A kind of production method of bus duct bridge frame

A production method and busway technology, applied in the field of busway bridges, can solve problems such as high brittleness, heavy overall weight, corrosion of busway bridges, etc., increase elongation at break and yield strength, eliminate melt defects and product shrinkage effect of improving crystallinity and crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

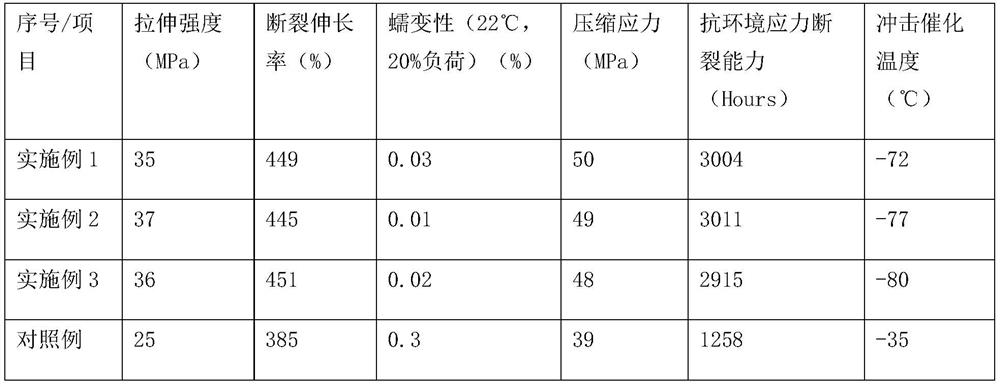

Examples

Embodiment 1

[0017] A production method of a busway bridge, the method is as follows:

[0018] (1) 72 parts of high-density polyethylene and 43 parts of medium-density polyethylene are taken in parts by mass and placed in a reactor to stir evenly, then 22 parts of cross-linking agent and 6 parts of initiator are added to carry out cross-linking modification, the described The crosslinking agent is triallyl isocyanurate and aniline methyl trimethoxysilane in a mass ratio of 1:1, the initiator is dicumyl peroxide, and the reaction temperature of the crosslinking modification is 200 ℃, the reaction time is 2h;

[0019] Then put 2 parts of catalyzers, 11 parts of maleic anhydride, and 5 parts of polymerization inhibitors in an open mill to carry out the melt graft polymerization reaction, the catalyzer is dibutyltin dilaurate, and the polymerization inhibitor is an inhibitor. Polymerization agent 510, the reaction temperature of the melt graft polymerization reaction is 205 ℃, and the reactio...

Embodiment 2

[0023] A production method of a busway bridge, the method is as follows:

[0024] (1) 62 parts of high-density polyethylene and 39 parts of medium-density polyethylene are taken by mass and placed in a reaction kettle and stirred evenly, then 23 parts of cross-linking agent and 5 parts of initiator are added to carry out cross-linking modification, the described The cross-linking agent is vinyl tributanone oximo silane and aniline methyl trimethoxy silane mixed in a mass ratio of 1:1, the initiator is dicumyl peroxide, and the reaction temperature of the cross-linking modification is 202℃, the reaction time is 3h;

[0025] Then place in open mill and add 2 parts of catalysts, 9 parts of maleic anhydride and 4 parts of polymerization inhibitors to carry out the melt graft polymerization reaction, the catalyst is dibutyl tin dilaurate, and the polymerization inhibitor is an inhibitor. Polymerization agent 701, the reaction temperature of the melt graft polymerization reaction i...

Embodiment 3

[0029] A production method of a busway bridge, the method is as follows:

[0030] (1) Count 74 parts of high-density polyethylene and 35 parts of medium-density polyethylene by mass and place them in a reaction kettle and stir evenly, then add 20 parts of cross-linking agent and 6 parts of initiator to carry out cross-linking modification, the described The cross-linking agent is triallyl isocyanurate, vinyl tributyl ketoximo silane and anilinomethyl trimethoxy silane in a mass ratio of 1:1:1, and the initiator is peroxide Cumene, the reaction temperature of crosslinking modification is 195℃, and the reaction time is 3h;

[0031] Then put 2 parts of catalyzers, 11 parts of maleic anhydride, and 5 parts of polymerization inhibitors in an open mill to carry out the melt graft polymerization reaction, the catalyzer is dibutyltin dilaurate, and the polymerization inhibitor is an inhibitor. The polymerization agent MZTQ, the reaction temperature of the melt graft polymerization re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com