Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed rheological properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silica shear thickening liquid

The invention discloses a preparation method of a silica shear thickening liquid. The preparation method comprises the following steps of: preparing monodisperse silica microspheres with certain grain size in an alcohol-water mixed liquid according to a multi-level seed growth method by utilizing tetraethoxysilane serves as a raw material and ammonia as a catalyst; after reaction is finished, adding shear thickening liquid dispersion media (polyethylene glycol, glycerol and the like) into a SiO2 suspension liquid; after mixing uniformly, removing ethanol, water and ammonia from the mixed liquid by adopting a heating and pressure-reducing method to finally prepare the silica shear thickening liquid, wherein the ethanol which is collected under reduced pressure can serve as a solvent and can be reused. In the preparation method, the SiO2 microspheres exist in the form of a uniformly dispersed suspension liquid from the synthesis link to the preparation link of the shear thickening liquid, so the agglomeration phenomenon of powder in drying and redispersion processes is avoided, and the stability and rheological property of the shear thickening liquid are improved.

Owner:浩华科技实业有限公司

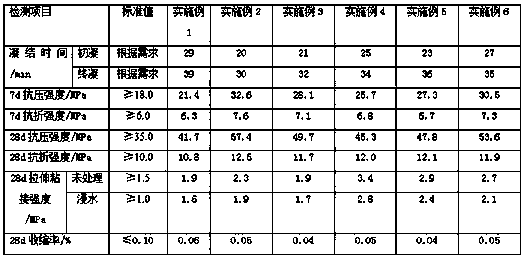

Repair mortar for tap water pipeline PCCP (Prestressed Concrete Cylinder Pipe)

The invention discloses repair mortar for a tap water pipeline PCCP (Prestressed Concrete Cylinder Pipe), and belongs to the technical field of polymer cement mortar. The repair mortar is prepared from raw materials including gelling materials, fine aggregate, heavy calcium carbonate, hydroxyethyl cellulose, water reducing agents, redispersible adhesive powder, lithium carbonate and boracic acid,wherein the initial setting time of the repair mortar is 20 to 30min; the final setting time is 30 to 40min; the 28d intensity is 35 to 50MPa; the processless boding intensity is greater than 1.5MPa.The repair mortar has excellent performance; the prepared repair material has the advantages of safety, high intensity, strong bonding force, excellent cracking resistant performance, corrosion resistance and the like.

Owner:JIAHUA SPECIAL CEMENT

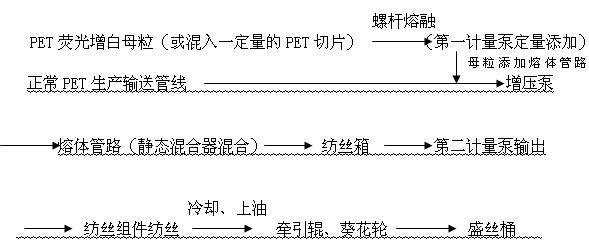

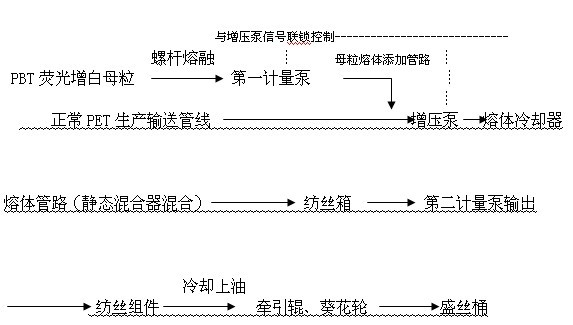

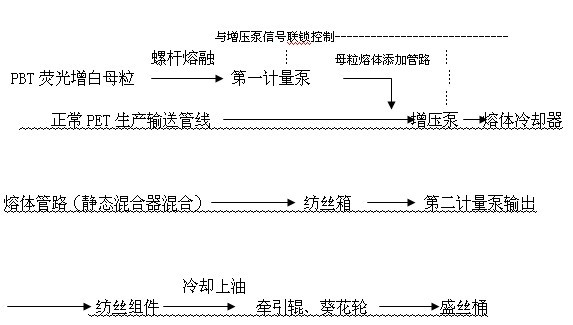

Method for controlling homogeneity of fluorescent-whitened polyester staple fiber product

InactiveCN102134756AStable addition ratioAdd the same proportionFilament forming substance formingSpinning head liquid feederFiberTemperature control

The invention relates to a method for controlling homogeneity of a fluorescent-whitened polyester staple fiber product, which comprises the following process procedures of fusing and extruding a PBT (polybutylece terephthalate) fluorescent-whitening master batch by a screw extruder, quantitatively adding the extrudate to a PET (Positron Emission Tomography) fusant of a normal PET production and delivery pipeline through a first metering pump and a master batch fusant pipeline, pressurizing the extrudate through a booster pump to lead the extrudate to enter a fusant cooler to be cooled to normal spinning temperature, then leading the cooled extrudate to enter the fusant pipeline, mixing the extrudate through a static mixer to make the extrudate into a blending fusant of the PBT fluorescent-whitening master batch and PET, leading the blending fusant to enter a spinning box, metering the blending fusant by a second metering pump, leading the blending fusant to enter a spinning component for spinning, cooling and oiling spun silks, and dragging the spun silks by a dragging roller and a sunflower wheel to be sent into a silk holding barrel. The rotation speed of the booster pump and the first metering pump adopts signal interlock control; the master batch fusant pipeline and the first metering pump are respectively provided with a heat tracing temperature control system; and heat tracing media of the heat tracing temperature control systems adopt the primary heating medium series control of a heat tracing temperature control system of a normal PET fusant pipeline. By the control method, the addition proportion of a fluorescent whitening ingredient can be ensured to be a set value when production capacity is changed.

Owner:江苏华西村股份有限公司

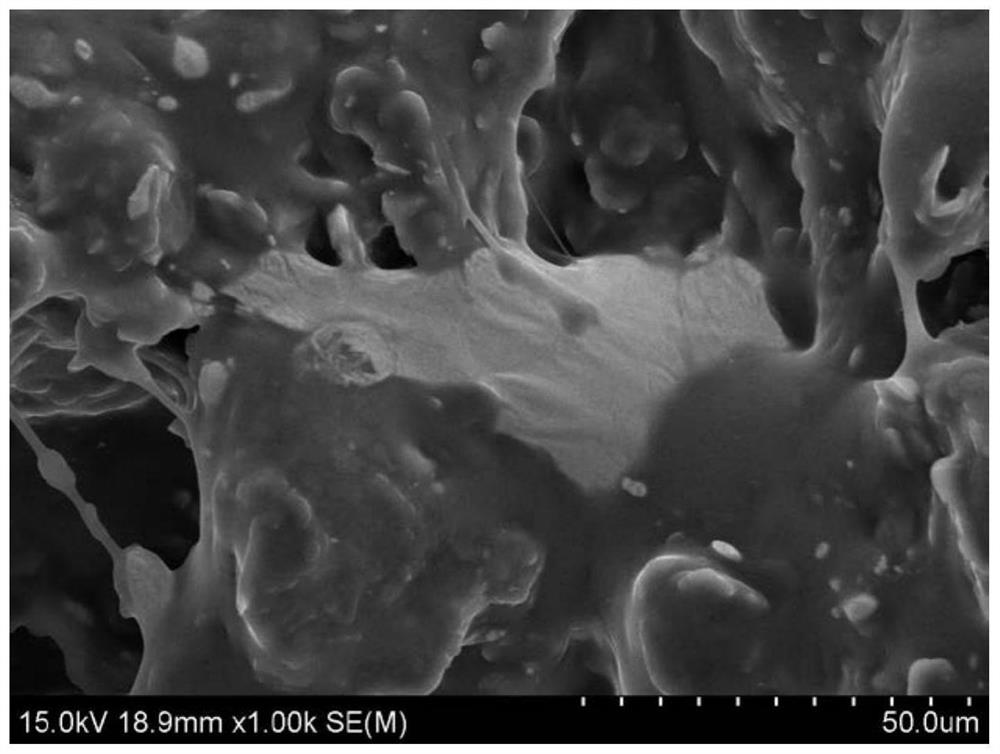

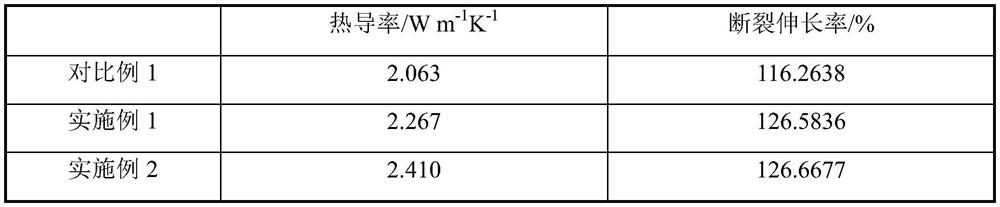

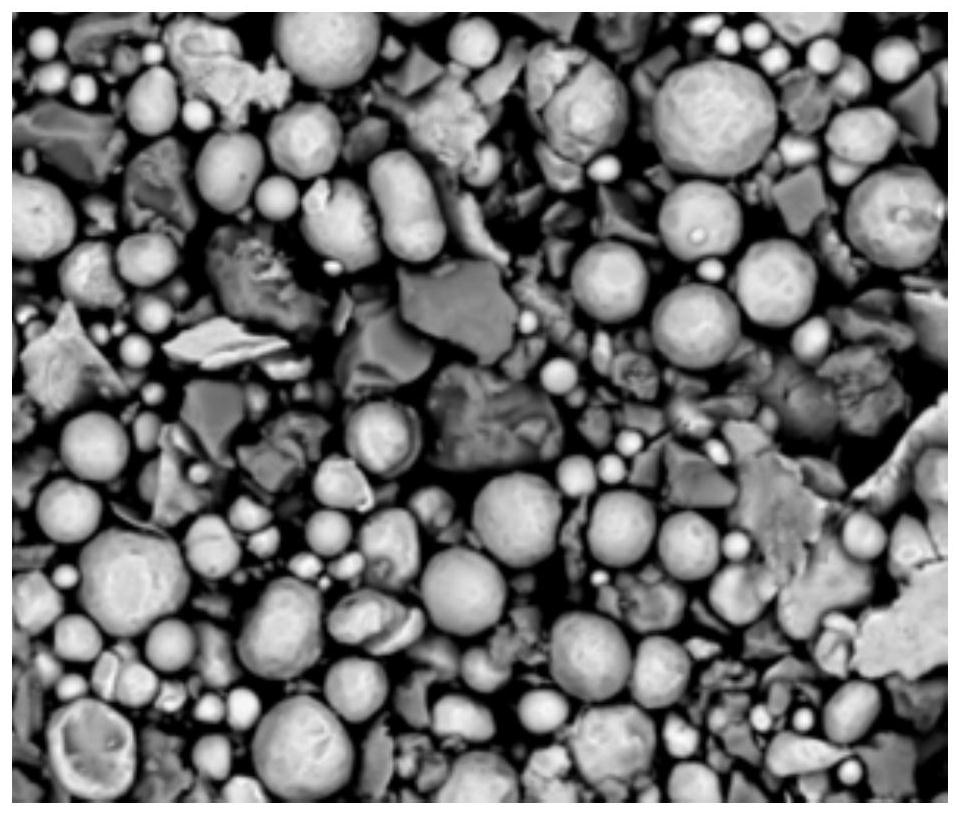

Polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material as well as preparation method and application thereof

The invention discloses a polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material as well as a preparation method and application thereof. The composite material comprises the following components in parts by weight: 600 parts of silicone oil, 400-600 parts of spherical boron nitride, 40-600 parts of gallium-indium alloy and 1-2 parts of a catalyst. The preparation method comprises the following steps: placing the silicone oil and the gallium-indium alloy in a container, performing vacuumizing, and stirring to obtain a dispersion liquid of the gallium-indium alloy and the silicone oil; placing spherical boron nitride into the dispersion liquid, performing mixing, and stirring in vacuum to obtain uniform flowable paste A; dropwise adding a catalyst into the flowable paste A, mixing, and stirring in vacuum to obtain uniform flowable paste B; and calendering the flowable paste B, and curing to obtain the composite material. The polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material disclosed by the invention shows high heat conductivity and good mechanical properties, and an SEM (Scanning Electron Microscope) can clearly observe that the liquid metal plays a bridging role, so that the polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material can exert excellent properties in a TIM material.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Material for maintaining molten iron pretreatment tools online, preparation method and applications thereof

The invention discloses a repairing material for maintaining molten iron pretreatment tools online, a preparation method and applications thereof. The repairing material comprises the following raw materials in parts by weight: 75 to 85 parts of Al2O3 containing used fireproof reclaimed material, 10 to 20 parts of fireproof clay, 0 to 5 parts of silicon carbide, 0 to 5 parts of dry quenching furnace dust-free coke powder, 3 to 6 parts of kyanite, 1 to 10 parts of binder, and 0.85 to 3.7 parts of additive. The weighed raw materials mentioned above are dry-mixed and evenly stirring in a stirring machine, and the mixture is directly packaged to obtain a finished product, namely the repairing <{EN0}>mMmaterial for maintaining molten iron pretreatment tools online. The cost of raw materials is low, the source of regenerated resources is wide, the repairing material is user-friendly, the repairing is convenient to carry out, the interface bonding strength of the repaired layers is strong, the anti-peeling performance is strong, and the repairing and maintaining effect is excellent.

Owner:武汉钢铁有限公司

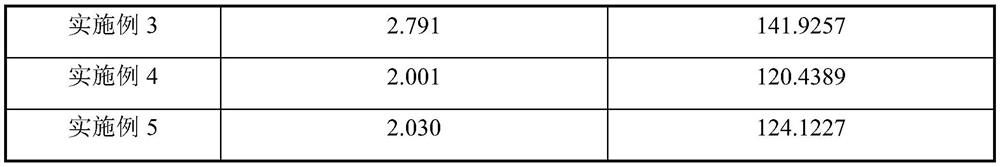

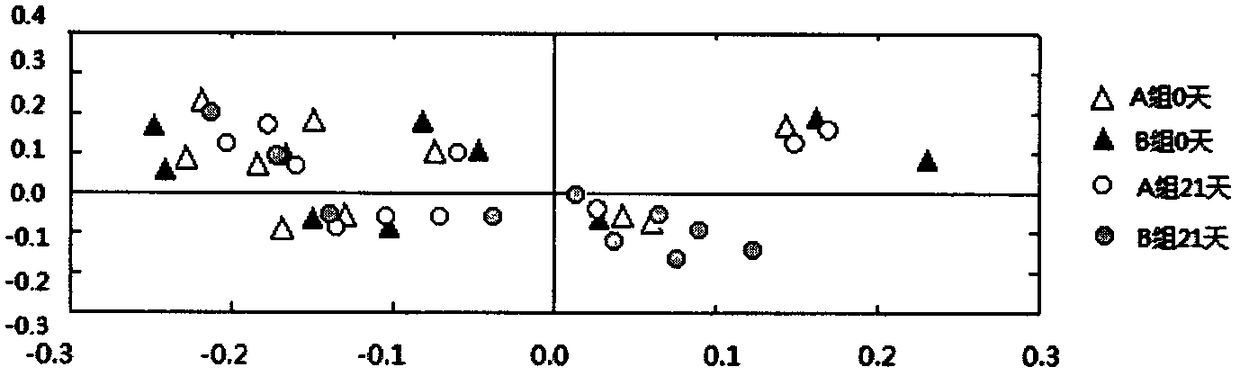

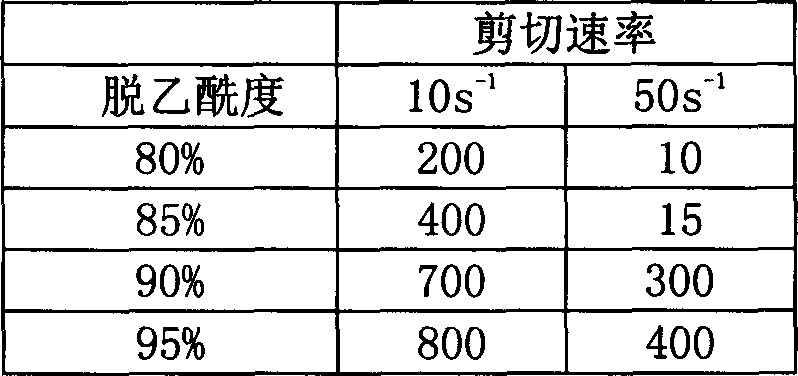

Nutrient preparation used for elderly patients with swallowing dysfunction

ActiveCN108936609AReduce diarrheaReduce indigestion and other phenomenaOrganic active ingredientsFood ingredient as thickening agentNutrientVomiting

The present invention discloses a liquid oral enteral nutrient preparation containing chitosan, probiotics and dietary fibers. The preparation is suitable for elderly patients with swallowing dysfunction, has proper initial viscosity, has resistance to salivary amylase, has fluidics property change due to the appropriate shearing in the swallowing process, and significantly reduces the occurrencerate of misinhalation to lung and vomiting for the patients with swallowing dysfunction; and the preparation is fine in taste and easy to absorb, helps to repair intestinal barrier, and can obviouslyimprove nutrition, immunity and nerve functions of elderly patients. The nutrient preparation disclosed by the invention comprises the following components in parts by weight: nutrient substances: 10-15 parts of proteins, 20-30 parts of fat and 40-50 parts of carbohydrate; thickeners: 1-5 parts of chitosan and 1-5 parts of chitosan oligosaccharide; probiotics: 0.01-0.1 part of acetobacter pasteurianus CGMCC No.12930, 0.01-0.1 part of lactobacillus rhamnosus LGG, and 0.01-0.1 part of bifidobacterium; and other ingredients: 1-5 parts of mannan-oligosaccharide.

Owner:WUXI PEOPLES HOSPITAL +1

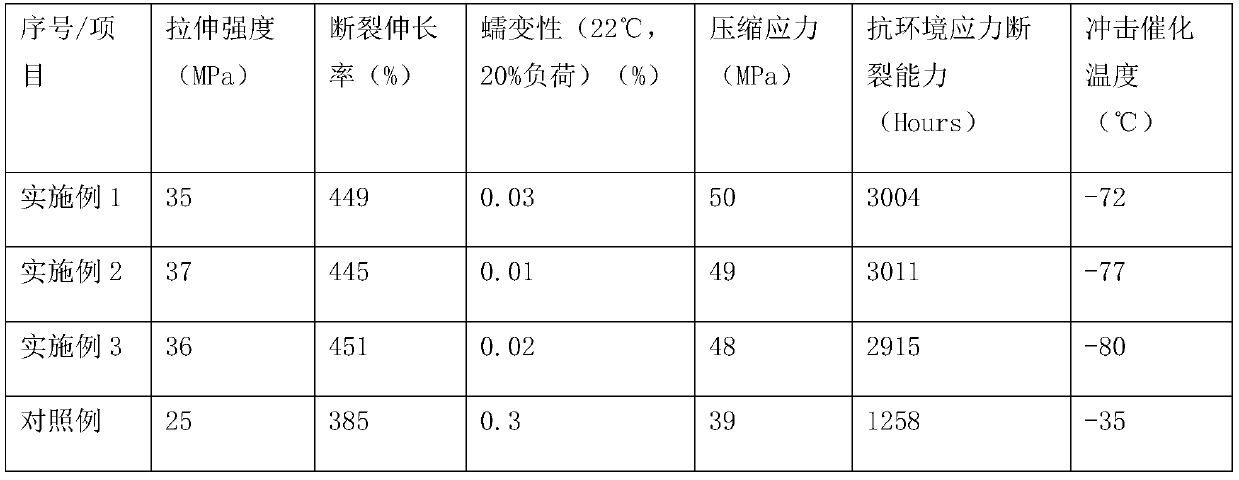

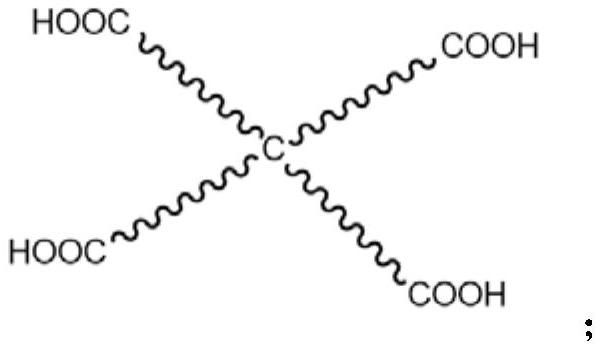

Regenerated polyester fiber containing metal modified cross ester compound and preparation method thereof

ActiveCN109440219AInsoluble infusibleHigh melting pointFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterMasterbatch

The invention relates to regenerated polyester fiber containing a metal modified cross ester compound and a preparation method thereof. The preparation method comprises the following steps: uniformlymixing flame retardant antibacterial masterbatch which is mainly prepared from a regenerated polyester chip and the metal modified cross ester compound with a regenerated polyester chip, and then carrying out melt spinning to obtain the regenerated polyester fiber containing the metal modified cross ester compound. The prepared fiber is mainly composed of a regenerated polyester fiber matrix and the metal modified cross ester compound which is uniformly dispersed in the regenerated polyester fiber matrix; the metal modified cross ester compound is a network polymer formed by a cross ester compound and metal ions; the metal modified cross ester compound has the characteristics of insolubility and infusibility, is insoluble in organic solvents at the temperature of 80 DEG C or below and doesnot melt in a range of the room temperature to T; T is greater than or equal to 380 DEG C. The preparation method disclosed by the invention has the advantages of simple technology and low cost; theprepared product has the advantages of high functional component content, good flame retardant property and antibacterial property and easy formability.

Owner:SHANGHAI DEFULUN CHEM FIBER +1

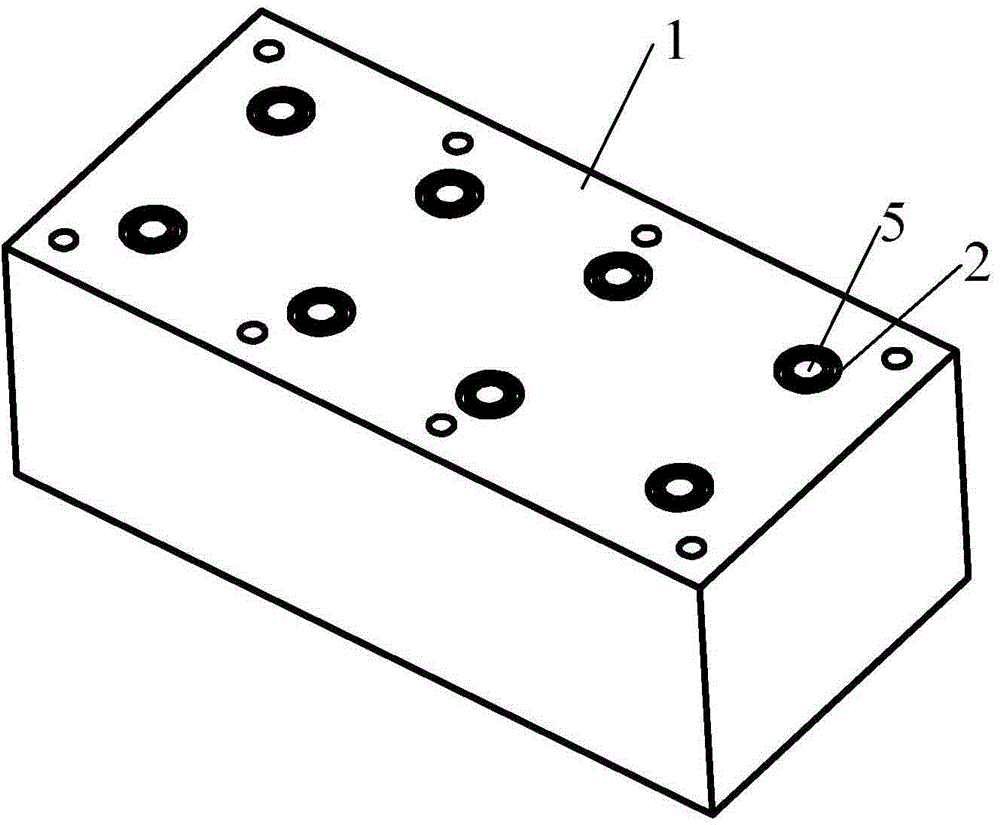

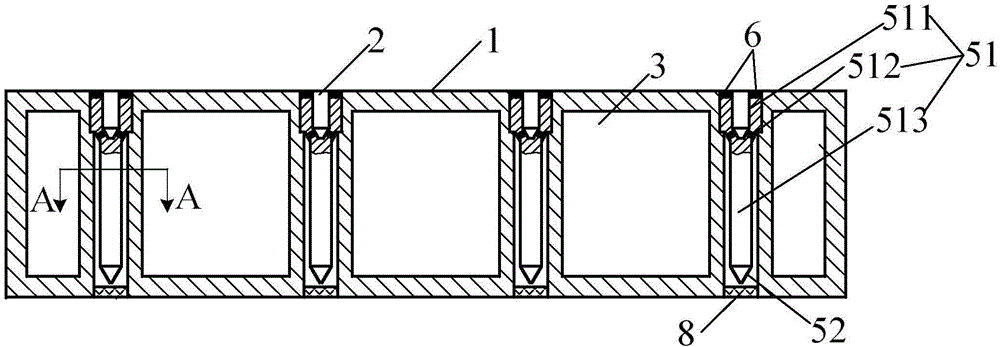

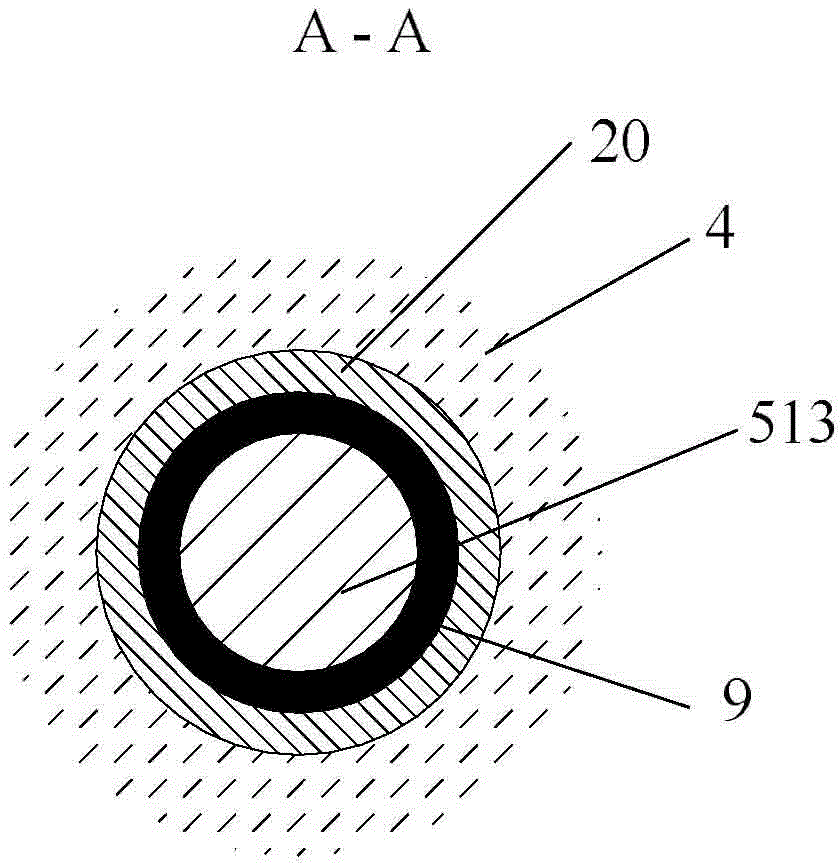

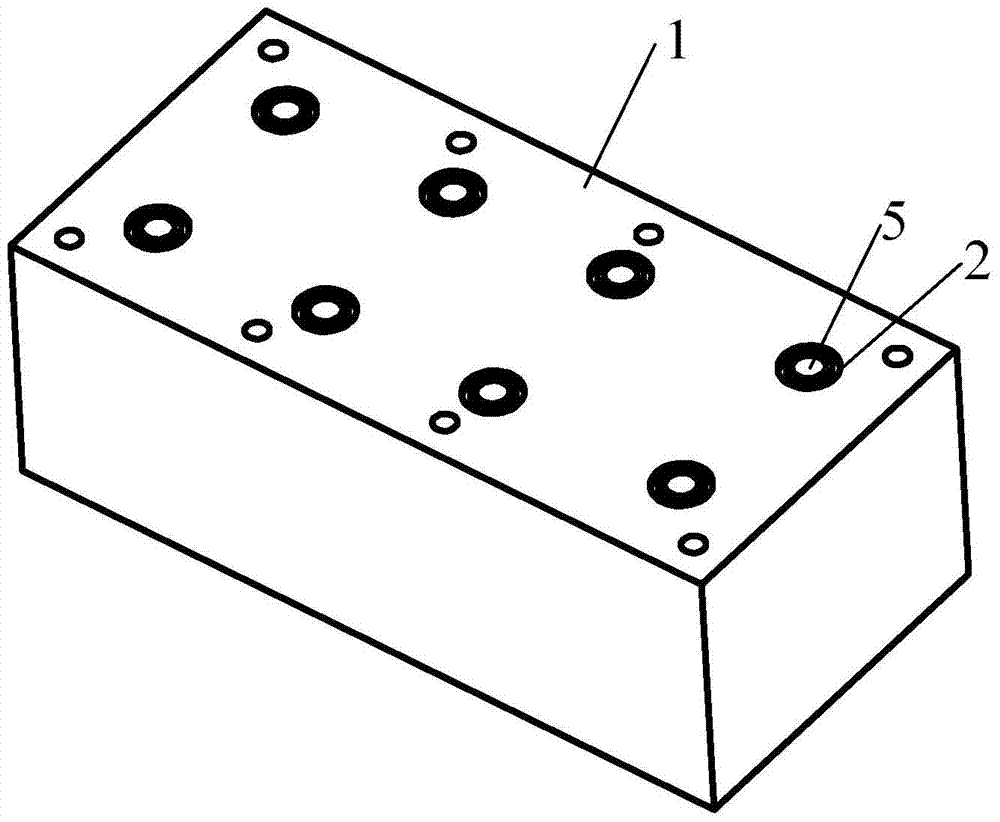

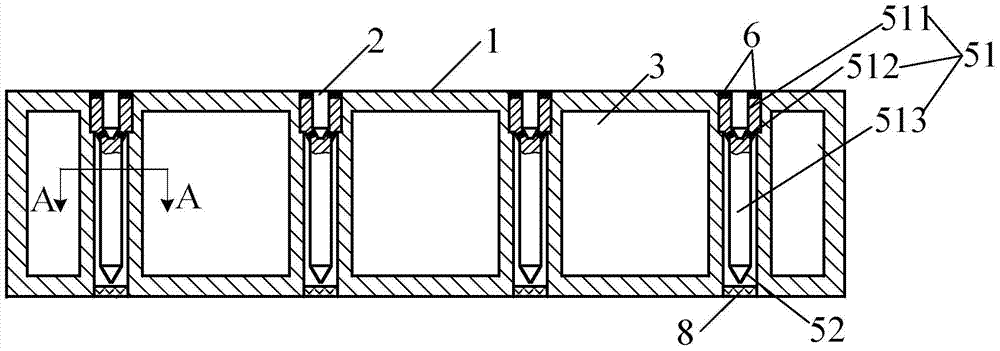

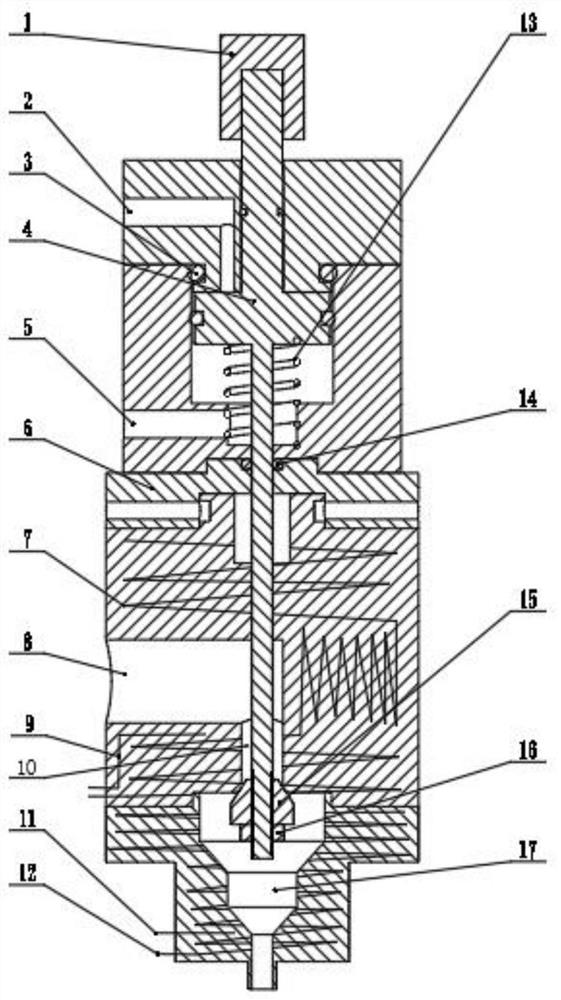

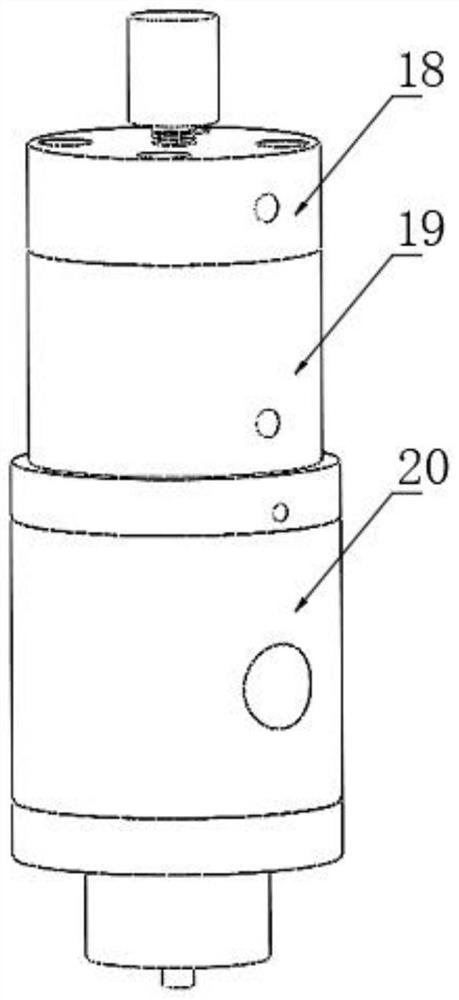

Temperature control box for dry spinning of elastic fibers

ActiveCN104389033AConstant temperature viscosityGuaranteed rheologySpinning head liquid feederDry spinning methodsSpin outEngineering

The invention relates to a temperature control box for dry spinning of elastic fibers. The temperature control box comprises a box body and intermediate components. A plurality of polymer solution passages isolated from one another are arranged in the box body longitudinally. Areas, except for the polymer solution passages, in the box body are cavities, and the cavities allow fluid media for heat exchange with polymer solution, used for dry spinning of the elastic fibers, in the polymer solution passages to flow through. Each intermediate component is arranged in one polymer solution passage, and the intermediate components are used for decreasing the temperature difference between different portions of the polymer solution flowing out of the polymer solution passages. According to the technical scheme, the temperature control box for dry spinning of the elastic fibers has the advantages that the temperature difference between different portions of the polymer solution flowing out of the polymer solution passages can be decreased, so that the polymer solution flowing out of the polymer solution passages is constant in temperature and uniform in viscosity, the rheological property of the polymer solution entering spinning nozzles is guaranteed beneficially, tows spun out of the spinning nozzles are enabled to be stable, and further, the quality of produced fibers is improved.

Owner:ZHENGZHOU ZHONGYUAN SPANDEX ENG TECH

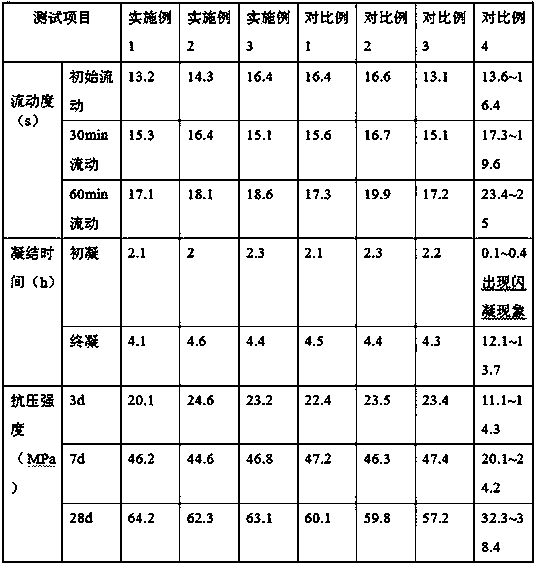

Cement accelerator

The invention discloses a cement accelerator and belongs to the field of buildings. According to the cement accelerator disclosed by the invention, a substance with a cement accelerating effect is prepared by taking aluminum sulfate octadecahydrate and calcium oxide as raw materials and carrying out high-speed shearing; lithium slag is used as a raw material, is subjected to microwave treatment and is enabled to have more free lithium salts and the like, so that condensation of cement concrete can be promoted and the initial set time is shortened; in addition, alumina and calcium sulfate in the lithium slag also react to generate calcium sulphoaluminate hydrate, so that early strength can be improved; bamboo fibers are added for compounding and raw bamboo fibers are doped, so that the volume shrinkage stress is digested, and further cracks are reduced; the breaking strength of cement-based mortar is improved along with the increase of the doping amount of the raw bamboo fibers; the anti-cracking and compressive strength of the cement slurry at later stage is improved, and further the quality of cement is improved.

Owner:赵顺全

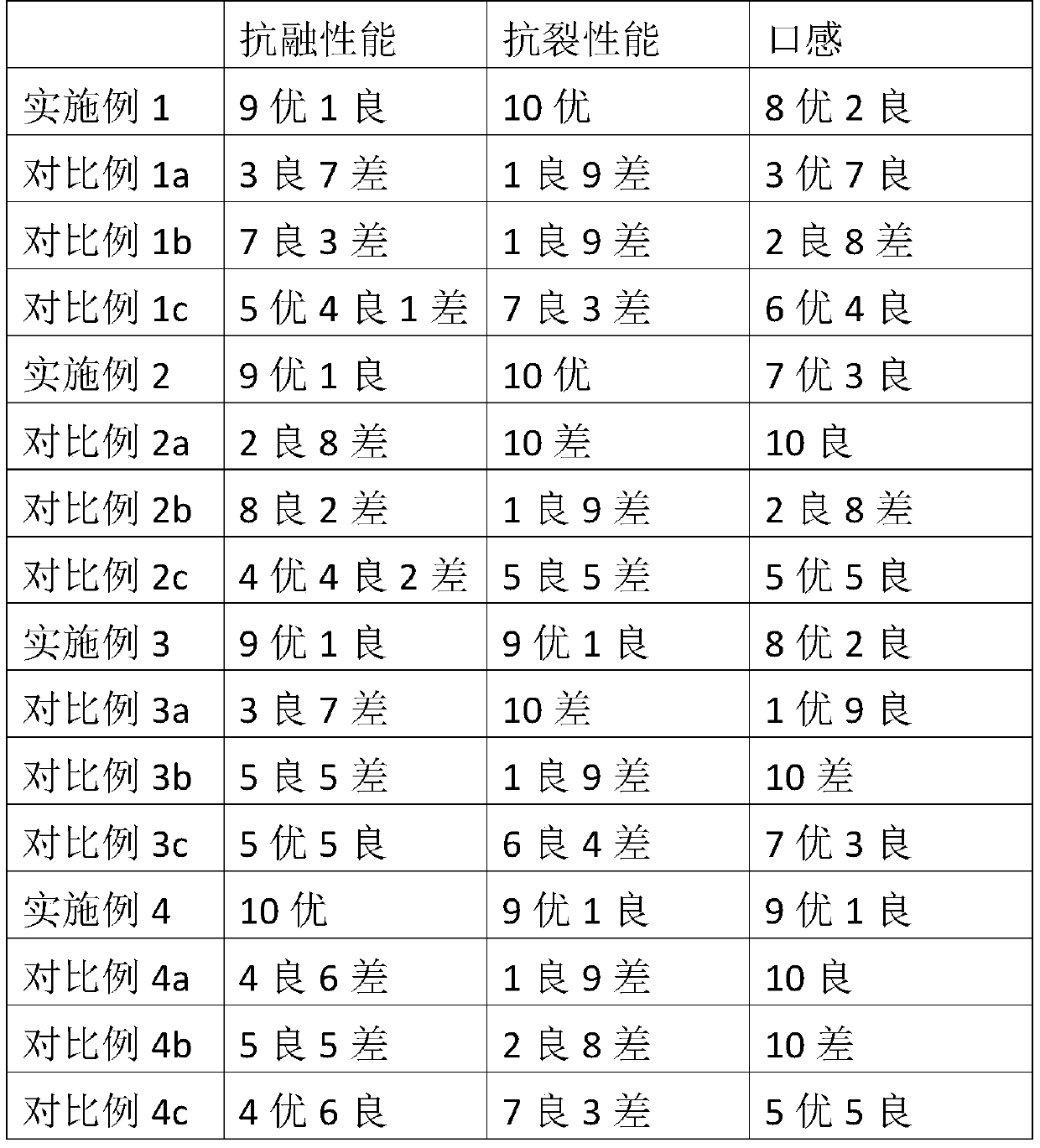

Chocolate coating formula

The invention relates to a chocolate coating formula, a chocolate coating sauce using same, a chocolate coating food and a production method of the chocolate coating sauce and the chocolate coating food. According to the chocolate coating formula, particular quantity of pectin is added, particular quantity of specific emulsifying agents are added, on one hand, heat stability of a chocolate coatingis unexpectedly and greatly improved and cannot be softened or thawed even if the coated is exposed in air for a long time at higher temperature, on the other hand, the rheological property of the chocolate coating sauce before coagulation is ensured, and good silky and smooth taste of a traditional chocolate coating can still be retained. More important, the surfaces of biscuits can be uniformlycoated with the formed chocolate coatings, the chocolate coatings are stably combined with the biscuits, and the chocolate coatings have good toughness and cracking resistance.

Owner:可可琳纳食品海门有限公司

Activated molybdenum-manganese slurry used in ceramic metallization and preparing method thereof

The invention provides activated molybdenum-manganese slurry used in ceramic metallization and a preparing method thereof. The slurry comprises, by mass percentage, 0.5% of added herring oil, and 0.1% of soybean lecithin, so that degree of finish of a prepared ceramic metallization printed layer can be raised from 85% to 95% or above, and the sealing strength of the metallization is raised from a range (larger than or equal to 70 MPa) to a range (larger than or equal to 100 MPa). The provided preparing method is simple in technology and easy to operate; meanwhile, the complexity of the preparing procedures is reduced, the preparing method has good repeatability, and thus the preparing method is suitable for industrial production.

Owner:康文涛

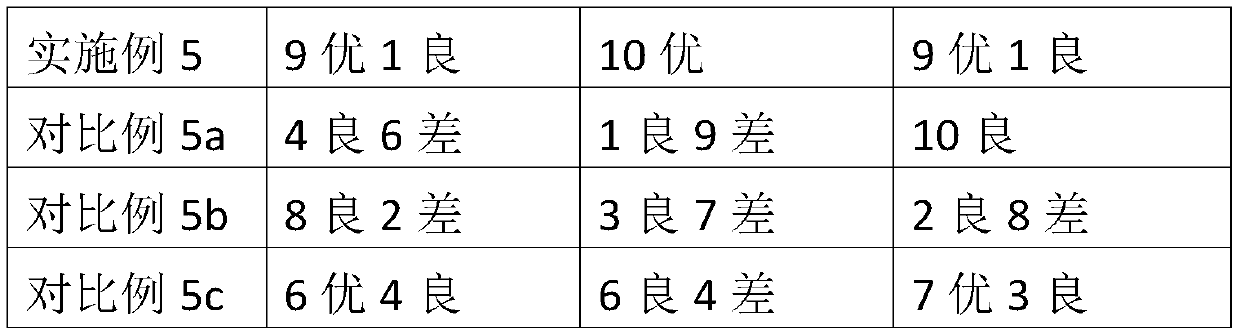

Control method of mixing drum and mixing truck

ActiveCN114012901AExtended service lifeGuaranteed rheological propertiesCement mixing apparatusControl apparatusControl engineeringControl theory

The invention belongs to the technical field of concrete mixing, and discloses a control method of a mixing drum and a mixing truck. According to the control method of the mixing drum, when the mixing drum mixes concrete at an initial gear, the torque value of the mixing drum is detected every preset number of turns, and the difference value between the detected later detection value and the detected previous detection value is compared with a preset torque range; if the difference value between the later detection value and the previous detection value is within the preset torque range, the initial gear of the mixing drum is not adjusted, and if the difference value between the later detection value and the previous detection value is not within the preset torque range, the initial gear is adaptively adjusted. According to the control method of the mixing drum, the difference value between the later detection value and the previous detection value is compared with the preset torque range, and the initial gear is correspondingly adjusted by analyzing the comparison result, so that the rotating speed of the mixing drum can be adjusted according to the change of the torque value, and the rheological property of concrete is effectively guaranteed.

Owner:GUANGXI LIUGONG MASCH CO LTD

Cross section fiber containing metal modified cross ester and preparation method of cross section fiber

ActiveCN109735922AInsoluble infusibleHigh melting pointFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterCross-link

The invention relates to a cross section fiber containing a metal modified cross ester and a preparation method of the cross section fiber. The preparation method comprises the following steps: performing melt blending on a functional master batch and a polyester chip to prepare spinning melt, and performing melt spinning, thereby obtaining the cross section fiber containing the metal modified cross ester. The functional master batch contains the metal modified cross ester; the metal modified cross ester is a network polymer formed by cross-linking a cross ester and a metal ion; and the metalmodified cross ester has insoluble and non-melting characteristics, cannot be dissolved into an organic solvent I at a temperature of 80 DEG C or below, and is not melted in a range from room temperature to T, wherein the temperature T is more than or equal to 380 DEG C. A fabric prepared from the cross section fiber containing the metal modified cross ester has a wicking height of 150-250mm within 10 minutes. The method disclosed by the invention is simple in operation, and the finally prepared fiber has excellent flame-retardant, antibacterial and moisture absorption and sweat releasing functions.

Owner:DONGHUA UNIV +1

Process for preparing drilling fluid based on weighting material

InactiveCN103045196AReduce the total solids contentGuaranteed rheological propertiesDrilling compositionSodium BentoniteReducer

The invention discloses a process for preparing a drilling fluid based on a weighting material. The process comprises the following steps of: (a) preparing sodium bentonite for future use; (b) adding a tackifier PAC-HV and completely dissolving the tackifier PAC-HV; (c) adding a filtrate reducer SMP-2; (d) adding KCl and NaCl; (e) adding a deformation blocking agent FT-1 and a rigidity blocking agent CaCO3; (f) adding 2-4% of a viscosity reducer PSC-1; (g) adding TRH-2 so that TRH-2 thoroughly acts; and (h) heating the system and then adding the weighing material barite, thereby obtaining the product. The process is characterized in that the weighing material in the preparation process is rationally selected so that the total solid phase content of the drilling fluid is reduced and the rheological property of the drilling fluid is guaranteed to be well controlled.

Owner:张彪

Production method of goose liver paste with low saturated fatty acid content

The invention relates to the technical field of paste food production, in particular to a production method of goose liver paste with low saturated fatty acid content. The method specifically comprises the steps as follows: fresh goose livers are obtained, soaked in an adenosine triphosphate aqueous solution with the concentration of 20-25 ppm and stirred for bitterness removal, pulping is performed after raw yolk is added, the pulp is inoculated with candida mycoderma bacteria for decomposition of saturated fatty acid, ultrasonic intermittent sterilization and emulsification are performed, and finally, steam is introduced for cooking and flavoring during grinding. The produced goose liver paste is thick and fine in nature, is in a quicksand shape after being poured out and has an attractive aroma.

Owner:界首市英琪养殖专业合作社

A kind of production method of bus duct bridge frame

The invention relates to a production method of a bus duct bridge, which uses high-density polyethylene and medium-density polyethylene as a combined modified matrix, and is cross-linked and modified with a cross-linking agent under the action of an initiator, and then melt-grafted and polymerized with maleic anhydride Form a multi-grafted modified polymer, and blend and modify with surface-treated inorganic rigid particles. The inorganic rigid particles are one or more of nano-calcium oxide, glass microspheres, nano-silica, and nano-magnesium carbonate. It is extruded with processing aids through a twin-screw extruder, melted and pre-plasticized and extruded into a mold on a shaping table to be shaped, and circulating water is added to the outside of the mold to cool and shape in a vacuum, and then pulled by a tractor, cut into shape, and anti-corrosion. On the basis of static electricity, the brittleness, creep resistance, yield strength and processing performance of extruded busway bridges are improved, and the service life is longer.

Owner:扬中市长龙管业有限公司

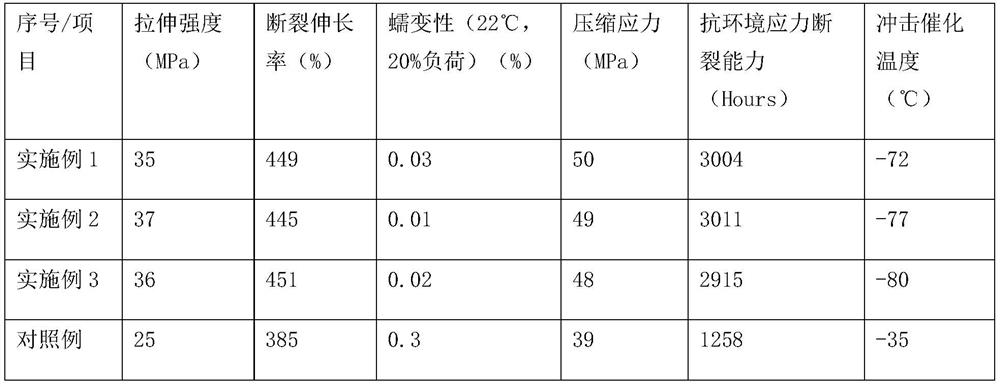

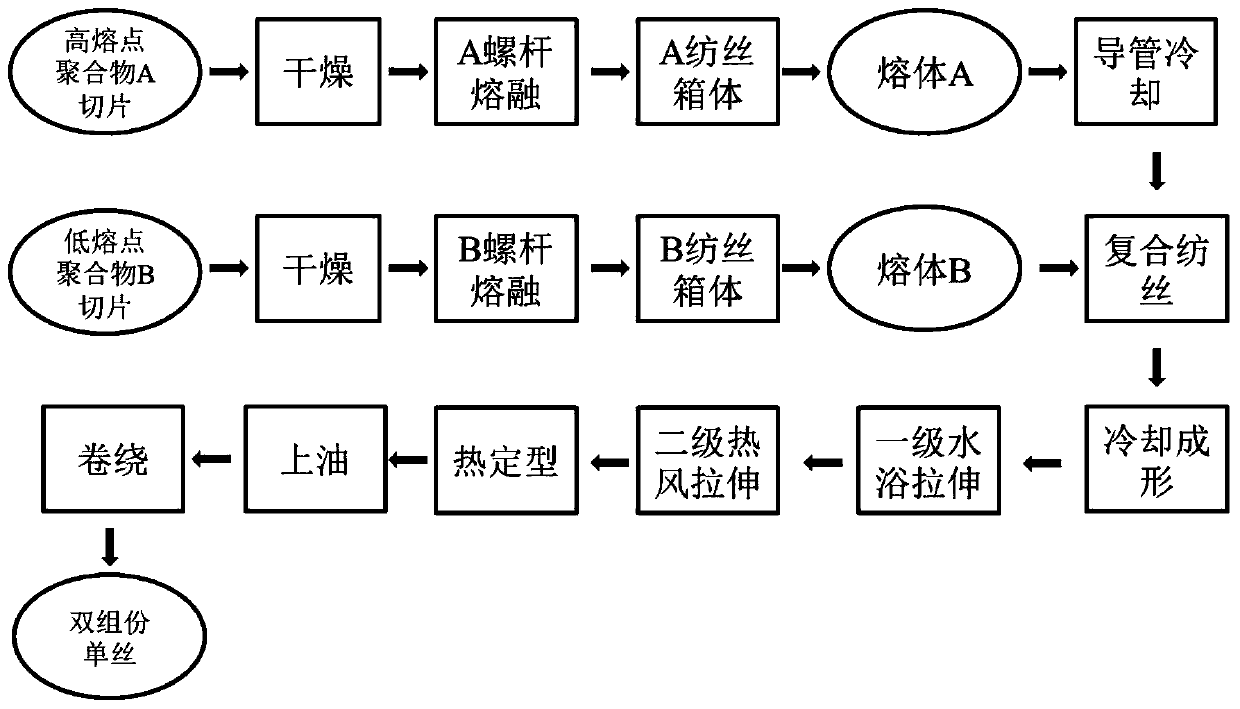

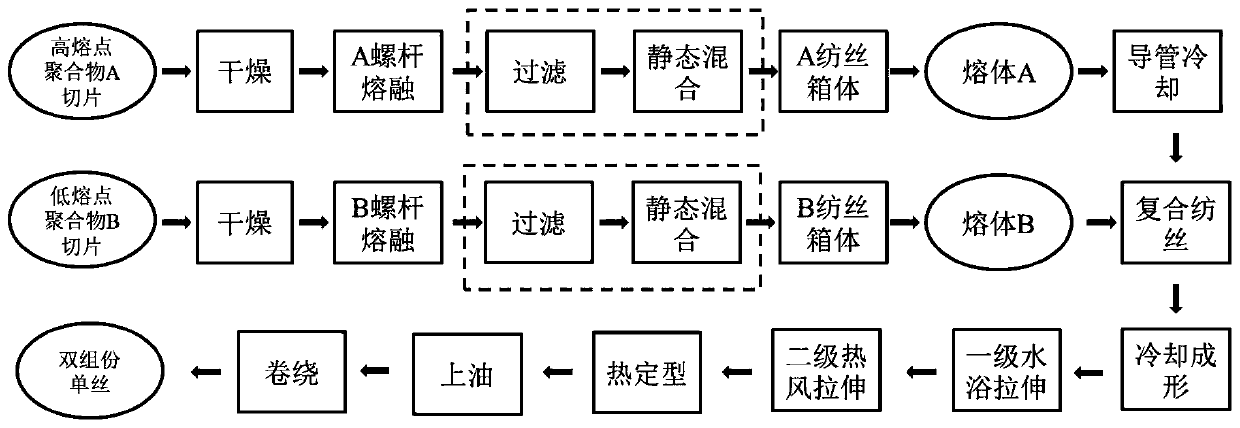

Production method of double-component monofilaments composited and formed in spinning tanks

ActiveCN110616468AImprove rheologyGuaranteed rheological propertiesFilament forming substance formingSpinning head liquid feederTemperature controlBreakage rate

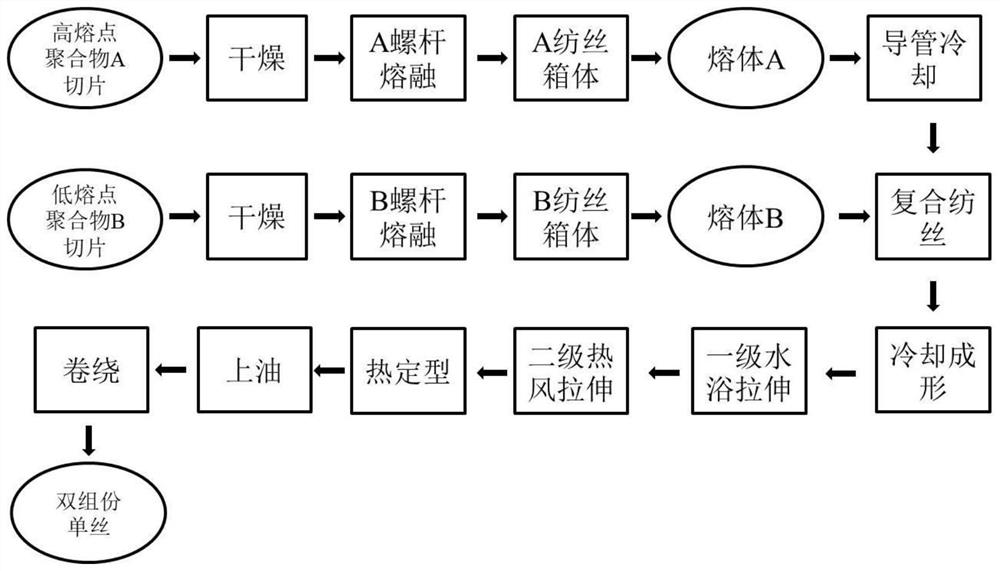

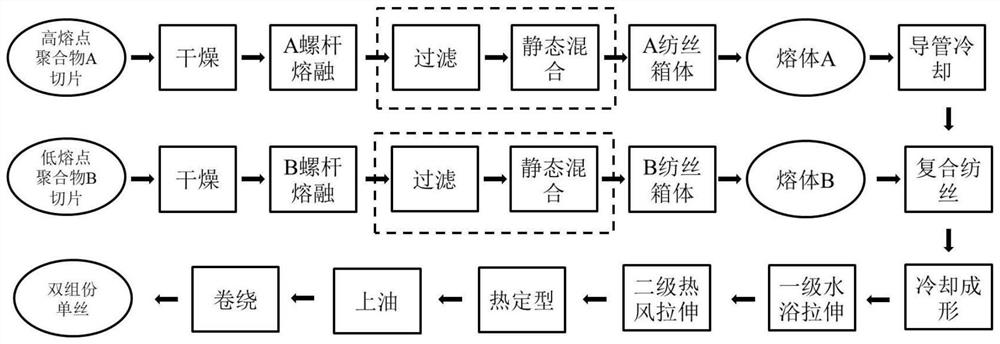

The invention provides a production method of double-component monofilaments composited and formed in spinning tanks. The production method has the advantages that by setting two spinning equipment, the spinning process temperature of each stage before the high-melting-point melt and the low-melting-point melt enter a composite spinning component can be conveniently and precisely controlled, and accordingly the rheological property of two polymer required by the spinning process can be achieved, and spinning quality can be improved; before the melt A enters the composite spinning component, the melt A high in temperature is cooled through precise temperature control by a guide pipe, the temperature of the melt A entering the composite spinning component can be stabilized in a reasonable range, and accordingly the rheological property of the melt can be guaranteed, the spinnability of the double-component monofilaments can be guaranteed, the quality of the double-component monofilamentscan be increased, and the broken-filament rate and the end breakage rate of the double-component monofilaments are lowered.

Owner:WUXI JINTONG CHEM FIBER

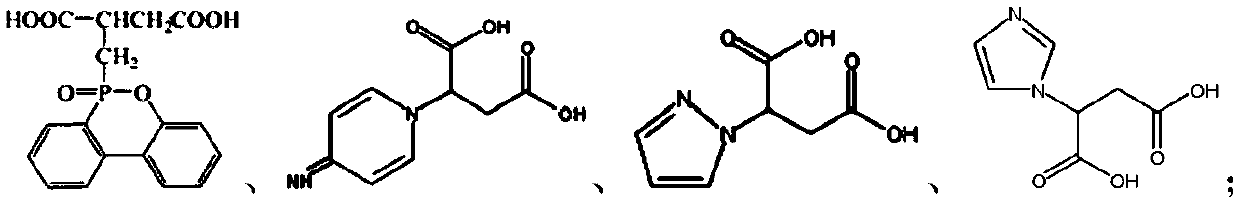

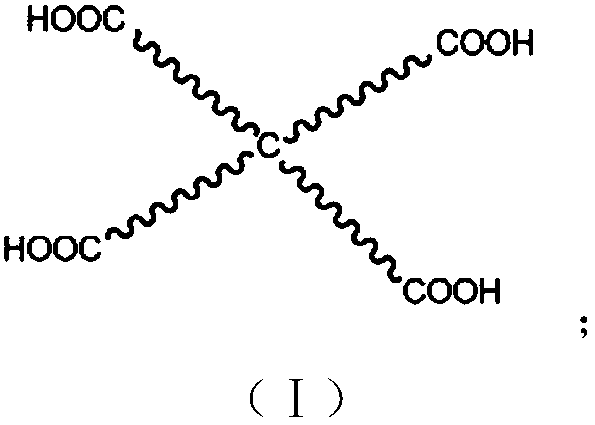

Flame-retardant polylactic acid fiber containing metal modified cross-shaped ester and preparation method of fiber

ActiveCN109629038AReduced influence of rheological propertiesGuaranteed rheological propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentOrganic solventPolymer science

The invention relates to a flame-retardant polylactic acid fiber containing metal modified cross-shaped ester and a preparation method of the fiber. A poly-L-lacticacid section, a poly-D-lacticacid section and a functional polylactic acid master batch containing a modifier A and a modifier B are mixed evenly, and then the flame-retardant polylactic acid fiber containing the metal modified cross-shaped ester is prepared through a melt spinning method, wherein the mass ratio of the poly-L-lacticacid section to the poly-D-lacticacid section is 1:1; the modifier A is a mixture obtained by mixing aluminum benzoate, hydrated magnesium silicate and silicon dioxide in the mass ratio of 2:1:1; the modifier B is insoluble infusible metal modified cross-shaped ester which is insoluble in most organicsolvents at the temperature of 80 DEG C or below and is infusible in the range from room temperature to T, and T is larger than or equal to 380 DEG C. The method is simple and easy to implement and low in cost, and the finally prepared polylactic acid fiber is high in melting point, excellent in flame retardancy and very good in popularization value.

Owner:SHANGHAI DEFULUN CHEM FIBER +1

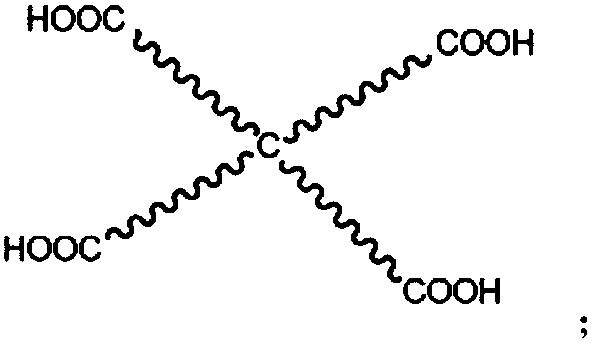

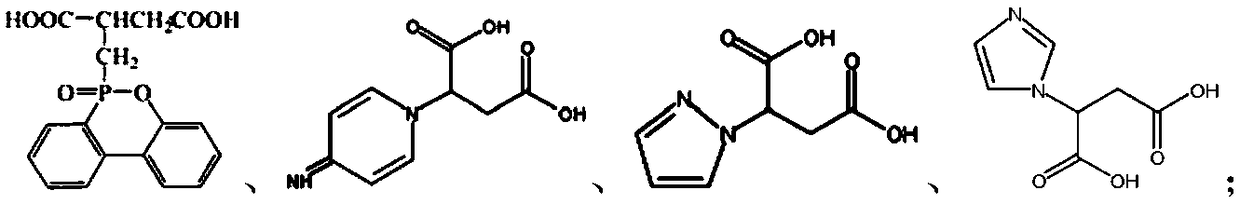

PET sheath-core fiber containing metal-modified cross-type esterified product and preparation method thereof

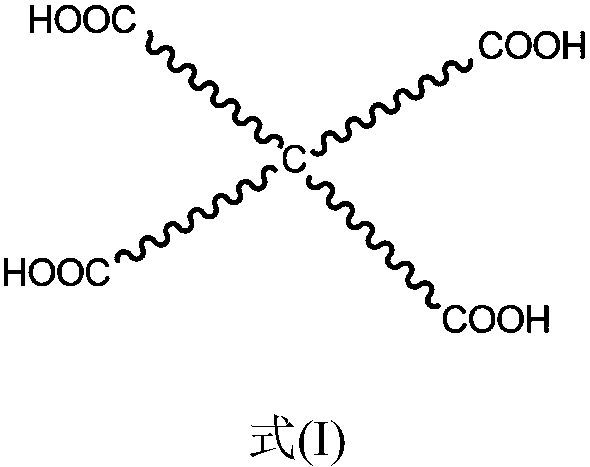

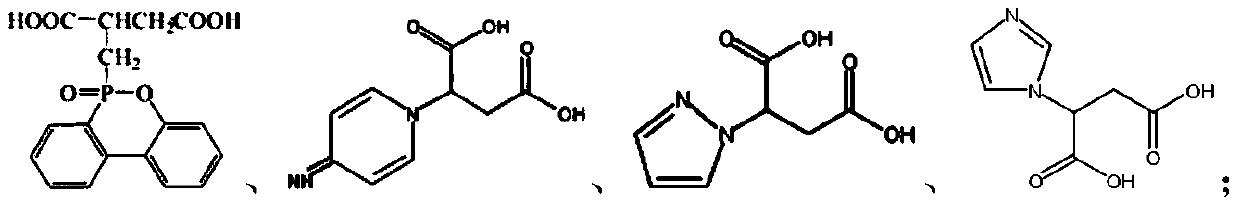

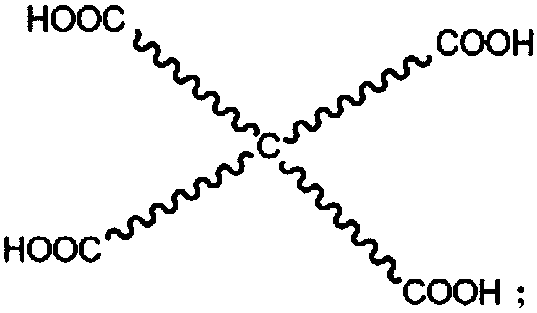

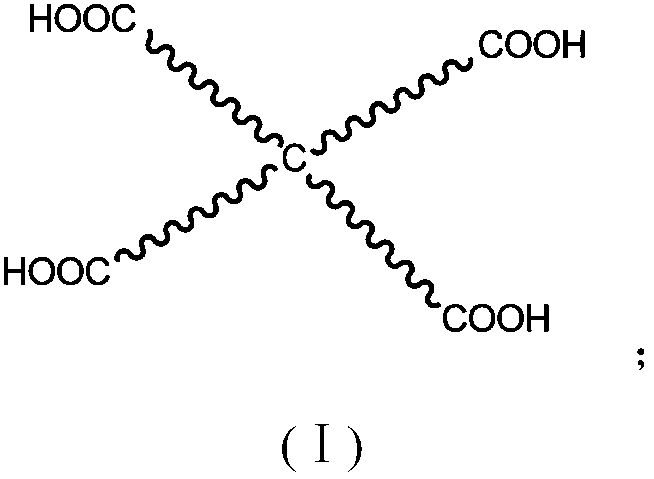

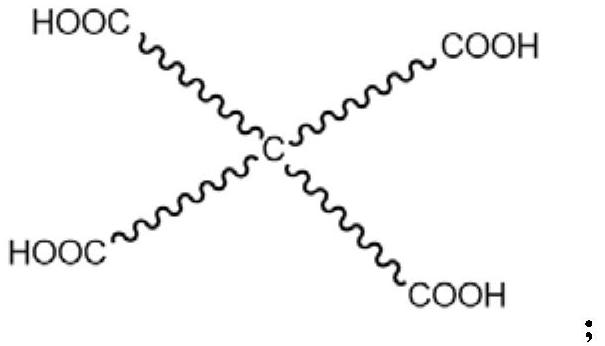

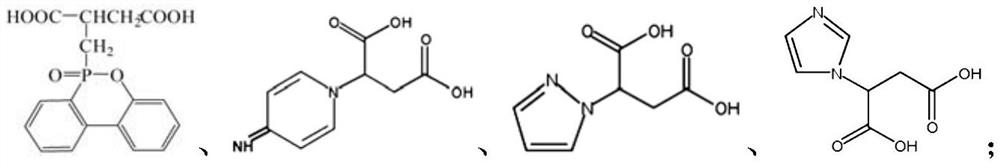

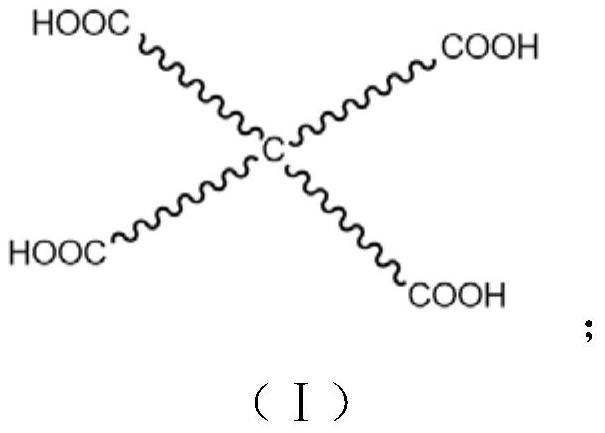

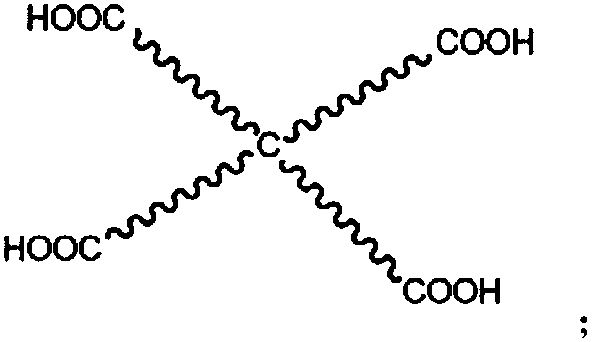

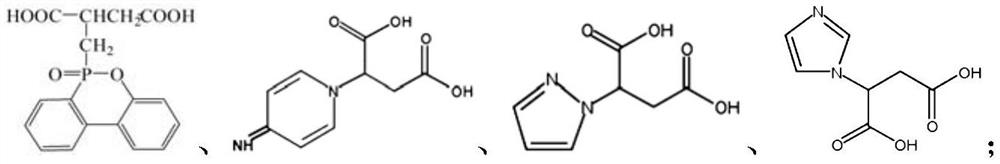

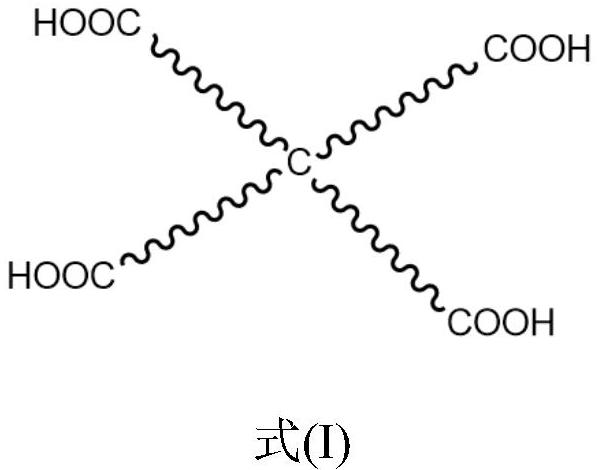

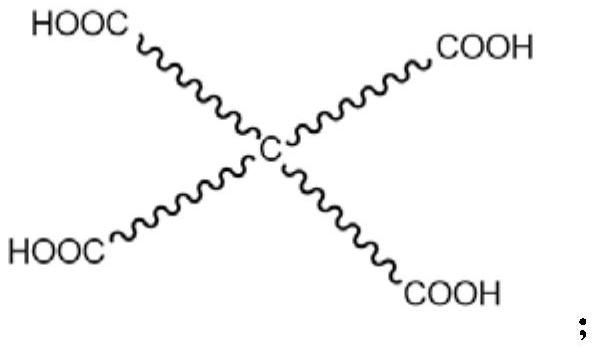

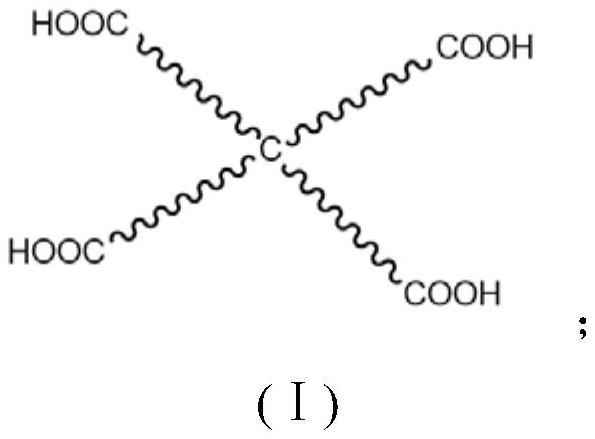

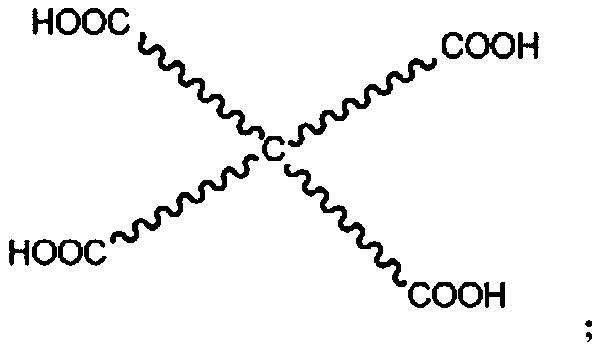

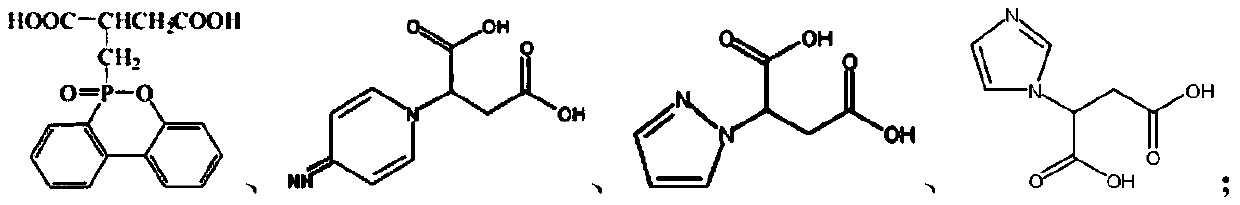

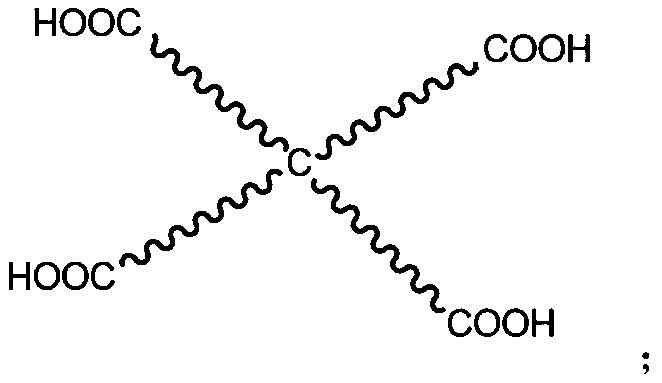

ActiveCN109440224BEasy to processImprove flame retardant performanceFlame-proof filament manufactureFilament/thread formingFiberPolymer science

The invention relates to a PET sheath-core fiber containing a metal-modified cross-type ester compound and a preparation method thereof. The mixture of PET slices and flame-retardant and antibacterial masterbatches and recycled PET slices are used as the source of the skin layer material and the source of the core layer material. The PET sheath-core fiber containing metal-modified cross-shaped esterified compound is prepared by melting sheath-core composite spinning method, wherein the flame-retardant and antibacterial masterbatch includes a flame-retardant and antibacterial modifier, and the flame-retardant and antibacterial modifier is an insoluble and infusible metal modified fiber. Sexual cruciform esters, specifically, network polymers formed by insoluble and infusible cruciform esters cross-linked with metal ions, insoluble in organic solvent I below 80°C, non-melting in the range from room temperature to T, T≥380°C The structural formula of the cross-type ester compound is as follows: In the formula, the chain segment between the quaternary carbon C and the terminal carboxyl group on behalf of the cross-type ester compound molecular center contains a double bond with an oxygen atom. The preparation method of the invention is simple and easy, and the prepared sheath-core fiber has excellent flame-retardant and antibacterial properties.

Owner:SHANGHAI DEFULUN CHEM FIBER

Production method for bus duct cable tray

The invention relates to a production method for a bus duct cable tray. The production method comprises the following steps: taking high-density polyethylene and medium-density polyethylene as a composite modified matrix; after carrying out cross-linking modification on the composite modified matrix and a cross-linking agent under the action of an initiator, fusing, grafting and polymerizing the product and maleic anhydride to obtain a multi-grafted modified polymer; blending the multi-grafted modified polymer and inorganic rigid particles subjected to surface treatment, and modifying, whereinthe inorganic rigid particles are selected from one or more of nano calcium oxide, glass microspheres, nano silicon dioxide and nano magnesium carbonate; extruding the blended product and a processing auxiliary agent through a double-screw extruder; fusing, pre-plasticizing and extruding into a mold of a sizing platform and sizing; adding circulating water outside the mold, and cooling and molding in vacuum; then pulling through a pulling machine, and cutting and molding. The fragility, creep resistance, yield strength and machinability of the extruded and molded bus duct cable tray are improved on the anticorrosion and antistatic basis, and the service life is longer.

Owner:扬中市长龙管业有限公司

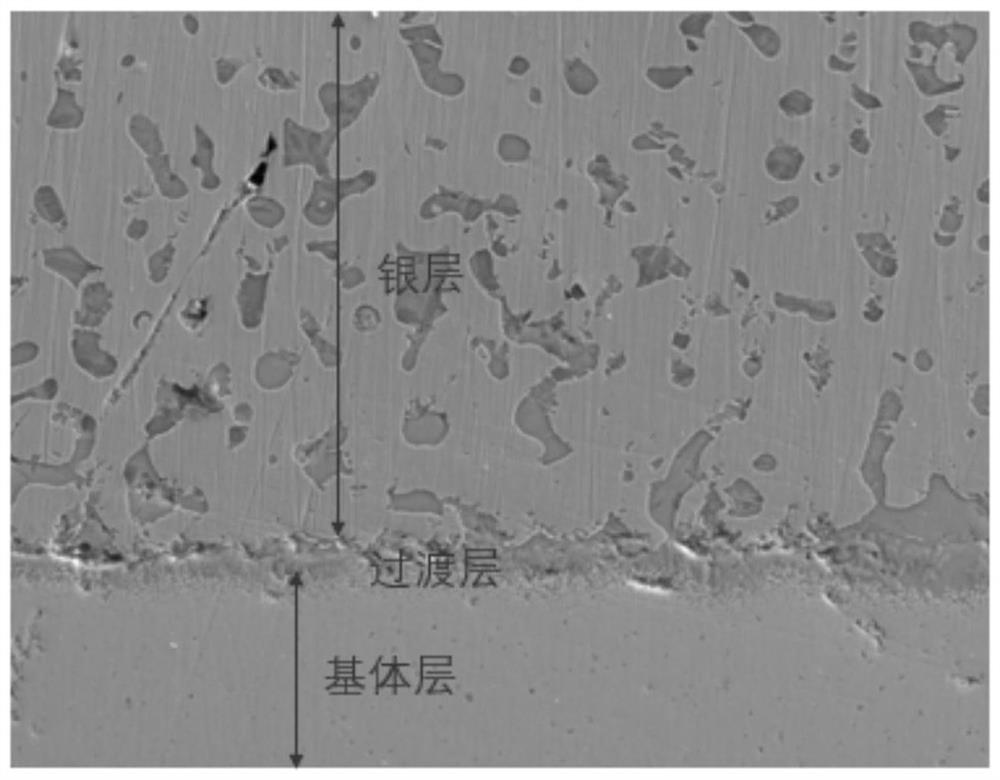

A kind of efficient 5g ceramic dielectric filter conductive silver paste and preparation method thereof

ActiveCN111312426BGood dispersionImproved rheological propertiesNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseAcrylic resin

The invention provides a high-efficiency 5G ceramic dielectric filter conductive silver paste and a preparation method thereof. The formula mainly consists of conductive fillers with preset mass percentages, inorganic binders, organic binders, solvents, inorganic oxide additives, and dispersants. The conductive filler is spherical silver powder; the inorganic binder is glass powder; the organic binder is one or more combinations of ethyl cellulose, rosin, and acrylic resin; the solvent is aliphatic hydrocarbon, aliphatic hydrocarbon Derivatives, derivatives of alcohols containing more than 8 carbon atoms and acetate derivatives; inorganic oxide additives are one or more combinations of zinc oxide, bismuth oxide, aluminum oxide, yttrium oxide, and magnesium oxide; dispersants It is one or both of triamine citrate and polymethacrylic acid amine; the thixotropic agent is polyamide wax or hydrogenated castor oil. The invention solves the problems in the prior art that the silver paste relies on imports and the silver coating efficiency is low.

Owner:大连海外华昇电子科技有限公司

Temperature control box for elastic fiber dry spinning

ActiveCN104389033BImprove qualitySmall temperature differenceSpinning head liquid feederDry spinning methodsFiberTemperature control

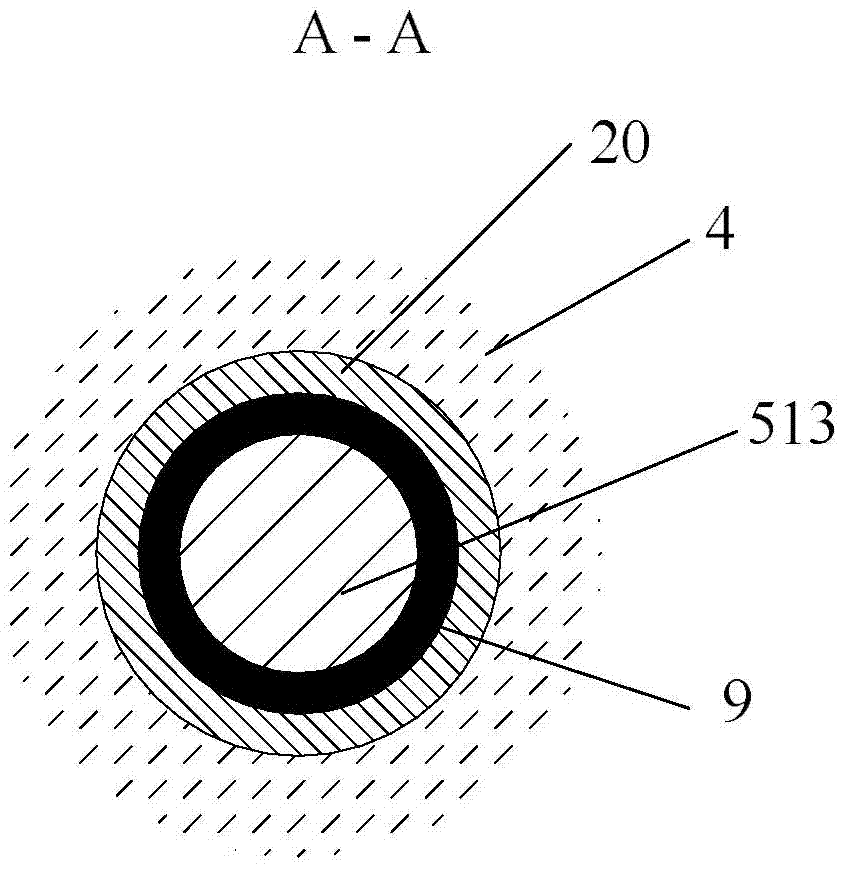

A temperature controlled box for use in spandex fiber dry spinning, comprising: a housing (1), where the housing (1) is longitudinally provided with multiple polymer solution channels (2) separated from each other. Areas in the housing (1) other than the polymer solution channels (2) are cavities (3). The cavities (3) are used for circulation of a fluid medium (4) that exchanges heat with a spandex fiber dry spinning polymer solution in the polymer solution channels (2). An intermediate component (5) is provided in each of the polymer solution channels (2). The intermediate component (5) is used for reducing any temperature difference between different portions of the polymer solution outflowing via the polymer solution channels (2). The temperature controlled box for use in spandex fiber dry spinning is capable of reducing the temperature difference between different portions of the polymer solution outflowing via the polymer solution channels, allows the polymer solution outflowing via the polymer solution channels to be at a constant temperature and uniform viscosity, facilitates ensured rheological properties of the polymer solution entering spinning nozzles, and allows the spinning nozzles to steadily extrude a filament bundle, thus increasing the quality of a fiber product so prepared.

Owner:ZHENGZHOU ZHONGYUAN SPANDEX ENG TECH

Method for preparing double-component monofilament compositely formed under spinning box

ActiveCN110616468BImprove rheologyGuaranteed rheological propertiesFilament forming substance formingSpinning head liquid feederTemperature controlPolymer science

The invention provides a production method of double-component monofilaments composited and formed in spinning tanks. The production method has the advantages that by setting two spinning equipment, the spinning process temperature of each stage before the high-melting-point melt and the low-melting-point melt enter a composite spinning component can be conveniently and precisely controlled, and accordingly the rheological property of two polymer required by the spinning process can be achieved, and spinning quality can be improved; before the melt A enters the composite spinning component, the melt A high in temperature is cooled through precise temperature control by a guide pipe, the temperature of the melt A entering the composite spinning component can be stabilized in a reasonable range, and accordingly the rheological property of the melt can be guaranteed, the spinnability of the double-component monofilaments can be guaranteed, the quality of the double-component monofilamentscan be increased, and the broken-filament rate and the end breakage rate of the double-component monofilaments are lowered.

Owner:WUXI JINTONG CHEM FIBER

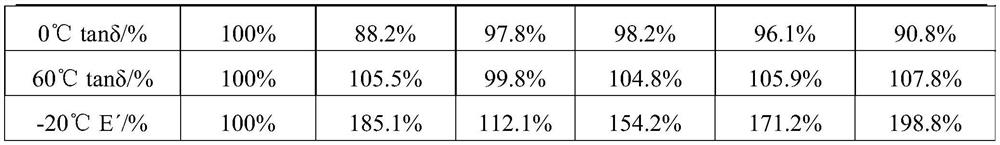

Application of modified rice bran oil in preparation of tire rubber material, rubber composition and tire

PendingCN113736154AGuaranteed rheological propertiesGuaranteed processing effectRubber materialPolymer science

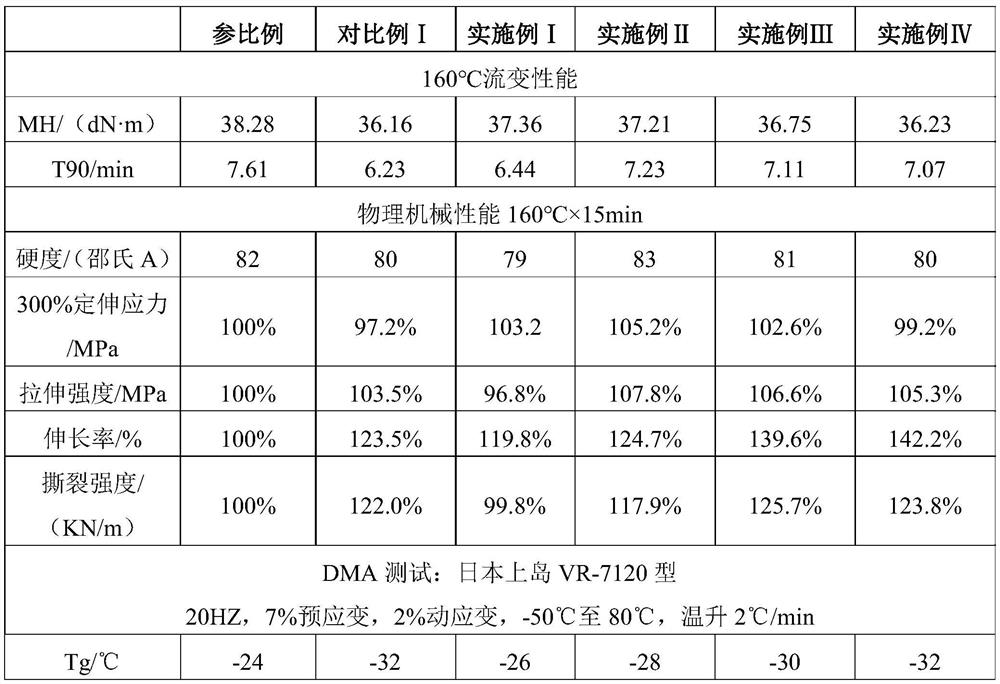

The invention belongs to the technical field of new materials for manufacturing rubber tires, and particularly relates to application of modified rice bran oil in preparation of tire rubber, a rubber composition and a tire. The rubber composition plasticized by using modified rice bran oil comprises 100 parts by weight of a pure rubber component, 1-40 parts by weight of modified rice bran oil and 30-120 parts by weight of a reinforcing material, wherein the modified rice bran oil is prepared from rice bran oil through olefin addition reaction. According to the composition, a petroleum-based plasticizer is replaced through the good plasticizing effect of the modified rice bran oil, the number of double bonds of the rice bran oil is reduced through modification from the perspective of modification, the influence on rheology and physical and mechanical properties is reduced, and a good foundation is laid for developing environment-friendly tires.

Owner:ZHONGCE RUBBER GRP CO LTD

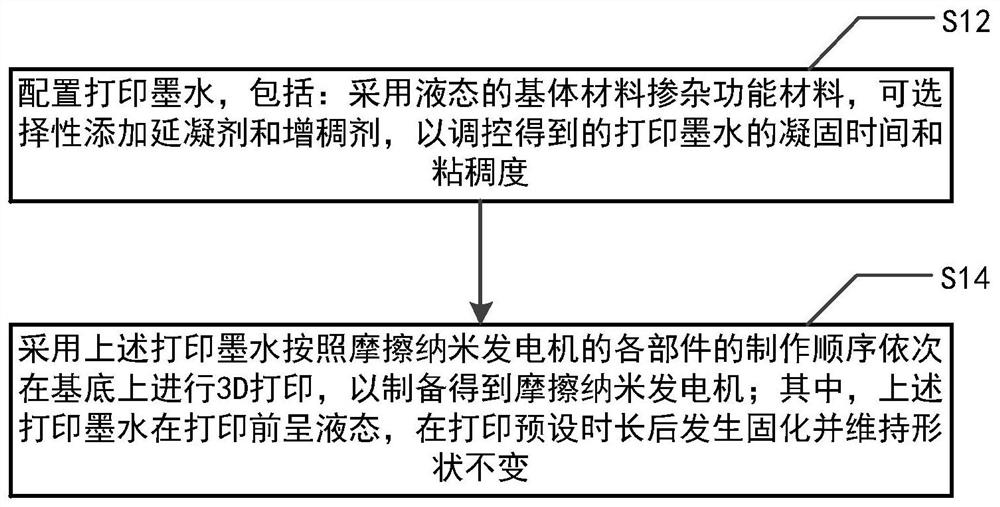

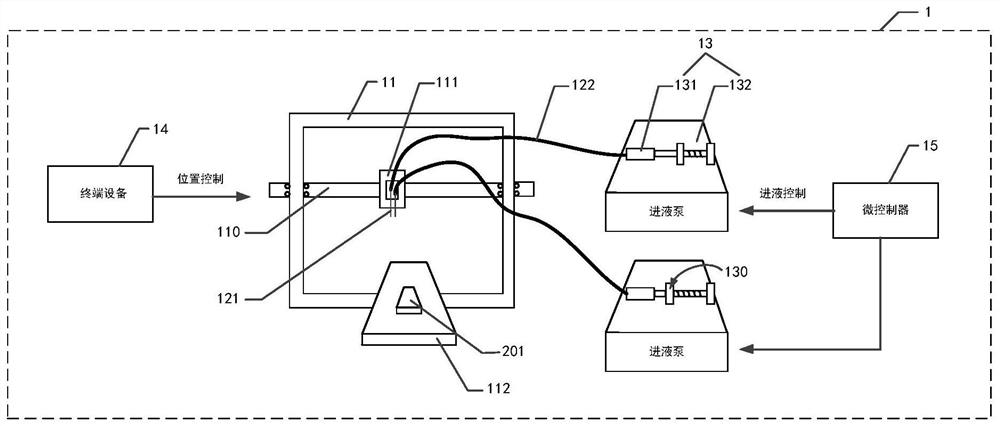

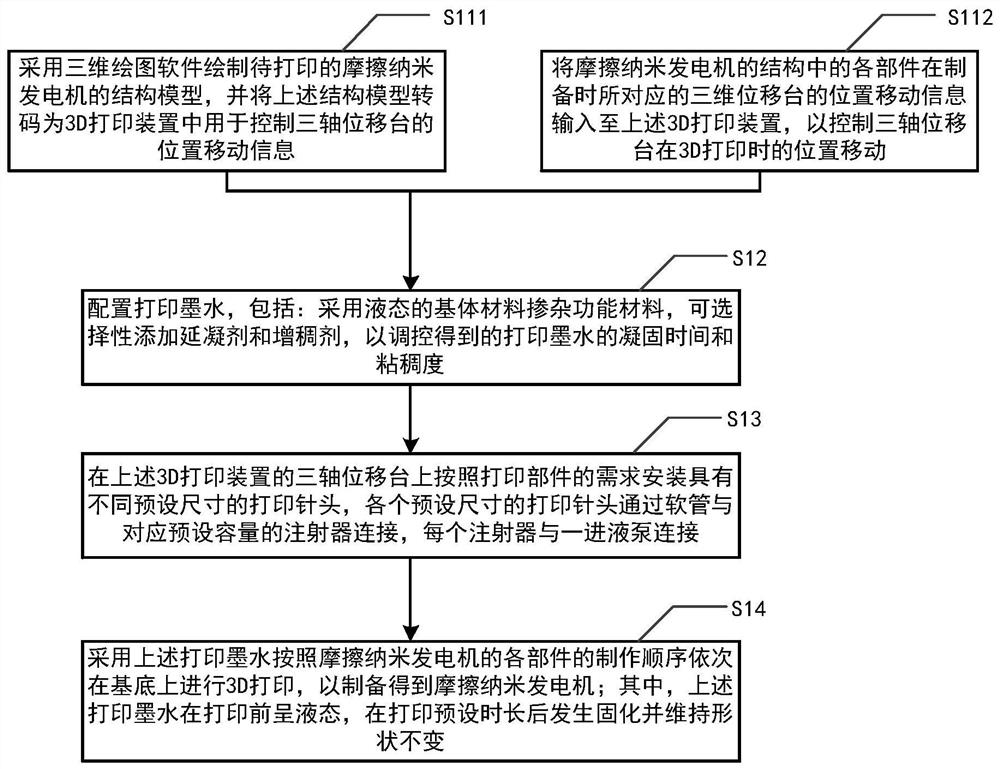

Method and device for preparing friction nanometer generator based on 3D printing

ActiveCN113172877AGood electrical propertiesThe energy conversion efficiency is not lowAdditive manufacturing apparatusFinal product manufactureLiquid statePrinting ink

The invention discloses a method for preparing a friction nanometer generator based on 3D printing. The method comprises the steps that printing ink is prepared, specifically, a liquid matrix material is doped with a functional material, and a delayed coagulant and a thickening agent are selectively added, so that the solidification time and viscosity of the obtained printing ink are adjusted and controlled; the functional material is used for preparing each part of the friction nano generator; and 3D printing is sequentially performed on a substrate by the aid of the printing ink according to the manufacturing sequence of each part of the friction nanometer generator, so that the friction nanometer generator is prepared; the printing ink is in a liquid state before printing and is cured after printing for a preset time, and the shape of the printing ink is kept unchanged. The invention further discloses a 3D printing device, the friction nanometer generator prepared by the preparation method and wearable equipment.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

PET sheath core fiber containing metal modified cross ester compound and preparation method thereof

ActiveCN109440224AEasy to processImprove flame retardant performanceFlame-proof filament manufactureFilament/thread formingFiberPolymer science

The invention relates to a PET sheath core fiber containing a metal modified cross ester compound and a preparation method thereof. The PET sheath core fiber containing the metal modified cross estercompound is prepared by respectively taking a mixture of a PET chip and flame retardant antibacterial masterbatch and a regenerated PET chip as a sheath layer material source and a core layer materialsource and adopting a melt sheath core composite spinning method, wherein the flame retardant antibacterial masterbatch comprises a flame retardant antibacterial modifier which is an insoluble and infusible metal modified cross ester compound, concretely is a network polymer formed by crosslinking an insoluble and infusible cross ester compound with metal ions; the insoluble and infusible metal modified cross ester compound is insoluble in an organic solvent I at the temperature of 80 DEG C or below and is infusible in a range of room temperature to T, and T is greater than or equal to 380 DEG C; a structural formula of the cross ester compound is shown as follows (the structural formula is shown in the description); in the formula, a chemical chain represents a chain segment between quaternary carbon C of a cross ester compound molecular center and terminal carboxyl, and contains double bonds with oxygen atoms. The preparation method disclosed by the invention is simple and feasible;the prepared sheath core fiber has excellent flame retardant and antibacterial properties.

Owner:SHANGHAI DEFULUN CHEM FIBER

Regenerated polyester fiber containing metal-modified cross-type esterified product and preparation method thereof

ActiveCN109440219BIncrease contentImprove flame retardant performanceFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to a regenerated polyester fiber containing metal-modified cross-shaped esterified products and a preparation method thereof. The preparation method includes combining flame-retardant and antibacterial masterbatches mainly composed of recycled polyester chips and metal-modified cross-shaped esterified products with recycled The recycled polyester fibers containing metal-modified cross-shaped esterified products were obtained by melt-spinning the polyester chips after mixing them uniformly. The prepared fiber is mainly composed of recycled polyester fiber matrix and metal-modified cross-shaped ester compound uniformly dispersed in the recycled polyester fiber matrix; the metal-modified cross-shaped ester compound is formed by cross-linking the cross-shaped ester compound and metal ions Network polymer, metal-modified cruciform ester compound has insoluble and infusible characteristics, insoluble in organic solvents below 80°C, and does not melt in the range from room temperature to T, T≥380°C. The preparation method of the invention has simple process and low cost; the prepared product has high content of functional components, good flame retardancy and antibacterial performance, and is easy to process and shape.

Owner:SHANGHAI DEFULUN CHEM FIBER +1

Extrusion and heating integrated device for chocolate printer

The invention relates to an extruding and heating integrated device for a chocolate printer. The extruding and heating integrated device comprises a pneumatic executing mechanism and a slurry extrusion mechanism which are sequentially connected from top to bottom. The chocolate extruding machine is scientific and reasonable in design, the pneumatic executing mechanism controls a variable-diameter pneumatic executing rod to move up and down through ventilation of a first air hole and a second air hole, and starting and stopping of chocolate paste extruding are achieved. A slurry plug of the slurry extrusion mechanism can block slurry at the lower end of a material barrel when the variable-diameter pneumatic executing rod moves upwards, so that the slurry can be instantly sucked back and broken while the slurry is stopped from being extruded from a feeding hole, residual materials on a needle head are reduced, the chocolate slurry does not generate the phenomena of dripping leakage, finedrawing and the like, and the finedrawing and salivation phenomena of the chocolate slurry are effectively relieved. Heating wires and temperature sensors are uniformly distributed in the material barrel and an extrusion head, so that the slurry entering the material barrel and the extrusion head can be quickly and uniformly heated, the rheological property of the chocolate slurry is ensured, and the chocolate slurry is stably and continuously extruded through the extrusion head.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cross-section fiber containing metal-modified cross-shaped ester compound and preparation method thereof

ActiveCN109735922BIncrease contentRheological influenceFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberCruciform

The invention relates to a cross-section fiber containing a metal-modified cross-shaped ester compound and a preparation method thereof. The preparation method is: melt-spinning a spinning melt prepared by melting and blending functional masterbatches and polyester chips. Cross-section fibers containing metal-modified cross-shaped ester compounds are obtained. The functional masterbatch contains metal-modified cross-shaped ester compounds. The metal-modified cross-shaped ester compounds are network polymers formed by cross-linking cross-shaped ester compounds and metal ions. , The metal-modified cruciform ester compound is insoluble and infusible, insoluble in organic solvent I below 80°C, and does not melt in the range from room temperature to T, and T≥380°C. The wicking height of the fabric made from the cross-section fiber containing the metal-modified cross-shaped ester compound is 150-250 mm within 10 minutes. The method of the invention is simple to operate, and the finally prepared fiber has excellent functions of flame retardancy, antibacterial and moisture absorption and perspiration.

Owner:DONGHUA UNIV +1

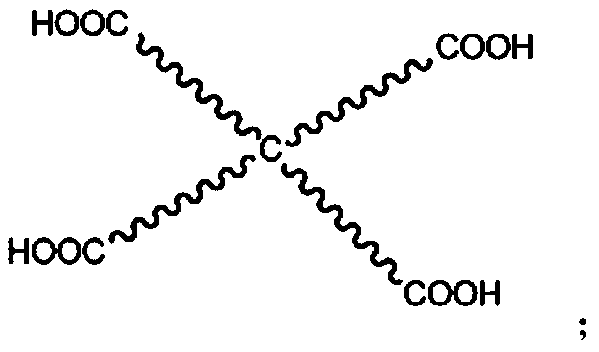

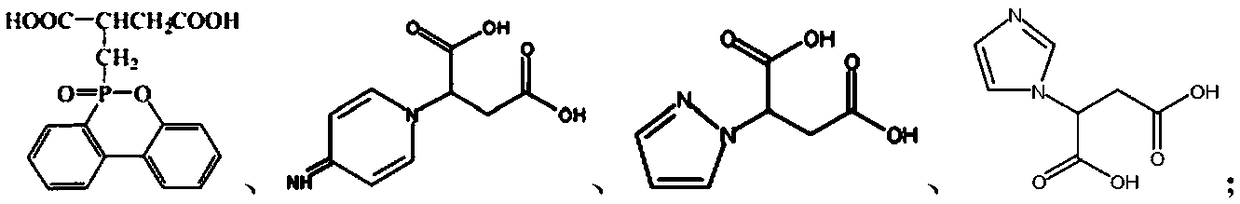

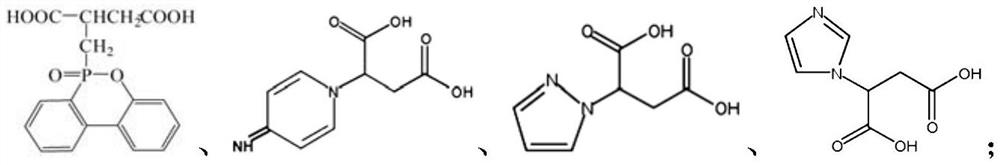

Insoluble infusible metal-modified cross-shaped esterified product and preparation method thereof

ActiveCN109749103AAvoid the defects of being easily soluble in organic solventsSolve solubilitySolubilityCross-link

The invention relates to an insoluble infusible metal-modified cross-shaped esterified product and a preparation method thereof. The insoluble infusible metal-modified cross-shaped esterified productis prepared by dripping a metal acetate solution into the cross-shaped esterified product solution, wherein the prepared metal-modified cross-shaped esterified product is a network polymer formed by cross-linking the cross-shaped esterified product and metal ions; the metal-modified cross-shaped esterified product has the characteristic of insolubility and infusibility, is insoluble in an organicsolvent I below 80 DEG C, and does not melt in the range of room temperature to T, wherein the T > / = 380 DEG C, and the organic solvent I is an aromatic hydrocarbon solvent, an aliphatic hydrocarbon solvent, an alicyclic hydrocarbon solvent, a halogenated hydrocarbon solvent, an alcohol solvent, an ester solvent, a ketone solvent, acetonitrile, pyridine, phenol, N, N-dimethylformamide or N, N-dimethylacetamide. The preparation method has simple process and low cost; the prepare product has the characteristics of insolubility and infusibility, and solves the problems of high solubility and lowmelting point of the existing functional cross-shaped esterified product.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com