Application of modified rice bran oil in preparation of tire rubber material, rubber composition and tire

A technology of rubber composition and rice bran oil, which is applied to the application of modified rice bran oil in the preparation of tire rubber and the field of rubber composition and tires, can solve the problems of rubber rheology and the influence of physical and mechanical properties, and achieve the guarantee Effects of rheological properties, excellent low-temperature performance, and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

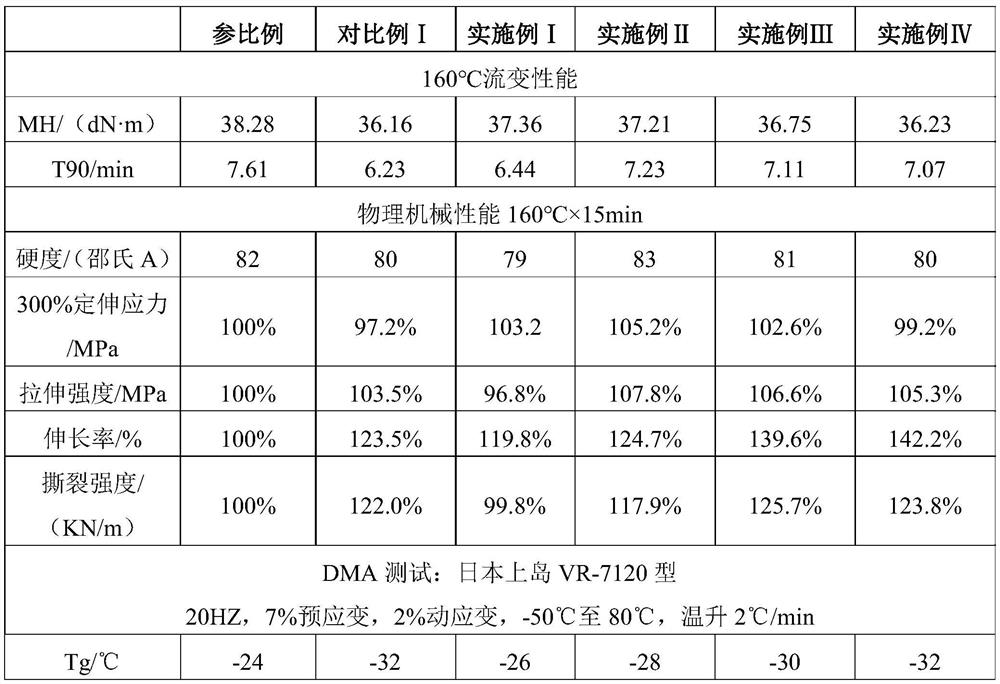

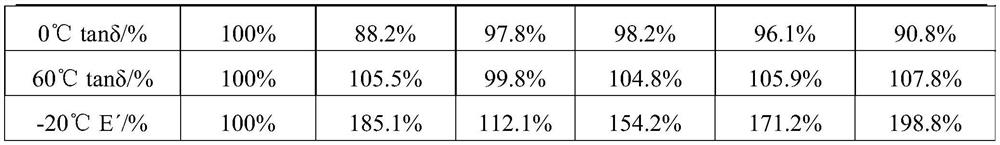

Examples

Embodiment

[0033] Composition of raw materials: 70.0 parts of solution polystyrene butadiene rubber, 30.0 parts of butadiene rubber, 80.0 parts of precipitated silica, 24.0 parts of modified rice bran oil, 6.4 parts of silane coupling agent, 3.0 parts of zinc oxide, 2.0 parts of stearic acid , 1.0 parts of anti-aging agent TMQ, 1.5 parts of anti-aging agent 6PPD, 1.5 parts of microcrystalline wax, 1.5 parts of accelerator CZ, 2.0 parts of accelerator DPG, 0.2 parts of accelerator TBzTD, 2.0 parts of sulfur. The modified rice bran oil is modified with 5 parts by weight of sulfur at a temperature above 130° C. for 2.5 hours.

[0034] Among them, solution-polymerized styrene-butadiene rubber, HPR355, JSR Corporation; butadiene rubber, BR9000, PetroChina Daqing Petrochemical Company; precipitated silica, 1165MP, Solvay; the rest of the raw materials are commercially available industrial grade raw materials.

[0035] Example IV

[0036] Raw material composition: 70.0 parts of solution polyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com