Method for preparing technical grade phosphate using wet method phosphoric acid as raw material

A wet-process phosphoric acid, industrial-grade technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of large volume of equipment in the stripping process, slow two-phase clarification and separation speed, increased energy consumption and expenditure, etc., to achieve separation coefficient Increase, reduce energy consumption, and reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] ——Preparation of technical grade sodium dihydrogen phosphate

[0023] The composition of raw material wet-process phosphoric acid used is as follows (wt%):

[0024] Element

P 2 o 5

F

SO 3

Fe 2 o 3

al 2 o 3

MgO

As

Pb

Org.

content

%

48.67

0.70

3.17

1.31

0.34

0.60

0.004

0.007

0.05

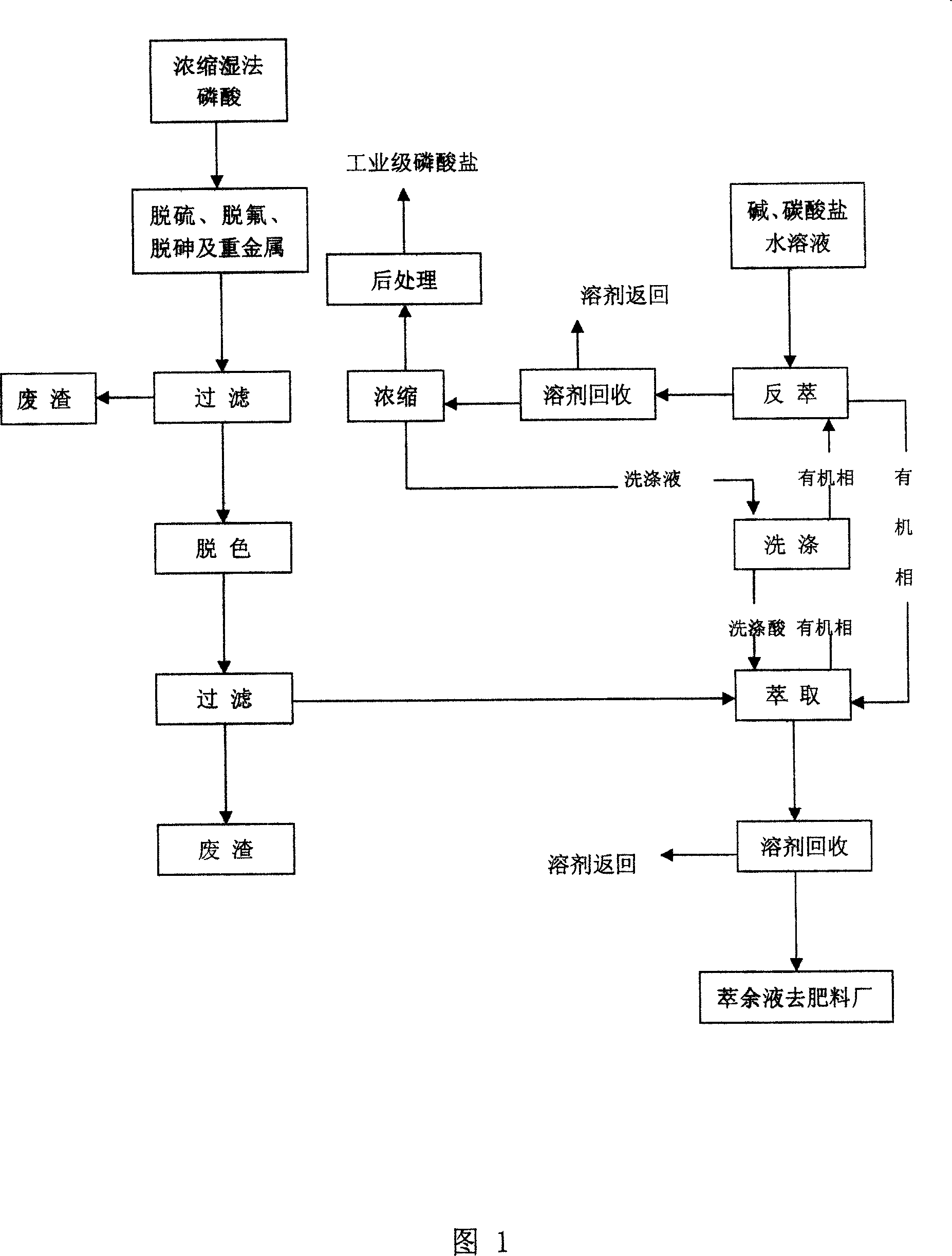

[0025] Continuous production, the process flow is shown in Figure 1, including pretreatment, extraction, washing, stripping, solvent recovery, and post-concentration treatment procedures.

[0026] (1) Pretreatment

[0027] The pretreatment is carried out in two steps. In the first step, phosphate rock powder is added as a desulfurizer, and a mixture of sodium carbonate and sodium sulfide is used to remove fluorine, arsenic and heavy metals; 4 2- 1.20 times of the stoichiometric ratio is added, and the defluorination, arsenic...

Embodiment 2

[0041] ——Preparation of industrial grade disodium hydrogen phosphate

[0042] In this embodiment, the composition and flow process of the raw material wet-process phosphoric acid used are the same as those in Embodiment 1. The processing condition that the present embodiment adopts and purification auxiliary agent (containing extraction agent) are all identical with embodiment 1 except following items:

[0043] Desulfurizer according to SO in phosphoric acid 4 2- 1.35 times the stoichiometric ratio is added, and the defluorination, arsenic and heavy metal agents are added according to 1.6 times the stoichiometric ratio of fluorine in phosphoric acid. The consumption of activated carbon is 0.2% of the mass of phosphoric acid. The back extraction is carried out in the extraction clarification tank and / or extraction tower, the extraction agent is 15% sodium carbonate aqueous solution, the ratio of the organic phase to the water phase is 4:1, and the reaction temperature is contr...

Embodiment 3

[0047] ——Preparation of industrial grade potassium dihydrogen phosphate

[0048] In this embodiment, the composition and flow process of the raw material wet-process phosphoric acid used are the same as those in Embodiment 1. The processing condition that the present embodiment adopts and purification auxiliary agent (containing extraction agent) are all identical with embodiment 1 except following items:

[0049] Back extraction is carried out in the extraction clarification tank and / or extraction tower, the extraction agent is 10% potassium hydroxide aqueous solution, the ratio of the organic phase to the water phase is 4:1, and the reaction temperature is controlled below 50°C; The tank is adjusted to pH=4.2-4.6 with industrial grade potassium hydroxide.

[0050] The technical grade potassium dihydrogen phosphate prepared by the present embodiment, the content of relevant components is as follows:

[0051] Element

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com