Copper dissolving tank with stirring and shoveling functions for copper foil production

A technology of stirring shovel and melting copper tank, which is applied in electroforming, chemical/physical/physical-chemical stationary reactor, electrolysis process, etc. The complete reaction of the material can be solved to ensure the quality of the product, improve the dissolution rate, and expand the effective range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

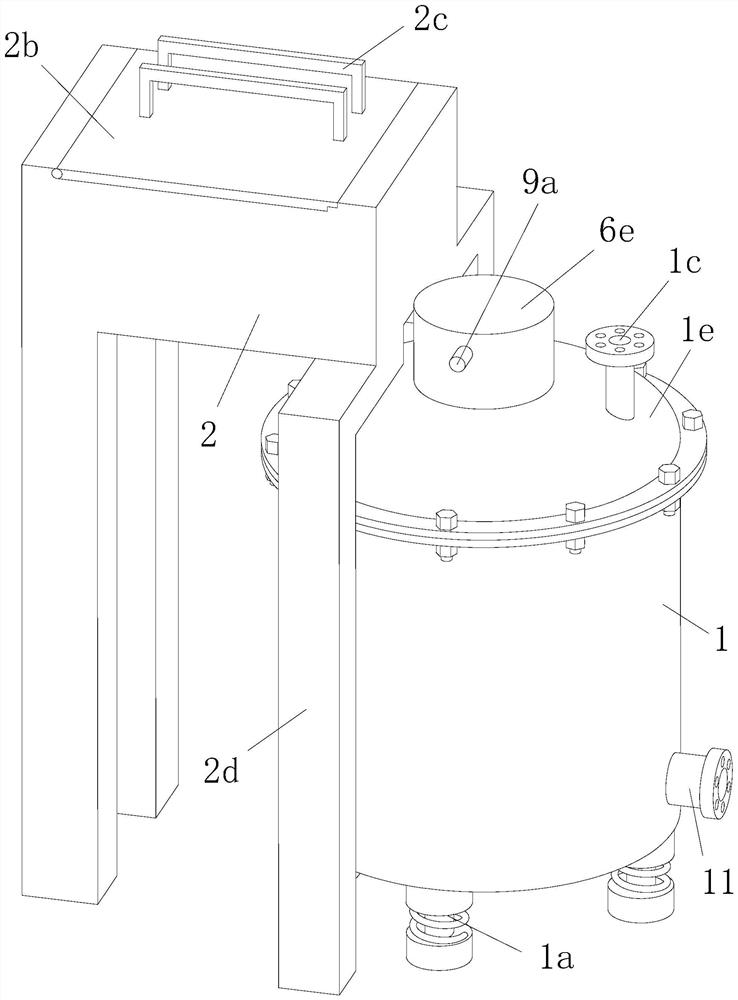

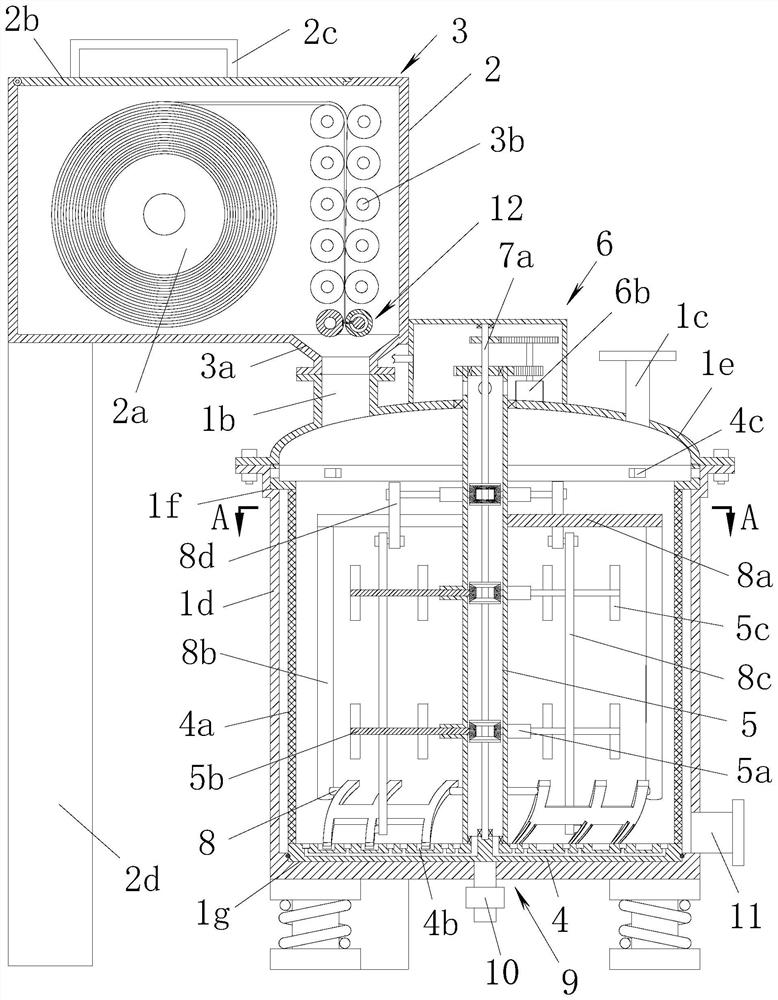

[0030] refer to Figure 1 to Figure 9 As shown, a copper-dissolving tank for copper foil production with a stirring and shoveling function of the present invention includes a tank body 1, a support 1a is provided at the bottom of the tank body 1, and a feed port 1b is provided at the top of the tank body 1. The top of the feeding port 1b is provided with a connected unwinding box 2, and an unwinding roller 2a for placing the copper foil coil to be dissolved is arranged in the unwinding box 2, and in the unwinding box 2 above the feeding port 1b A conveying and flattening mechanism 3 that cooperates with the unwinding roller 2a and is used for conveying and squeezing the copper foil coil is provided.

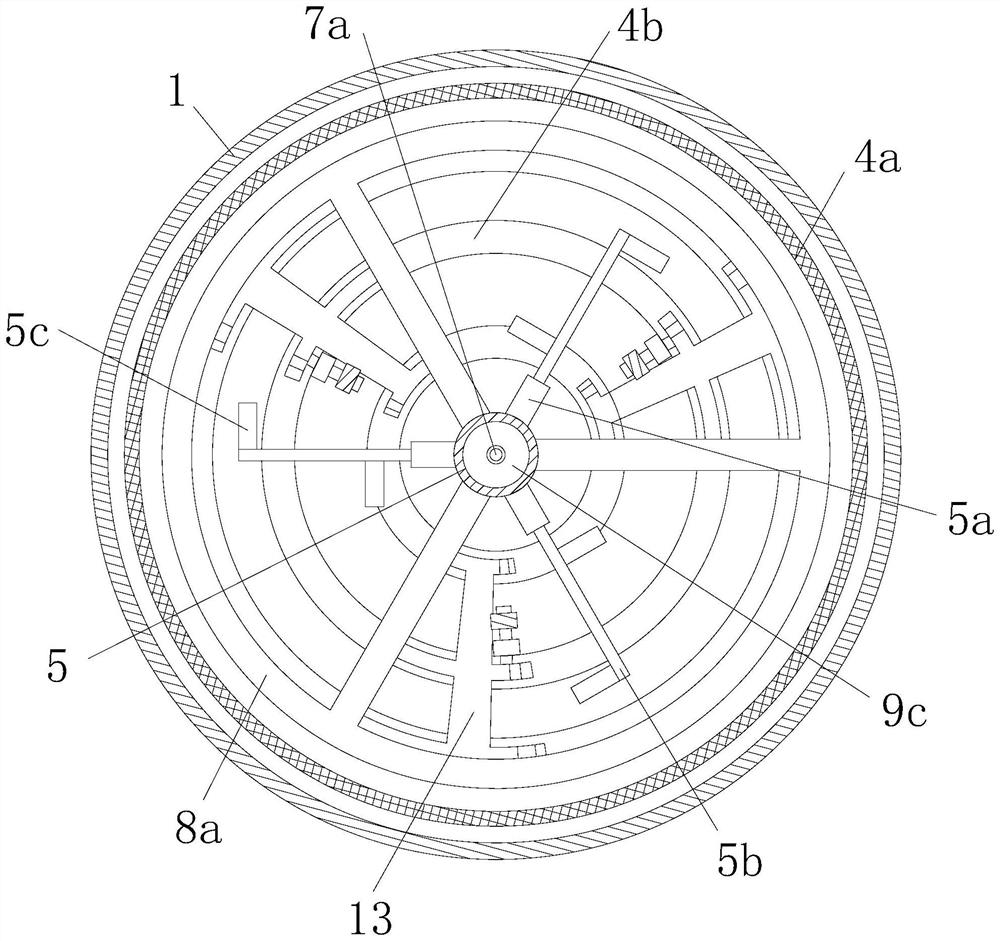

[0031] A matching copper melting frame 4 is arranged in the tank body 1, a filter screen 4a is arranged on the side wall of the copper melting frame 4, and a rotating cylinder 5 is arranged vertically in the melting copper frame 4, and the top of the rotating cylinder 5 protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com