Regenerative polyethylene plastic where novel cross-linking agents are added and preparation method thereof

A technology of recycled polyethylene and crosslinking agent, which is applied in the field of polymer materials and its preparation, can solve the problems of product crosslinking speed influence, slow water diffusion speed, slow crosslinking speed, etc. Convenience and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of palygorskite silane crosslinking agent:

[0027] (1) Acid treatment of silane cross-linking agent: Add 1 mL of silane cross-linking agent to 5 mL of absolute ethanol, then adjust the pH to 3~3.5 with glacial acetic acid, and stir at room temperature for 1 h.

[0028] (2) Activation of palygorskite: Add 100g of palygorskite clay into 250mL NaOH solution with a mass fraction of 5%, stir magnetically at 45°C for 12h, then rinse neutral with distilled water, centrifuge, and take the filter cake to dry to obtain activation palygorskite, ground for use.

[0029] (3) Preparation of palygorskite silane crosslinking agent: disperse 1g of activated palygorskite in 10mL of ethanol / water mixture (15mL of ethanol, 1mL of water), ultrasonically disperse for 15min, and then add the treated silane dropwise Cross-linking agent (the net content of silane cross-linking agent is 0.005g), add a certain amount of deionized water, stir and react at room temperature for 12 hour...

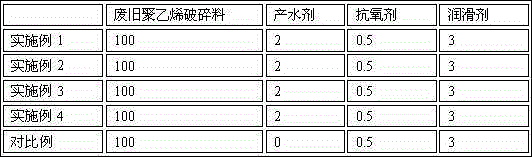

Embodiment 1

[0036] Set the temperature of the mill to 135~140°C, add 100 parts of processed recycled materials to the double rollers of the mill, add 0.5 parts of antioxidant 1010, and 5 parts of liquid paraffin. After it is melted and covered with rollers, add Palygorskite clay crosslinking agent 3 parts, initiator (BPO) 0.1 part, dicumyl peroxide (DCP) 0.1 part, catalyst dibutyltin dilaurate 0.2 part, water generating agent (HCOONa 2H 2 O) Mix 2 parts for 10 minutes, put the composite material into a flat vulcanizer, and prepare various performance test samples.

Embodiment 2

[0038] Set the temperature of the mill to 135~140°C, add 100 parts of processed recycled materials to the double rollers of the mill, add 0.5 parts of antioxidant 1010, and 5 parts of liquid paraffin. After it is melted and covered with rollers, add Palygorskite clay crosslinking agent 4 parts, initiator (BPO) 0.2 part, dicumyl peroxide (DCP) 0.1 part, catalyst dibutyltin dilaurate 0.3 part, water generating agent (HCOONa 2H 2 O) Mix 3 parts for 15 minutes, put the composite material into a flat vulcanizer, and prepare various performance test samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com