Extrusion and heating integrated device for chocolate printer

A printer and chocolate technology, applied in the field of food 3D printing, can solve the problems of complex installation, chocolate slurry drawing, high cost, etc., and achieve the effects of ensuring rheological properties, alleviating drawing salivation, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

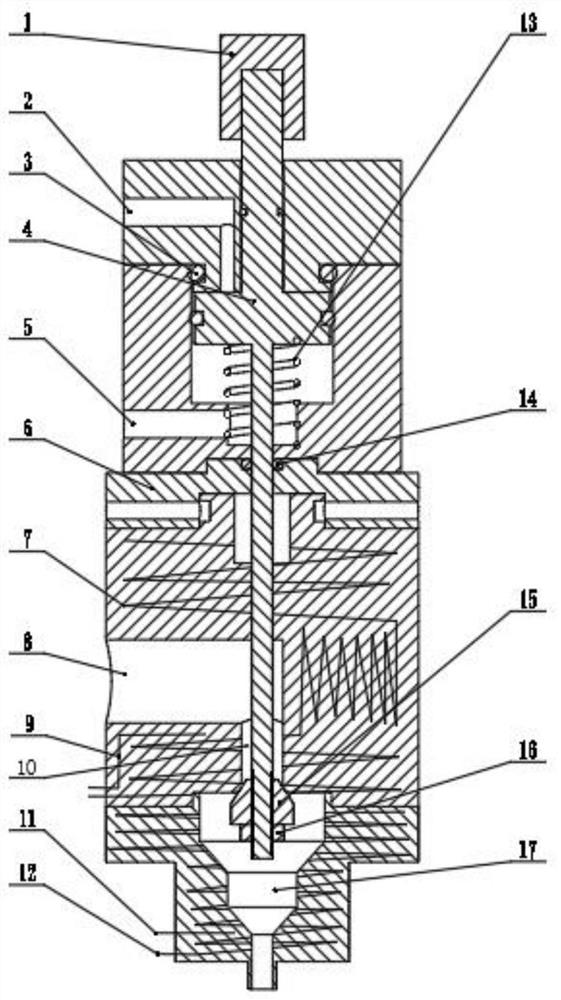

[0025] An integrated extruding and heating device for a chocolate printer is innovative in that it includes a pneumatic actuator and a slurry extruding mechanism that are sequentially connected from top to bottom.

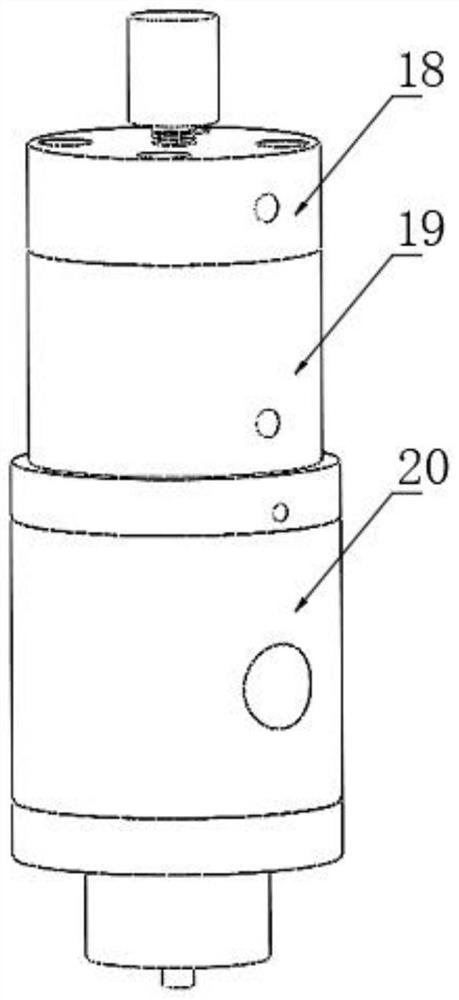

[0026] The pneumatic actuator includes a first pneumatic actuator block 18 and a second pneumatic actuator block 19. The first pneumatic actuator block 18 is provided with a first air hole 2 laterally, and the second pneumatic actuator block 19 is provided with a second air hole 5 laterally. The center of the pneumatic actuator block 18 and the second pneumatic actuator block 19 is coaxially provided with a variable-diameter pneumatic actuator rod 4, and the top end of the variable-diameter pneumatic actuator rod 4 protrudes from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com