Method for wet purification of phosphoric acid with phosphate mother liquor back extraction and co-production of industrial grade phosphate

A technology for wet purification and phosphate master, applied in the field of phosphorus chemical industry, can solve problems such as unfavorable cost and environmental protection, large equipment investment, unfavorable cost, etc., and achieve the effects of being beneficial to process control, improving process parameters, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

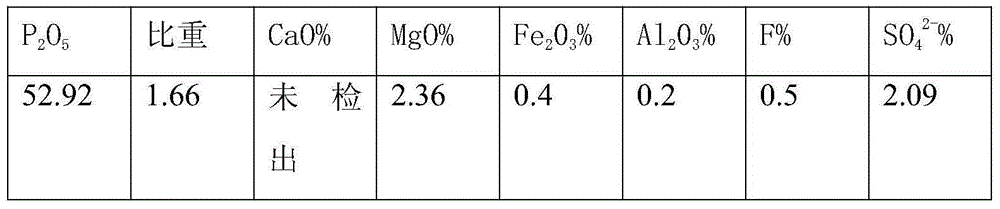

[0044] 12ktP of Sichuan Chuanheng Chemical Co., Ltd. 2 o 5 / a Industrial-grade wet purification phosphoric acid co-production fine salt plant wet purification phosphoric acid 290t (material), the indicators are as follows in Table 1:

[0045] Table 1

[0046]

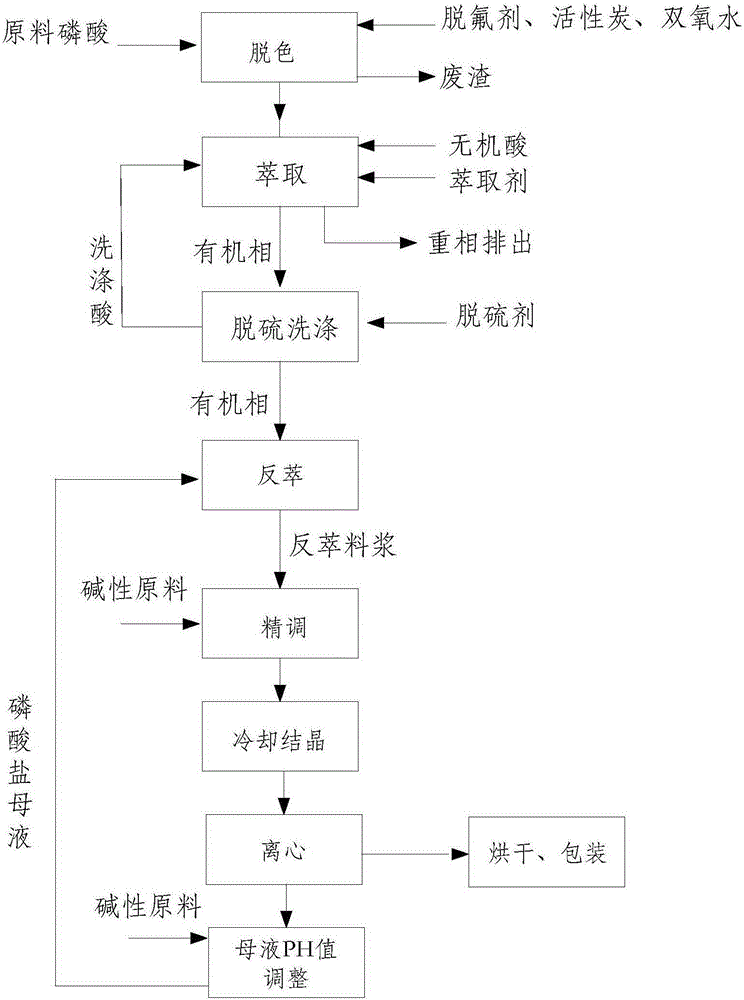

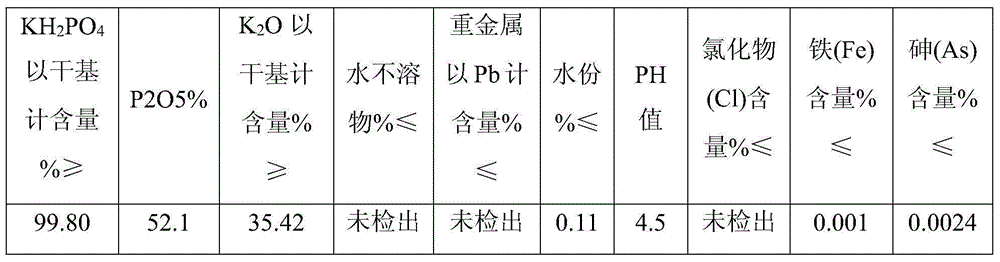

[0047] The steps for producing industrial-grade potassium dihydrogen phosphate are: defluorination and decolorization, extraction, desulfurization and washing, back-extraction of mother liquor, fine adjustment of slurry, cooling crystallization, centrifugation, drying and packaging.

[0048] (1) Defluorination and decolorization: After the phosphoric acid from the wet system enters the high-temperature concentration system for concentrated defluorination, it is measured at 5m 3 The flow rate of / h is added to the decolorization reaction tank, and 5.8t of wood powder activated carbon is added at a rate of 166kg / h (2% of the weight of phosphoric acid), and at the same time, 5.7t of defluorinating agent is added at a r...

Embodiment 2

[0058] 12ktP of Sichuan Chuanheng Chemical Co., Ltd. 2 o 5 / a Industrial-grade wet-purified phosphoric acid co-production fine salt plant raw material wet-purified phosphoric acid 132t (material), the indicators are as follows in Table 3:

[0059] table 3

[0060]

[0061] The steps for producing industrial-grade potassium dihydrogen phosphate are: defluorination and decolorization, extraction, desulfurization and washing, back-extraction of mother liquor, fine adjustment of slurry, cooling crystallization, centrifugation, drying and packaging.

[0062] (1) Defluorination and decolorization: After the phosphoric acid from the wet system enters the high-temperature concentration system for concentrated defluorination, it is measured at 5m 3 The flow rate of / h is added to the decolorization reaction tank, and 2.64t of wood powder activated carbon is added at an amount of 166kg / h (2% of the weight of phosphoric acid), and at the same time, 2.47t of defluorinating agent is a...

Embodiment 3

[0072] 12ktP of Sichuan Chuanheng Chemical Co., Ltd. 2 o 5 / a Industrial-grade wet-purified phosphoric acid co-production of fine salt plant raw material wet-purified phosphoric acid 215.5t (material), the indicators are as follows in Table 5:

[0073] table 5

[0074]

[0075] The steps of producing industrial-grade monoammonium phosphate are: defluorination and decolorization, extraction, desulfurization and washing, back-extraction of mother liquor, fine adjustment of slurry, cooling crystallization, centrifugation, drying and packaging.

[0076] (1) Defluorination and decolorization: After the phosphoric acid from the wet system enters the high-temperature concentration system for concentrated defluorination, it is measured at 5m 3 The flow rate of / h is added to the decolorization reaction tank, 4.31t of wood powder activated carbon is added at a rate of 163kg / h (2% of the weight of phosphoric acid), and at the same time, 4.23t of defluorinating agent is added at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com