Zirconium-based metal organic framework material as well as preparation method and application thereof

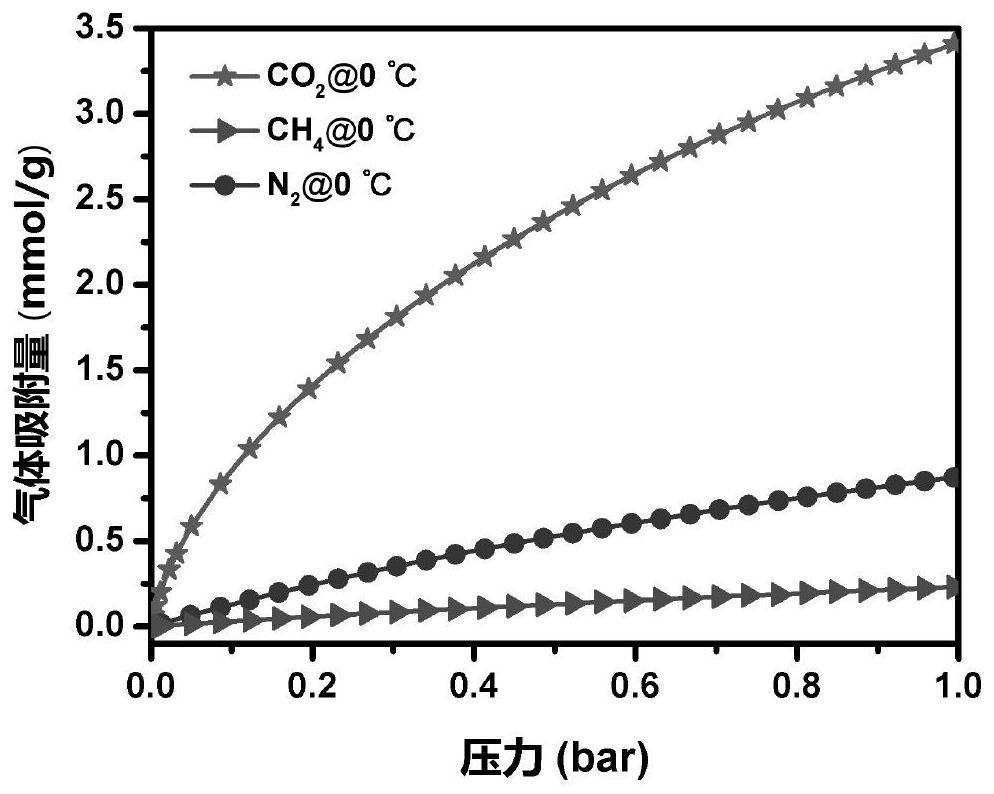

An organic framework and metal-based technology, applied in the field of zirconium-based metal-organic framework materials and their preparation, can solve the problems of low powder generation rate, low product synthesis rate, long reaction time, etc., and achieve good shape and repeatability The effect of high and high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example provides a method for preparing a zirconium-based metal organic framework material (i.e. Zr-fum-fcu-MOF powder, the same below). The specific preparation method is as follows:

[0030] (1) 0.92g ZrOCl 2 ·8H 2O was dispersed in 72ml of DMF (N,N-dimethylformamide), stirred and configured to obtain solution A; then 0.324g fum (fumaric acid) was added;

[0031] (2) Put the solution A in a water bath at 25°C and stir evenly, continue to add 15.9ml FA (formic acid), stir until clear, and obtain a mixed solution.

[0032] (3) Transfer the mixed solution to a microwave reactor, microwave reaction at 100°C for 1h, take out the reaction product after the reaction and wash it with DMF for several times, put the washed powder in a drying oven and dry it at 120°C for 24h , to obtain Zr-fum-fcu-MOF powder.

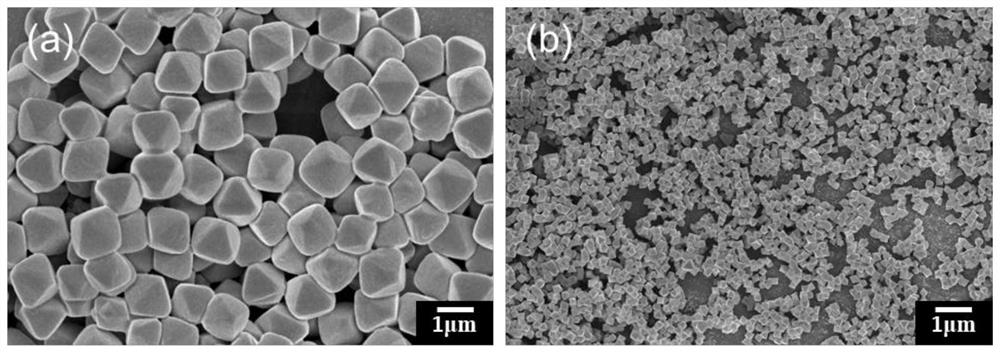

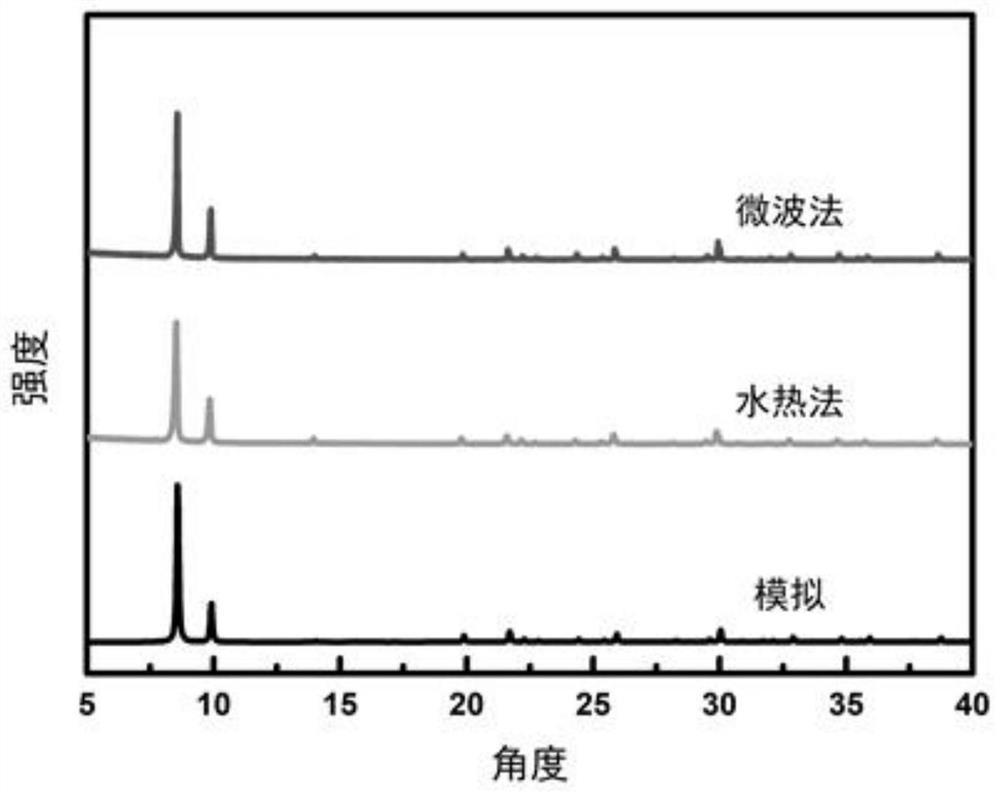

[0033] The Zr-fum-fcu-MOF powder obtained by this embodiment 1 is white, and its SEM photo is as follows figure 1 As shown in the figure (a), it shows that the p...

Embodiment 2

[0036] (1) 0.92g ZrOCl 2 ·8H 2 O was dispersed in 72ml DMF to obtain solution A; then 0.324g fum was added, and solution A was placed in a water bath at 25°C and stirred evenly;

[0037] (2) Put solution A in a water bath at 25°C and stir evenly, continue to add 10.6ml FA, stir until clear, and obtain a mixed solution;

[0038] (3) is the same as step (3) in Example 1.

Embodiment 3

[0040] (1) 0.92g ZrOCl 2 ·8H 2 O was dispersed in 36ml DMF to obtain solution A; then 0.324g fum was added, and solution A was placed in a water bath at 25°C and stirred evenly;

[0041] (2) Put solution A in a water bath at 25°C and stir evenly, continue to add 18.6ml FA, stir until clear, and obtain a mixed solution;

[0042] (3) is the same as step (3) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com