Method for separating and extracting gold from cyanide gold-leaching barren solution

A cyanide leaching and extraction technology, applied in the field of separation and extraction of gold, can solve the problems that the recovered gold has not reached industrial application, the loss of extraction agent is large, the lack of extraction agent, etc., and achieves significant economic and environmental benefits, and the phase separation time is short. , the extraction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

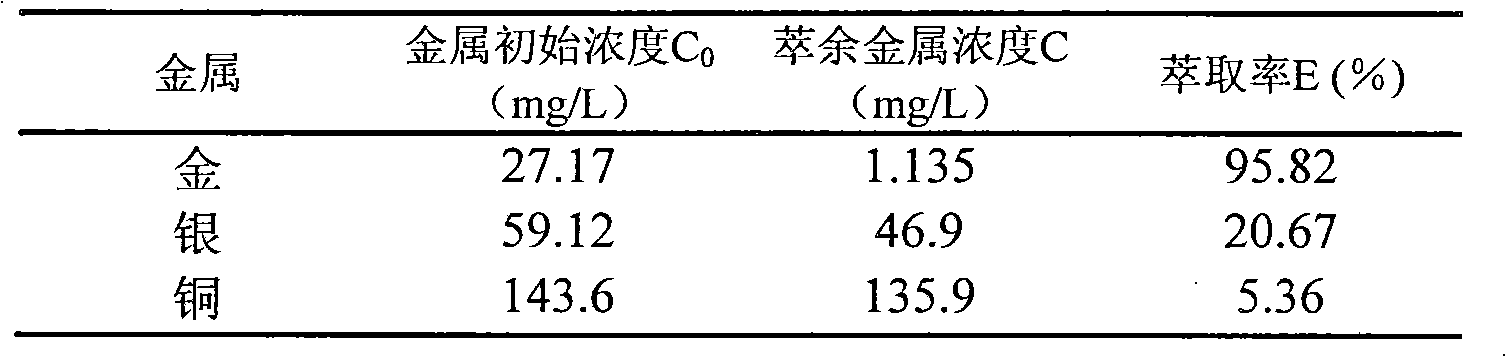

Examples

Embodiment 1

[0019] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 1:1, and kerosene with a volume percentage concentration of 50% is added to obtain an extracted organic phase;

[0020] (2) Add potassium sulfate solution to the barren solution for cyanidation gold leaching and mix evenly, wherein the initial gold concentration is 26.78mg / L, and the potassium sulfate concentration is 2mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:10, shaken and contacted at room temperature for 5 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the measured gold concentration in the raffinate was 1.07 mg / L, and The rate is 96%;

[0021] (3) Under the condition of 60° C., the gold-loaded organic phase obtained in step (2) is back-extracted with water, and the volume ratio (compared to O / A) of water and gold-loaded organic phase is 1: 1 to obt...

Embodiment 2

[0023] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 2:1, and xylene with a volume percentage concentration of 90% is added to obtain an extracted organic phase;

[0024] (2) Add potassium chloride solution to the poor cyanidation gold leaching solution and mix evenly, wherein the initial gold concentration is 26.78mg / L, and the potassium chloride concentration is 5mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:5, shaken and contacted at room temperature for 5 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the gold concentration of the raffinate was 0.33 mg / L, Grade extraction rate is 98.8%;

[0025] (3) under the condition of 50 DEG C, the sodium chloride solution that the molar concentration is 0.01mol / L carries out back extraction to step (2) gained gold-loaded organic phase, the volume ratio of water and g...

Embodiment 3

[0027] (1) Trialkylphosphine oxide (TRPO) and tributyl phosphate (TBP) are mixed uniformly at a volume ratio of 2:1, and n-dodecane with a volume percentage concentration of 70% is added to obtain an extracted organic phase;

[0028] (2) Add lithium sulfate solution to the cyanide gold leaching barren solution and mix evenly, wherein the initial gold concentration is 50.14mg / L, and the lithium sulfate concentration is 1mol / L. The extracted organic phase and the cyanide gold leaching barren solution were mixed at a volume ratio of 1:5, shaken and contacted at room temperature for 10 minutes, and allowed to stand for phase separation to obtain a gold-loaded organic phase; the gold concentration of the raffinate was 0.5 mg / L, Grade extraction rate is 99.0%;

[0029] (3) under the condition of 60 DEG C, the gold-loaded organic phase obtained in step (2) is back-extracted with a molar concentration of 0.01mol / L sodium chloride solution, and the volume ratio of back-extraction liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com