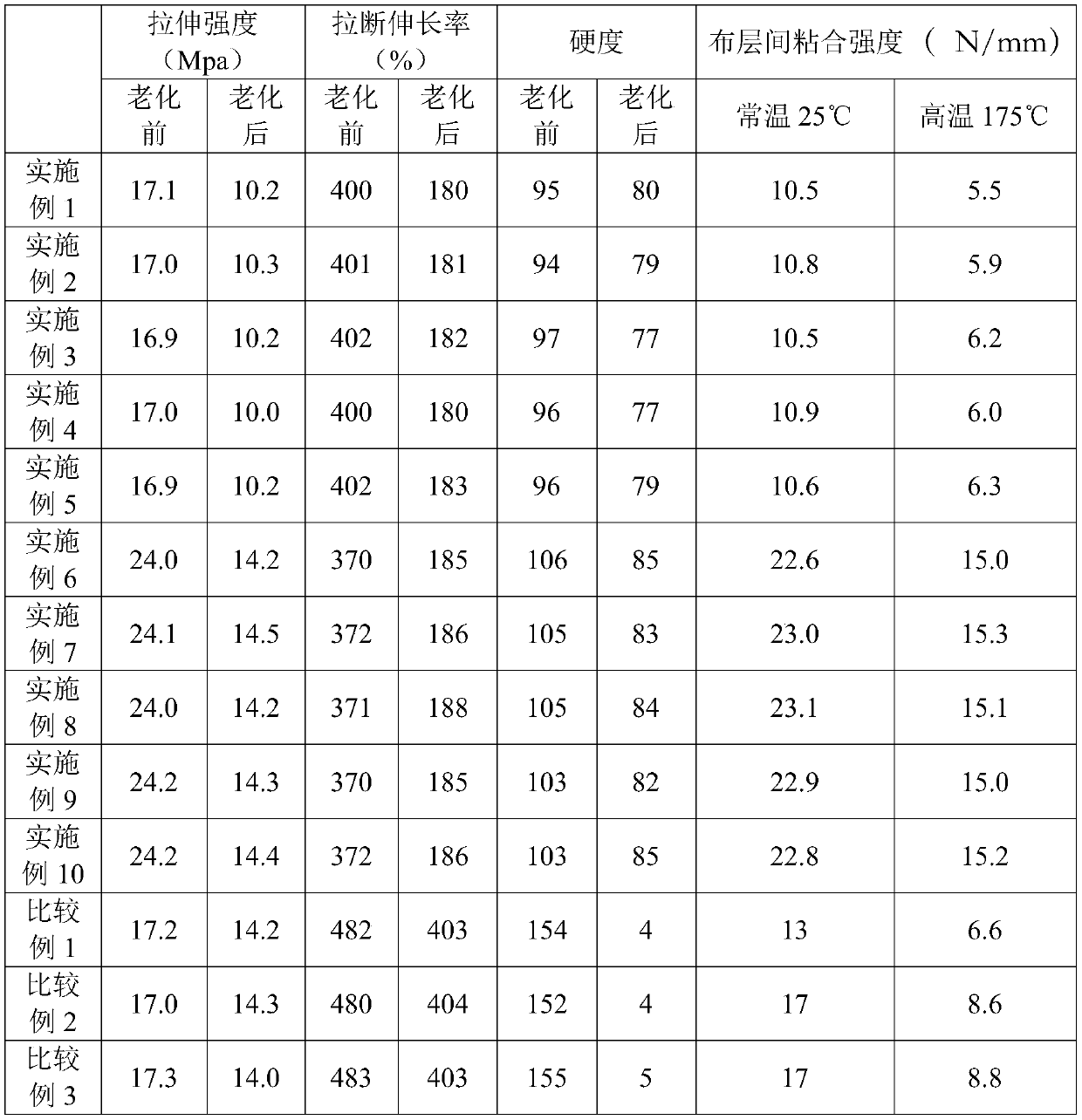

Examples

Embodiment 1

[0022] A kind of high-temperature-resistant conveyor belt covering glue for a cement plant, in parts by mass, raw materials include 88 parts of EPDM rubber, 12 parts of neoprene, 8 parts of high-temperature-resistant resin, 8 parts of softening agent, 30 parts of carbon black, 5 parts of nano-zinc oxide, 1 part of stearic acid, 20 parts of high-temperature resistant filler, 5 parts of vulcanizing agent, 3 parts of accelerator, 3 parts of anti-aging agent, and 3 parts of heat-resistant oxygen agent; the high-temperature-resistant resin is selected from phenolic resin BN-1, the high-temperature-resistant filler is selected from silica-alumina carbon black, the vulcanizing agent is selected from vulcanizing agent DTDM, the accelerator is selected from accelerator NS, the anti-aging agent is selected from anti-aging agent 4010NA, and the anti-heat oxidation agent is selected from antioxidant 1010.

[0023] The preparation process of the high-temperature-resistant conveyor belt cove...

Embodiment 2

[0029] A kind of high-temperature-resistant conveyor belt covering glue for a cement plant, in parts by mass, raw materials include 93 parts of EPDM rubber, 8 parts of neoprene, 10 parts of high-temperature-resistant resin, 6 parts of softening agent, 40 parts of carbon black, 4 parts of nano-zinc oxide, 2 parts of stearic acid, 10 parts of high-temperature resistant filler, 7 parts of vulcanizing agent, 2 parts of accelerator, 4 parts of anti-aging agent, 2 parts of heat-resistant oxygen agent; Vinyl fluoride, the high temperature resistant filler is selected from clay, the vulcanizing agent is selected from sulfur, the accelerator is selected from ethylene thiourea, the anti-aging agent is selected from anti-aging agent RD, and the anti-heat oxygen agent is selected from antioxidant DSTDP.

[0030] The preparation process of the high-temperature-resistant conveyor belt cover glue for the above-mentioned cement plant includes the following steps:

[0031] A. According to the ...

Embodiment 3

[0036] A kind of high-temperature-resistant conveyor belt covering glue for a cement plant, in parts by mass, raw materials include 90 parts of EPDM rubber, 10 parts of neoprene, 9 parts of high-temperature-resistant resin, 7 parts of softening agent, 35 parts of carbon black, 4.5 parts of nano zinc oxide, 1.5 parts of stearic acid, 15 parts of high temperature resistant filler, 6 parts of vulcanizing agent, 2.5 parts of accelerator, 3.5 parts of antioxidant, 2.5 parts of heat resistant oxygen agent; the high temperature resistant resin is selected from epoxy The resin, the high temperature resistant filler is selected from kaolin, the vulcanizing agent is selected from bisphenol AF, the accelerator is selected from diphenylguanidine, the anti-aging agent is selected from anti-aging agent MB, and the anti-heat oxidation agent is selected from antioxidant BHT.

[0037] The preparation process of the high-temperature-resistant conveyor belt cover glue for the above-mentioned ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com