Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Guaranteed reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

InactiveCN101699187AEasy to handleReduced compression energy consumptionExothermal chemical reaction heat productionCarbon compoundsCycloneEngineering

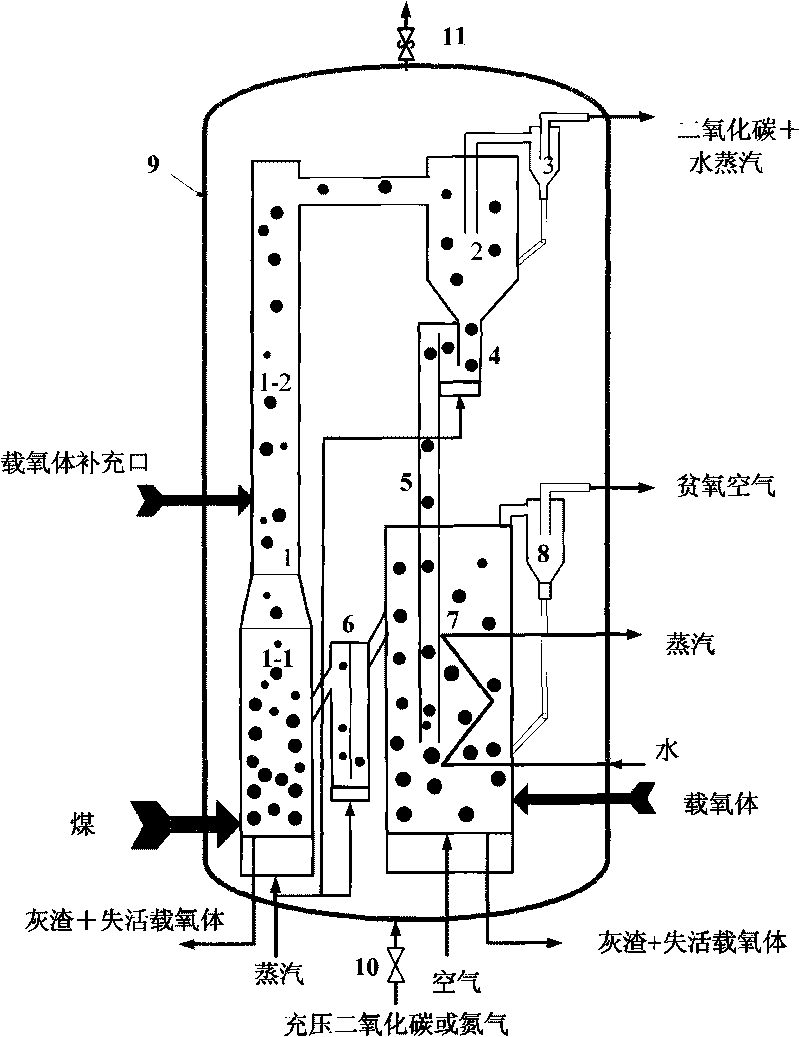

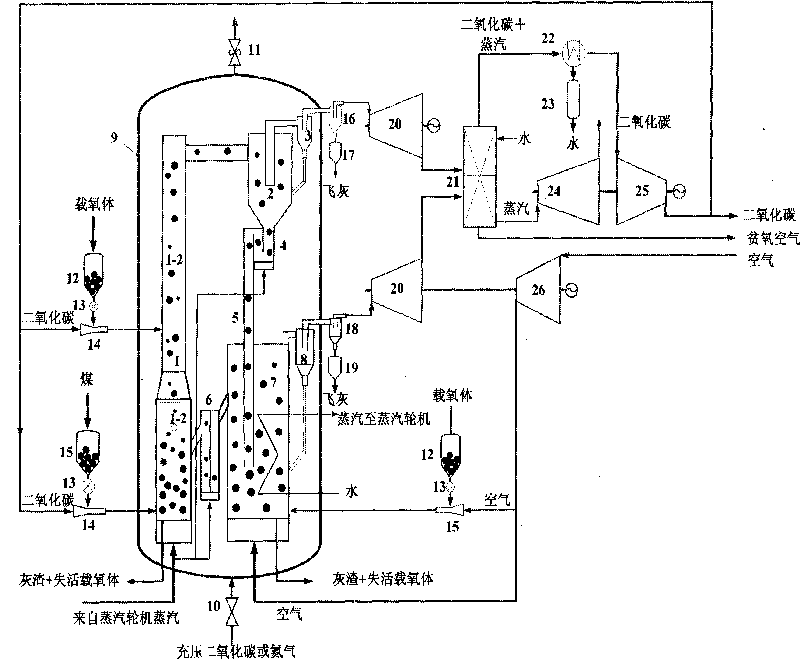

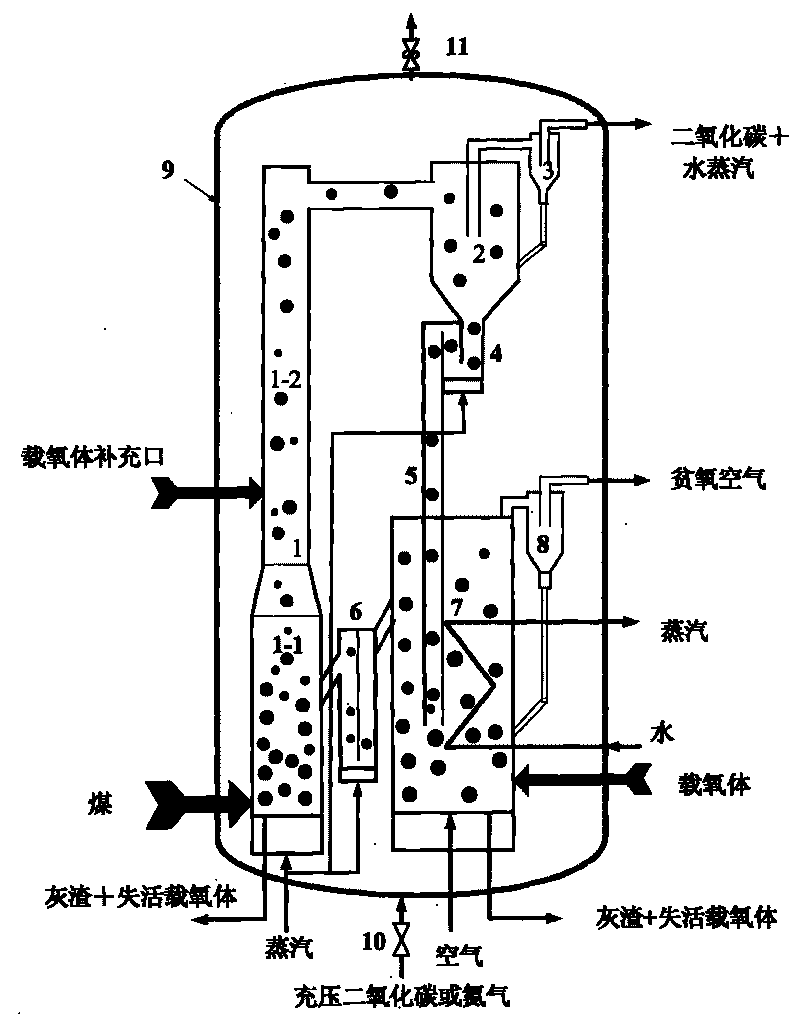

The invention provides a coal combustion apparatus capable of separating carbon dioxide, which is mainly formed by connecting a fuel reactor, a primary cyclone separator, a dipleg and an air reactor in series; wherein the lower part of the fuel reactor is provided with a mixing chamber with large cross section, and the upper part thereof is provided with a lifting tube with small cross section; and the height of the lifting tube is over three times higher than that of the mixing chamber. The invention also provides a method using the coal combustion apparatus capable of separating the carbon dioxide to separate the carbon dioxide. The fuel reactor adopts the structure of a reactor with long residence time, internal circulation can be formed by granules, and the gas-solid turbulence is improved; the air reactor adopts a moving fluidized bed to ensure the operation to be stable, so that the heat can be evenly released; meanwhile, a heat exchanger is arranged inside the bed, so that coking caused by local overheating since a great deal of heat is released in a centralized way in oxidation reaction can be avoided. Furthermore, the fuel reactor and the air reactor run under the pressure, so that the equipment can be compact, the utilization efficiency of system energy is high, and the subsequent carbon dioxide compression energy consumption is reduced.

Owner:SOUTHEAST UNIV

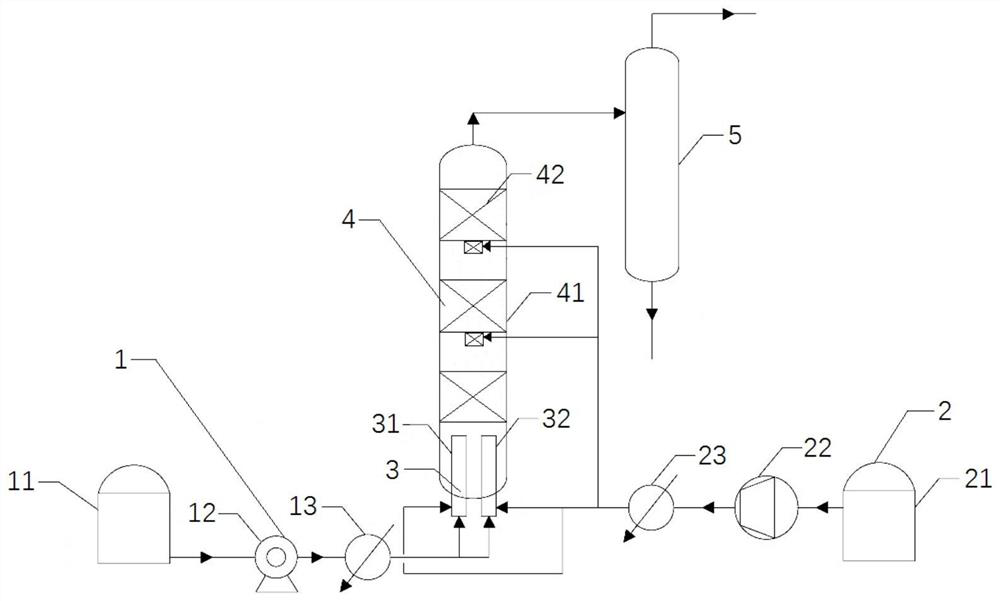

Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

InactiveCN101693581AGuaranteed reaction efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentWater qualityTherapeutic effect

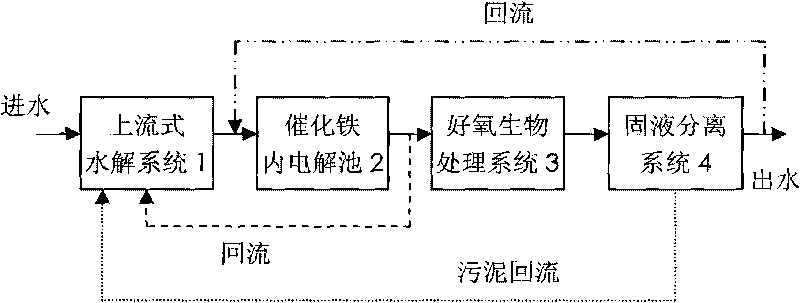

The invention pertains to the technical field of treatment of waste water, and particularly relates to a method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water, which comprises the following steps: waste water after primary treatment directly enters an up flow type hydrolysis system 1 and stays for 4.0-10.0 hours; the effluent enters an electrolytic cell in the catalytic iron; the mass ratio of iron scraps and copper scraps in the electrolytic cell of the catalytic iron is 1:1 to 20:1, the bulk specific weight thereof is 0.1 to 0.3, the contact time thereof in a filling area is 0.5 to 2.0 hours, and the reflux ratio of the effluent refluxing to the up flow type hydrolysis system is 20 to 100 percent; the effluent enters an aerobic biological treatment system and stays for 6.0 to 12.0 hours; then the effluent enters a solid-liquid separation system with a reflux ratio of sludge being 10 to 50 percent; and the effluent of the solid-liquid separation system refluxes to the electrolytic cell of the catalytic iron with the reflux ratio being 20 to 200 percent. Under the premise of fully playing the function of different treatment units and maintaining the treatment effect and respective advantages, the treatment method of waste water realizes the coupling synergetic action of the three units, strengthens the impact of the system to water quality and water quantity load, reduces a plurality of steps of pretreatment, effectively improves the removal rate of ammonia nitrogen, and can be flexibly adjusted.

Owner:TONGJI UNIV +1

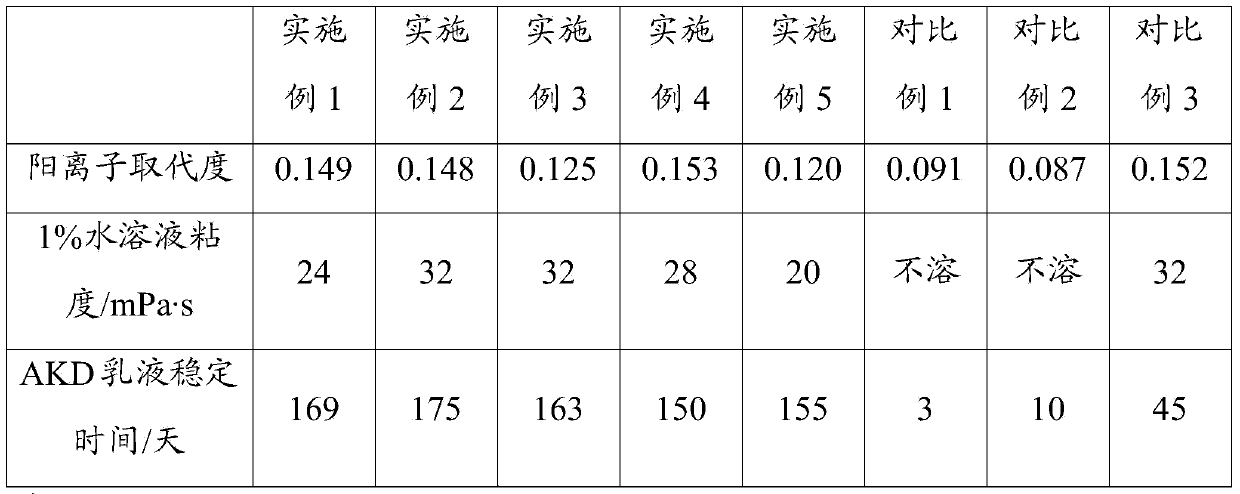

Cationic starch as well as preparation method and application of cationic starch

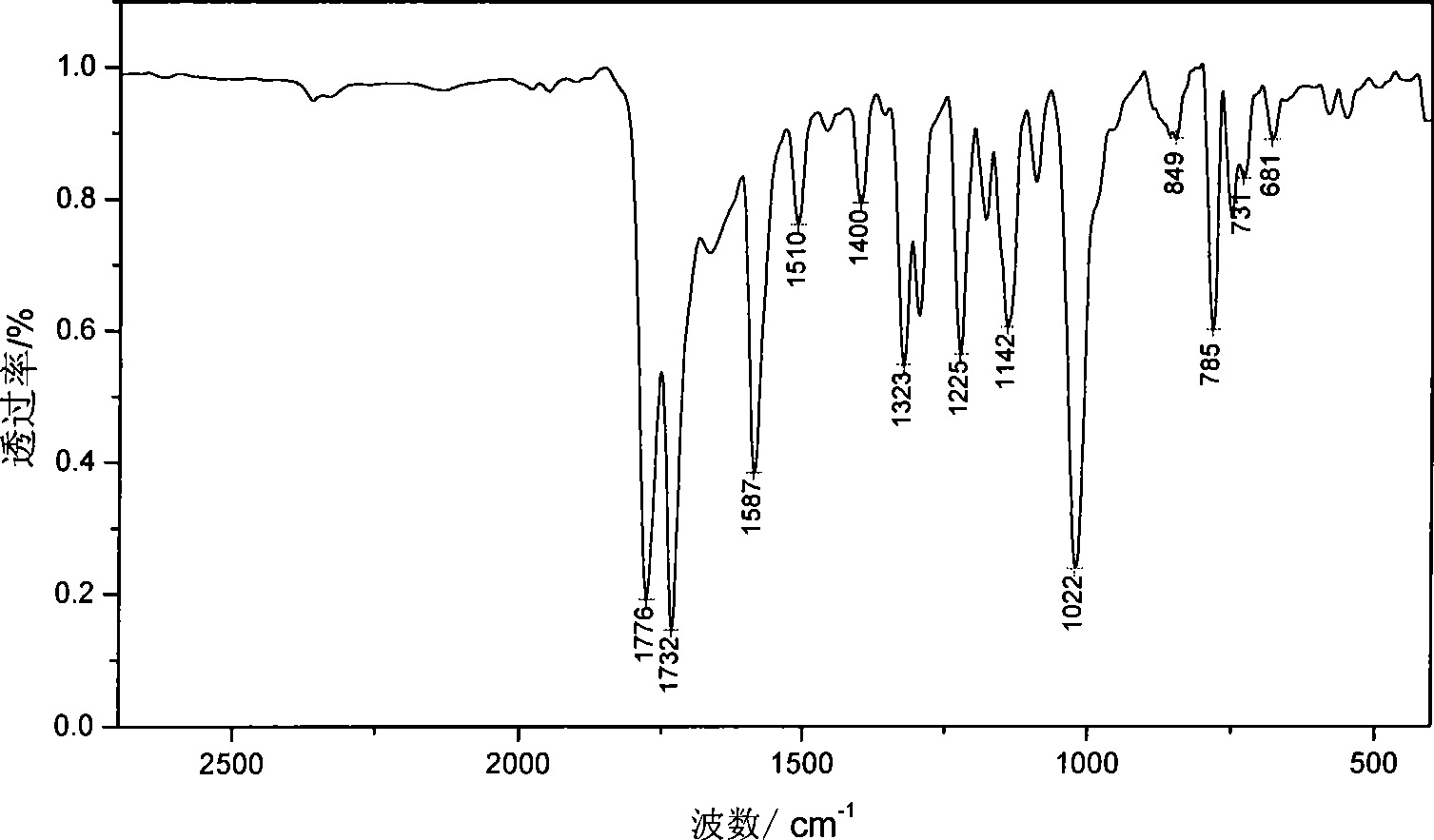

ActiveCN104193839AHigh degree of cationic substitutionImprove emulsion stabilityWater-repelling agents additionPaper coatingOrganic solventAqueous solution

The invention discloses a cationic starch as well as a preparation method and application of the cationic starch. The preparation method comprises the steps of (1) mixing starch and a water solution of 50-90% of organic solvent, and then, placing the mixture into a reaction vessel; (2) adding a catalyst, stirring and heating to 50-90 DEG C; (3) adding an etherifying agent, and reacting for 1-5h; (4) adding an oxidant, and reacting for 10-60 minutes; (5) adding acid until the pH value of the reaction system is up to 4-7; and (6) carrying out vacuum drying at the temperature of 50-90 DEG C and the vacuum degree of 0.07-0.1MPa to obtain the cationic starch. If the cationic starch obtained by using the preparation method disclosed by the invention is used as an AKD (Alkyl Ketene Dimer) emulsifier, the stability time of the AKD emulsifier at normal temperature can exceed three months.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

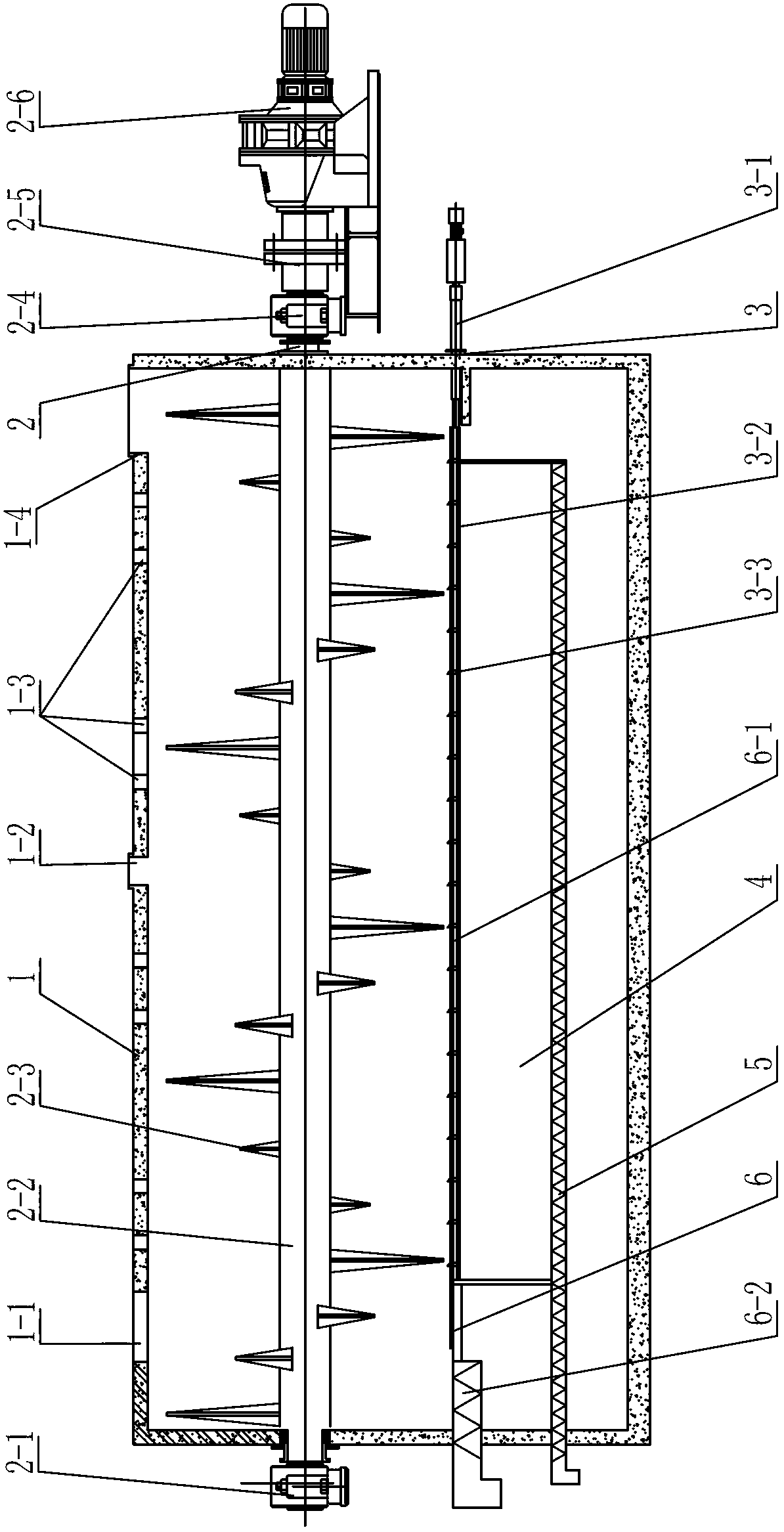

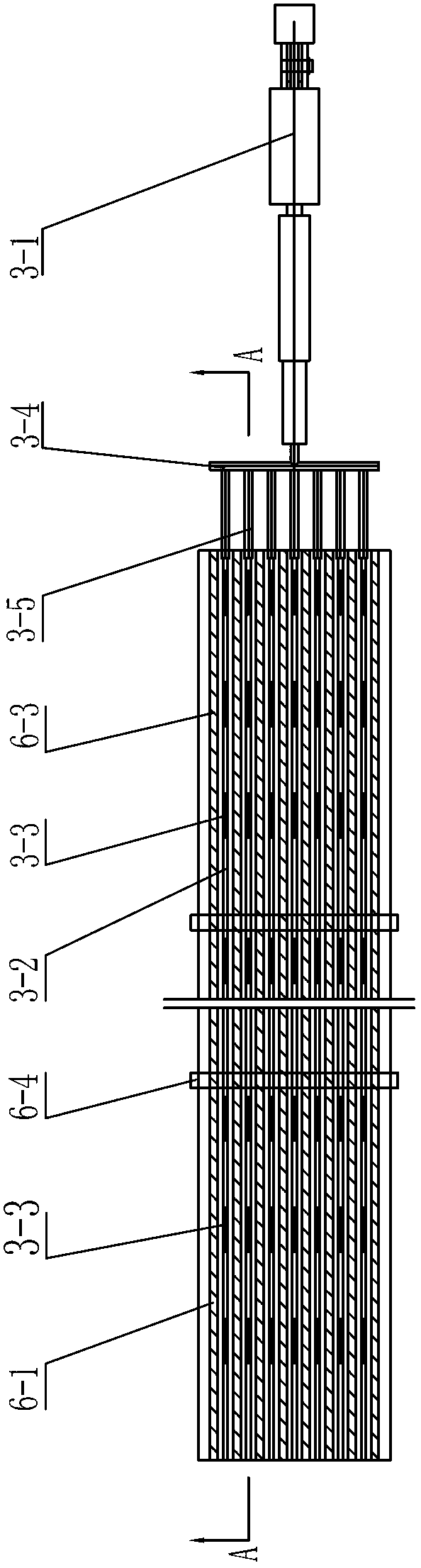

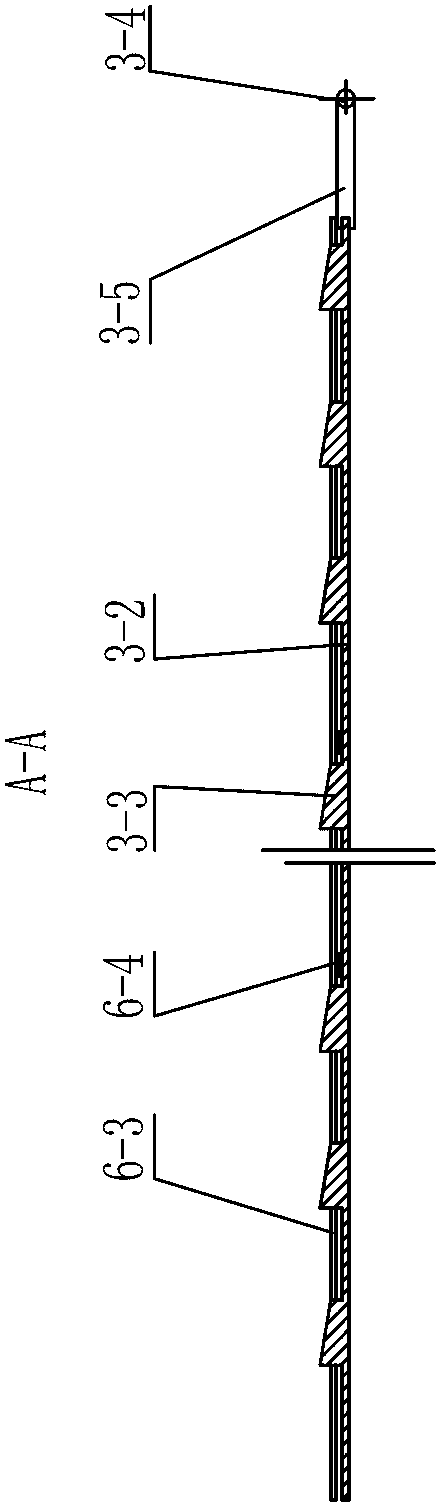

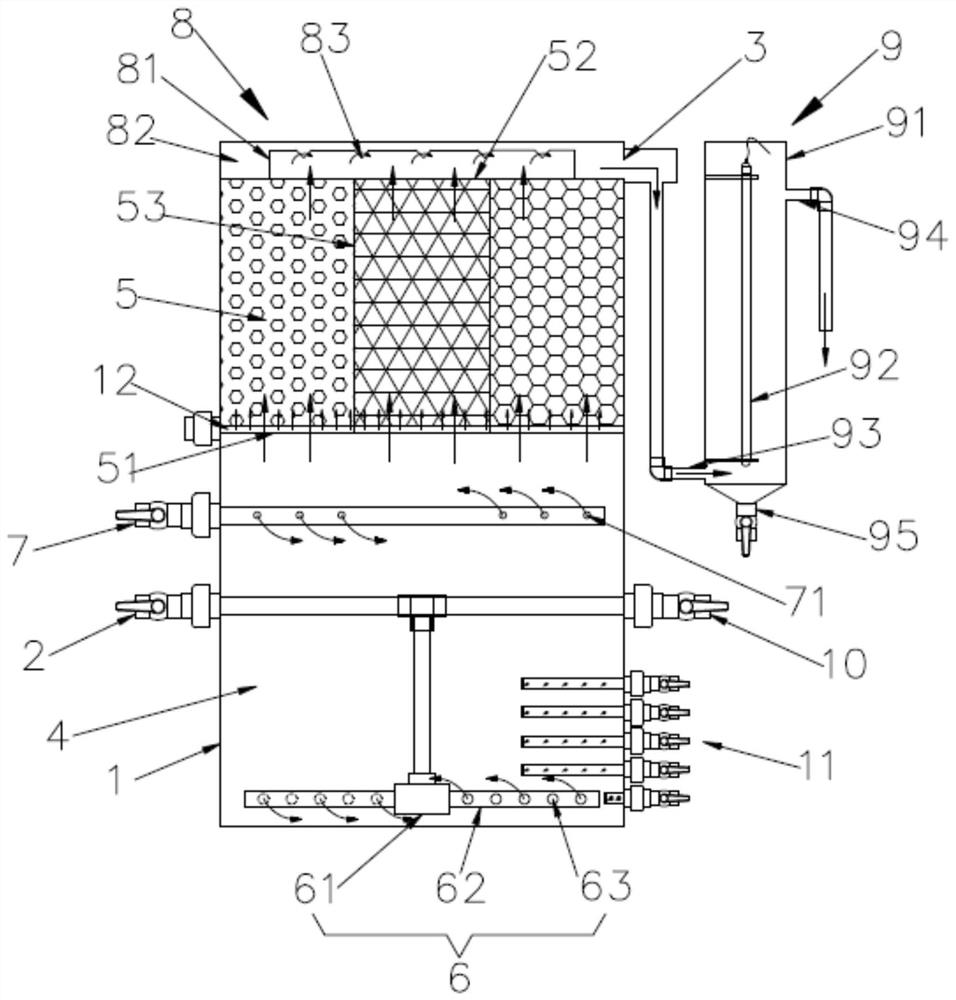

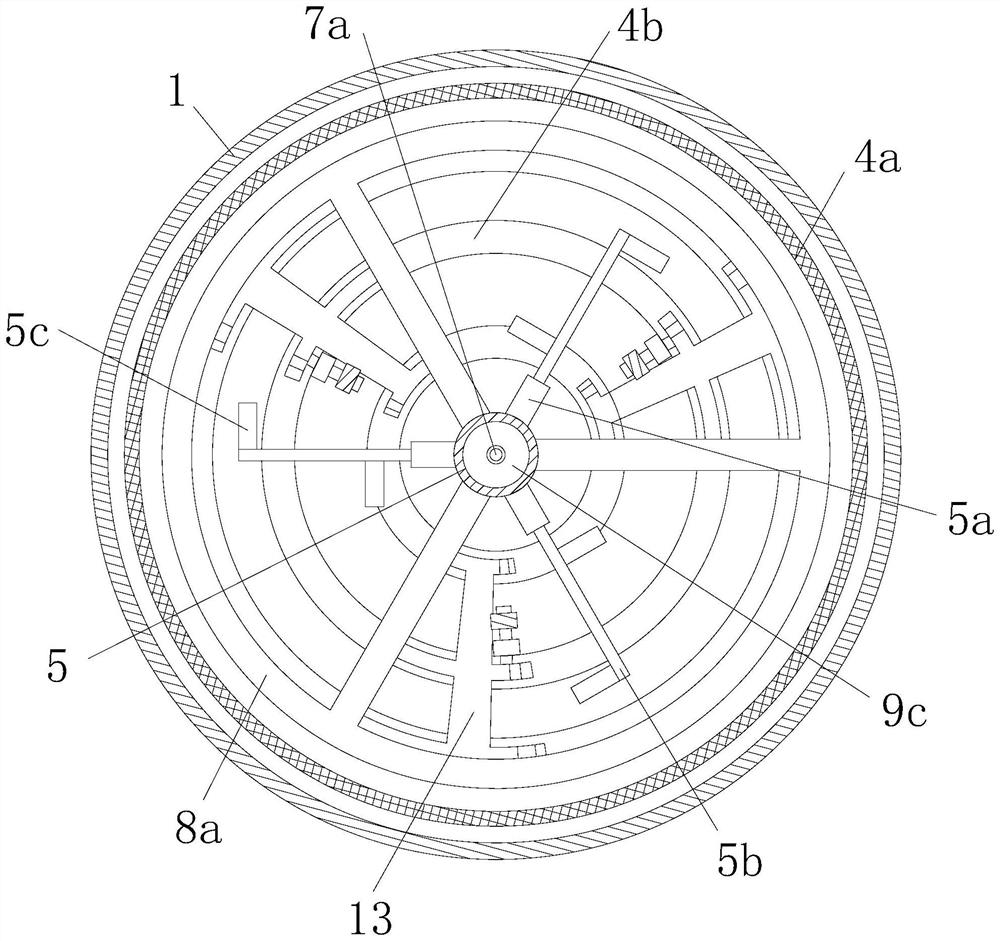

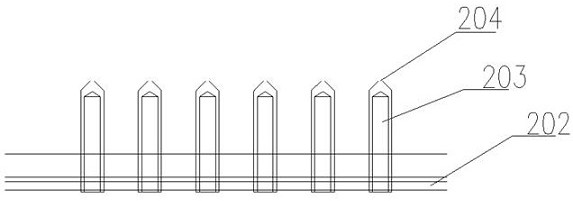

Leaching mechanical-biological reactor for treating household garbage

The invention relates to a leaching mechanical-biological reactor for treating household garbage. The leaching mechanical-biological reactor comprises a charging hole, a waste gas collecting hole and a liquid inlet box body, wherein a stirring mechanism, a filtering and deslagging mechanism, a grating clearing mechanism and a liquid collecting box are arranged in the box body; the filtering and deslagging mechanism comprises a grating set and a deslagging spiral feeder, wherein the grating set is connected with the box body; a connecting rod and more than three cutter bars are arranged on a blade supporting frame of the grating clearing mechanism; a drive shaft of a power driver arranged on the outer part of the box body extends into the box body and is connected with the blade supporting frame; more than three clearing blades on each cutter bar are arranged in a grating gap corresponding to the grating set and are higher than the end surfaces of grid bars; the liquid collecting box is arranged on the lower part of the box body; and the leaching spiral feeder is arranged on the bottom of the liquid collecting box. The leaching mechanical-biological reactor has a reasonable structure, a small volume, is stable in treatment, and can remove most of inorganic substances which are not easy to biodegrade; furthermore, the operation stability of the device can be improved; and moreover, when the organic substance serous fluid enters an anaerobic reactor, the treatment efficiency of the anaerobic reactor can be ensured.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

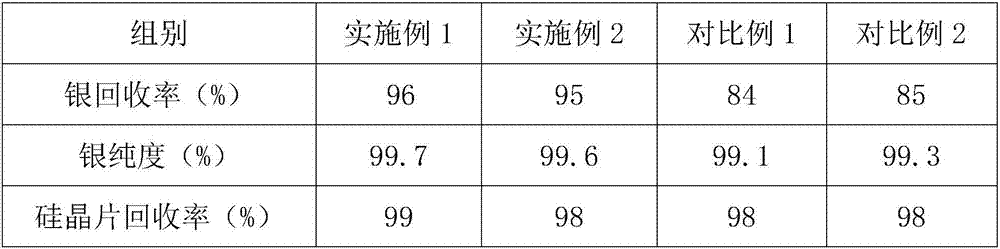

Waste battery piece recycling process

InactiveCN107321766AHigh economic valueReduce manufacturing costWaste processingSolid waste disposalProduction lineHydrofluoric acid

A waste battery piece recycling process includes the following steps that an aluminum layer is removed, a silver layer is removed, silver powder is recycled, a silicon nitride layer is removed, and a pure silicon wafer is recycled. The waste battery piece recycling process is provided in the invention, alkali liquor and a hydrofluoric acid solution which are used are both discarded liquor discharged by a solar battery production line, further use is conducted, the production cost is reduced, and meanwhile the optimal temperature of the reaction in each step is regulated and controlled. Utilization of energy can also be considered on the premise of ensuring efficiency, the recycled silver powder and the recycled silicon wafer have very high economic value, the recycling rate of silicon of the recycled silicon wafer reaches 99% or above, and the recycling rate of silver can also reach 95% or above. These materials can be used for manufacturing silicon wafer batteries again, the production cost is reduced, environment friendliness is achieved, pollution is little, and the waste battery piece recycling process has very high popularization value.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

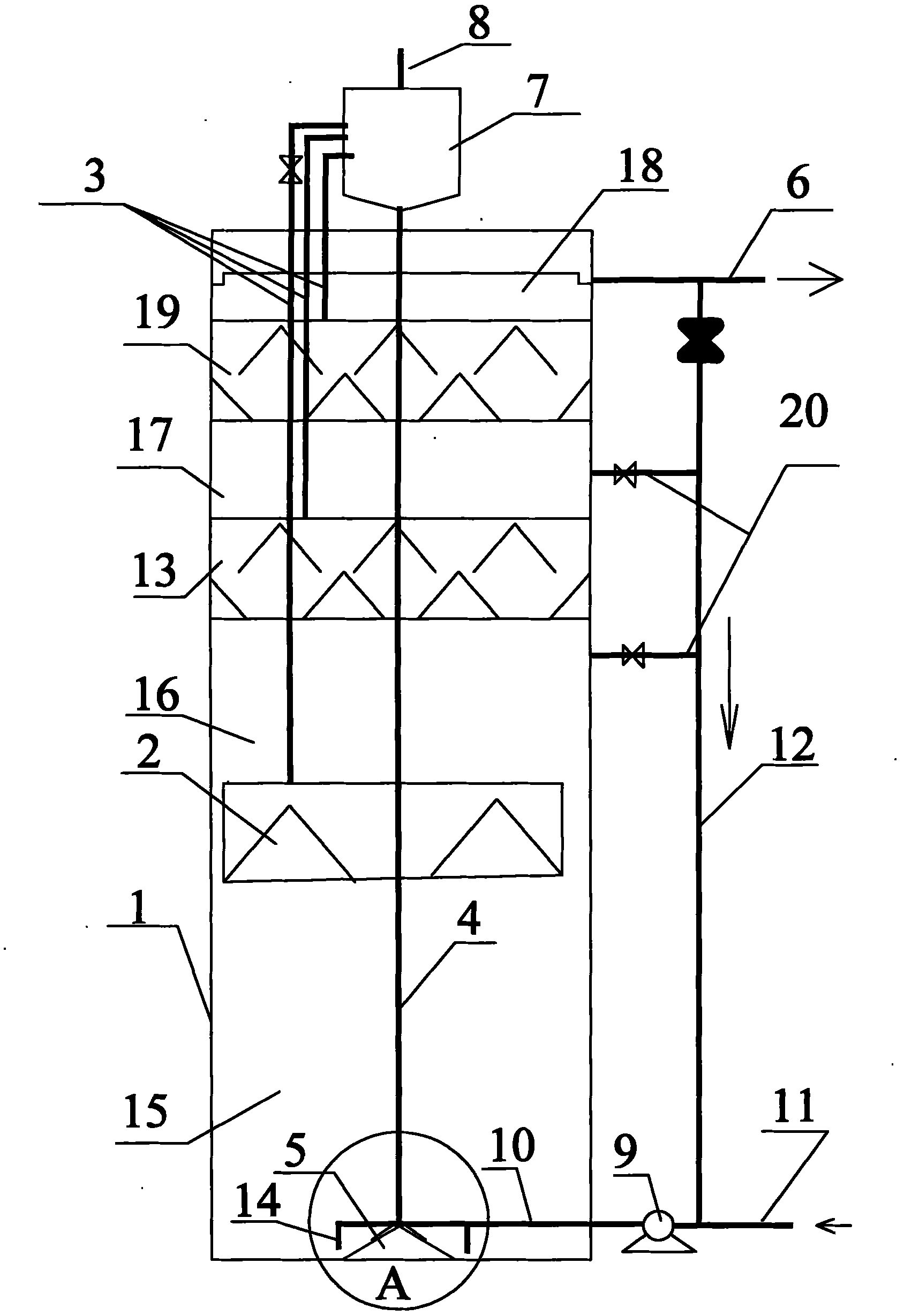

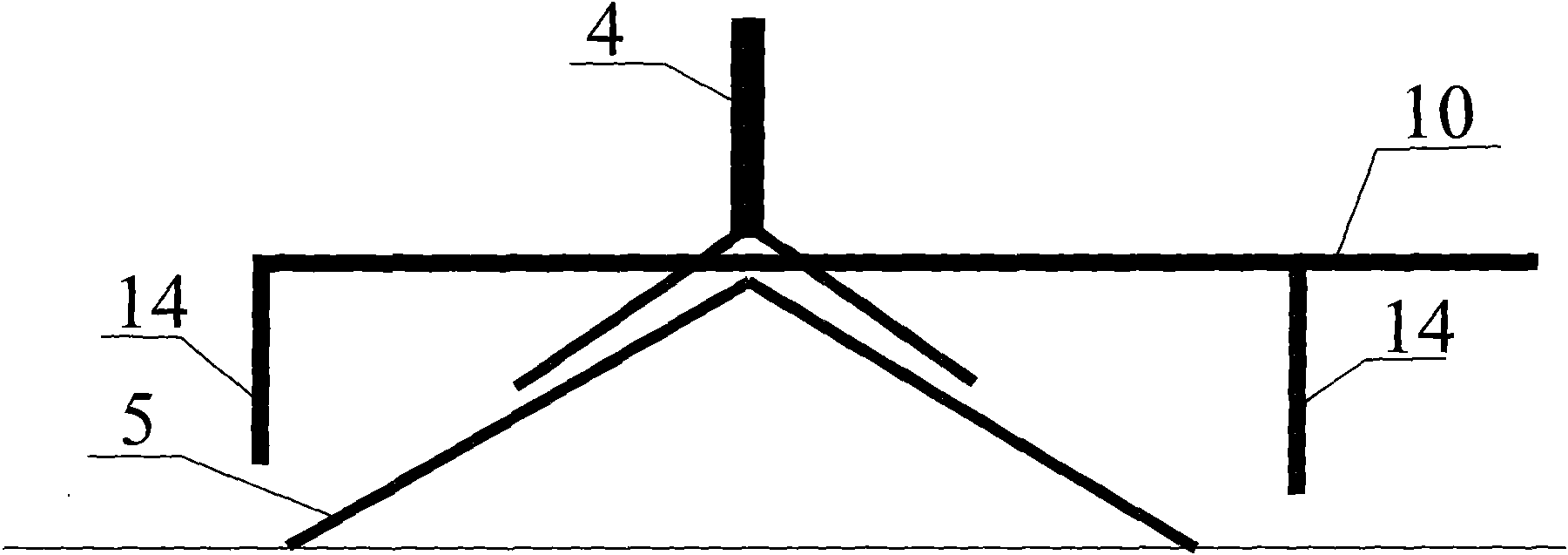

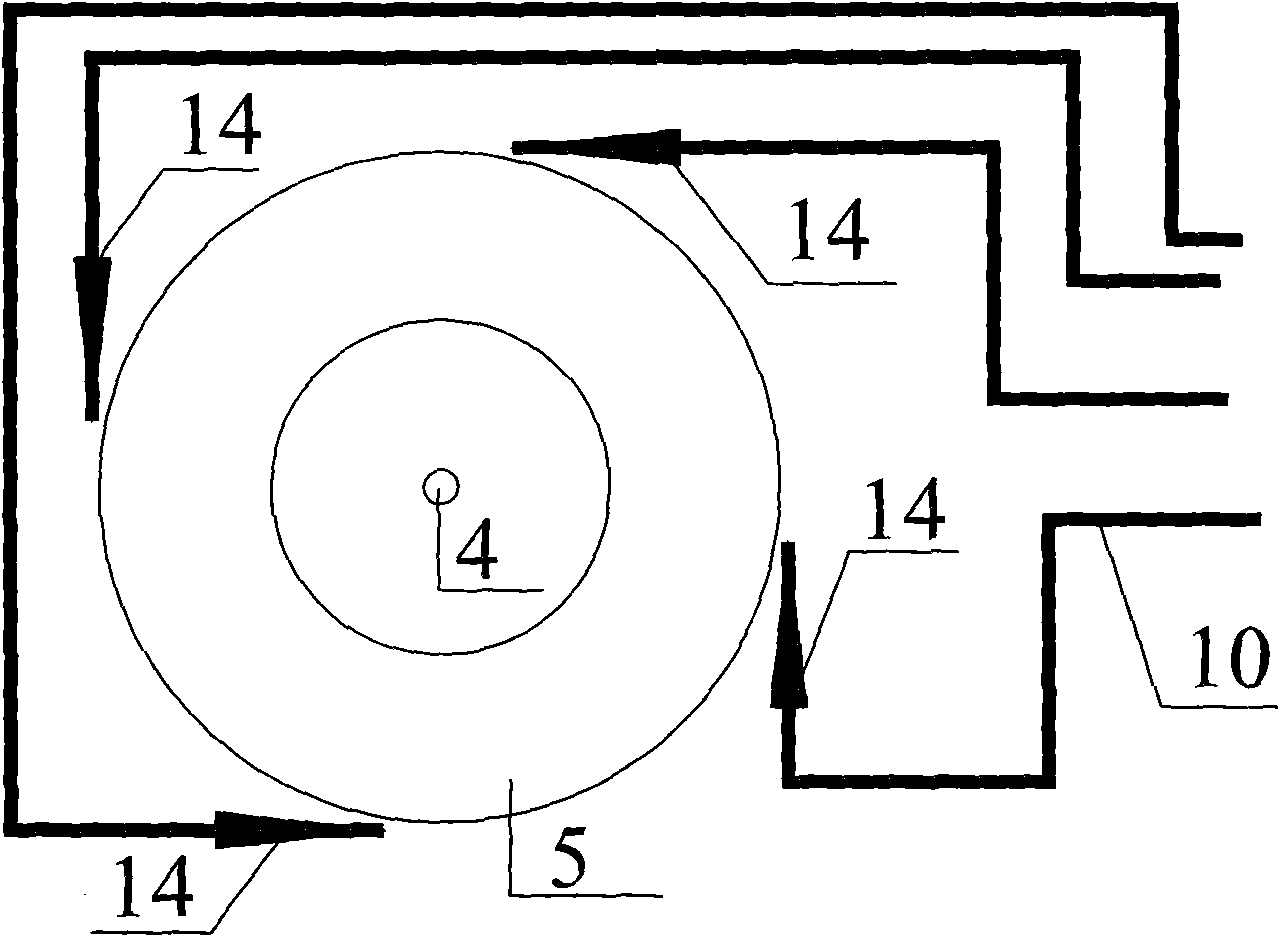

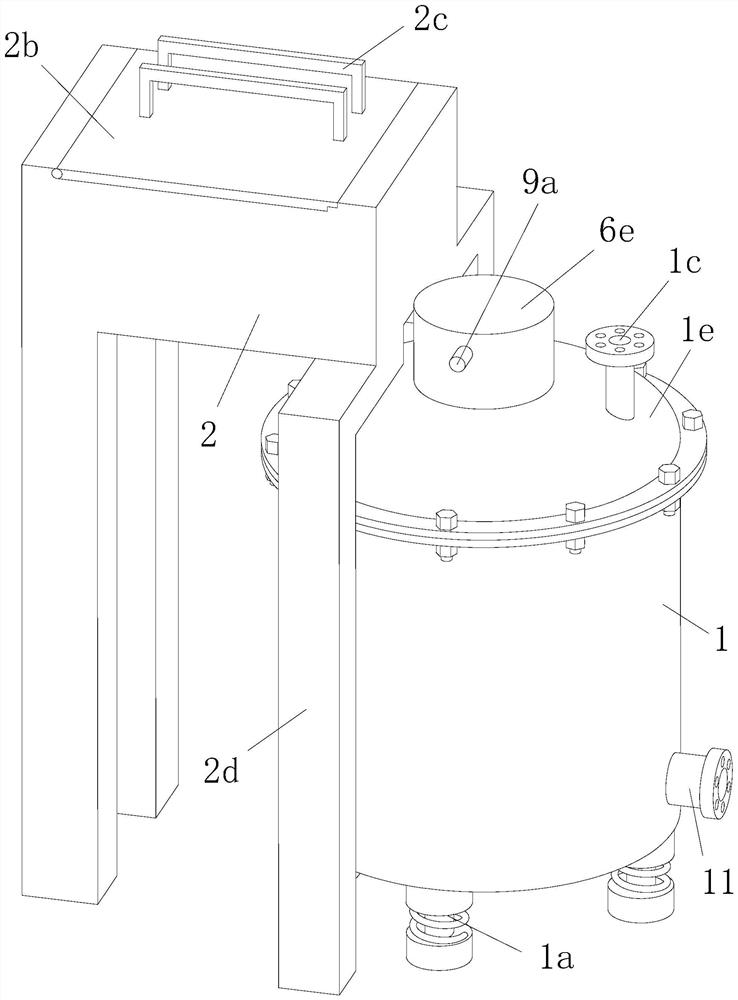

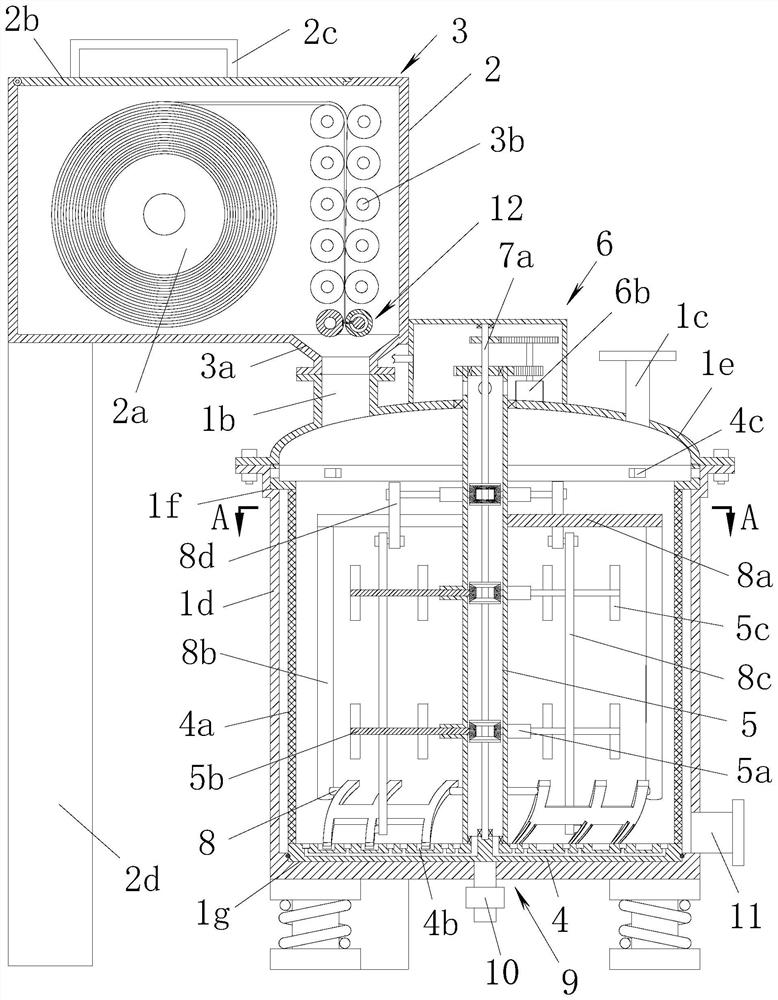

Multistage recirculation reactor for anaerobic sludge

InactiveCN102139955AIncrease contact areaWell mixedTreatment with anaerobic digestion processesGuidance systemReflux

The invention relates to a sewage treatment device, in particular relates to a multistage recirculation reactor for anaerobic sludge. The whole reactor is divided into a precipitation zone, an upper reaction zone, a middle reaction zone and a lower reaction zone through an upper three-phase separator, a middle three-phase separator and a lower gas collector which are successively arranged inside the reactor from up to down; the bottom of a gas-liquid separation tank is connected with an inner reflux circulation pipe which stretches to the bottom inside the reactor; the bottom inside the reactor is provided with an inner reflux liquid guiedvane and a water distribution pipe, wherein the inner reflux liquid guiedvane is corresponding to the outlet of the inner reflux circulation pipe, the effluent direction is tangent to the inner reflux liquid guiedvane, and the water distribution pipe is connected with a water inlet pipe II; the lower parts of the upper reaction zone and the middle reaction zone are respectively provided with an external duct; and the outside of the reactor is provided with an outer reflux circulation pipe which is respectively connected with a water outlet pipe, a water inlet pipe I and the external duct. By using the reactor, the external flow of sludge can be effectively prevented, and the sludge can be effectively mixed by utilizing inner and outer double steam guidance systems and the water distribution device.

Owner:SHANDONG JIANZHU UNIV

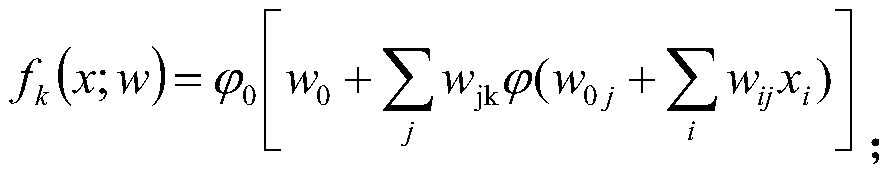

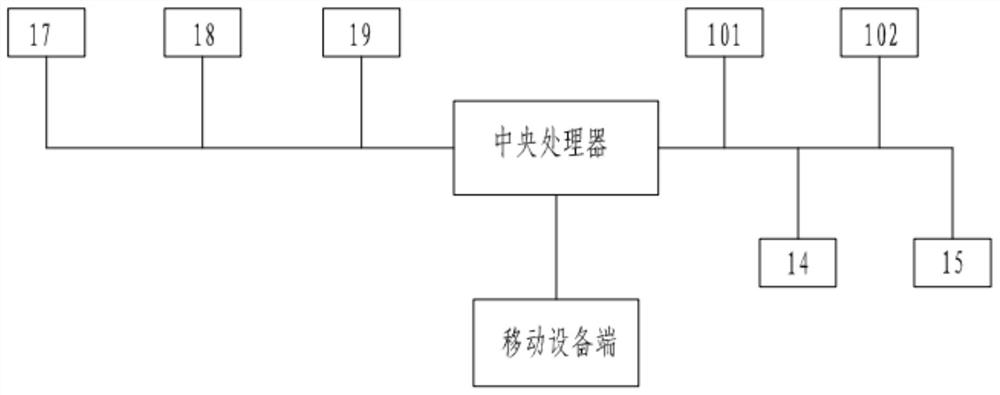

Wetland early warning method based on artificial intelligence and random adaptive threshold

ActiveCN111210128AWith adaptive adjustment functionGuaranteed reaction efficiencyClimate change adaptationNeural architecturesEarly warning systemNormal density

The invention discloses a wetland early warning method based on artificial intelligence and a random self-adaptive threshold, and the method builds a random self-adaptive parameter learning module through employing a loop iteration principle, and enables an early warning system to have a self-adaptive adjustment function. Numerous uncertainties faced by a wetland water system are considered, an uncertainty quantification theory (random) is applied to construction of a random adaptive threshold, concepts such as a normal threshold parameter probability density function (PDF) and a normal threshold parameter cumulative distribution density function (CDF) are used for quantifying random uncertainty, and an artificial intelligence algorithm is used for ensuring the reaction efficiency of real-time early warning. Residual analysis of the prediction data and the observation data is used as index data for monitoring the wetland ecological state, so that the early warning system is more sensitive; the introduction of Bayesian reduces the false alarm rate, and introduces the iterative early warning rate. Therefore, the accuracy of wetland health early warning is comprehensively improved.

Owner:GUANGDONG UNIV OF TECH

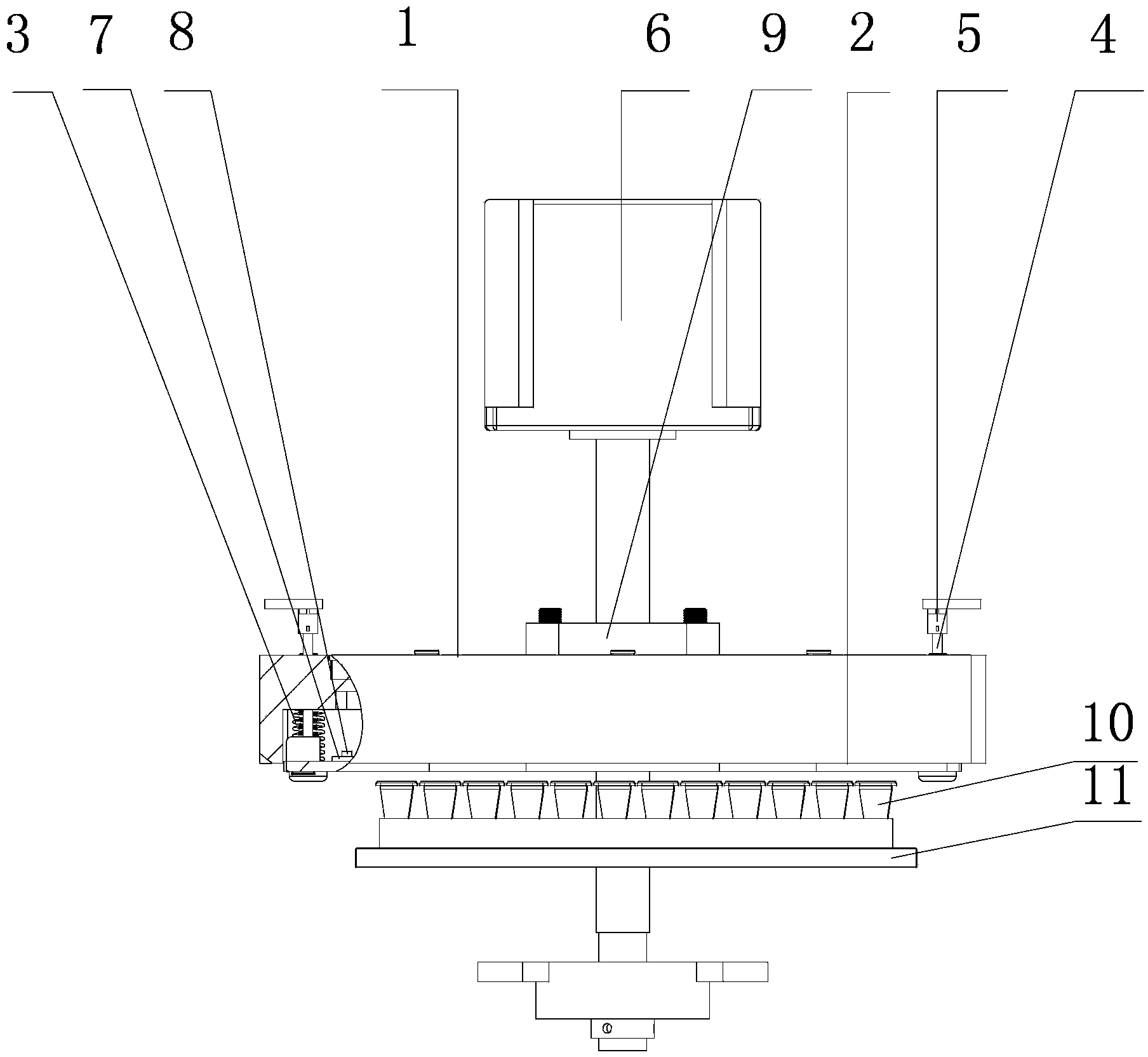

Thermal cover plate used in nucleic acid amplification detector

ActiveCN103725602AAccurate compensationControl consistencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNucleic acid

The invention relates to a thermal cover plate used in a nucleic acid amplification detector. The thermal cover plate comprises an upper cover plate and a lower press plate which are horizontally and oppositely arranged, wherein the upper cover plate and the lower press plate are fixedly connected through at least two springs; at least two probes are fixedly mounted on the lower press plate; displacement sensors capable of quantitatively measuring the displacement of the probes relative to the upper cover plate are fixedly mounted on the upper cover plate; the number of the displacement sensors is equal to that of the probes and the mounting positions of the displacement sensors correspond to those of the probes; at least one heating component and at least one temperature sensor which is capable of detecting the temperature of the lower press plate are fixedly mounted on the lower press plate. The problem that the nucleic acid reaction can be failed as the pressure cannot be controlled due to the fact that the conventional nucleic acid amplification detector is lack of a device which can accurately control the pressure is solved, and the pressure and the temperature can be accurately controlled.

Owner:CHANGZHOU FUSHENG BIOTECH

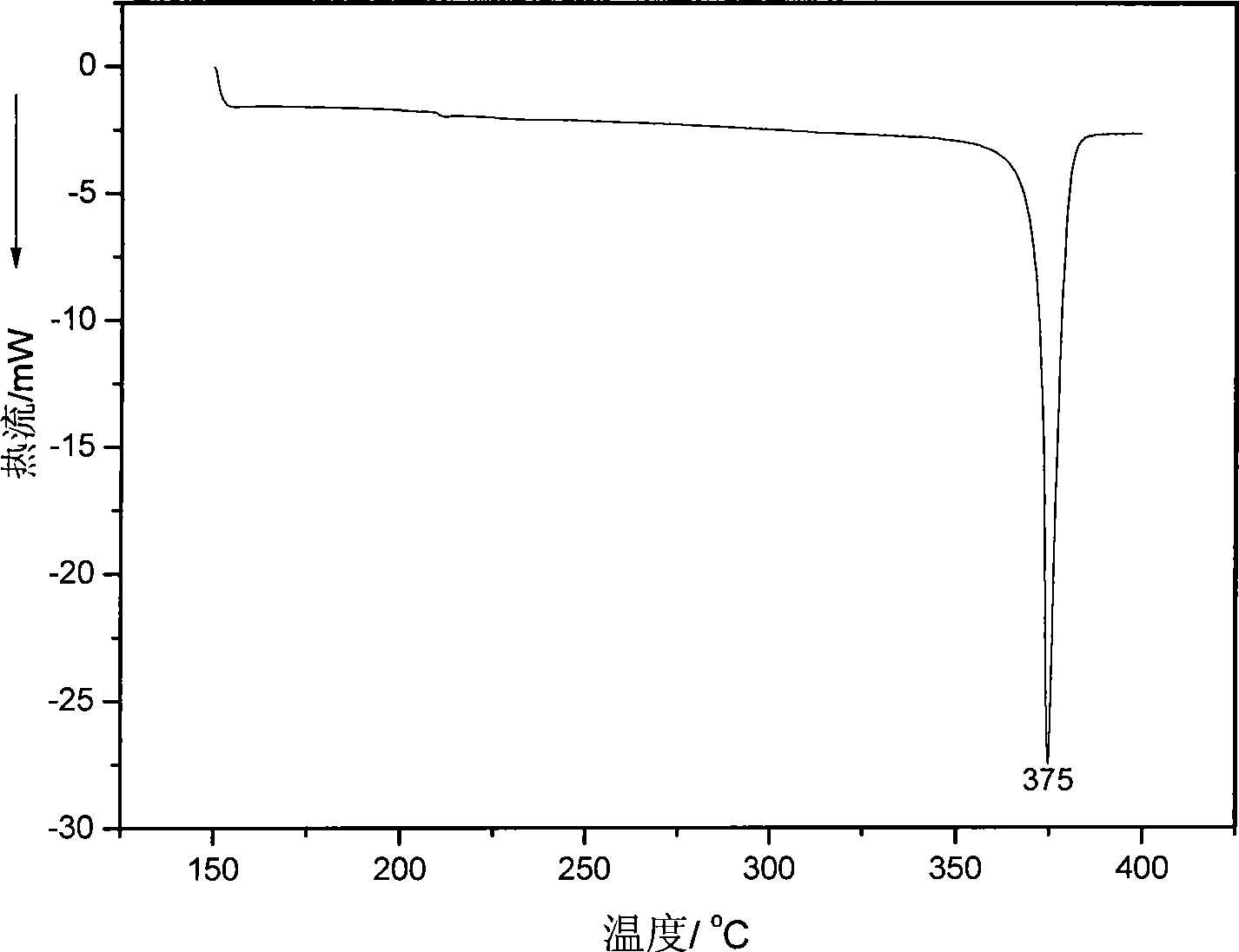

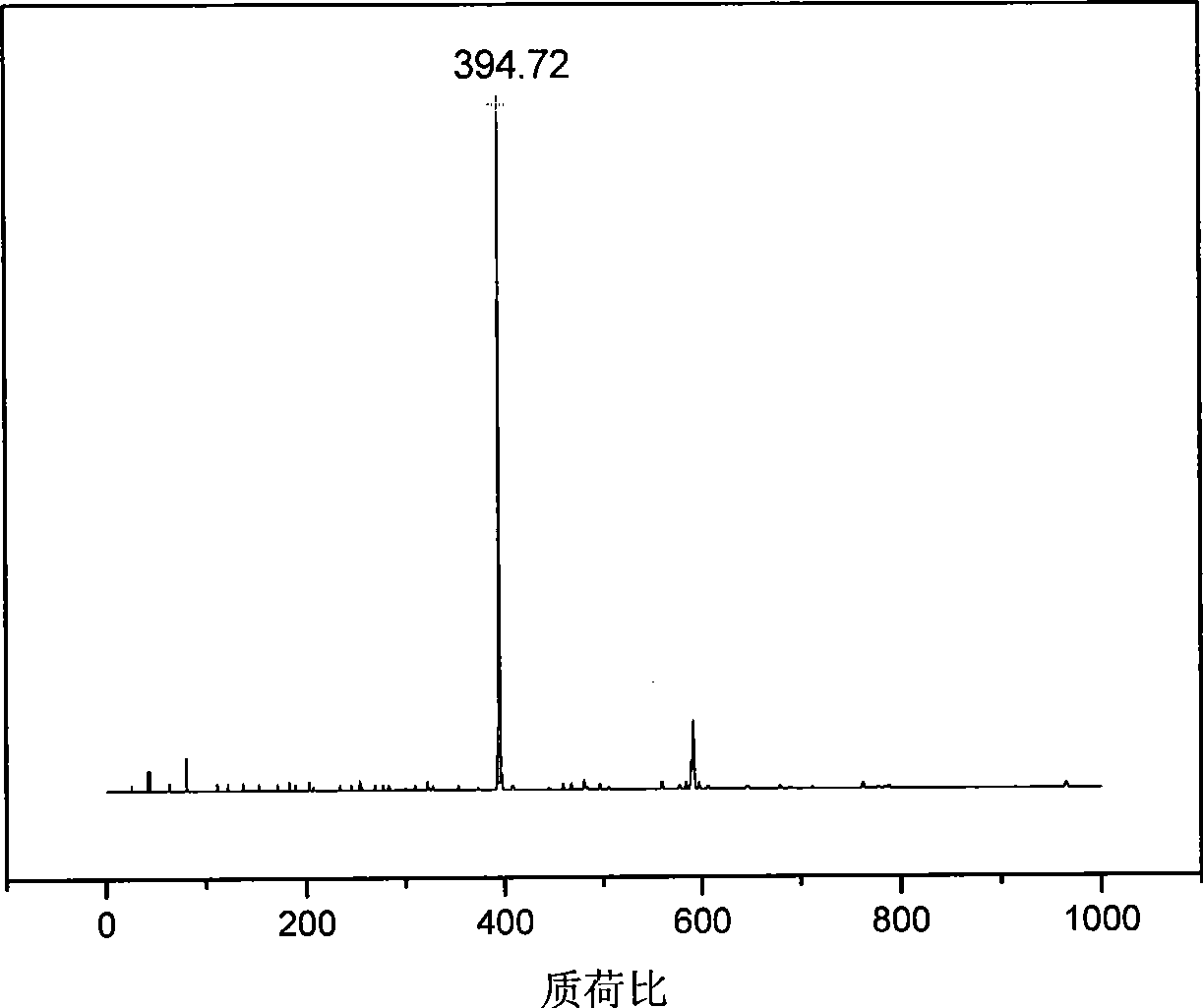

Method for preparing 4,4,5,5-dinaphthalene tetracarboxylic acid dianhydride

InactiveCN101397287AImprove efficiencyReduce usageOrganic chemistryNaphthalenetetracarboxylic dianhydridePotassium hydroxide

The invention relates to a preparation method widely used for preparing a 4, 4', 5, 5'-binaphthyl-tetracarboxylic dianhydride monomer of polyimide materials. The method is as follows: 4-halo-1, 8-anhydride naphthalene and potassium hydroxide which is 4 to 10 times of the molar volume of the 4-halo-1, 8-anhydride naphthalene are added with distilled water and heated for dissolving; then a Pd / C catalyst and a reducer are added, the temperature of a reaction system is controlled in a range between 80 and 120 DEG C and the reflux reaction is carried out for 3 to 40 hours; the Pd / C and impurities are filtered out and then hydrochloric acid or nitric acid is added into the filtrate for acidification so as to lead the pH value of the reaction system to be 1 to 3 and obtain yellow emulsion precipitation; the precipitation is washed by distilled water for 3 to 5 times and then is dried in a vacuum oven for 10 to 20 hours at the temperature of 180 to 200 DEG C so as to obtain yellow powder solids; then DMF is adopted for recrystallization so as to obtain the 4, 4', 5, 5'-binaphthyl-tetracarboxylic dianhydride monomer. The method of the invention is characterized by simple and convenient operation, being practical and having good effect.

Owner:JILIN UNIV

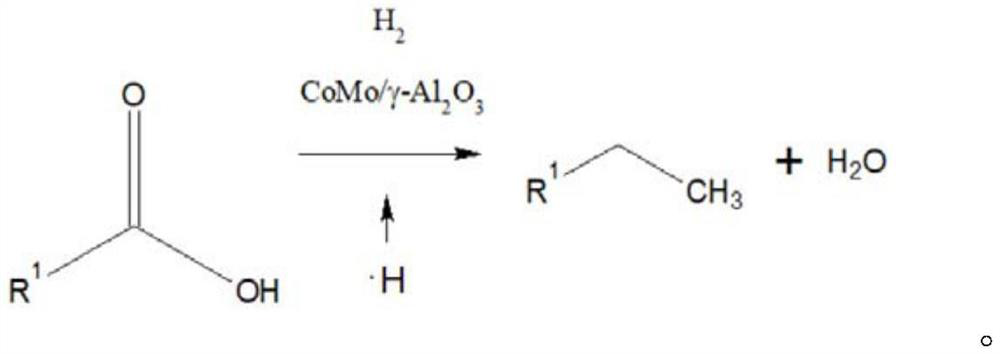

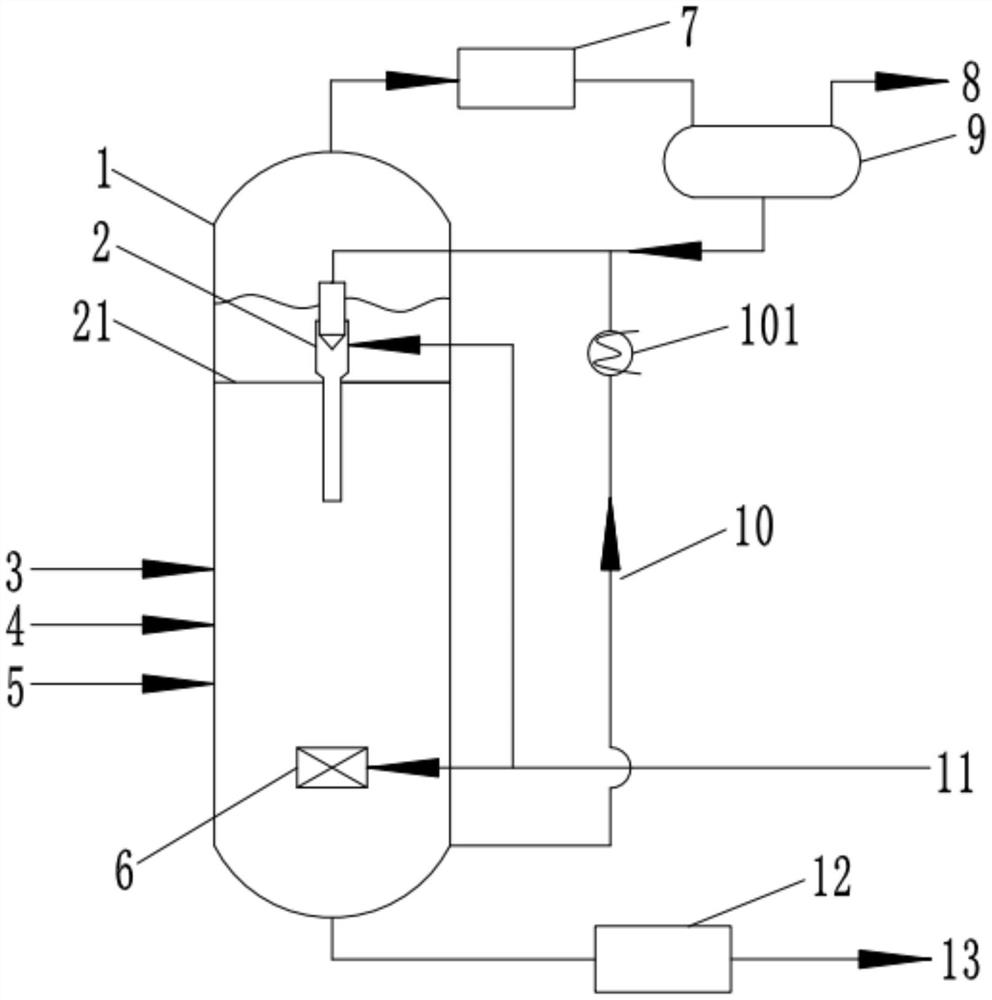

Gasoline hydrodesulfurization modification micro-interface enhanced reaction system and method

PendingCN111686646AReduce energy consumptionIncrease the interphase areaChemical/physical processesHydrocarbon oils treatmentEmulsionFluid phase

The invention relates to gasoline hydrodesulfurization modification micro-interface enhanced reaction system and method. The system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, according to the invention, gas is crushed to form micron-scale micro-bubbles, and the micro-bubbles and gasoline are mixed to form an emulsion, so that the gas-liquid two-phase interphase area is increased, the effect of enhancing mass transfer within a relatively low preset range is achieved, and the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is ensured; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced; the energy consumption of subsequent gas circulating compression is also reduced; therefore, the method is low in process severity, highin production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Preparation method for cyclohexanecarboxylic acid

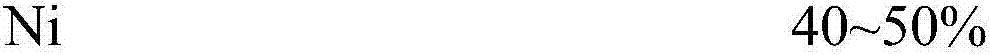

ActiveCN107365251ALow priceHigh yieldCarboxylic preparation by ozone oxidationCyclohexanecarboxylic acidMedicinal chemistry

The invention discloses a preparation method for cyclohexanecarboxylic acid. The preparation method comprises the following steps: performing a reduction reaction on benzoic acid under the action of a hydrogenation catalyst and hydrogen; after the reaction is ended, treating to obtain the cyclohexanecarboxylic acid, wherein the hydrogenation catalyst contains the following components in percentage by weight: 40 to 50 percent of Ni, 10 to 15 percent of Fe, 5 to 8 percent of Cu and the balance of Al. The catalyst used in the preparation method is low in cost; meanwhile, the yield of the reaction is high, so that the preparation method has better industrial application significance.

Owner:SHANGYU SUNFIT CHEM

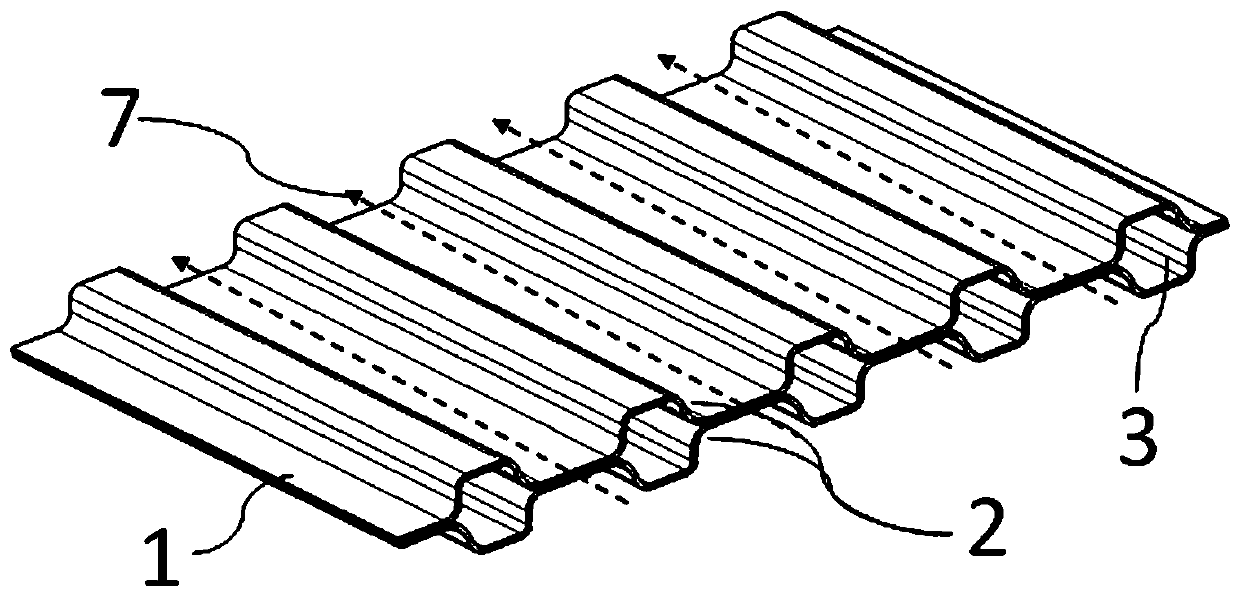

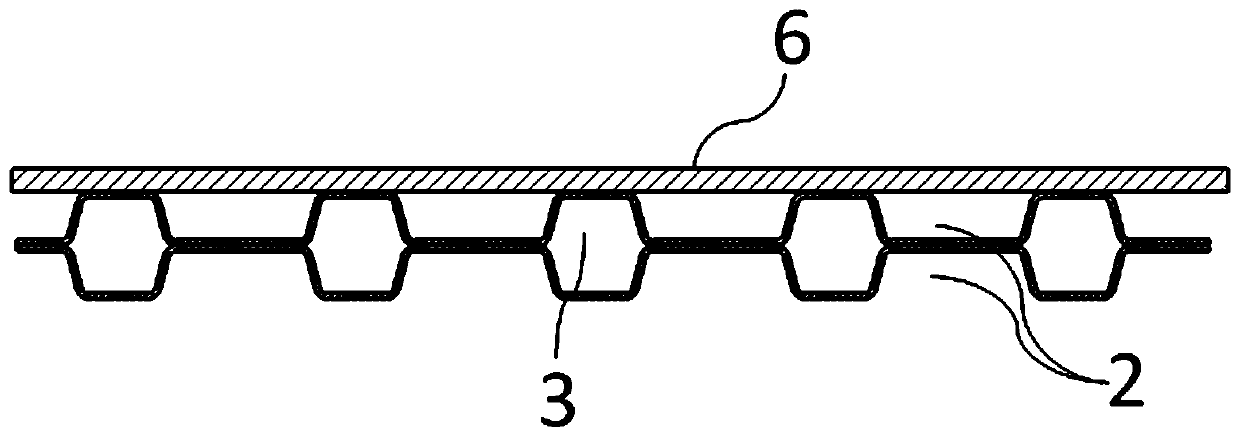

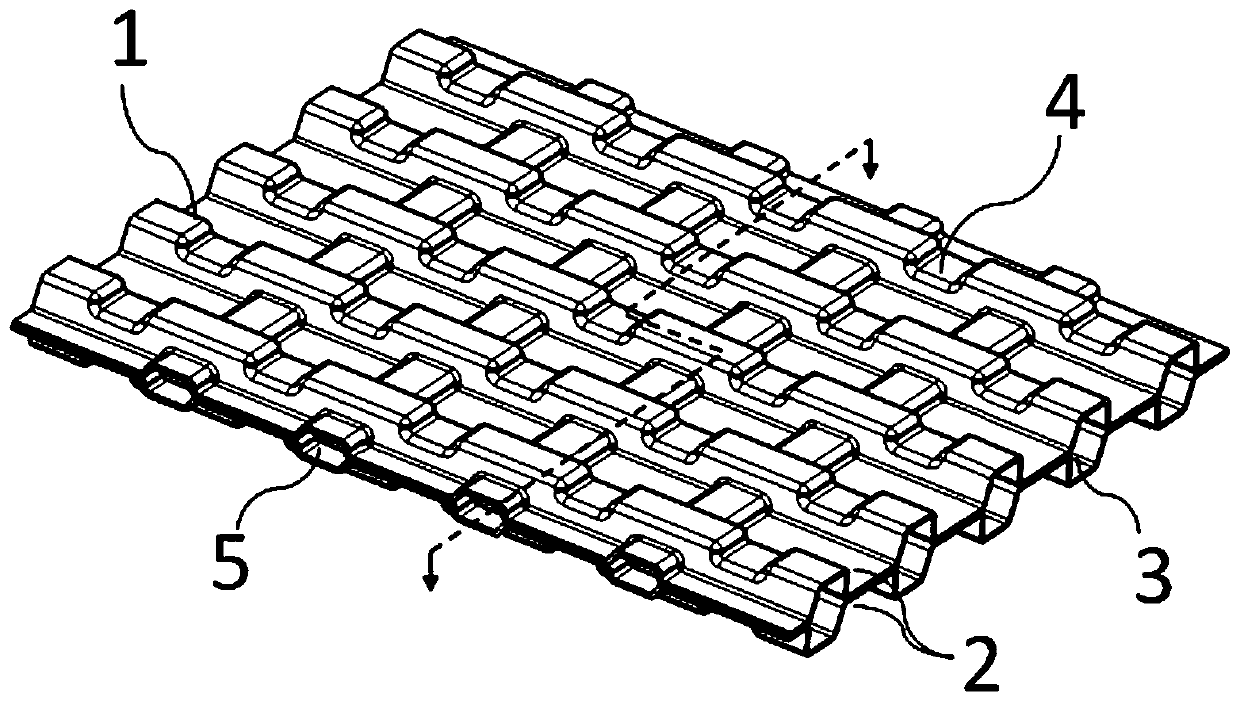

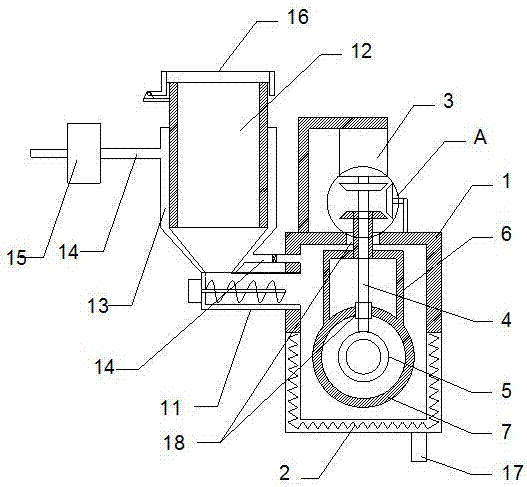

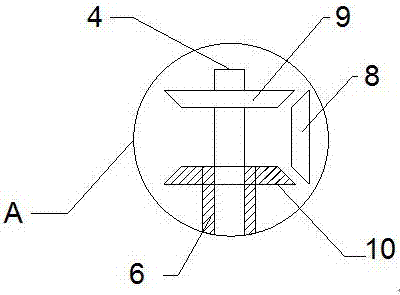

Fuel cell metal electrode plate and forming method

PendingCN110380073AImprove reaction efficiencyGuaranteed reaction efficiencyFinal product manufactureCollectors/separatorsFuel cellsEngineering

The invention provides a fuel cell metal electrode plate and a forming method. Through the arrangement of a group of gas flow channels which are communicated with each other and a group of liquid flowchannels which are communicated with each other, reaction gas can be uniformly diffused into all the gas flow channels when flowing through the gas flow channels, thereby improving and guaranteeing the uniform contact with a membrane electrode, and improving the reaction efficiency of the fuel cell; moreover, when cooling liquid flows through the liquid flow channels, the cooling liquid is distributed more uniformly through mutual communication and diffusion, so that a membrane electrode is cooled more uniformly, large temperature change of a local part of the membrane electrode can be avoided, the reaction efficiency of the membrane electrode is further ensured, and the output power of a fuel cell is further ensured.

Owner:苏州治臻新能源装备有限公司

Method of preparing phosphatidylserine

ActiveCN105177073AAvoid pollutionGuaranteed reaction efficiencyPhosphatide foodstuff compositionsFermentationDistillationDouble phase

The invention relates to a method of preparing phosphatidylserine. The method comprises the following steps: taking phospholipase D to catalyze a basic group exchange reaction of marine animal phospholipid and L-serine; centrifuging and carrying out molecular distillation, and separating and purifying to prepare the phosphatidylserine. By utilizing a liquid-liquid double-phase reaction system formed by middle-chain and long-chain fatty acid ethyl esters and a buffering solution, and utilizing the middle-chain and long-chain fatty acid ethyl esters which have high boiling points and are safe to eat to replace the organic solvents including diethyl ether, ethyl acetate and the like which have low boiling points, are flammable and combustible and are toxic and harmful, the production safety is improved while the reaction efficiency is guaranteed and the environmental pollution is not caused, so that the method is suitable for industrial production.

Owner:威海博宇食品有限公司

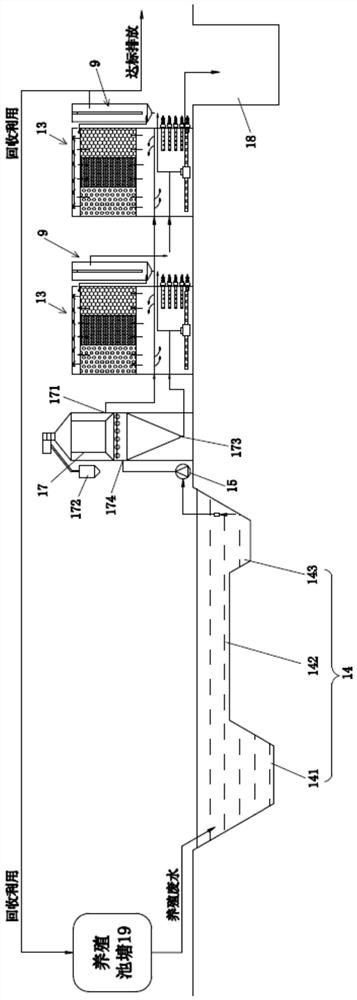

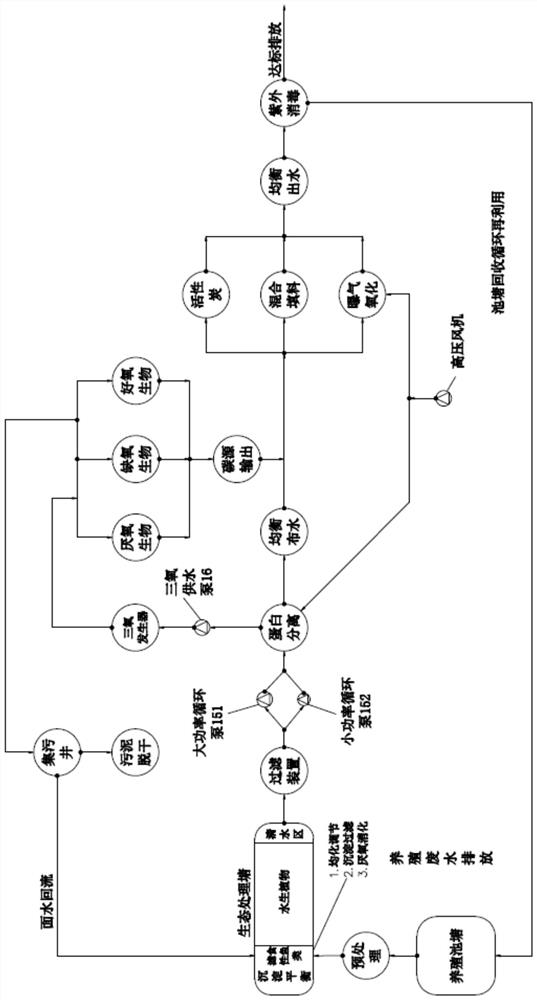

Culture wastewater purification treatment system and process

PendingCN112390467AIncrease dissolved oxygenIncrease diversityWater/sewage treatment by irradiationSpecific water treatment objectivesMicroorganismAmmoniacal nitrogen

The invention discloses a culture wastewater purification treatment system and process. The treatment system comprises an ecological treatment pond, a protein separator and a microbial nitrogen and phosphorus removal filter which are sequentially connected in the flow direction of wastewater. In the treatment process, after the culture wastewater in a culture pond is sequentially treated by the ecological treatment pond and the protein separator, circulating wastewater is introduced into a treatment container with anaerobic and anoxic microorganisms and aerobic microorganisms, and phosphorus in the circulating wastewater is subjected to denitrification reaction through the anaerobic and anoxic microorganisms; aerobic microorganisms are used for carrying out nitration reaction on ammonia nitrogen and nitrite in the circulating wastewater. According to the culture wastewater purification treatment system and process provided by the invention, ammonia nitrogen, nitrite, phosphorus and other substances in the wastewater are completely treated, and the treated water can be reused as culture water, so that water resources are saved.

Owner:GUANGZHOU CHUANGLING AQUATIC TECH CO LTD

Copper dissolving tank with stirring and shoveling functions for copper foil production

ActiveCN114432995AIncrease dissolution rateImprove reaction efficiencyChemical/physical/physico-chemical stationary reactorsProcess efficiency improvementEngineeringCopper foil

The invention discloses a copper dissolving tank with stirring and shoveling functions for copper foil production. Belongs to the technical field of copper foil production equipment. According to the technical key points, the device comprises a tank body and a feeding port, the top of the feeding port communicates with an unwinding box internally provided with an unwinding roller, and a conveying and flattening mechanism is arranged in the unwinding box; a copper dissolving frame is arranged in the tank body, a filter screen is arranged on the side wall of the copper dissolving frame, a rotating cylinder is arranged in the copper dissolving frame, and a rotating driving mechanism matched with the rotating cylinder is arranged at the top of the tank body; a plurality of stirring sleeves are arranged on the side wall of the rotating cylinder, a stirring rod is rotationally connected into each stirring sleeve, and a rotating stirring mechanism is arranged between each stirring rod and the rotating cylinder; a plurality of annular shoveling grooves are formed in the bottom of the copper dissolving frame, and a lifting shoveling device is arranged between the rotating cylinder and the copper dissolving frame; the top of the tank body communicates with an exhaust pipe, and an air-blowing sealing mechanism is arranged between the copper dissolving frame and the rotating cylinder; the copper dissolving tank with the stirring and shoveling functions for copper foil production is compact in structure, good in effect and capable of effectively preventing copper material accumulation.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

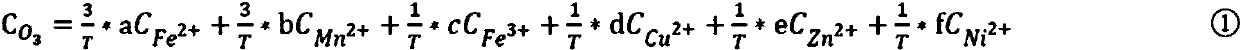

Wastewater processing control method for promoting advanced oxidation effect

ActiveCN110451681AReduce secondary pollutionGuaranteed response speedWater contaminantsMultistage water/sewage treatmentWater qualityOxidative treatment

The invention discloses a wastewater processing control method for promoting the advanced oxidation effect, and belongs to the field of wastewater processing. The method comprises following steps: (1)detecting the kinds and corresponding mole concentrations of heavy metal ions in wastewater; (2) adding an oxidizing agent into wastewater to carry out an advanced oxidation treatment, wherein the addition amount of the oxidizing agent is determined based on the content of heavy metal ions in the wastewater; (3) detecting the effluent of the step (2), and stopping the advanced oxidation treatment, if the COD concentration is not greater than 50 mg / L and the TOC concentration is not more than 20 mg / L; if not, carrying out a further advanced oxidation treatment. The method has the advantages that the actual water quality is taken into account, the oxidation reaction efficiency is maximized, the medicaments are effectively saved at the same time, and the operation cost is reduced therefore.

Owner:NANJING UNIV +1

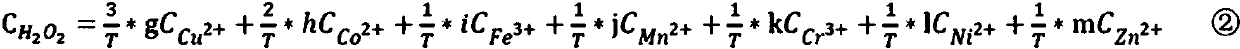

Biological retention pond capable of removing phosphorus and removing peculiar smell

ActiveCN110745951AEfficient removalPurification Effect ChangesSpecific water treatment objectivesWater contaminantsActivated sludgeMicroorganism

The invention discloses a biological detention pond capable of removing phosphorus and removing peculiar smell. The biological detention pond comprises a detention pond main body and an air inlet system, the detention pond main body sequentially comprises a detention submerged layer, a green plant planting layer, a soil fixing layer, a deodorization filler layer, a phosphorus removal filler layerand a supporting layer from top to bottom, and the deodorization filler layer comprises a microreactor, activated sludge and zeolite; the air inlet system comprises an air inlet pipe, the air inlet pipe is connected with the air inlet of an air blower, and the air outlet of the air blower is communicated with the deodorization filler layer and the supporting layer through air guide pipes; and a water guide pipe is arranged in the supporting layer. The structure of the detention pond has a long hydraulic retention time and a long seepage path, and the deodorization filler area provides a largenumber of attachment sites and a proper growth environment for growth of microorganisms, so the microorganisms can be in full contact with pollutants in runoff, the pollutant retention capacity of themicroorganisms is brought into play to the maximum extent, and the phosphorus removal effect and the treatment effect of black and odorous water are effectively improved; and the biological detentionpond has the advantages of simple process, and low operation and maintenance cost.

Owner:NANJING UNIV OF TECH

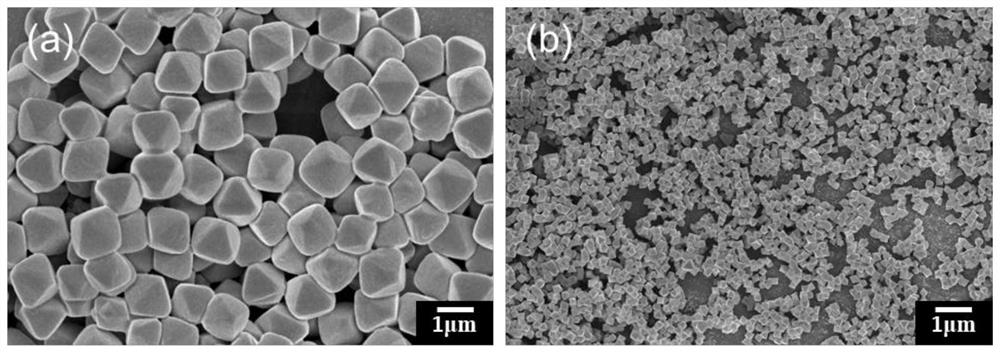

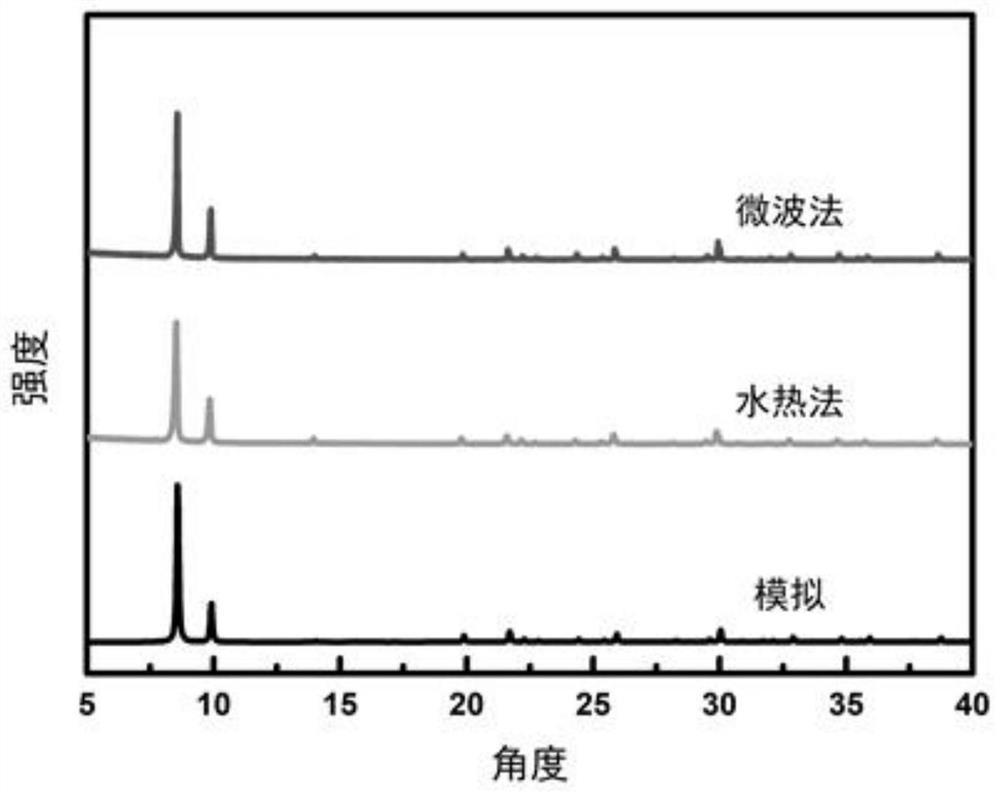

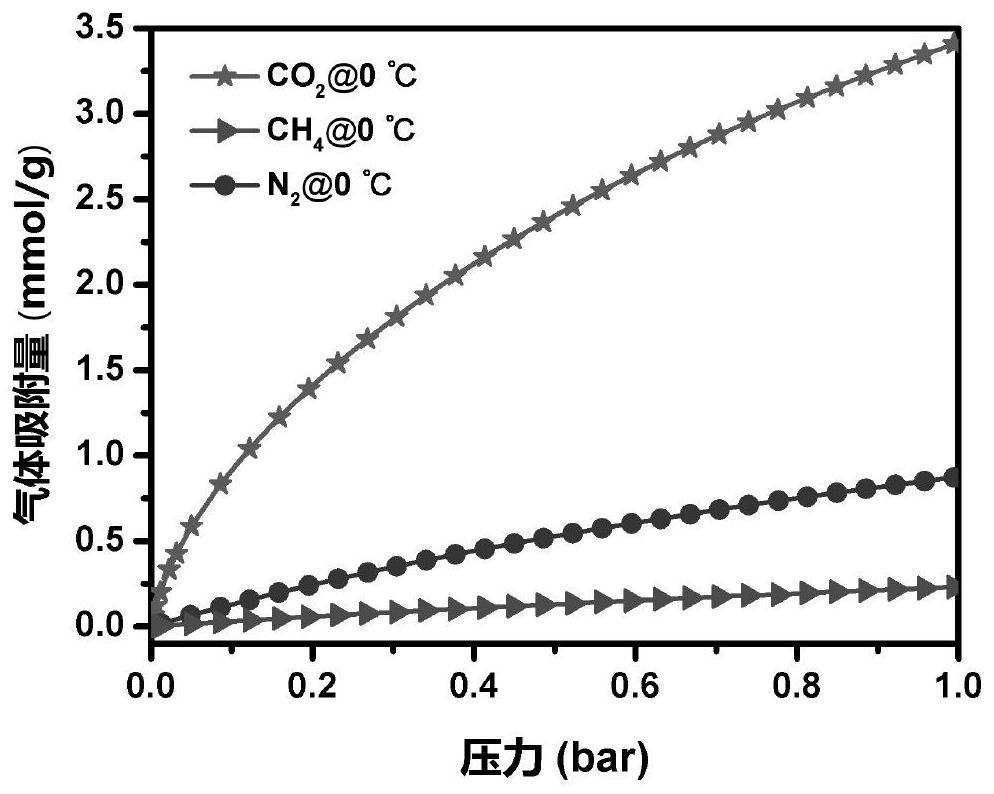

Zirconium-based metal organic framework material as well as preparation method and application thereof

ActiveCN113087918AHigh yieldImprove reaction efficiencyProductsReagentsPhysical chemistryMetal-organic framework

The invention discloses a zirconium-based metal organic framework material, the molecular formula of the zirconium-based metal organic framework material is Zr6O4(OH)4(C4H4O4)6.solvent. In the Zr6O4(OH)4(C4H4O4)6.solvent, the connection mode of Zr6O4(OH)4 is 12 connection, and Zr6O4(OH)4 is crystallized in a Pn-3 space group. The invention also provides a preparation method and application of the zirconium-based metal organic framework material, the preparation method is mainly a microwave-assisted synthesis method. The prepared zirconium-based metal organic framework material has a good application effect on gas adsorption and separation, especially has a good adsorption and separation effect on CO2, propylene and ethylene gas, and the preparation method is high in synthesis efficiency, high in utilization efficiency of raw materials and high in popularization and use value.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method for preparing sulfonamide sodium salt of sulfadoxine

InactiveCN102584648AReduce consumptionReduce bring inSulfonic acid amide preparationPhysical chemistryPharmaceutical drug

The invention discloses a preparation method for preparing a sulfonamide sodium salt of sulfadoxine, belonging to the technical field of preparation of a sulfonamide antibacterial medicament. The method comprises the following steps of: putting solid sodium hydrate, technical grade sulfonamide or recrystallized sulfonamide and water into a reaction pot with a stirrer; heating and dissolving in a stirring state; after the solid sodium hydrate and the recrystallized sulfonamide are fully dissolved, continually heating and carying out distilling for removing water to dryness; further heating till materials in the reaction pot become powder; and discharging and drying to obtain the sulfonamide sodium salt of which the sodium content is more than or equal to 90 percent and the nitrogen content is more than or equal to 92 percent. The method has the advantages that: the sodium content and the nitrogen content of the obtained sulfonamide sodium salt are stable; the quality of the sulfonamide sodium salt can be guaranteed, the reaction efficiency of a next procedure is ensured, and impurities in a finished product are reduced; impurities brought into the finished product can be reduced, and the product purity is ensured; and a final finished product, i.e. sulfadoxine, prepared from the sulfonamide sodium salt obtained by the method has high purity.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

Process for improving tar quality

InactiveCN106753497AImprove responseExtended Blend PathTar working-up by water removalTar working-up by chemical refiningSlagTar

The invention relates to a process for improving tar quality. The process comprises the following steps of arranging a dosing port in the top part of a slag scraping tank, injecting a demulsifying agent into the dosing port from a dosing barrel through a first dosing pipe and a quantitative dosing pump, and realizing primary separation of ammonia liquor from tar; then feeding slag-removed ammonia liquor and tar into a separating tank from the slag scraping tank so as to carry out secondary separation; arranging two paths of outlets on a side wall part above a separating cylinder of the separating tank, wherein one path of outlet is used for outputting ammonia liquor obtained after separation of ammonia liquor from tar, and the other path of outlet is respectively communicated with an anammonia liquor and tar inlet of the separating tank and an inlet of a tar and ammonia liquor separator; standing for separating an ammonia liquor and tar mixture entering the tar and ammonia liquor separator, and recycling after collecting tar separated in the tar and ammonia liquor separator and tar discharged by a screw augur of the separating tank. According to the process for improving tar quality provided by the invention, continuous dosing is carried out in the separating tank, and the combined application of primary separation and second separation is utilized, so that the ammonia liquor and tar emulsification degree can be effectively controlled, and the separation efficiency of the tar and the ammonia liquor is speeded up.

Owner:SHANDONG IRON & STEEL CO LTD

Method for preparing dichlorosilane

ActiveCN103408026AGuaranteed reaction efficiencyImprove efficiencyHalogenated silanesReaction temperatureDichlorosilane

The invention discloses a method for preparing dichlorosilane, which comprises the following steps: under the condition that anion exchange resin is taken as a catalyst, trichlorosilane is enabled to be in disproportionation reaction to obtain a reaction product containing silicon tetrachloride and dichlorosilane; dichlorosilane is separated from the reaction product. Through the application of the method, dichlorosilane is prepared safely and efficiently, the method is low in cost, low in reaction temperature and pressure, safe, easy to operate, strong in adaptability, and free from pollution, and the quality of prepared dichlorosilane is very good.

Owner:CHINA ENFI ENGINEERING CORPORATION

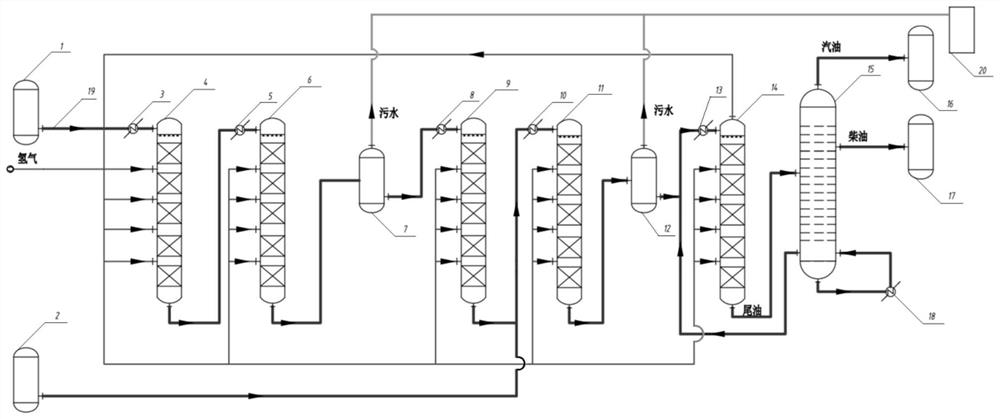

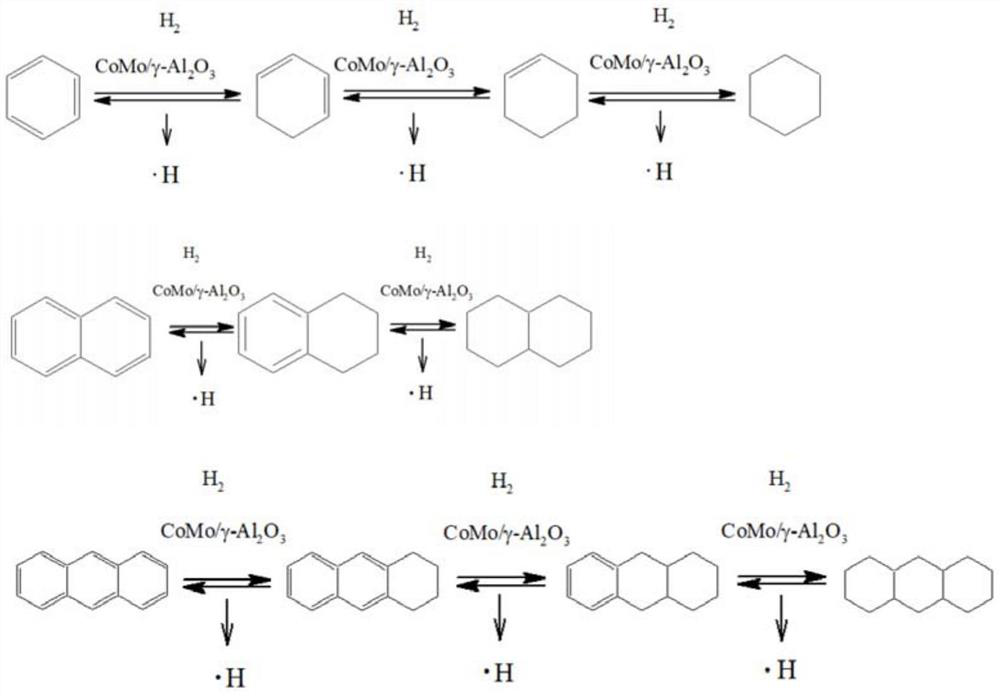

Method and system for preparing gasoline and diesel by mixing and hydrogenating coal tar and biomass oil

ActiveCN112029533AExpand sourceAlleviate the lackTreatment with hydrotreatment processesBio-feedstockOil and greaseHydrodeoxygenation

The invention discloses a method and a system for preparing gasoline and diesel oil by mixing and hydrogenating coal tar and biomass oil, and belongs to the technical field of petrochemical engineering energy. The method comprises the steps of carrying out catalytic hydrogenation on coal tar to obtain a coal tar system subjected to hydrogenation pretreatment, mixing the coal tar system subjected to hydrogenation pretreatment with biomass oil to obtain a mixed oil system, continuously carrying out catalytic hydrogenation on the mixed oil system, and carrying out rectification treatment to obtain a gasoline and diesel oil product, wherein the coal tar system subjected to hydrogenation pretreatment is subjected to catalytic hydrogenation to form a hydrogen-donor solvent, and hydrogen free radicals are utilized to perform hydrodeoxygenation on the biomass oil. The system disclosed by the invention is provided with a plurality of staged reactors, so that the staged catalytic hydrogenation reaction is realized, and the coal tar is subjected to hydrogenation pretreatment and then is mixed with the biomass oil for catalytic hydrogenation. Compared with a single raw material hydrogenation technology, the hydrogenation speed is high, the coking influence is small, and the raw material adaptability is also improved.

Owner:XI'AN PETROLEUM UNIVERSITY

Preparation method of oxidized nanocellulose

The invention provides a preparation method of oxidized nanocellulose, which is characterized in that polyhydric alcohol is added, and under the catalytic action of sulfuric acid, the reaction efficiency can be guaranteed, and side reactions occurring in the reaction process can be inhibited. The preparation method disclosed by the invention is environment-friendly and relatively low in cost, and can ensure the output rate of cellulose in unit time, thereby being beneficial to reducing the production cost. Besides, a sodium hypochlorite solution is added, so that the reaction is gentle, the oxidation of the nanocellulose is more uniform, and the oxidized nanocellulose with better uniformity and quality is obtained. Generally, the problems that the prepared nanocellulose is not environmentally friendly enough, equipment is prone to corrosion, and nanocellulose oxidation is uneven in the prior art can be solved.

Owner:水木山海科技(佛山)有限责任公司

Control system and process for producing terephthalic acid by m-xylene oxidation

InactiveCN112552160AImprove mass transfer efficiencyShort reaction timeOrganic compound preparationChemical/physical/physico-chemical microreactorsXylyleneTemperature control

The invention discloses an intelligent control system and process for producing terephthalic acid by m-xylene oxidation. The intelligent control system comprises a slurry bed reactor, a first micro-interface generator, a second micro-interface generator, a condensation unit, a separation unit, a temperature control circulation unit and a crystallization filter, wherein the slurry bed reactor is used as a reaction place of xylene oxidation and is filled with liquid-phase phthalic acid; at least one first micro-interface generator is arranged on a fixed plate positioned in the slurry bed reactor; and at least one second micro-interface generator is arranged in the slurry bed reactor and is positioned below the first micro-interface generator. The system is further provided with the temperature control circulation unit which is used for pumping liquid at the bottom of the slurry bed reactor into a liquid phase inlet of the second micro-interface generator so as to achieve the effect of circulating a solvent in the reactor. The micro-interface generator and other devices are arranged in the reactor, so that the mass transfer efficiency of the gas phase and the liquid phase is improved,the reaction time is shortened, and the material consumption and energy consumption are reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

A kind of treatment method of waste lithium iron phosphate power battery

ActiveCN104282961BRealize harmless treatmentImprove securityWaste accumulators reclaimingBattery recyclingPower batteryLithium iron phosphate

Owner:WANXIANG 123 CO LTD

System and process for producing phthalic acid by strengthening xylene oxidation

PendingCN112546973AImprove mass transfer efficiencyShort reaction timeOrganic compound preparationChemical/physical/physico-chemical microreactorsXylyleneFluid phase

The invention provides a system and process for producing phthalic acid by strengthening xylene oxidation. The system comprises a slurry bed reactor, micro-interface generators, a circulating pipeline, a gas inlet pipeline and a separation unit, wherein the upper part of the slurry bed reactor is communicated with the condensation unit, and the lower part is communicated with the crystallization filter; the micro-interface generators are arranged in the slurry bed reactor and used for crushing gas into micron-sized micro bubbles, so that the mass transfer efficiency of gas and liquid is improved, and the reaction pressure is reduced; the circulating pipeline is used for pumping a liquid-phase material at the bottom of the slurry bed reactor into the second micro-interface generator; and afeed port of the separation unit is connected with the condensation unit, and a liquid-phase material outlet of the separation unit is communicated with a liquid-phase material inlet of the first micro-interface generator.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Method for recovering mixed ammonium salt and lead titanate from waste SCR denitration catalyst

InactiveCN111646498AEfficient recyclingImprove qualityMolybdeum compoundsTitanatesPtru catalystPhysical chemistry

The invention belongs to the field of non-ferrous metal recovery, and particularly relates to a method for recovering mixed ammonium salt and lead titanate from a waste SCR denitration catalyst. The recovery method mainly comprises the steps of waste catalyst pretreatment, ammonia leaching, impurity removal, evaporative crystallization, titanium precipitation and the like. By means of the recoveryprocess, vanadium-tungsten or vanadium-molybdenum mixed ammonium salt and high-purity lead titanate products can be obtained through recovery, the process element recovery rate is high, the product quality is excellent, and the recovery process is simple and easy to implement and has certain applicability in the field of waste catalyst recovery.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

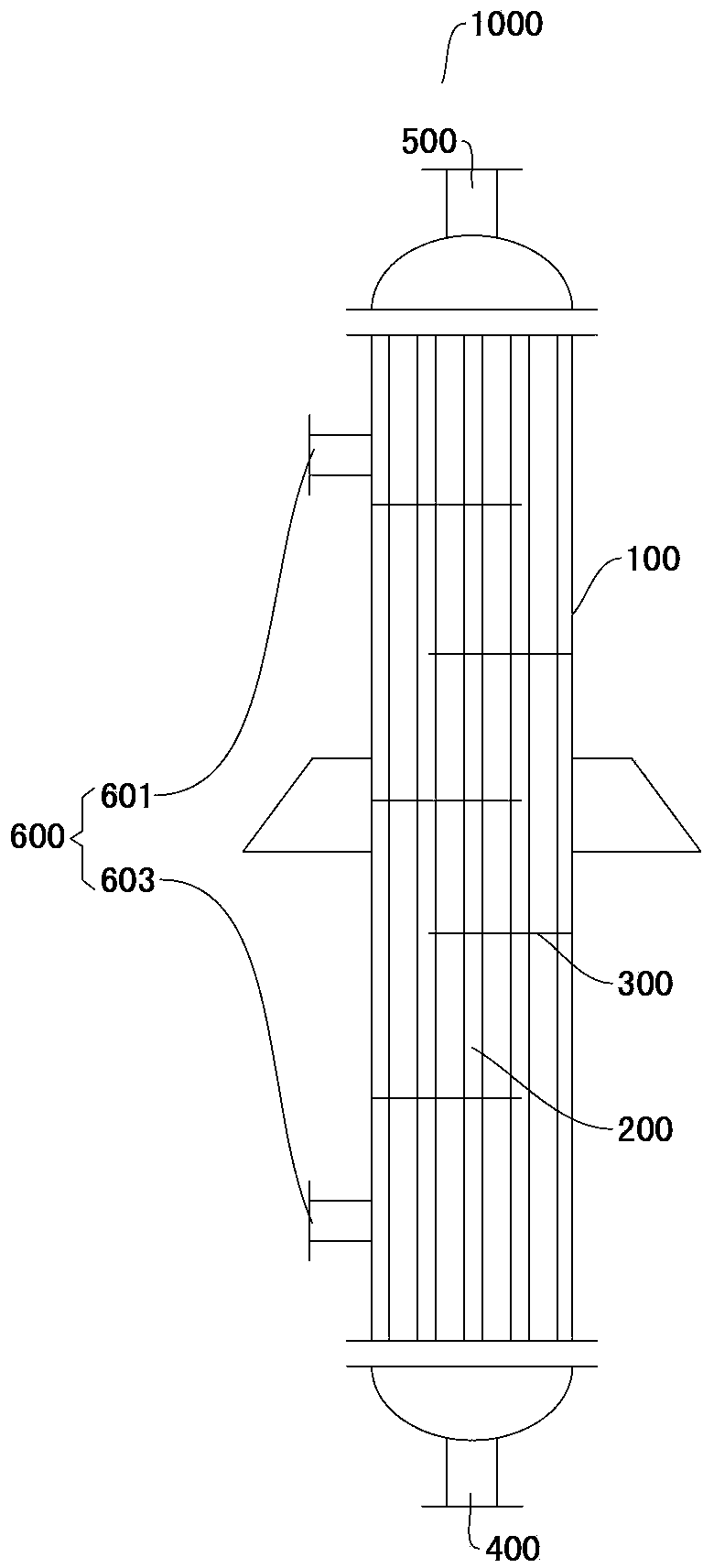

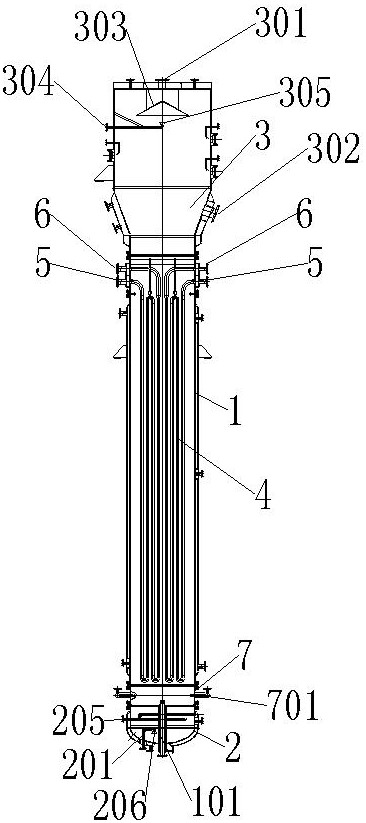

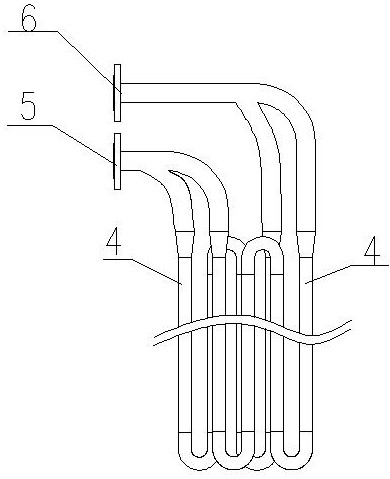

Hydrophobic white carbon production fluidized bed reactor capable of recycling materials

PendingCN112546975AReduce in quantityEasy to installSilicaChemical industryFluidized bedProcess engineering

The invention relates to the field of fluidized beds, and discloses a hydrophobic white carbon production fluidized bed reactor capable of recycling materials. The hydrophobic white carbon productionfluidized bed reactor capable of recycling materials comprises a bed body, a gas distribution chamber is arranged at the bottom of the bed body, and an upper seal head is arranged at the top of the bed body; a plurality of groups of heat exchange tube assemblies are mounted in the bed body, each group of heat exchange tube assembly at least comprises two U-shaped heat exchange tube groups, and theU-shaped heat exchange tube groups share the same heat conduction oil inlet and the same heat conduction oil outlet; and each U-shaped heat exchange tube group is formed by connecting at least threeU-shaped heat exchange tubes in series. Compared with the prior art, the hydrophobic white carbon black production fluidized bed reactor capable of recycling the materials is large in number of heat exchange tubes, high in heat exchange efficiency, small in model selection limitation on a heat conduction oil pump and high in heat conduction efficiency; especially for solid materials with light weight, the solid materials and gas materials can be fully and uniformly mixed, the reaction is uniform and stable, the content of effective components in the reaction product is high, and the comprehensive production cost is low.

Owner:JIANGSU KESHENG CHEM MACHINERY

Molten reaction device for chemical fiber manufacturing

InactiveCN107366026AImprove reaction efficiencyGuaranteed reaction efficiencyFilament forming substance formingFiberMetallurgy

The invention discloses a melting reaction device for chemical fiber manufacturing, which comprises a melting barrel, a screw feeding barrel and a waste gas treatment device; a heating wire is embedded in the inner wall of the melting barrel; an inner stirring ring is arranged in the melting barrel; An outer stirring ring is provided outside the inner stirring ring; a bolt feeding cylinder is connected to the left side of the melting barrel; a raw material storage box is connected above the bolt feeding cylinder; a heating jacket is arranged outside the raw material storage box, and the heating jacket It communicates with the melting barrel through the waste gas pipe; the heating jacket is connected with the waste gas treatment device. The present invention is equipped with the inner stirring ring and the outer stirring ring with the opposite rotation direction to fully stir the high-viscosity molten reaction raw materials, so that the reaction can be carried out thoroughly and the reaction efficiency is improved; The heat in the generated exhaust gas is fully utilized, and the exhaust gas is treated before being discharged to protect the environment.

Owner:盐城市净博士机械有限公司

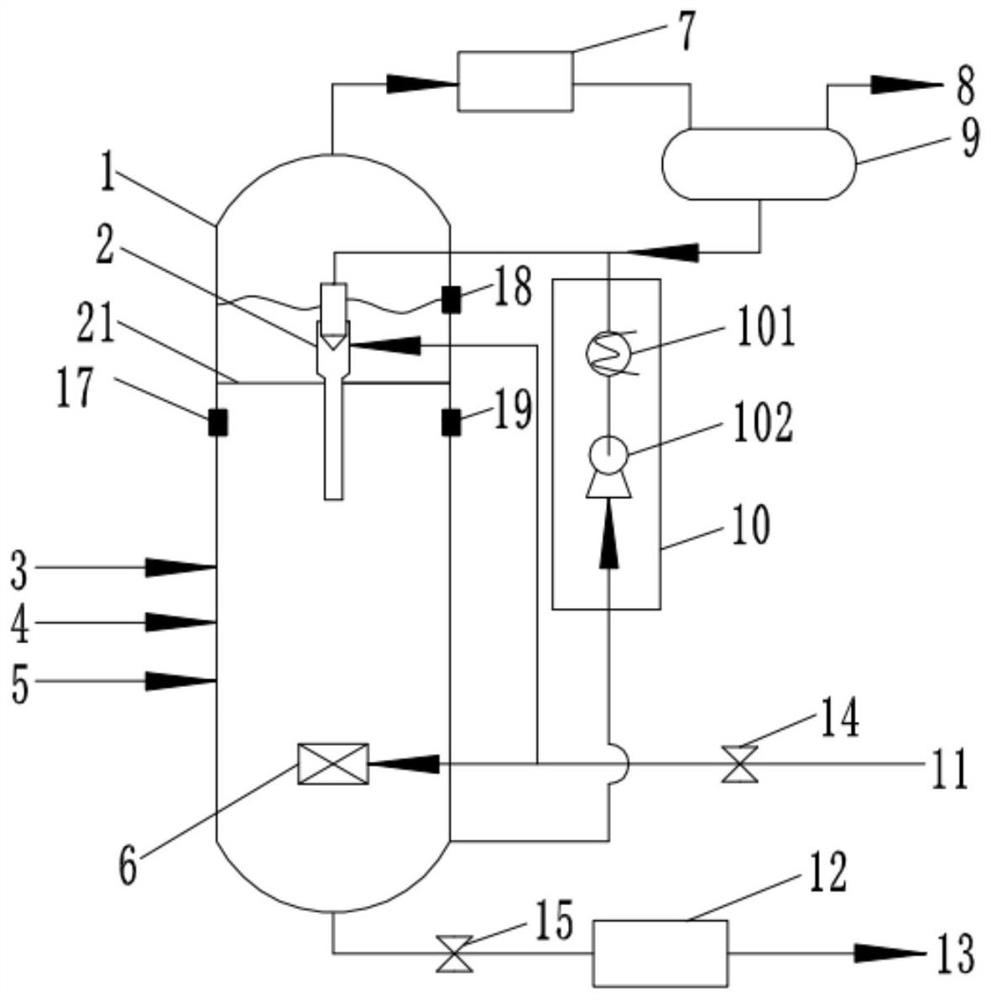

Oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system

InactiveCN111686657AReduce material consumptionReduce energy consumptionChemical/physical processesHydrocarbon oils treatmentEmulsionFluid phase

The invention relates to an oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system. The system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fluidized bed reactor and a separation tank. Compared with a traditional fluidized bed reactor, according to the invention, gas is crushed to form micron-scale micro-bubbles, and themicro-bubbles are mixed with a mixed oil product to form an emulsion, so that the gas-liquid two-phase interphase area is increased, the effect of enhancing mass transfer within a relatively low preset range is achieved, and the pressure in the reaction process can be reduced by 10-80% while the reaction efficiency is ensured; meanwhile, mass transfer is greatly enhanced, so that the gas-liquid ratio can be greatly reduced, the material consumption of gas is reduced, and meanwhile, the energy consumption of subsequent gas circulating compression is also reduced; the method is low in process severity, high in production safety, low in ton product cost and high in market competitiveness.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com