A metering control system

A technology of control system and metering pump, which is applied in the direction of feeding solution to the spinneret, etc., can solve the problem of inability to ensure the measurement accuracy of color masterbatch, and achieve the effect of eliminating asynchronous addition, stable addition ratio and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

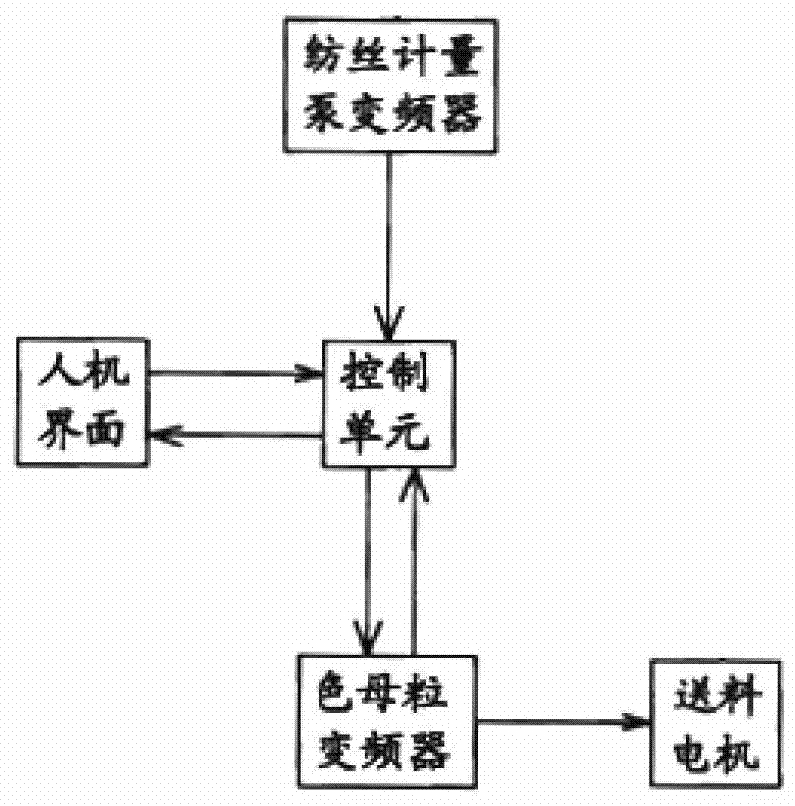

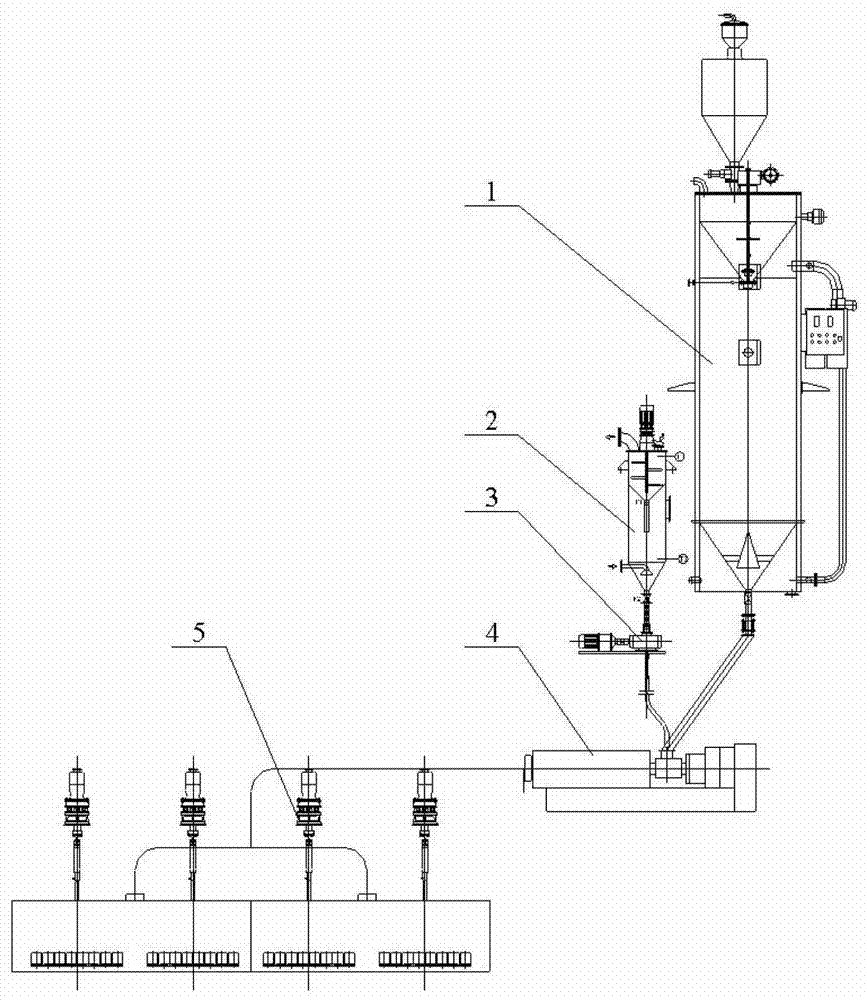

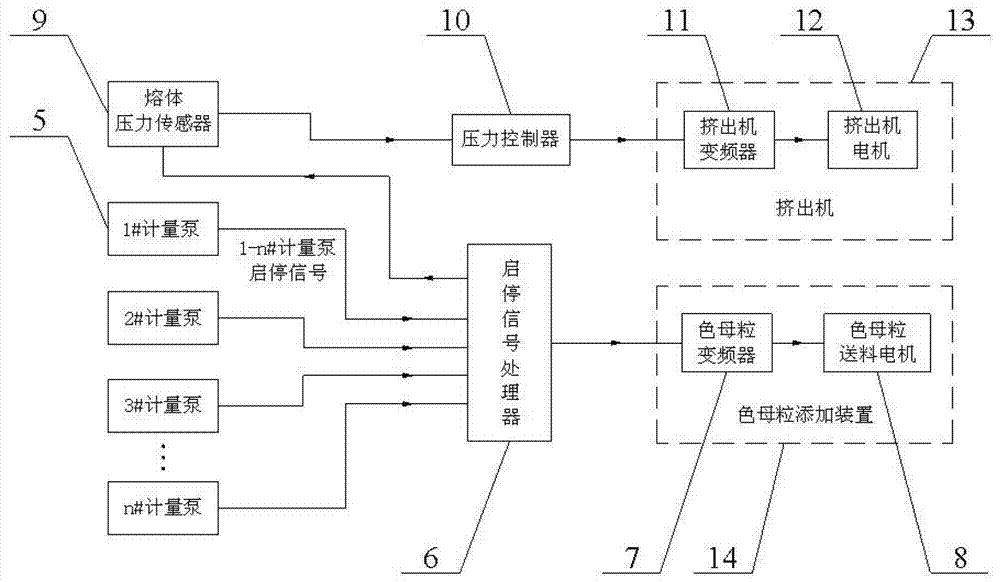

[0023] combine figure 2 with image 3 Illustrate the working principle of the metering and adding system of the color masterbatch of the present invention. In the production process of producing polyester colored filaments, the main material and the color masterbatch are dried respectively through the main material dryer 1 and the color masterbatch dryer 2. After being metered by the masterbatch metering device 3, the processed color masterbatch is mixed with the main material according to a certain ratio, and is squeezed and melted by the extruder 4 and then enters the metering pump 5. Since one main material dryer 1 and one masterbatch dryer 2 need to supply multiple metering pumps 5 to work, in order to ensure that the addition ratio of color masterbatch in each metering pump 5 is consistent, when a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com