Water-soluble ceramic core for investment precision casting aluminum alloy and preparation method of water-soluble ceramic core

A technology of investment precision casting and ceramic core, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of demanding core performance, easy oxidation, low strength of aluminum alloy, etc., and meet the requirements of casting technology , Improve core stripping performance and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

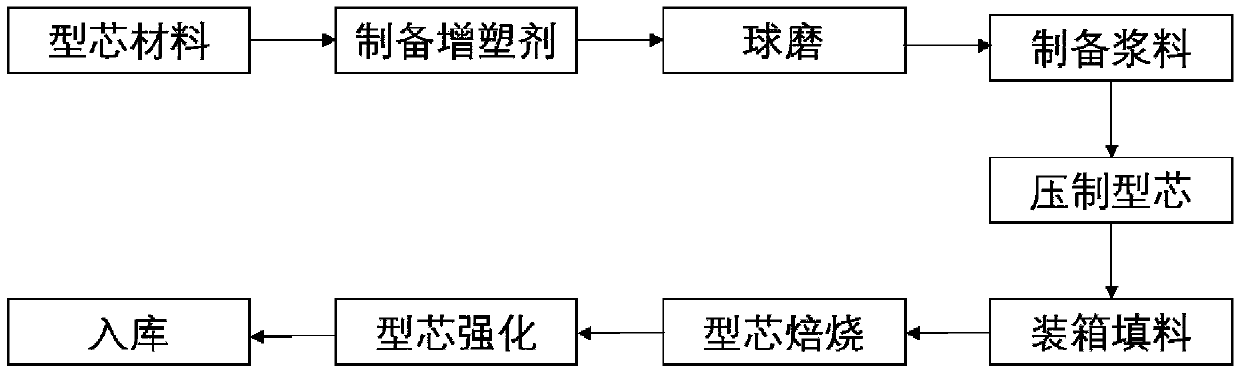

Method used

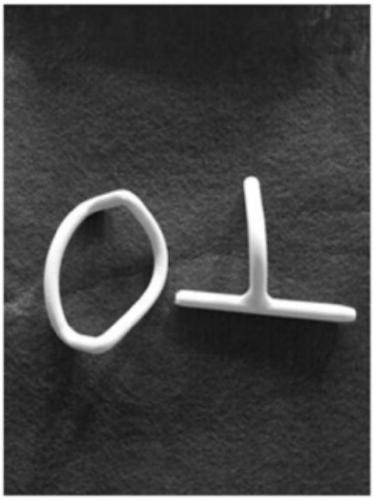

Image

Examples

Embodiment 1

[0033] This embodiment proposes a water-soluble ceramic core material for precision casting aluminum alloy by investment pattern. Since the water-soluble ceramic core technology is difficult and the size requirements are high, the present invention uses high-purity corundum powder as the base material. High-purity alumina powder has A certain degree of refractoriness, and no reaction with aluminum alloy, its structure is stable, and it has good dissolution performance.

[0034] Adding a certain mineralizer to the alumina matrix material can promote the sintering performance of the alumina water-soluble ceramic core, increase the sintering strength, reduce the deformation of the core, and facilitate the formation of a liquid phase at the sintering temperature to bond the matrix material. . At the same time, the mineralizer reacts with the matrix material to form a solid solution phase, which can improve the performance of the ceramic core.

[0035] On the one hand, the mineral...

Embodiment 2

[0040] In this embodiment, a plasticizer and an adhesive are added to the components of the ceramic core material in Example 1, and the mass percentage of the plasticizer is 15% of the total mass of the matrix material and the mineralizer; adding silicic acid Sodium is used as a binder, the mass percentage of sodium silicate is 3% of the total mass of the matrix material and the mineralizer, and the particle size of the sodium silicate is 210 mesh.

[0041] Plasticizer proportioning, as shown in table 1:

[0042] Table 1 Plasticizer material ratio

[0043]

[0044] The above-mentioned ingredients are ball milled, and the paraffin wax is selected from semi-refined paraffin wax 54#-60#.

[0045] According to demand weight, carry out batching by the percentage among the present embodiment. Put the weighed powder into a ball mill tank for mixing for 2 hours, pour it into a pan and stir, put it in a baking oven at a temperature of 150°C, and hold it for 2 hours to obtain a pla...

Embodiment 3

[0049] In this embodiment, the components of the core material are corundum powder, fused silica powder, sodium chloride, potassium chloride, and sodium silicate, wherein the mass percentages of each component are: corundum powder 45%, Fused quartz powder 15%, sodium chloride 5%, potassium chloride 35%, plus 3% sodium silicate, 7% plasticizer.

[0050] The particle size of fused silica powder is 310 mesh, the particle size of sodium chloride and potassium chloride is 190 mesh, and the particle size of sodium silicate is 230 mesh.

[0051] The sintered strength of the core material in this embodiment is 13 MPa, and the strength of the strengthened ceramic core is 27 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com