Method for separating and extracting gold from cyanide gold-leaching barren solution

A cyanide leaching and extraction technology, applied in the field of separation and extraction of gold, to achieve the effect of fast extraction speed, good extraction effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

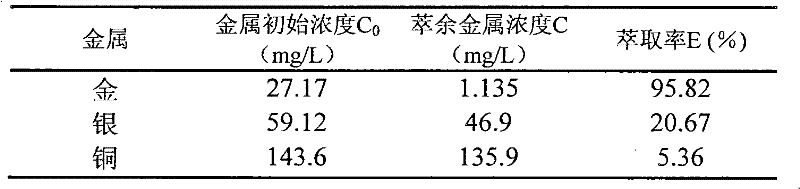

Embodiment 1

[0021] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 1:1, and kerosene with a volume percentage concentration of 50% is added to obtain an extracted organic phase;

[0022] (2) Add potassium sulfate solution to the barren solution for cyanidation gold leaching and mix evenly, wherein the initial gold concentration is 26.78mg / L, and the potassium sulfate concentration is 2mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:10, shaken and contacted at room temperature for 5 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the measured gold concentration in the raffinate was 1.07 mg / L, and The rate is 96%;

[0023] (3) Under the condition of 60° C., the gold-loaded organic phase obtained in step (2) is back-extracted with water, and the volume ratio (compared to O / A) of water and gold-loaded organic phase is 1: 1 to obt...

Embodiment 2

[0025] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 2:1, and xylene with a volume percentage concentration of 90% is added to obtain an extracted organic phase;

[0026] (2) Add potassium chloride solution to the poor cyanidation gold leaching solution and mix evenly, wherein the initial gold concentration is 26.78mg / L, and the potassium chloride concentration is 5mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:5, shaken and contacted at room temperature for 5 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the gold concentration of the raffinate was 0.33 mg / L, Grade extraction rate is 98.8%;

[0027] (3) under the condition of 50 DEG C, the sodium chloride solution that the molar concentration is 0.01mol / L carries out back extraction to step (2) gained gold-loaded organic phase, the volume ratio of water and g...

Embodiment 3

[0029] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 2:1, and n-dodecane with a volume percentage concentration of 70% is added to obtain an extracted organic phase;

[0030] (2) Add lithium sulfate solution to the cyanide gold leaching barren solution and mix evenly, wherein the initial gold concentration is 50.14mg / L, and the lithium sulfate concentration is 1mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:5, shaken and contacted at room temperature for 10 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the gold concentration of the raffinate was 0.5 mg / L, Grade extraction rate is 99.0%;

[0031] (3) under the condition of 60 DEG C, the gold-loaded organic phase obtained in step (2) is back-extracted with a molar concentration of 0.01mol / L sodium chloride solution, and the volume ratio of back-extraction liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com