Method for controlling homogeneity of fluorescent-whitened polyester staple fiber product

A polyester staple fiber, fluorescent whitening technology, applied in rayon manufacturing, textile and papermaking, fiber chemical characteristics, etc., can solve unevenness, product appearance whiteness and physical property deviation, and affect the dispersion performance of fluorescent whitening active ingredients And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

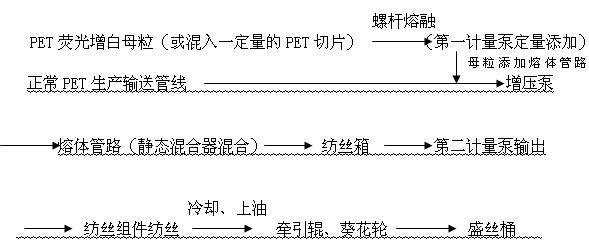

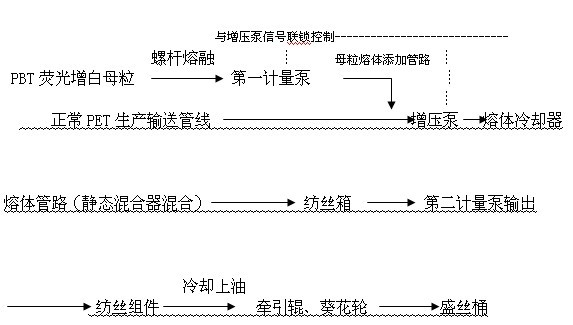

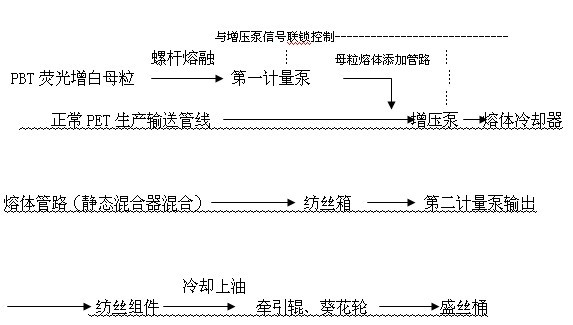

[0023] see figure 2 , figure 2 It is a process flow chart of the method for controlling the uniformity of fluorescent whitening polyester staple fiber products of the present invention. Depend on figure 2 As can be seen, the method for controlling the homogeneity of fluorescent whitening polyester staple fiber products of the present invention, said method comprises the following processes:

[0024] The PBT fluorescent whitening masterbatch is melted and extruded by a screw extruder to obtain a PBT fluorescent whitening masterbatch melt, and the PBT fluorescent whitening masterbatch melt is quantitatively added to the normal The PET melt in the PET production pipeline is pressurized by the booster pump and then enters the melt cooler to cool to the normal spinning temperature (286-292°C), then enters the melt pipeline, and is mixed by a static mixer on the melt pipeline , to make a blended melt of PBT fluorescent whitening masterbatch and PET, the blended melt enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com