Silk fibroin micro-needle patch and preparation method thereof

A silk fibroin microneedle and silk fibroin technology are applied in the field of silk fibroin microneedle stickers and their preparation, and can solve the problem of small drug loading, unsuitable for mass production, complex electroplating, and photoetching microchannel casting. Technical preparation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of small molecule silk fibroin solution: the silkworm cocoon shell of 80g is 0.25% Na in 4000mL mass fraction 2 CO 3 In the solution, boil it three times at 98-100°C for 30 minutes each time, and wash it with deionized water. After degumming and drying, silk fibroin was dissolved in 9.3M lithium bromide solution at 60°C with a bath ratio of 1:10, dialyzed in deionized water for 3-4 days, concentrated to 0.09g / mL, and stored in a refrigerator at 4°C for use.

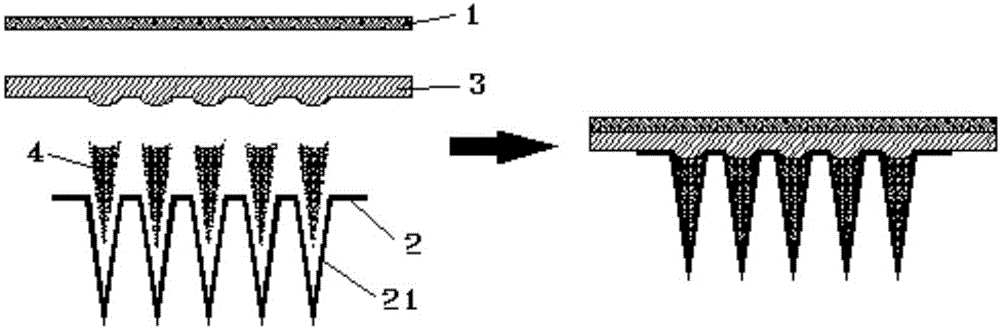

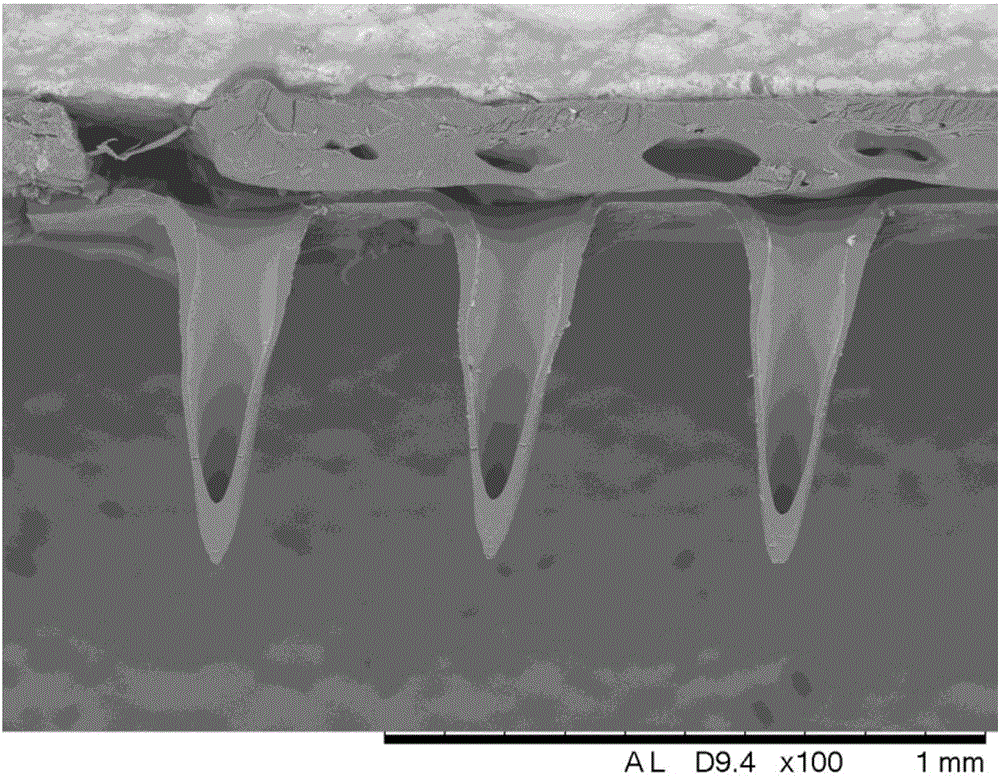

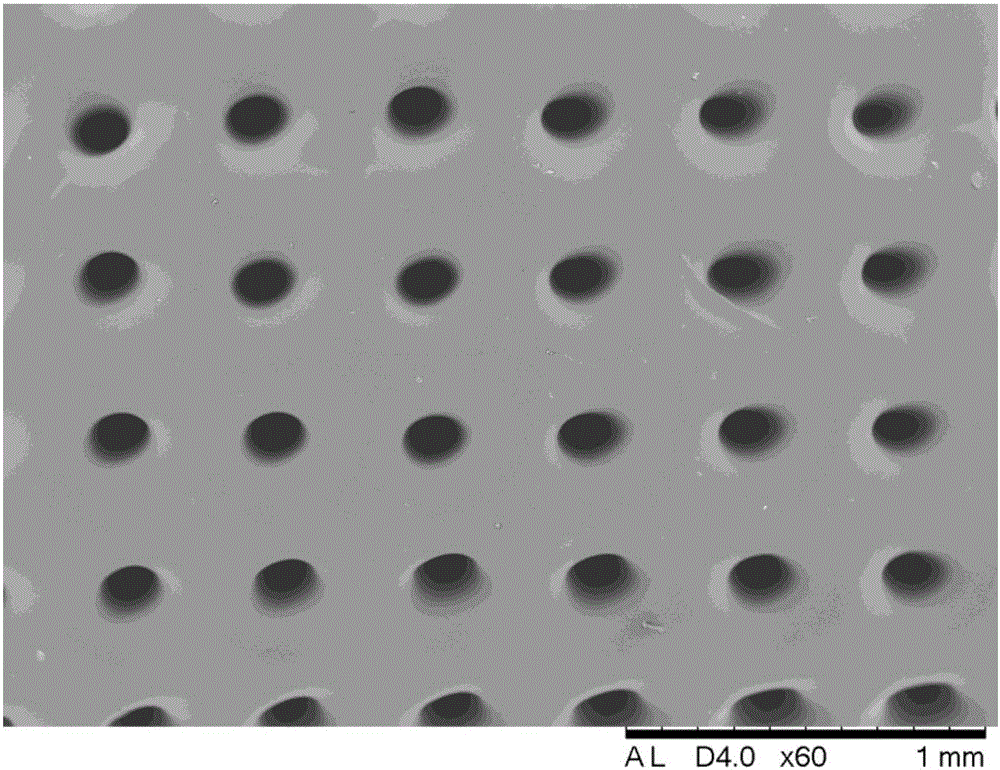

[0030] (2) Preparation of the microneedle layer: The small molecule silk fibroin solution with a concentration of 0.09g / mL was poured into a PDMS (polydimethylsiloxane) mold at a pressure of more than 0.09MPa at 4.5mg per 15*15 array. After vacuum degassing under vacuum conditions, dry at constant temperature and humidity (temperature: 40°C, relative humidity: 75%) for 24 hours;

[0031] (3) Loading of ibuprofen: Dissolve a certain dose of powdered cold medicine ibuprofen in chloroform, pour it on...

Embodiment 2

[0034] (1) Preparation of small molecule silk fibroin solution: the silkworm cocoon shell of 40g is added to 2000mL mass fraction of 0.25% Na 2 CO 3 In the solution, boil it three times at 98-100°C for 30 minutes each time, and wash it with deionized water. After degumming and drying, silk fibroin was dissolved in 9.3M lithium bromide solution at 60°C with a bath ratio of 1:10, dialyzed in deionized water for 3-4 days, concentrated to 0.09g / mL, and stored in a refrigerator at 4°C for use.

[0035] (2) Preparation of the microneedle layer: the small molecule silk fibroin solution with a concentration of 0.09g / mL was poured into a PDMS (polydimethylsiloxane) mold at a density of 0.09g / mL per 15*15 array, and the After vacuum degassing under high temperature conditions, dry at constant temperature and humidity (temperature: 25°C, relative humidity: 65%) for 24 hours;

[0036] (3) Loading of insulin: Dissolve a certain dose of powdered hypoglycemic drug insulin in HCL-Tris buffe...

Embodiment 3

[0039] (1) Preparation of small molecule silk fibroin solution: the silkworm cocoon shells of 800g are added to 40000mL of Na with a mass fraction of 0.25%. 2 CO 3In the solution, boil it three times at 98-100°C for 30 minutes each time, and wash it with deionized water. After degumming and drying, silk fibroin was dissolved in 9.3M lithium bromide solution at 60°C with a bath ratio of 1:10, dialyzed in deionized water for 3-4 days, concentrated to 0.09g / mL, and stored in a refrigerator at 4°C for use.

[0040] (2) Preparation of the microneedle layer: The small molecule silk fibroin solution with a concentration of 0.09g / mL was poured into a PDMS (polydimethylsiloxane) mold at a pressure of more than 0.09MPa at 10.5mg per 15*15 array. After vacuum degassing under vacuum conditions, dry at constant temperature and humidity (temperature: 15°C, relative humidity: 25%) for 24 hours;

[0041] (3) Loading of hyaluronic acid: Dissolve a certain dose of hyaluronic acid, a solid pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com