Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Good stripping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

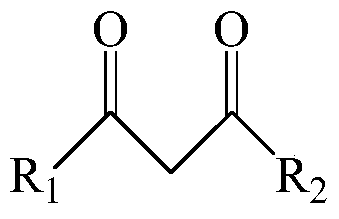

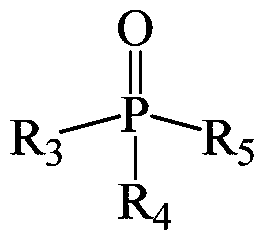

Extraction system for extracting alkaline metals or alkaline-earth metals and application of extraction system

ActiveCN105331817AReduce usageAvoid pretreatment such as acidificationProcess efficiency improvementLithiumAlkaline earth metal

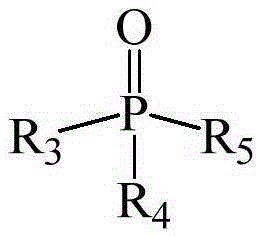

The invention discloses an extraction system for extracting alkaline metals or alkaline-earth metals. The extraction system comprises an extraction agent and a synergistic extraction agent, wherein the extraction agent is a diketone compound, and the synergistic extraction agent is a neutral phosphoric-oxygenic compound. The invention further discloses a method for extracting lithium ions from an alkaline metal solution and extracting alkaline-earth metals from a mixed solution of alkaline metals and alkaline-earth metals through the extraction system. The extraction system has excellent effects for extracting and separating alkaline metals or alkaline-earth metals; and meanwhile, a synergistic extraction agent, ferric trichloride, in the prior art is avoided in the extraction system, so that problems such as high acidity caused by the ferric trichloride and the like can be avoided, the acid dosage and the cost can be reduced, and the corrosion to devices can be reduced as well. After lithium ions or alkaline-earth metal irons are extracted by using the extraction system, the reverse extraction and regeneration processes are simple, and the operation is facilitated.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

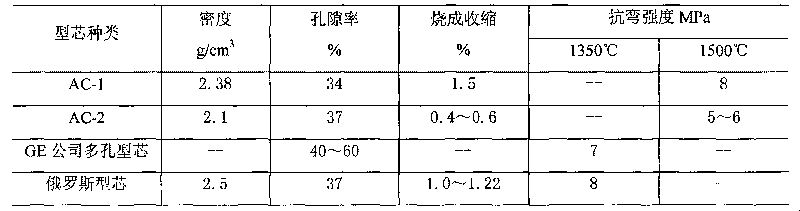

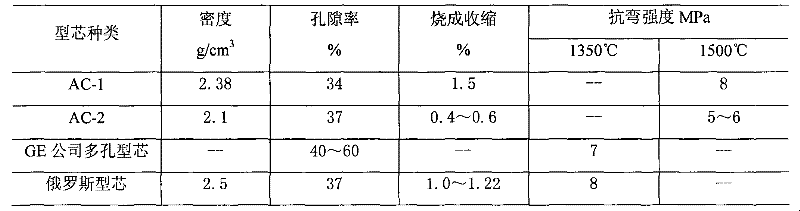

Method for preparing porous alumina ceramic core

The invention provides a method for preparing a porous alumina ceramic core. The ceramic core comprises the following raw materials: electric melting-corundum powder, porous alpha-Al2O3 powder, TiO2 powder and paraffin. The method comprises the following steps: mixing the electric melting-corundum powder, the porous alpha-Al2O3 powder and the TiO2 powder; heating an oil bath crucible type stirrer to 100 to 120 DEG C; adding the paraffin into the oil-bath crucible type stirrer to be melted; adding mixed powder to the paraffin, and stirring the mixture to obtain mixed slurry; pressing a core by adopting a hydraulic core-pressing machine, controlling the temperature of the mixed slurry to between 95 and 110 DEG C and the injection pressure to between 3.0 and 3.5MPa; and roasting the pressed core by adopting a bell type sintering furnace. The porous alumina ceramic core prepared by the method has the porosity of between 45 and 55 percent, and can effectively improve the core removing performance of the core.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

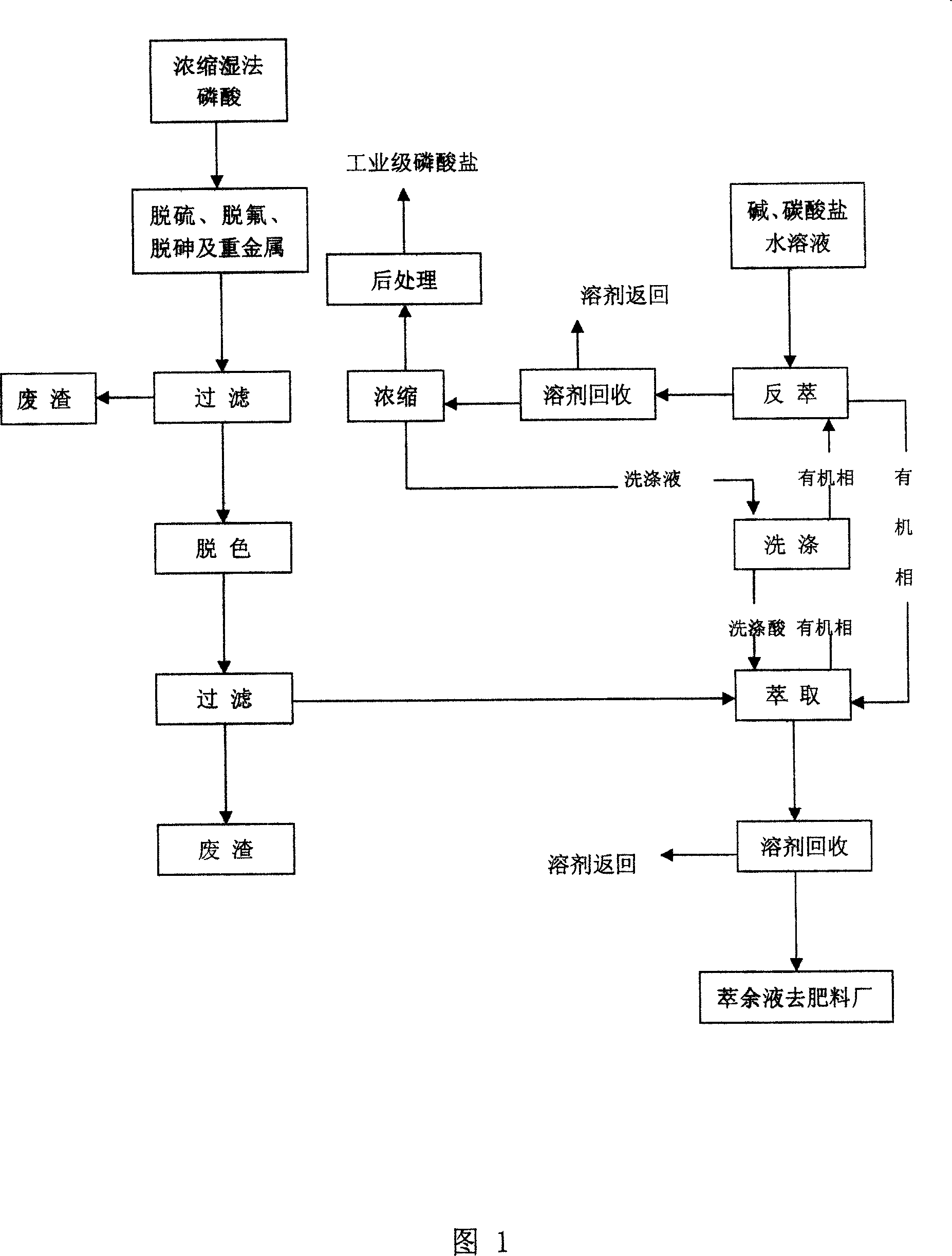

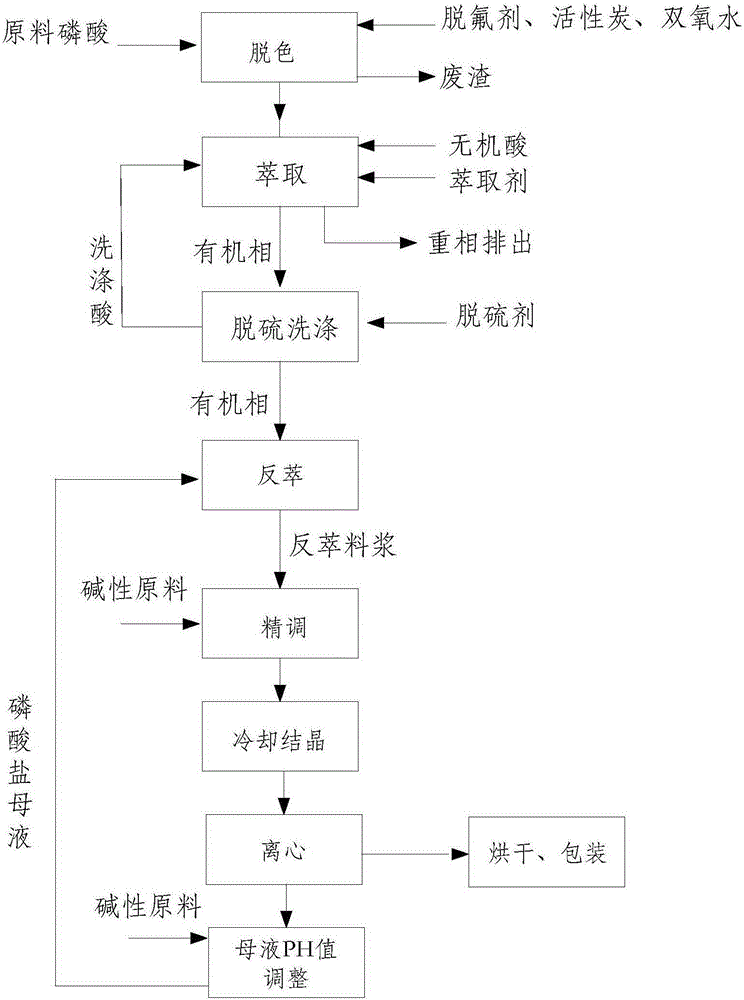

Method for preparing technical grade phosphate using wet method phosphoric acid as raw material

InactiveCN1994871ATake full advantage of the combined utilityReduce lossesPhosphatesCompound organicAlkaline earth metal

The invention discloses a making method of industry-grade phosphate based on wet process phosphoric acid as raw material, which comprises the following steps: desulfurizing; defluorinating; stripping arsenic; removing heavy metal; decoloring; extracting predisposed wet process phosphoric acid through compound organic solvent of ketone and phosphate ester; washing; reextracting; condensing; post-processing to obtain the product; adopting alkali solution of potassium carbonate, sodium carbonate or alkaline-earth metal as extractor.

Owner:YUNNAN CHEM RES INST

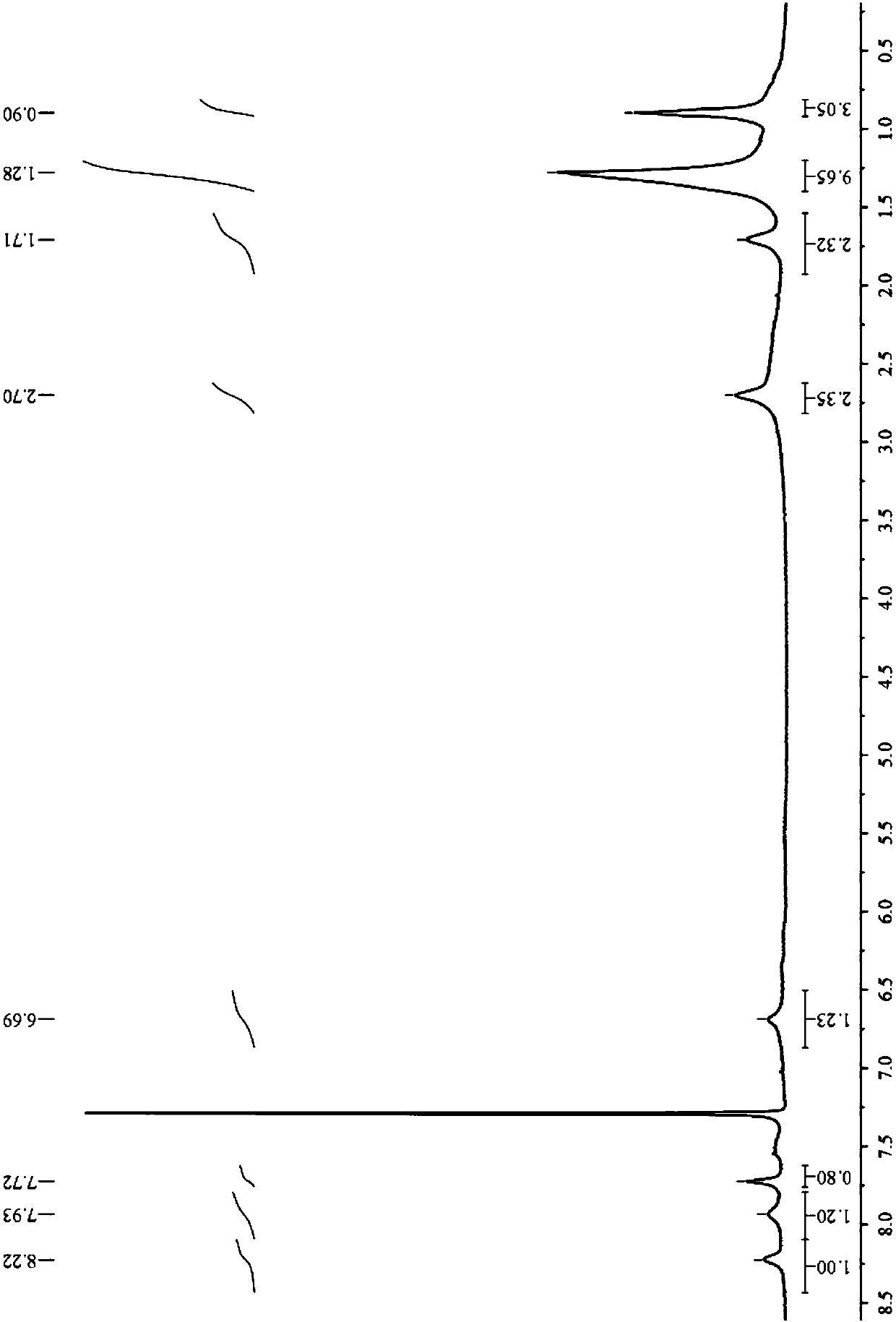

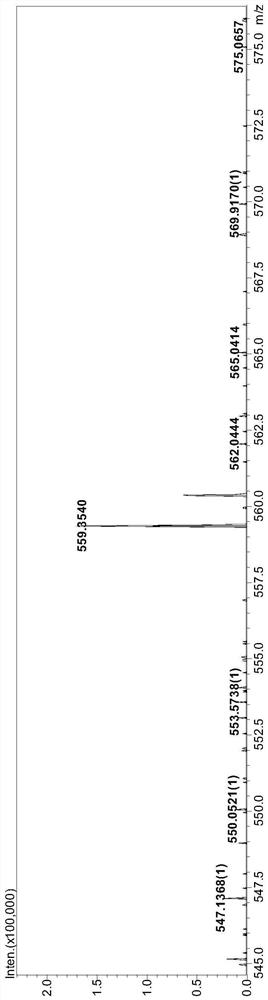

Double-pyrazole extracting agent derived from o-phenanthroline, and preparation method and application of double-pyrazole extracting agent

ActiveCN108017632AUnique rigid structureImprove extraction kineticsOrganic chemistryRadioactive decontaminationSolubilityLanthanide

The invention discloses a double-pyrazole extracting agent derived from o-phenanthroline with the following structural general formula, and a preparation method and application of the double-pyrazoleextracting agent. In the formula, R is any one selected from n-octyl, n-butyl, isobutyl, ethyl, pyridyl and phenyl. The double-pyrazole extracting agent derived from the o-phenanthroline provided by the invention has a unique rigid structure and an alkyl chain for improving the solubility, and simultaneously only four elements of C, H, O and N are contained, so that the extraction kinetics of a separation extraction system can be greatly increased, the extraction capacity of an organic phase can be increased, secondary pollutants cannot be produced, and thus the environmental protection is facilitated. The extraction agent can be used to separate Ans (actinide elements) / Lns (lanthanide elements), and can not only form a separation extraction system of the Ans / Lns, but also can be used to form a separation reverse extraction system of the Ans / Lns.

Owner:SICHUAN UNIV

Method for producing germanium concentrated ore from germanium-containing industrial liquor

The invention relates to a method for producing germanium concentrated ore from germanium-containing industrial liquor, and belongs to the technical field of nonferrous metallurgy. The method comprises that: a, a germanium complexing agent is added into the germanium-containing industrial liquor of which pH is 0.5 to 3, wherein the complexing agent is organic acid containing hydroxyl or carboxyl or / and salt of the organic acid, and the weight ratio of the complexing agent to the germanium is 3-10:1; b, an organic reagent of quaternary ammonium with an R4N structure or tertiary amine with an R3N structure is used as an extracting agent to extract the germanium in the liquor obtained in step a, wherein R is hydrocarbyl or alkyl or fatty group, N is organic ammonium salt, and the extracting agent accounts for 10 to 50 percent of the extracted liquor by volume; c, NaOH water solution or Na2CO3 water solution of which the concentration in percentage by weight is 5 to 30 percent is used for reversely extracting the germanium-containing organic phase obtained in step b; and d, the pH of the obtained reverse extracted liquor is adjusted to 8 to 12 by acid, then the liquor is dehydrated twice and filtered, and the sediment is dried to form the germanium concentrated ore. The method can produce the germanium concentrated ore from various germanium industrial liquors, the extracting agent and the complexing agent are easily obtained, the extracting and reverse extracting effects are good, and the yield of the germanium is high.

Owner:YUNNAN WUXIN IND

Composite extraction agent and method for extracting, separating and recycling indium through composite extraction agent

ActiveCN105018753AEnhanced selective extraction capacityStrong selective extraction abilityProcess efficiency improvementIndiumPhase splitting

The invention relates to a composite extraction agent and a method for extracting, separating and recycling indium through the composite extraction agent, and belongs to the technical field of wet metallurgy. The composite extraction agent comprises, by volume, 5%-30% of P204, 5%-20% of TBP, 5%-20% o TRPO and 40%-70% of sulfonated kerosene. The method includes the steps that firstly, the composite extraction agent is added to an indium raffinate stock solution for extraction, and indium-loaded organic phases are obtained after extraction and separation are completed; mixed acid composed of sulfuric acid and hydrochloric acid is added to the obtained indium-loaded organic phases for reverse extraction for 10-15 min, the phase ratio of the indium-loaded organic phases to the sulfuric acid and the hydrochloric acid is 5:1-15:1, and a stripping solution is obtained after phase splitting; and metal is added to the stripping solution for displacement according to the liquid-solid ratio of 8-15 ml / g, and sponge indium is obtained finally. All functional groups which have different natures and are included in the composite extraction agent participate in the extraction reaction, so that the selective extraction capacity of the extraction agent is improved, and the reverse extraction property of indium is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Rare earth coated calcium oxide based ceramic core

The invention discloses a rare earth coated calcium oxide based ceramic core, which is characterized by being composed of the following raw materials by weight: 6-12wt% a mineralization agent, 10-17wt% of a plasticizer, 1-1.4wt% of oleic acid, and the balance rare earth coated calcium oxide powder. The product has enough room temperature, high temperature strength, good chemical stability, low firing shrinkage and linear expansion rate, adopts rare earth coated calcium oxide as aggregate and has very good core removal ability, thus reducing the use cost.

Owner:WUHU ZHEXIN NEW ENERGY

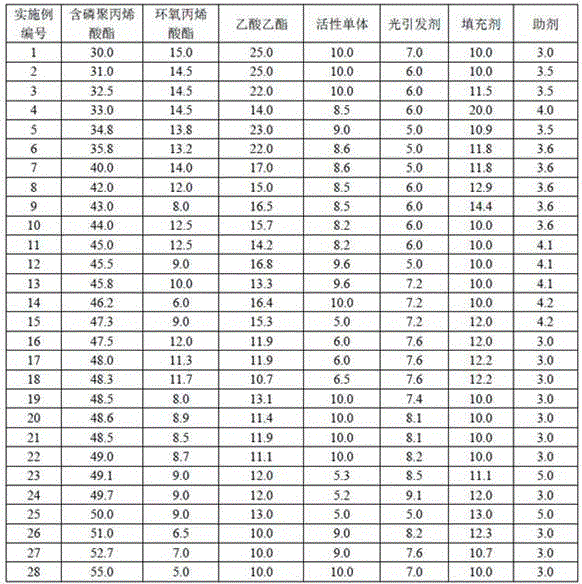

Method for improving poriness of alumina ceramic mold core

The invention relates to the technical field of preparation of ceramic, in particular to a method for improving the poriness of an alumina ceramic mold core. The technical scheme is as follows: feeding plasticizer which occupies 15 to 20 percent of core material by weight into a container with a stirrer and heating up to 100 to 120 DEG C; pressing mold core slurry into a mold core on an injection machine, insulating the mold core for 4 hours under the temperature of 200 DEG C, heating up to 400 DEG C and insulating for 2 hours, heating up to 600 DEG C and insulating for 2 hours, heating up to 900 DEG C and insulating for 2 hours, heating up to 1250 DEG C and insulating for 4 hours, and cooling down to 100 DEG C along with a furnace and taking out from the furnace; soaking the mold core in ethylsilicate digest with the viscosity of (3.6 to 8)*10<-6> Pa.s for 30 to 40 minutes, air drying for 24 hours and then ammonia drying for 30 minutes; placing the mold core which is strengthened for the first time in phenolic alcohol-soluble varnish, soaking for 2 to 3 hours under ambient temperature, and then air drying for 24 hours; and baking the strengthened mold core under the temperature of 150 DEG C for 2 hours to make the end product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

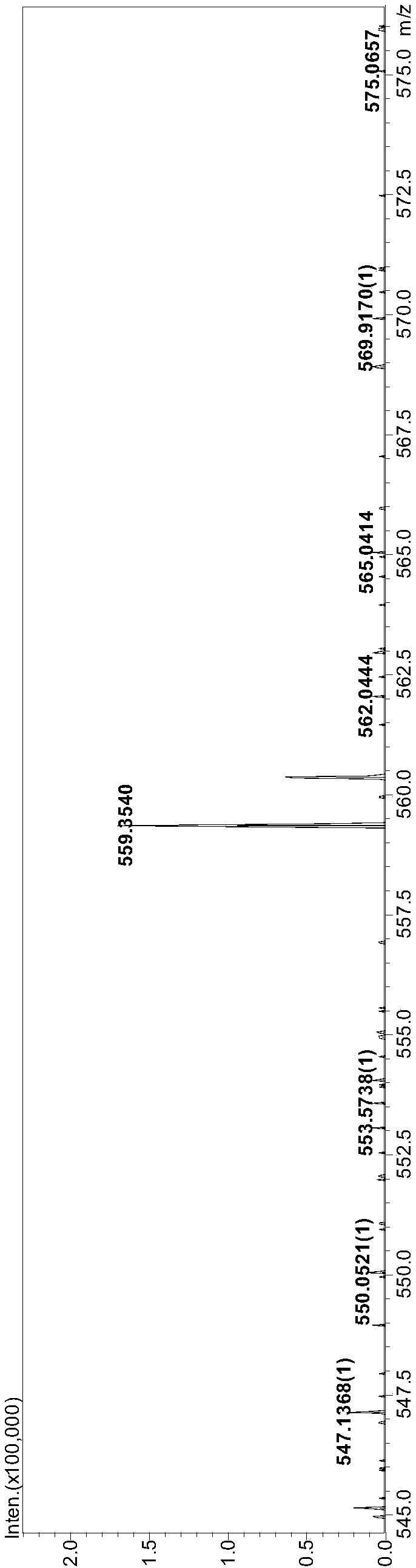

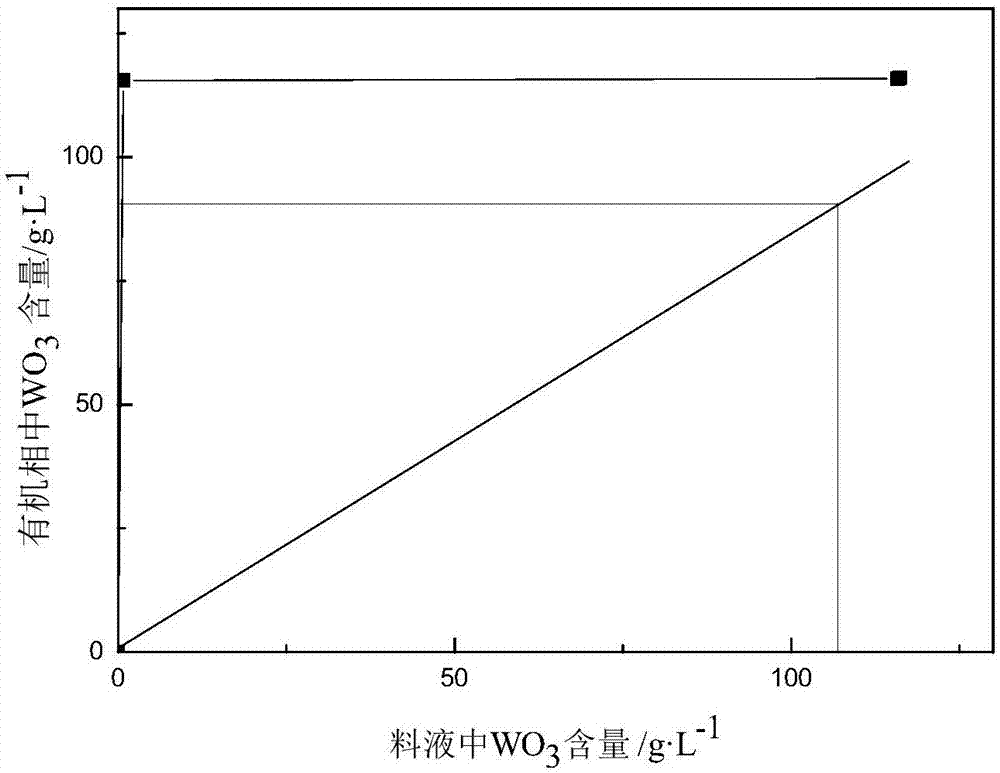

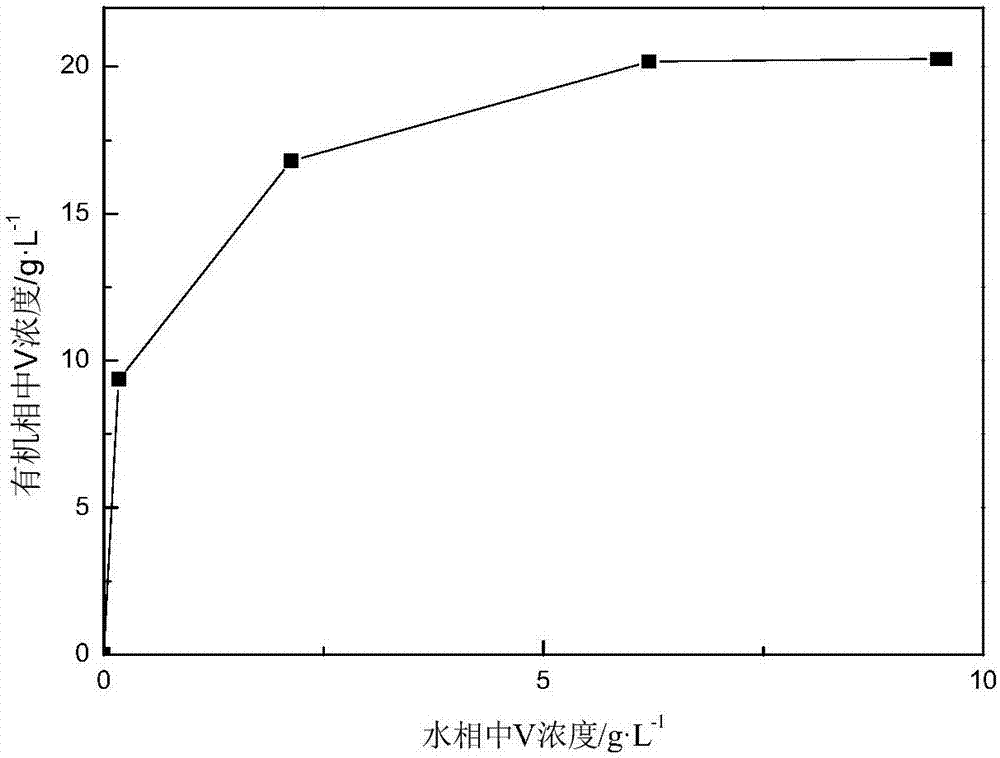

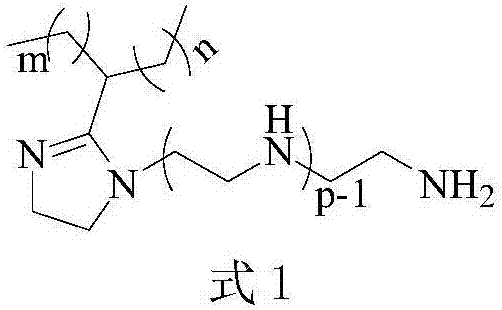

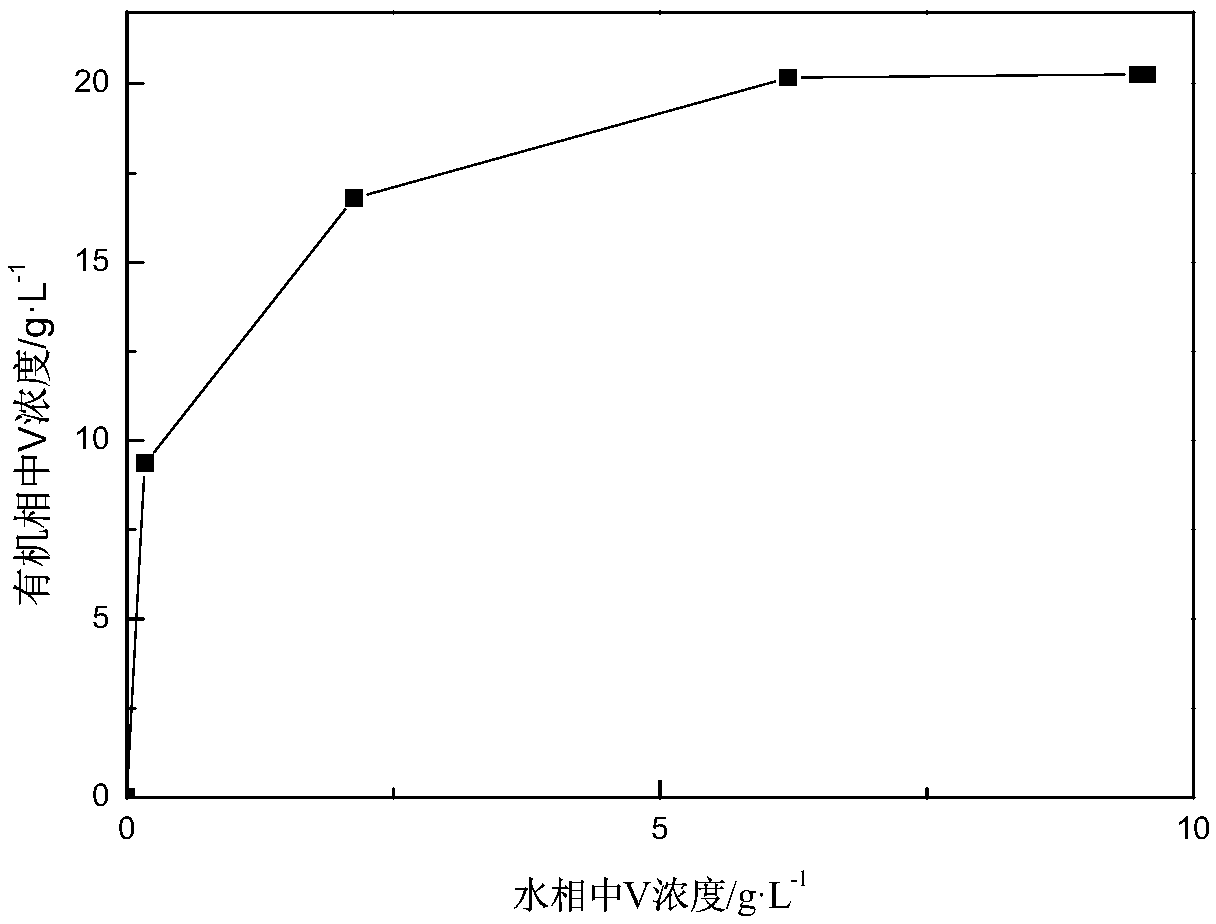

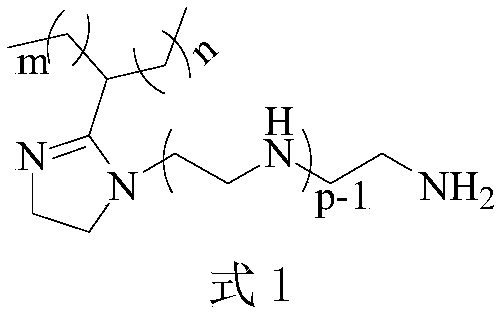

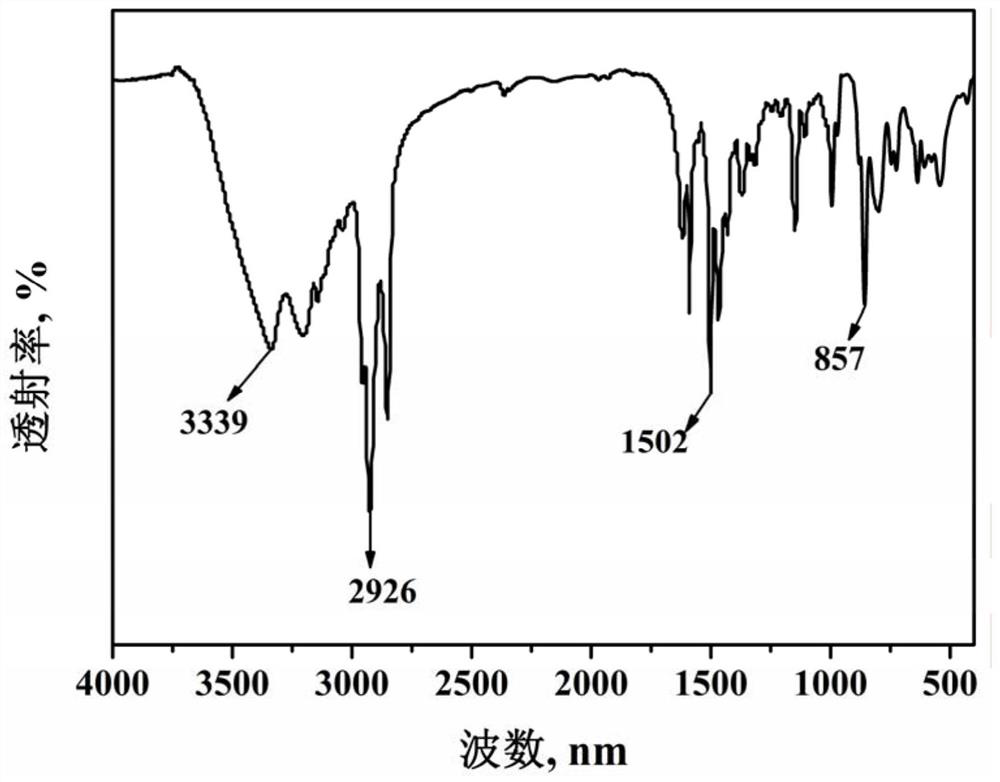

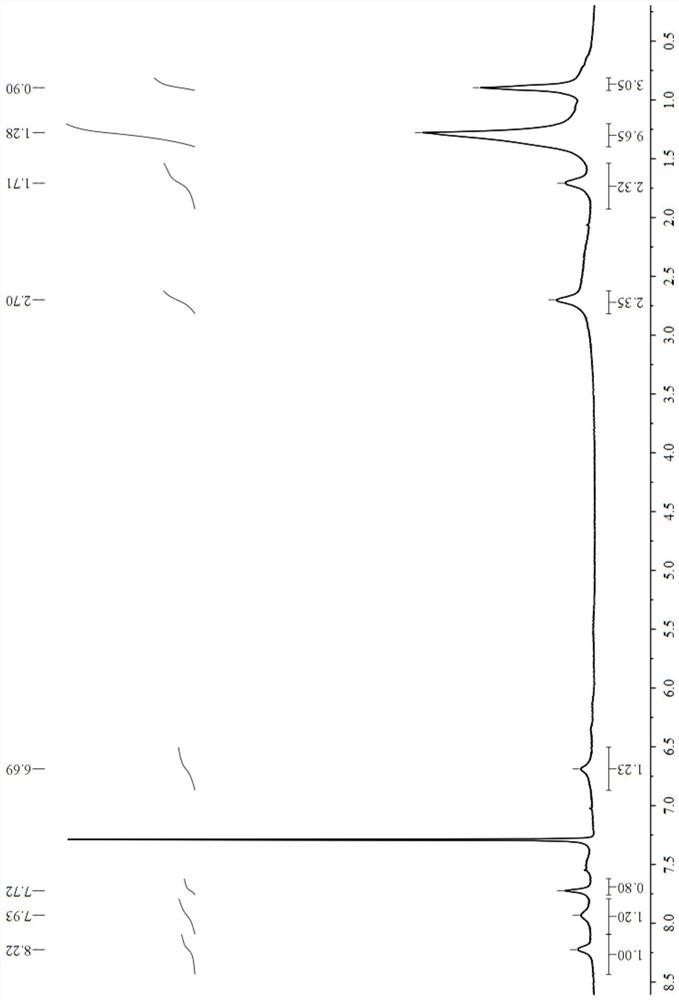

Branched-chain long-chain fatty acid base imidazoline extraction agent and preparing method and application thereof

ActiveCN107385211AImprove extraction abilityLarge saturated capacityOrganic chemistryChemical recyclingLong chain fatty acidPhase splitting

The invention discloses a branched-chain long-chain fatty acid base imidazoline extraction agent and a preparing method and application thereof. The imidazoline extraction agent comprises multiple N atoms and long-branch-chain alkyl groups. The preparing method of the imidazoline extraction agent comprises the steps that in the normal pressure, carboxylic acid and polyethylene polyamine are subjected to the reaction under the action of a solid catalyst, after the reaction is finished, the solid catalyst is recycled through solid-liquid separation, the liquid mixture is distilled, the raw material incompletely reacted is recycled, and then the branched-chain long-chain fatty acid base imidazoline extraction agent is obtained. The preparing method has the beneficial effects that reaction conditions are moderate, the catalyst can be repeatedly used, and equipment investment and operation cost are low; the imidazoline extraction agent is used for extraction negative ions including tungsten, molybdenum and vanadium, the beneficial effects that the extraction volume is high, the phase splitting time is short, and the extraction and reverse extraction performance is excellent; and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

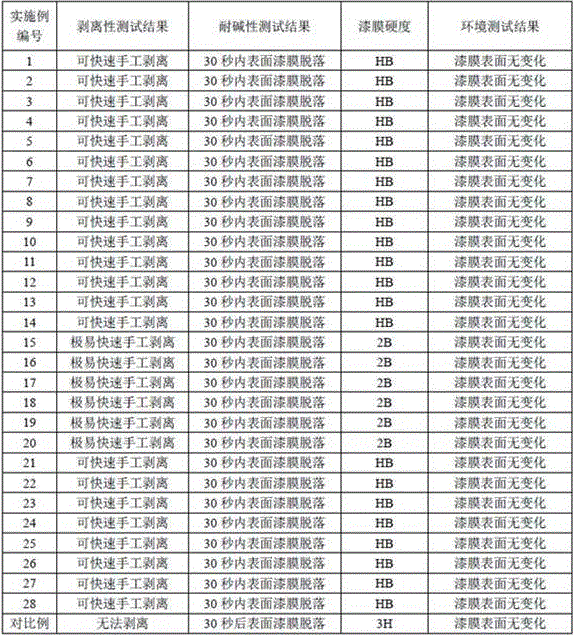

Formula and preparation method of peelable photocuring glass coating

ActiveCN105820744AGood protectionGood stripping performancePolyurea/polyurethane coatingsEpoxy resin coatingsPhotoinitiatorChemistry

The invention discloses a peelable photocuring glass coating in which phosphorus-containing urethane acrylate, epoxy acrylate and ethyl acetate are used together as main body resin, and active monomers, photoinitiator, filling agents and other additives are also added. When glass is coated with the peelable photocuring glass coating, not only is a good protection function achieved for the glass, but also a good peeling property is achieved. Meanwhile, a preparation method and a use method of the coating are both energy-saving and environment-friendly, the cost of a procedure of glass surface protection can be effectively lowered, a soft film can be formed, and the machining process is not affected.

Owner:FOSHAN CITY GREEND CHEM

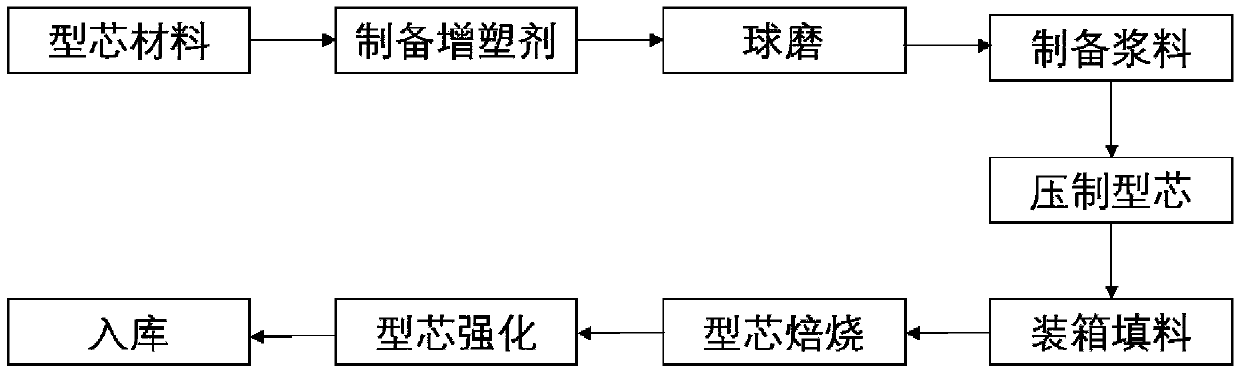

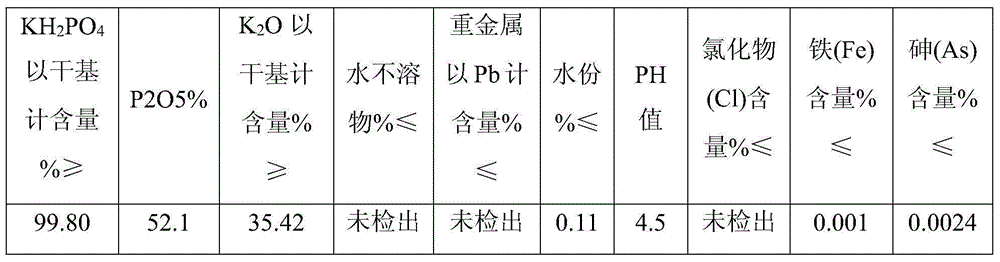

Water-soluble ceramic core for investment precision casting aluminum alloy and preparation method of water-soluble ceramic core

InactiveCN109574636AMeet casting technical requirementsPerfect stripping performanceFoundry mouldsFoundry coresPotassiumWater soluble

The invention provides a water-soluble ceramic core for investment precision casting aluminum alloy and a preparation method of the water-soluble ceramic core. The water-soluble core is prepared fromthe following ingredients: a base material and mineralizing agents, wherein the base material is emery powder, and the mineralizing agents are electric melting quartz powder, sodium chloride and potassium chloride. The water-soluble ceramic core solves a complex inner cavity passage structure part for aluminum alloy investment precision casting, not only guarantees the dimensional precision of thecore and press formability, but also achieves good wet strength and sintering strength, the strength after sintering is 7-10MPa, and the strength after strengthening is 20-25MPa.

Owner:SHANGHAI JIAO TONG UNIV +1

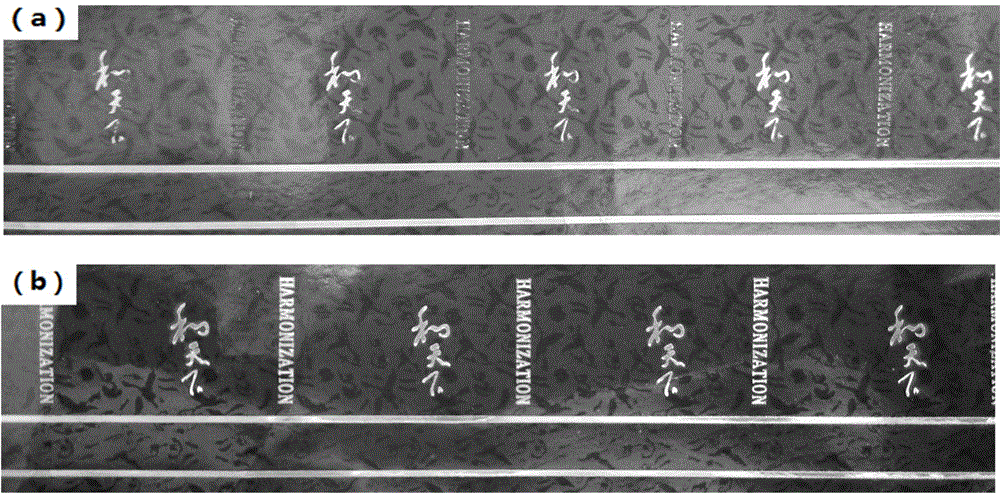

High spectral image strip noise elimination method with integration of wavelet transformation and local interpolation

InactiveCN106504214AProtection detailsEasy to handleImage enhancementImage analysisBroadbandWavelet transform

The invention relates to a high spectral image strip noise elimination method with integration of wavelet transformation and local interpolation. The high spectral image strip noise elimination method with integration of wavelet transformation and local interpolation includes the following steps: inputting a high spectral image data cube; judging the high spectral image wave band data; rejecting the damaged high spectral image wave band data; reading the normal high spectral image data of the kth wave band; respectively using two dimension stationary wavelet and local interpolation to filtering strip noise of the high spectral image data; and then performing fusion processing. The high spectral image strip noise elimination method with integration of wavelet transformation and local interpolation can effectively eliminate common thin strip noise, can eliminate the strip noise of broadband and ultra wide band and the strip noise which is distributed without rules, can preferably keep some details and edge geometrical information in the images, at the same time can be applied to different high spectral images, and has relatively high universality.

Owner:XIJING UNIV

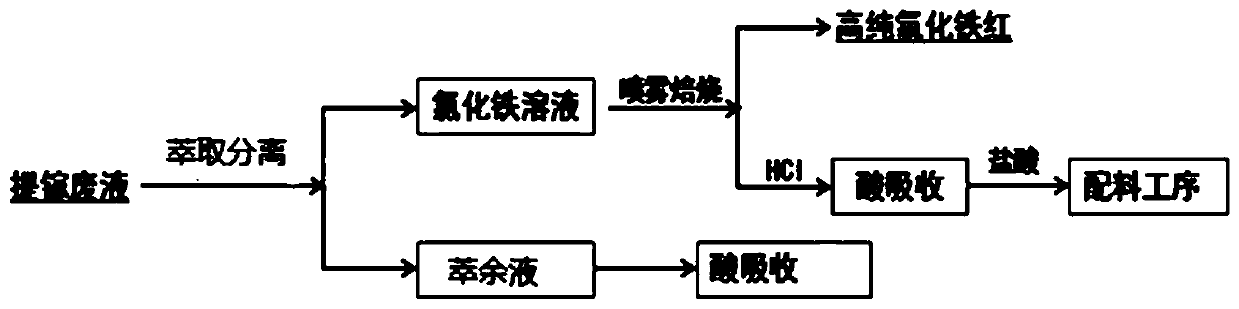

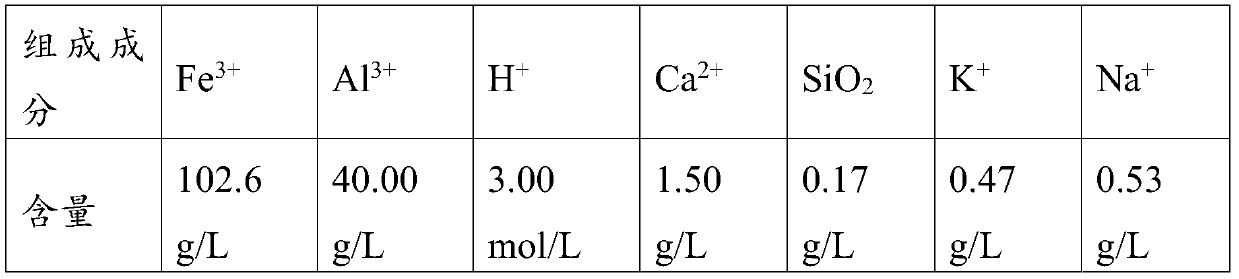

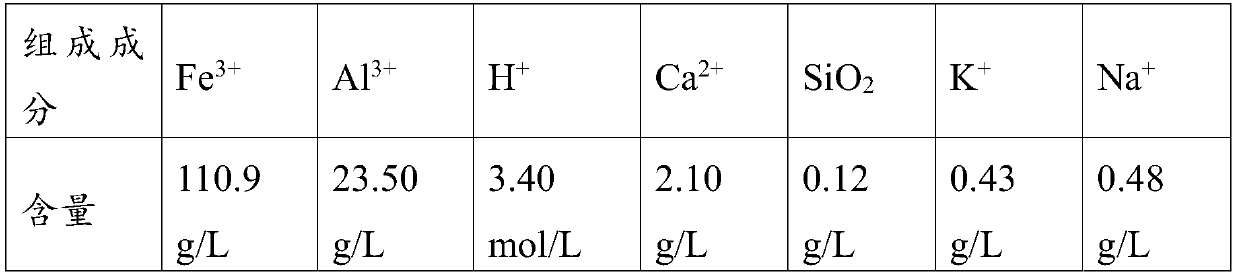

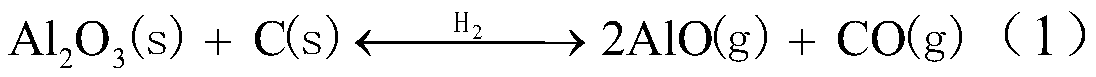

Gallium extracted waste liquor resource utilization technology in process of one-step acid solution method technology

InactiveCN110885931ARealize recycling of resourcesExtract ironChlorine/hydrogen-chlorideProcess efficiency improvementPhysical chemistryIron chloride

The invention discloses a gallium extracted waste liquor resource utilization technology in the process of the one-step acid solution method technology. The technology comprises the following steps that firstly, iron in gallium extracted waste liquor is extracted, and low-iron raffinate and an iron-contained load organic phase are obtained; secondly, a stripping agent is used for carrying out reverse extraction on the load organic phase, and a reverse extraction liquid ferric chloride solution is obtained; and thirdly, the ferric chloride solution is subjected to mist spraying and roasting, thus ferric chloride is decomposed to obtain ferric oxide red and chlorine hydride gas, the low-iron raffinate is utilized for absorbing and dissolving the chlorine hydride gas in the acid absorbing working procedure, and an obtained acid solution serves as acid for coal ash acid solution in the one-step acid solution method. According to the technology, resource recycling of iron ions, aluminum ions and hydrochloric acid in the waste liquor can be achieved with the low cost, and the technology is environmentally friendly and saves energy.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

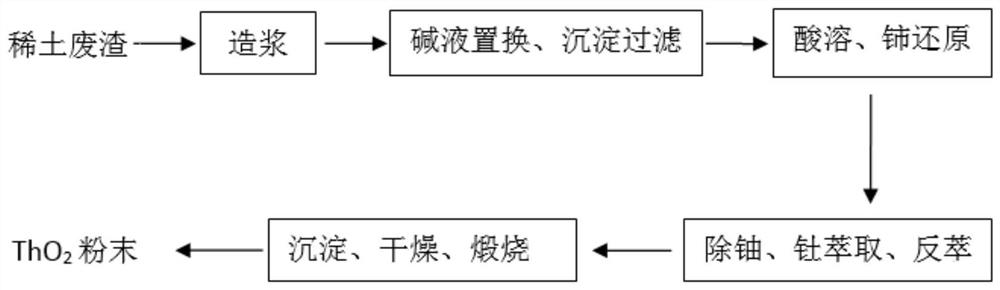

Method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues

PendingCN112593099AReduce dosageEasy extractionProcess efficiency improvementRare-earth elementEngineering

The invention belongs to the technical field of radioactive waste treatment, and particularly relates to a method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues.The method is used for alkalization treatment of the rare earth waste residues, not only can realize preliminary separation of thorium elements and part of impurity elements, but also can effectivelysolve the problem of equipment corrosion, meanwhile, the generated thorium hydroxide is easily converted into a thorium nitrate solution, and the next extractive purification process is carried out.According to the method, the thorium nitrate is extracted and purified by adopting a centrifugal extraction technology, the method has the characteristics of high recovery rate, continuous operation,low energy consumption and the like, the thorium elements are efficiently separated from other rare earth elements, and therefore the method has important significance in extracting and preparing nuclear-grade ThO2 powder from the rare earth waste residues.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

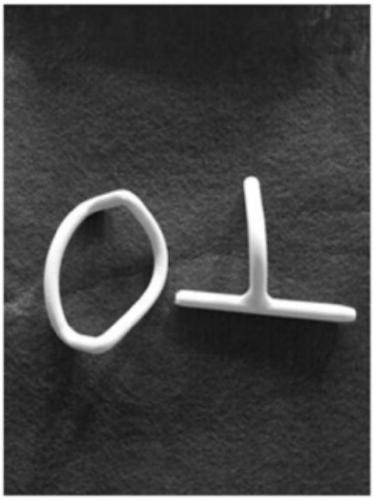

Nanometer composite ceramic core

The invention discloses a nanometer composite ceramic core which is characterized by comprising the following raw materials in percentage by weight: 12%-18% of mineralizing agents, 14%-20% of plasticizing agents, 2%-3% of nanometer silicon dioxide, 1%-2% of nanometer magnesium oxide, 2%-3% of microcrystalline wax and the balance of rare earth coated nanometer composite powder. The nanometer composite ceramic core disclosed by the invention is sufficient in bending strength and small in firing shrinkage rate and can ensure the invariability of a dimension and a shape and effectively enhance the porosity of a core by adopting the raw materials with different fineness, thereby well improving the core stripping property.

Owner:浙江振兴阿祥集团有限公司

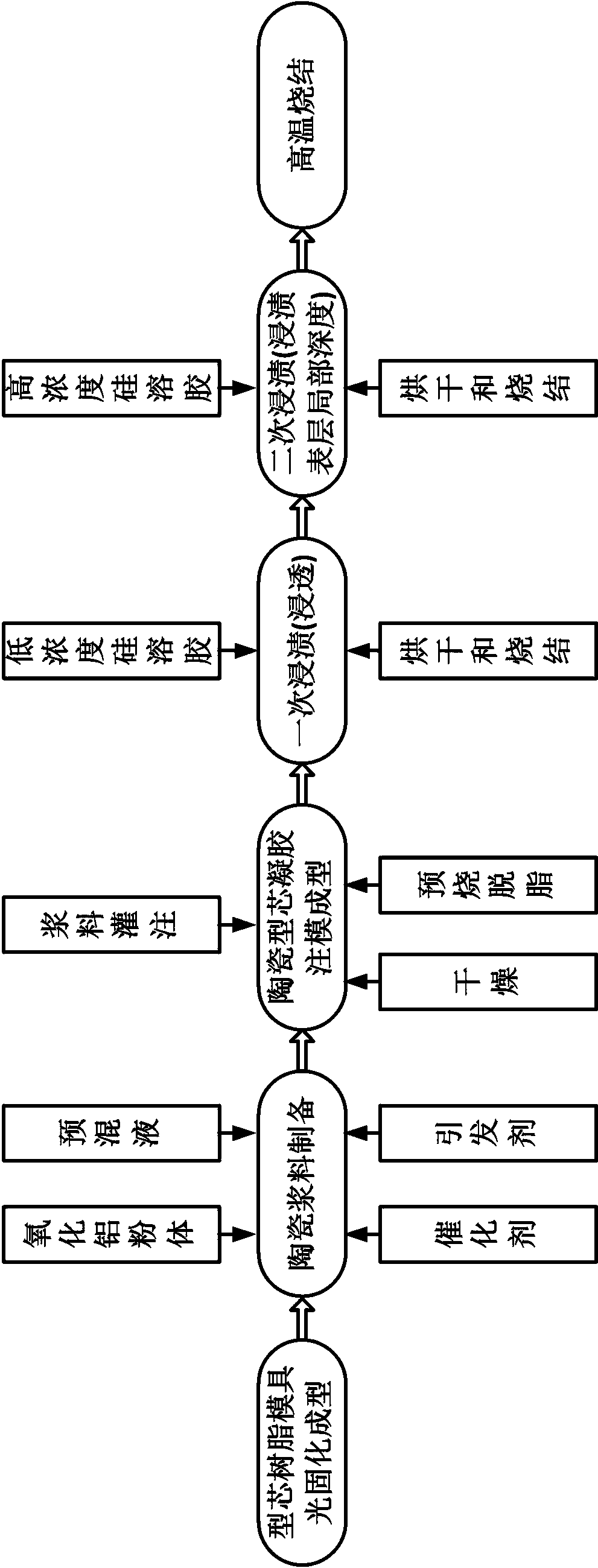

Method for manufacturing surface compact internal loose ceramic core for precision casting of hollow turbine blade

ActiveCN110465627AImprove mechanical propertiesEasy to crushFoundry mouldsFoundry coresHigh concentrationSurface layer

The invention relates to a method for manufacturing the surface compact internal loose ceramic core for precision casting of the hollow turbine blade, and effectively solves the problems of insufficient deformability and difficulty in core removal of the ceramic core. The method comprises the following steps of 1, preparing a resin mold, specifically, manufacturing a core resin mold by adopting aphotocuring rapid molding method; 2, preparing a ceramic slurry, specifically, preparing the ceramic slurry for gel injection molding; 3, manufacturing a ceramic core, specifically, pouring the ceramic slurry into a ceramic core resin mold; 4, carrying out first dipping treatment, specifically, carrying out impregnation treatment on the pre-sintered degreased ceramic core by adopting a low-concentration silica sol; and 5, carrying out secondary impregnation treatment, specifically, carrying out dipping treatment on the core by adopting a high-concentration silica sol. According to the method,a ceramic core blank is manufactured on the basis of a photo-curing rapid molding technology and a gel injection molding technology, silica sol with different concentrations is impregnated twice, thedipping depth of the silica sol is controlled, and therefore the preparation of the aluminum oxide-based ceramic core with dense surface layer and central porous is realized.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

A kind of extraction system for extracting alkali metal or alkaline earth metal and its application

ActiveCN105331817BReduce usageAvoid pretreatment such as acidificationProcess efficiency improvementLithiumAlkaline earth metal

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

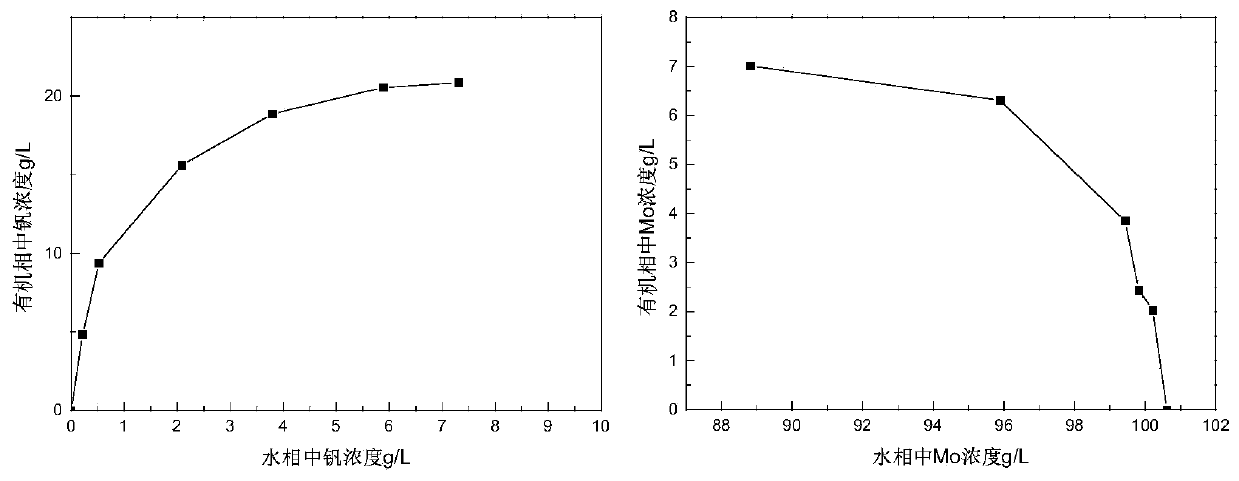

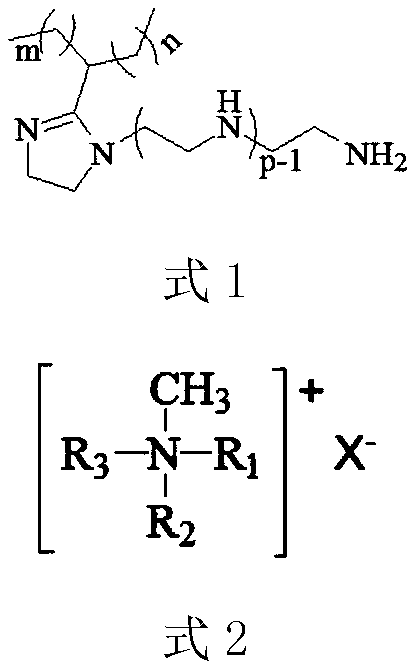

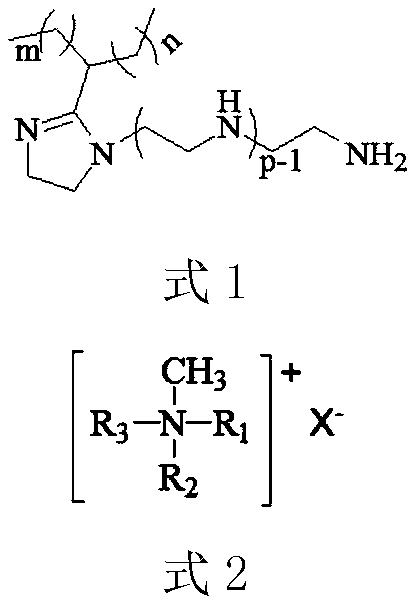

A mixed amine extractant for the separation of molybdenum and vanadium and a method for separating and recovering molybdenum and vanadium from spent catalysts

ActiveCN109022797BLarge saturated capacityShort split timeProcess efficiency improvementPtru catalystPhysical chemistry

The invention relates to a mixed amine extractant for the separation of molybdenum and vanadium and a method for separating and recovering molybdenum and vanadium from waste catalysts. The mixed amine extractant includes imidazole compounds and quaternary ammonium salt compounds, which are separated from waste catalysts. The method for recovering molybdenum and vanadium is as follows: the waste catalyst containing molybdenum and vanadium is leached with alkali to obtain a leach solution containing molybdenum and vanadium, and the leach solution containing molybdenum and vanadium is extracted and separated by an organic phase containing a mixed amine extractant, and the raffinate The solution is a molybdenum-containing solution, and the loaded organic phase is washed and stripped to obtain a vanadium-containing solution; the mixed amine extractant has the characteristics of large saturation capacity, short phase separation time, excellent extraction and stripping performance, and high separation coefficient of molybdenum and vanadium. The method can realize high-efficiency separation of vanadium and molybdenum in the alkaline solution system, and has good industrial application prospects.

Owner:肇庆市珈旺环境技术研究院

Alumite sticky layer coating containing acrylic monomers and using method thereof

InactiveCN105694562AExcellent ironing performanceGood ironing performancePolyurea/polyurethane coatingsHot stampingPolymer science

The invention belongs to the technical field of high polymer materials, and relates to an alumite sticky layer coating and a using method, in particular to an alumite sticky layer coating containing acrylic monomers. The alumite sticky layer coating is prepared from, by mass, 40-60 parts of acrylic monomers, 1-4 parts of silicon oxide powder, 1-6 parts of rosin and 50-70 parts of a dispersion solvent. The invention further discloses a using method of the alumite sticky layer coating containing the acrylic monomers. Various auxiliary materials and acrylic resin are adopted for forming the alumite sticky layer coating with the excellent stamping performance according to the certain ratio, and acrylic resin with the single good stamping performance is converted into the alumite sticky layer coating with the good stamping performance, slitting performance, adhesive force and stripping performance. According to industrial application, compared with common alumite, alumite obtained through the alumite sticky layer coating containing acrylic monomers overcomes the defects of not solid hot stamping, leakage stamping and the like and has the obvious advantage.

Owner:YANGZHOU XIANGHUA NEW MATERIAL TECH CO LTD

Spinel-magnesium-based ceramic core and preparation method thereof

ActiveCN112794711ASufficient bending strengthImprove thermal shock resistanceFoundry mouldsFoundry coresCompression moldingSlurry

The invention discloses a spinel-magnesium-based ceramic core and a preparation method thereof, and belongs to the field of ceramic core preparation in the field of precision casting. Raw materials of the spinel-magnesium-based ceramic core comprise a powder raw material and a binder, and the powder raw material comprises the following components in percentage by mass: 50%-90% of spinel powder, 0%-30% of zirconium oxide powder, 0%-5% of titanium dioxide powder and the balance of magnesium oxide powder; and the mass of the binder accounts for 15-25% of the mass of the powder raw material. The preparation method of the spinel-magnesium-based ceramic core comprises the following steps: mixing powder according to the ratio, preparing a binder, mixing the preheated mixed powder and the binder to prepare slurry, carrying out compression molding on the slurry by adopting a hot-press injection molding method, and sintering to obtain the spinel-magnesium-based ceramic core. The spinel-magnesium-based ceramic core has the advantages of being high in strength, small in shrinkage rate and easy to remove, and meanwhile the thermal shock resistance is improved.

Owner:NORTHEASTERN UNIV

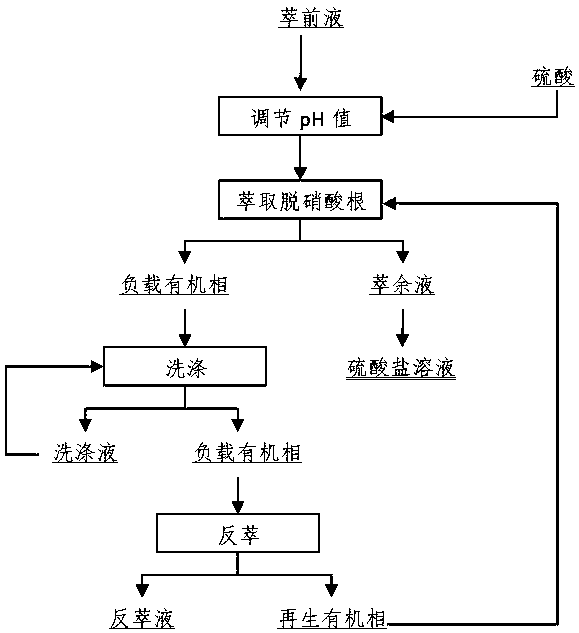

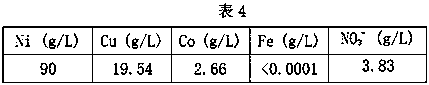

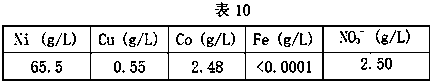

Method for removing nitrate from nickel copper cobalt sulfate solution

InactiveCN109911948ARealize selective extraction and separationSolve the problem of removing nitrateNickel sulfatesHydrometallurgyCopper

The invention discloses a method for removing nitrate from a nickel copper cobalt sulfate solution, belongs to the technical field of nickel copper cobalt hydrometallurgy, and solves the problem thatthe nitrate in the nickel copper cobalt sulfate solution is difficult to remove. The method comprises the following steps: A, adjusting the pH value: adding a sulfuric acid solution for adjusting thepH value of the nickel copper cobalt sulfate solution to 1.0-2.0; B, extracting for removing nitrate ions: extracting by using an extracting organic phase to obtain a nitrate ion-containing supportedorganic phase and a sulfate-containing raffinate respectively, wherein an extractant in the extracting organic phase is N235. Selective extraction separation of the nitrate is achieved by using the N235, so that the nitrate ion removing rate is high, and the purity of the sulfate solution and the metal ion concentration can be maintained in the technological process.

Owner:JINCHUAN GROUP LIMITED

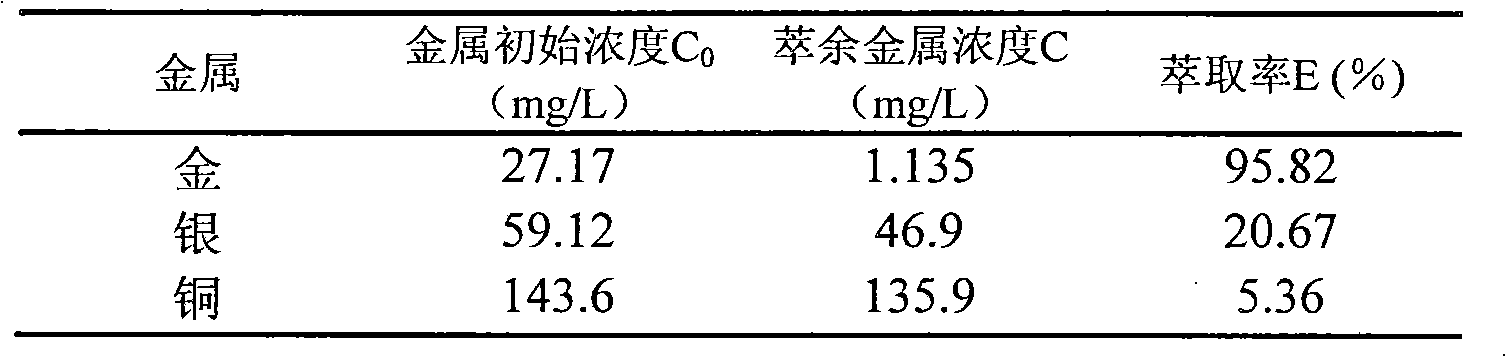

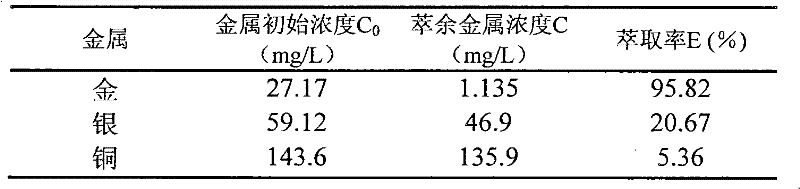

Method for separating and extracting gold from cyanide gold-leaching barren solution

The invention discloses a method for separating and extracting enriched gold from cyanide gold-leaching barren solution, which comprises the following steps: evenly mixing trialkyl phosphorus oxide and tributyl phosphate, and adding diluent to obtain extracted organic phase; adding salting-out agent into cyanide gold-leaching solution; adding the extracted organic phase, oscillating and contacting for 1-20 min at the normal temperature, and setting aside for phase-splitting to obtain gold-bearing organic phase, wherein the volume ratio between the extracted organic phase and the cyanide gold-leaching liquid is 1:1-1:20; and carrying out back-extraction on the gold-bearing organic phase by back extracting agent at 40-70 DEG C to obtain back-extracted gold solution. By adopting the method, the extraction ratio reaches more than 96 percent, and the back-extraction ratio reaches more than 90 percent; and the extracted organic phase can be recycled circularly and has remarkable economic and environmental benefits. The invention has simple operation, good extraction effect, simple and easily-obtained extraction agent, low price, less consumption amount, fast extraction speed, short phase-spitting time, higher selectivity, convenient industrial achievement, saved cost and improved efficiency.

Owner:JINAN UNIVERSITY

Hollow blade ceramic core material, preparation method thereof and method for manufacturing hollow blade ceramic core by using material

InactiveCN110734278AImprove high temperature resistanceOptimized for ease of core removalAdditive manufacturing apparatusFoundry mouldsCeramicSilicon oxide

The invention discloses a 3D printed hollow blade ceramic core material, a preparation method thereof and a method for manufacturing a hollow blade ceramic core by using the material. The preparationmethod is characterized in that modifier zirconite is added into a traditional 3D printing pure silicon oxide ceramic formula; therefore, the high-temperature performance of the 3D printing silicon oxide ceramic product is obviously improved; the average high-temperature bending strength is improved from 6.72 Mpa of pure silicon oxide to 24.76 Mpa after heat preservation is conducted for 30 min atthe temperature of 1340 DEG C, the soda boiling core removal effect of the hollow blade ceramic core made of the material is further optimized, and the soda boiling core removal time of a turbine blade is shortened from about 30 days to 2 days.

Owner:康硕(德阳)智能制造有限公司

Emulsion liquid membrane for extracting copper and cyanide in cyanide waste water and use method thereof

InactiveCN105692752AReduce effluxGood stripping performanceWater contaminantsWaste water treatment from metallurgical processEmulsion liquid membraneOil phase

Provided are an emulsion liquid membrane for extracting copper and cyanide in cyanide waste water and a use method thereof.Raw materials are composed of an oil phase and a water phase, and the raw materials of the oil phase comprise an extraction carrier, a mass transfer modifying agent, a diluent and an emulsifying agent or comprise an extraction carrier, a mass transfer modifying agent, a stabilizer, a diluent and an emulsifying agent.The use method comprises the steps that the emulsion liquid membrane used for extracting copper and cyanide in the cyanide waste water is mixed with cyanide-containing waste water, mechanical stirring is conducted for dispersing and extracting, and standing is conducted for phase separation; 2, an enriched emulsion obtained after phase separation is conducted is demulsified, a regeneration oil phase and an enriched water phase are obtained, and copper and cyanide are recycled from the enriched water phase.By means of the use method, the accumulation problem of copper in minerals in cyanide leaching liquid in the cyanide gold leaching process is effectively solved, the recycling problem of cyanide waste liquid is also solved, and dual value of improving economic benefit and promoting environmental protection is achieved in the cyanide-containing waste water treatment process.

Owner:NORTHEASTERN UNIV

A branched long-chain fatty acid-based imidazoline extractant and its preparation method and application

ActiveCN107385211BSpecial molecular structureEasy extractionOrganic chemistryChemical recyclingLong chain fatty acidPhase time

The invention discloses a branched long-chain fatty acid-based imidazoline extractant and its preparation method and application. The imidazoline extractant includes a plurality of N atoms and long-chain branched alkyl groups. The preparation method is: , reacting carboxylic acid and polyethylene polyamine under the action of a solid catalyst, after the reaction is completed, the solid catalyst is recovered by solid-liquid separation, and the liquid mixture is recovered by distillation to obtain unreacted raw materials; the preparation method has the advantages of mild reaction conditions, catalyst Reusable, low equipment investment and operating costs; imidazoline extractant is used for the extraction of anions containing tungsten, molybdenum, vanadium, etc. It has the characteristics of high extraction capacity, short phase separation time, and excellent extraction and stripping performance. Good prospects for industrial application.

Owner:CENT SOUTH UNIV

Ceramic core for titanium alloy casting

ActiveCN104072145BImprove sinterabilityGood mechanical properties at room temperatureChemical reactionPhosphate

The invention discloses a ceramic core for casting a titanium alloy. The ceramic core is characterized by comprising the following raw materials in percentages by weight: 10-14wt% of a mineralizer, 13-20wt% of a plasticizer, 3-5wt% of aluminum dihydrogen phosphate, 0.5-1wt% of xanthan gum and the balance of rare earth-coated boron nitride powder. The ceramic core disclosed by the invention has the characteristics that the sintering property is excellent, mechanical properties at room temperature are good and the chemical reaction inertia with melt titanium is good, the core removal performance is good, the maximum bending strength at room temperature is 27MPa and the maximum flexural strength at room temperature is 6.5MPa.

Owner:WUHU ZHEXIN NEW ENERGY

Bispyrazole extractant derived from o-phenanthroline and its preparation method and use

ActiveCN108017632BUnique rigid structureImprove extraction kineticsOrganic chemistryRadioactive decontaminationPhenanthrolineEthyl group

The invention discloses a double-pyrazole extracting agent derived from o-phenanthroline with the following structural general formula, and a preparation method and application of the double-pyrazoleextracting agent. In the formula, R is any one selected from n-octyl, n-butyl, isobutyl, ethyl, pyridyl and phenyl. The double-pyrazole extracting agent derived from the o-phenanthroline provided by the invention has a unique rigid structure and an alkyl chain for improving the solubility, and simultaneously only four elements of C, H, O and N are contained, so that the extraction kinetics of a separation extraction system can be greatly increased, the extraction capacity of an organic phase can be increased, secondary pollutants cannot be produced, and thus the environmental protection is facilitated. The extraction agent can be used to separate Ans (actinide elements) / Lns (lanthanide elements), and can not only form a separation extraction system of the Ans / Lns, but also can be used to form a separation reverse extraction system of the Ans / Lns.

Owner:SICHUAN UNIV

Method for separating and extracting gold from cyanide gold-leaching barren solution

The invention discloses a method for separating and extracting enriched gold from cyanide gold-leaching barren solution, which comprises the following steps: evenly mixing trialkyl phosphorus oxide and tributyl phosphate, and adding diluent to obtain extracted organic phase; adding salting-out agent into cyanide gold-leaching solution; adding the extracted organic phase, oscillating and contacting for 1-20 min at the normal temperature, and setting aside for phase-splitting to obtain gold-bearing organic phase, wherein the volume ratio between the extracted organic phase and the cyanide gold-leaching liquid is 1:1-1:20; and carrying out back-extraction on the gold-bearing organic phase by back extracting agent at 40-70 DEG C to obtain back-extracted gold solution. By adopting the method, the extraction ratio reaches more than 96 percent, and the back-extraction ratio reaches more than 90 percent; and the extracted organic phase can be recycled circularly and has remarkable economic and environmental benefits. The invention has simple operation, good extraction effect, simple and easily-obtained extraction agent, low price, less consumption amount, fast extraction speed, short phase-spitting time, higher selectivity, convenient industrial achievement, saved cost and improved efficiency.

Owner:JINAN UNIVERSITY

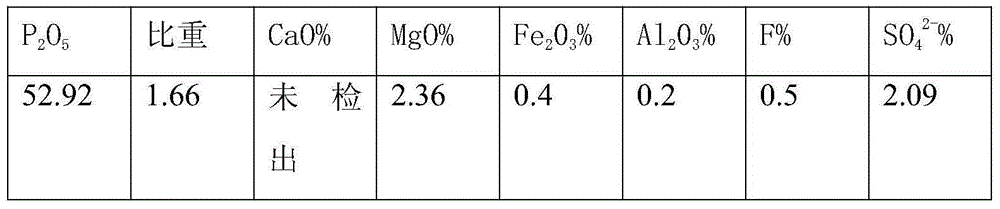

Method for wet purification of phosphoric acid with phosphate mother liquor back extraction and co-production of industrial grade phosphate

ActiveCN103771378BHigh recovery rateGood stripping performancePhosphatesPurification methodsPhosphate

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method for preparing porous alumina ceramic core

The invention provides a method for preparing a porous alumina ceramic core. The ceramic core comprises the following raw materials: electric melting-corundum powder, porous alpha-Al2O3 powder, TiO2 powder and paraffin. The method comprises the following steps: mixing the electric melting-corundum powder, the porous alpha-Al2O3 powder and the TiO2 powder; heating an oil bath crucible type stirrerto 100 to 120 DEG C; adding the paraffin into the oil-bath crucible type stirrer to be melted; adding mixed powder to the paraffin, and stirring the mixture to obtain mixed slurry; pressing a core byadopting a hydraulic core-pressing machine, controlling the temperature of the mixed slurry to between 95 and 110 DEG C and the injection pressure to between 3.0 and 3.5MPa; and roasting the pressed core by adopting a bell type sintering furnace. The porous alumina ceramic core prepared by the method has the porosity of between 45 and 55 percent, and can effectively improve the core removing performance of the core.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com