Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Excellent fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

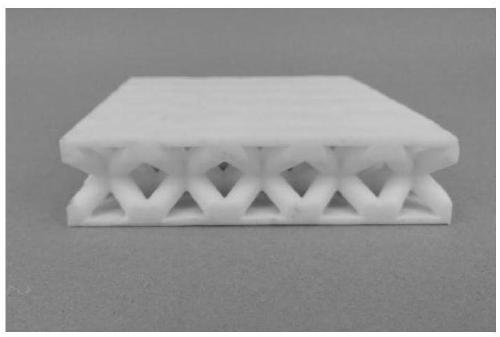

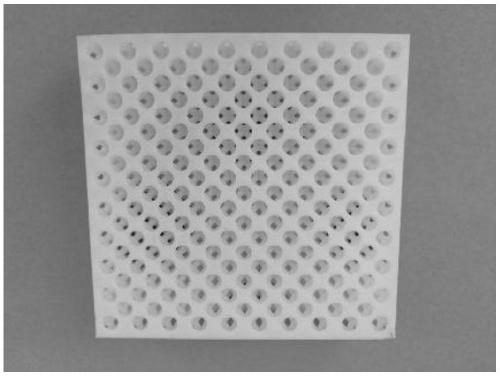

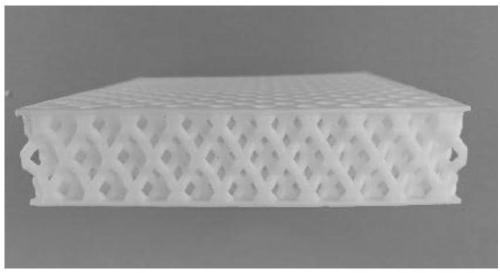

High-elastic foamed shoe insole material, and preparation method and application thereof

ActiveCN109206892AReduce weightHigh reboundAdditive manufacturing apparatusSolesCushioningThermoplastic elastomer

The invention provides a high-elastic foamed shoe insole material, and a preparation method and an application thereof, wherein the insole material is prepared by 3D-printing a thermoplastic resin compound material to form a green body, and performing supercritical fluid foaming shaping. The thermoplastic resin compound material includes: 55-100 parts of thermoplastic polyurethane resin, 0-50 parts of thermoplastic elastomer resin, 0.2-5 parts of a compatibilizer, 0.5-10 parts of a nucleating agent, 0-1.2 parts of an antioxidant, 0-1.2 parts of stearic acid, and 0-0.9 parts of a foam pore stabilizer. The insole material has a 3D structure, is light in weight, and has advantages of high resilience, low shrinking deformation and high cushioning effect. The insole material is shaped through 3D printing with the supercritical fluid impregnation and rapid pressure relief foaming. The method is green and environment-protective, is shorter in preparation process and higher in efficiency, andcan achieve customization.

Owner:ANTA CHINA

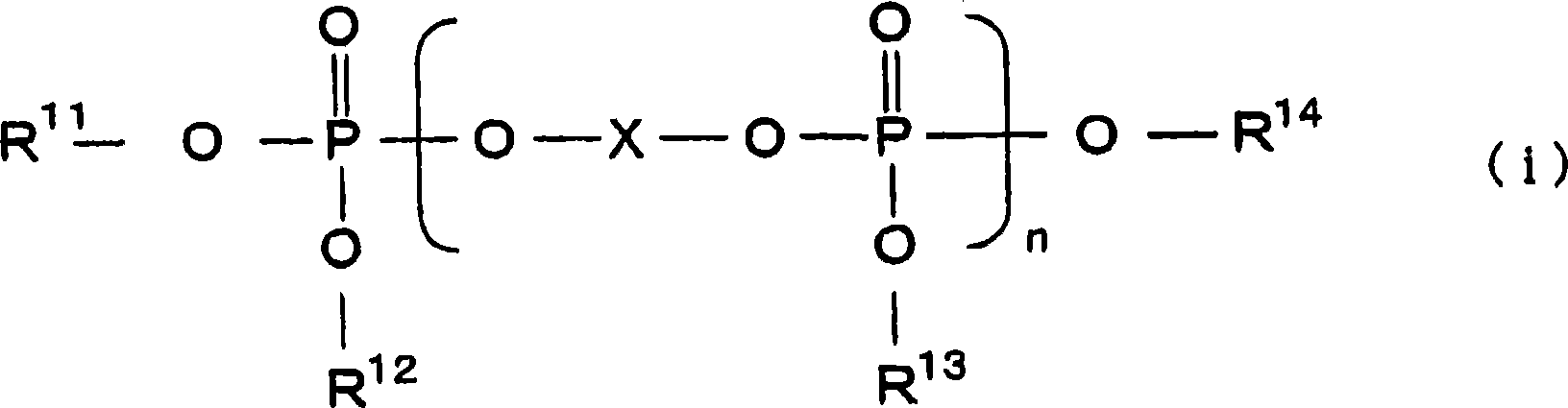

Aromatic polycarbonate resin composition and process for producing the same

InactiveCN101023134AImprove flame retardant performancePrevent molten drippingIon contentIon chromatography

A process of manufacturing the resin compositon and a method of preventing the melt dripping during combustion of the resin composition. The flame retardancy of the above aromatic polycarbonate resin composition comprising the fluorine-containing organic metal salt compound is improved. An aromatic polycarbonate resin composition containing a fluorinated organometal salt compound. The resin composition has improved flame retardancy. The resin composition comprises (1) 100 parts by weight of an aromatic polycarbonate resin (ingredient (A)), (2) 0.005-0.6 parts by weight of a fluorinated organometal salt (ingredient (B)) having a fluoride ion content as measured by ion chromatography of 0.2-20 ppm by weight, and (3) at least one ingredient selected from the group consisting of a flame retardant (ingredient (C)), fatty acid ester (ingredient (D)), ultraviolet absorber (ingredient (E)), polytetrafluoroethylene having fibril-forming ability (ingredient (F)), filler (ingredient (G)), silicate mineral (ingredient (H)), and titanium dioxide pigment (ingredient (I)). Also provided is a method of preventing a resin composition from melting / dripping upon combustion.

Owner:TEIJIN LTD

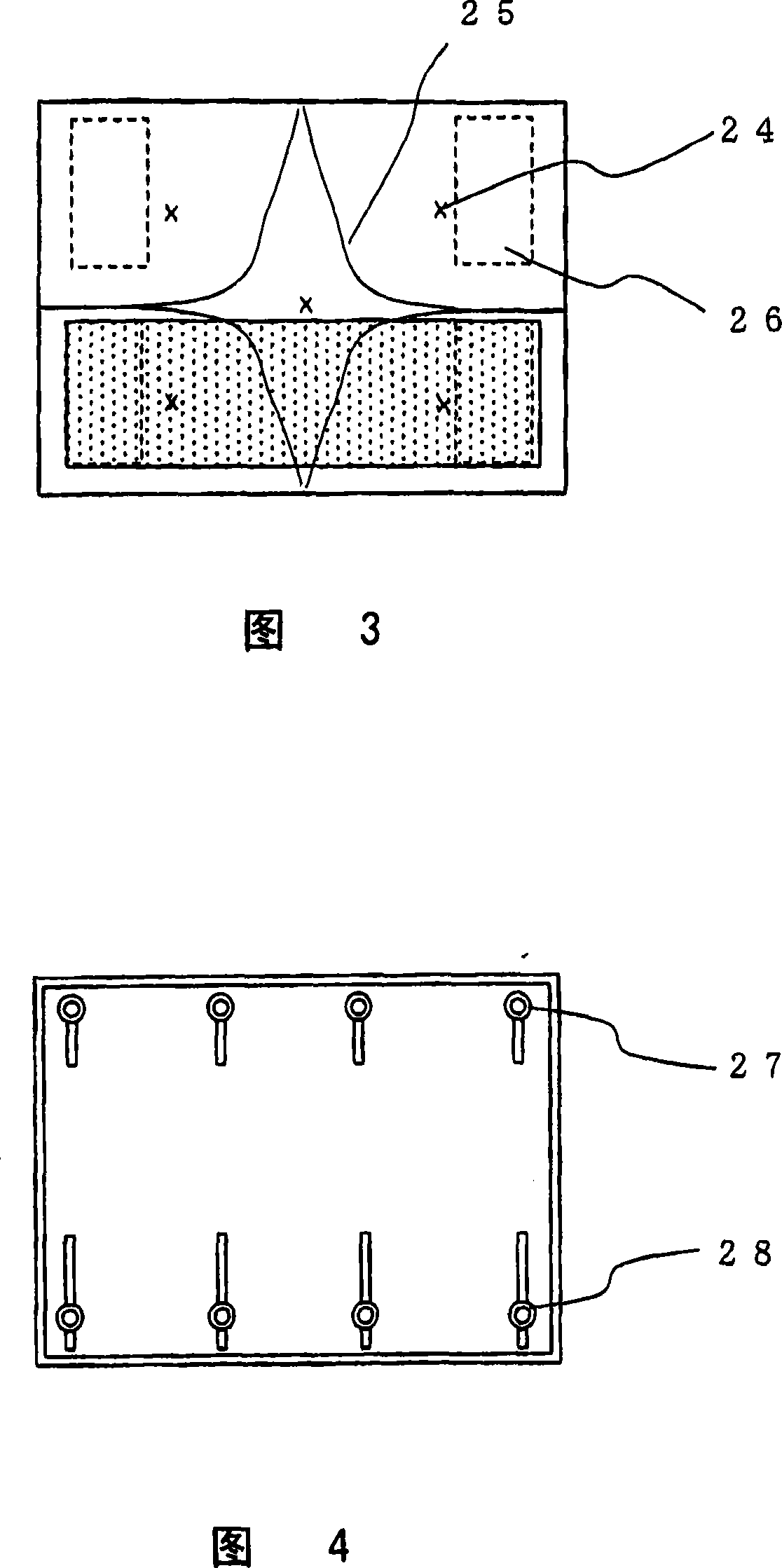

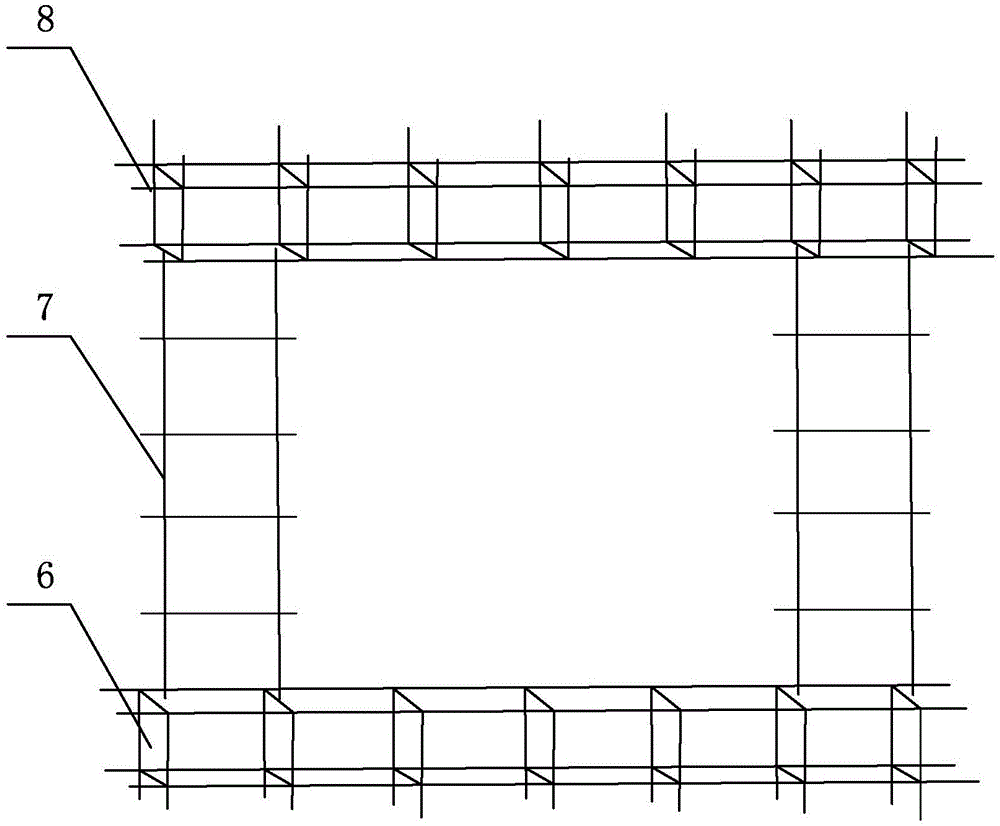

High-strength biomass fiber insulation composite lightweight exterior wallboard and manufacture method thereof

InactiveCN106639140AExcellent self-respectLight weightCeramic shaping apparatusBuilding componentsFiberResource consumption

A high-strength biomass fiber insulation composite lightweight exterior wallboard and a manufacture method thereof are provided; the high-strength biomass fiber insulation composite lightweight exterior wallboard comprises an inner leaf board, an insulation board and an outer leaf board sequentially from inside to outside, one side of the outer leaf board facing the insulation board is provided with a plurality of connection members, the outer leaf board, the insulation board and the inner leaf board are integrally connected through the connection members, and the high-strength biomass fiber insulation composite lightweight exterior wallboard is suitable for production by both a horizontal die and a vertical die. The high-strength biomass fiber insulation composite lightweight exterior wallboard is firm in structure, good in performance, environmentally friendly, low in energy and resource consumption, convenient to construct, and low in total cost.

Owner:孔祥雨 +2

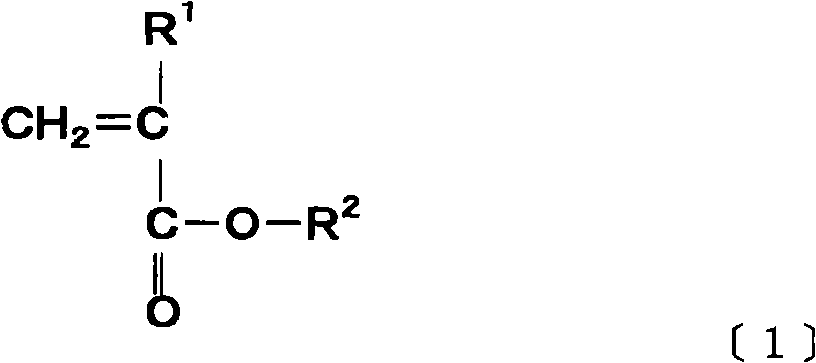

Photocurable resin composition

ActiveCN101356204AExcellent fatigue resistanceExcellent durability against vibration fatigueAntioxidantElastic modulus

Disclosed is a photocurable resin composition suitable for photocuring cast molding, particularly a photocurable resin composition having excellent vibration fatigue durability. The photocurable resin composition comprises (A) at least one resin selected from a photoradical-polymerizable resin, photoradical-addition-polymerizable resin and a photocation-polymerizable resin, (B) a photopolymerization initiator, and one or both of (C) an antioxidant and (D) a photostabilizer. When cured, the photocurable resin composition shows a tensile elastic modulus of 1-30 MPa and a tensile elongation at break of 200% or more. The photocurable resin composition may additionally comprise (E) a rubber composition.

Owner:DENKA CO LTD

Cold construction color cementing material for resin concrete

ActiveCN103265922AGood high temperature performanceExcellent water stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesLiquid stateRoad surface

The invention relates to a cold construction color cementing material for resin concrete. According to the invention, a composite epoxy resin used as a substrate is prepared by mixing a bisphenol A type epoxy resin and a flexible epoxy resin and subjecting an obtained mixture to modification by a flexibilizer, a coupling agent and an anti-ageing agent; a curing agent is prepared by modifying a conventional curing agent with a dispersant and a defoaming agent; the cementing material has obviously superior high temperature performance, low temperature performance, water stability and fatigue resistance to those of common asphalt and SBS modified asphalt; the cementing material in a liquid state needs no extra heating in the processes of mixing, transporting, paving and compacting, according with requirements for energy saving and low carbon; when the prepared resin concrete for cold construction is used for laying of a pavement, a curing period is short, and traffic is rapidly opened; an inorganic pigment or organic pigment is added for preparation of the color cementing material which is applicable to pavements with different functional requirements; composition materials are easily available, and the cold construction color cementing material is prepared by using a conventional method and is easy for large scale popularization.

Owner:重庆市智翔铺道技术工程有限公司

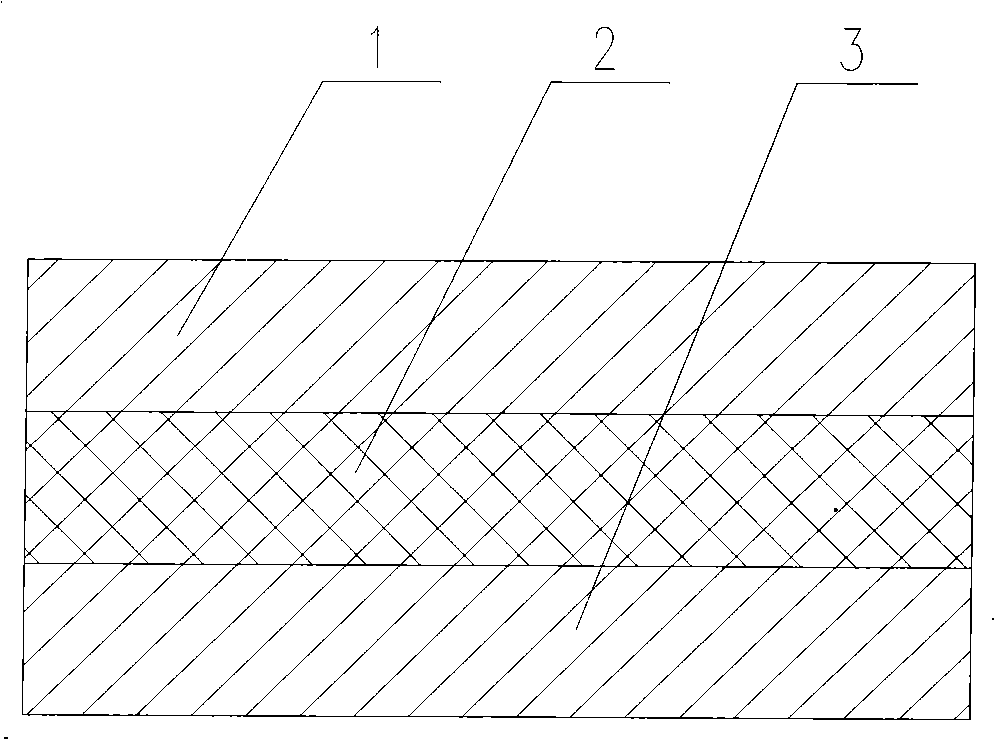

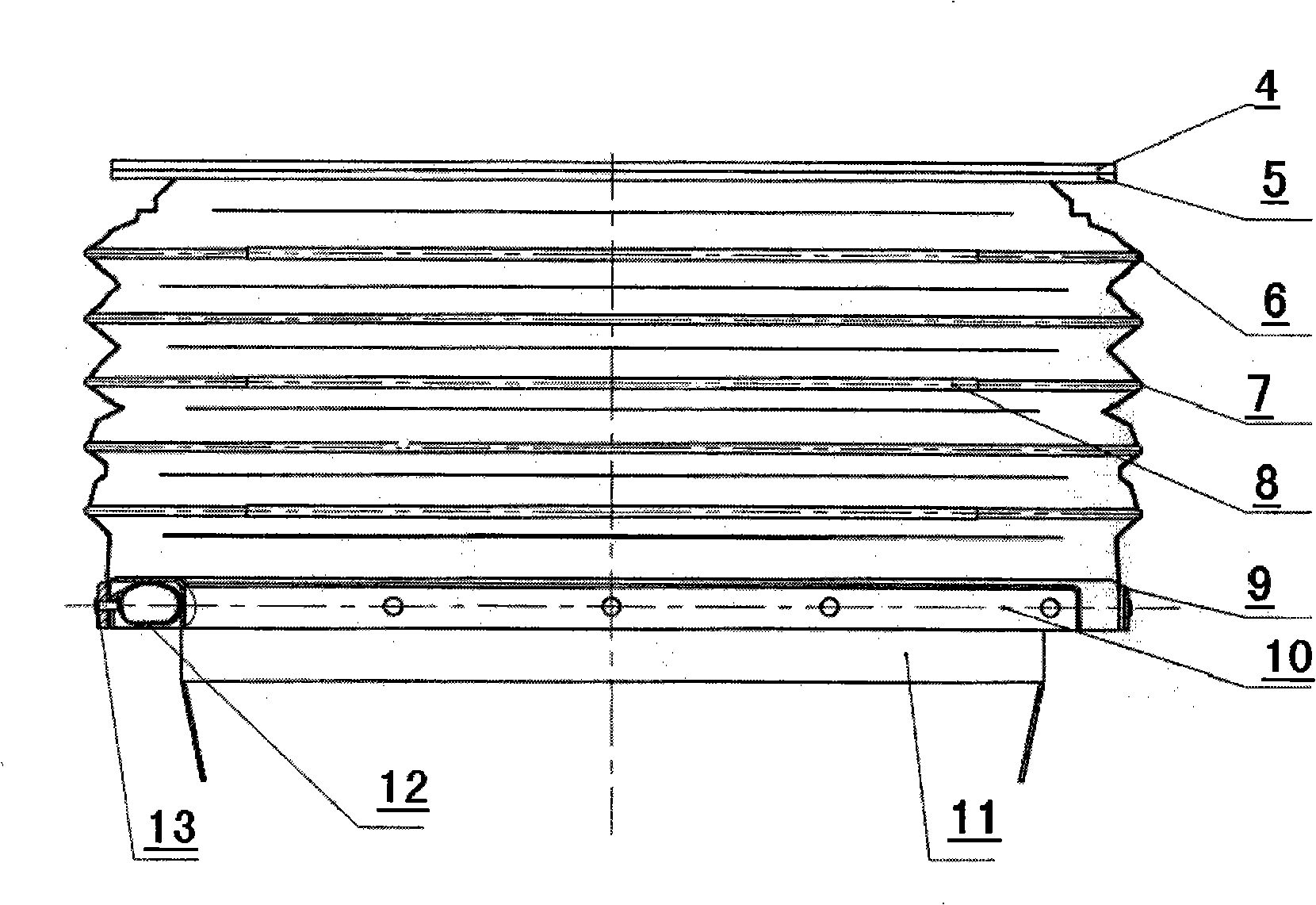

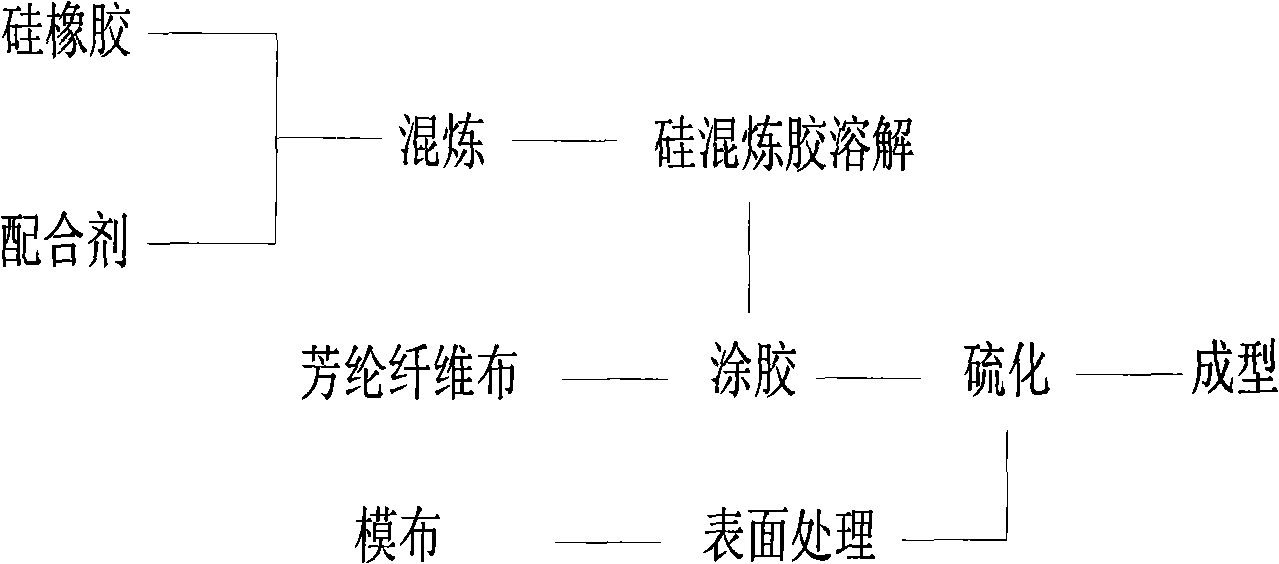

Aramid fiber fibre-silastic fabric, production method thereof and use in soft pipeline

InactiveCN101328650AEnables direct bondingImprove adhesionFibre typesLiquid/gas/vapor textile treatmentRubber materialPolymer science

The invention relates to an aromatic polyamide fiber-silicone rubber cloth, a method for producing the same and an application thereof in the aspect of manufacturing a hose. The production method comprises the following steps that: silicone rubber virgin rubber is added with an auxiliary agent to be mixed into silicone gross rubber through a rubber refining machine; the silicone gross rubber is added with the auxiliary agent and a coupling agent to be stirred and prepared into silicone gross rubber paste; the silicone gross rubber paste is applied on the surface of an aromatic polyamide fiber cloth; sulfur treatment is performed; etc. The production method realizes direct adherence of the rubber and the surface of the aromatic polyamide fiber cloth by adoption of the method of adding the coupling agent in the silicone gross rubber. The product of the aromatic polyamide fiber-silicone rubber cloth produced by the method can meet the following performance indexes: the tensile strength of rubber materials is more than or equal to 6 MPa; the tear strength of the rubber materials is more than or equal to 30 N.mm<-1>; the adhesive strength between Ib rubber with flame-retardant property and a base-cloth layer is more than or equal to 3 N.mm<-1>; the service temperature is between 60 DEG C below zero and 200 DEG C; and the folding fatigue resistant time is more than or equal to 2 million times. The aromatic polyamide fiber-silicone rubber cloth is used for manufacturing various flexibly connected pipes and is a superior cloth for manufacturing a transition air channel hose of a pulling motor of a locomotive.

Owner:株洲市华丰复合材料有限公司

Cu-Ti BASED COPPER ALLOY SHEET MATERIAL AND METHOD FOR PRODUCING THE SAME, AND ELECTRIC CURRENT CARRYING COMPONENT

ActiveUS20140283963A1Excellent in strength , bend workability and stress relaxation resistanceExcellent fatigue resistanceConductive materialMetal/alloy conductorsMetallurgyGrain boundary

A Cu—Ti based copper alloy sheet material contains, in mass %, from 2.0 to 5.0% of Ti, from 0 to 1.5% Ni, from 0 to 1.0% Co, from 0 to 0.5% Fe, from 0 to 1.2% Sn, from 0 to 2.0% Zn, from 0 to 1.0% Mg, from 0 to 1.0% Zr, from 0 to 1.0% Al, from 0 to 1.0% Si, from 0 to 0.1% P, from 0 to 0.05% B, from 0 to 1.0% Cr, from 0 to 1.0% Mn, and from 0 to 1.0% V, the balance substantially being Cu. The sheet material has a metallic texture wherein in a cross section perpendicular to a sheet thickness direction, a maximum width of a grain boundary reaction type precipitate is not more than 500 nm, and a density of a granular precipitate having a diameter of 100 nm or more is not more than 105 number / mm2.

Owner:DOWA METALTECH CO LTD

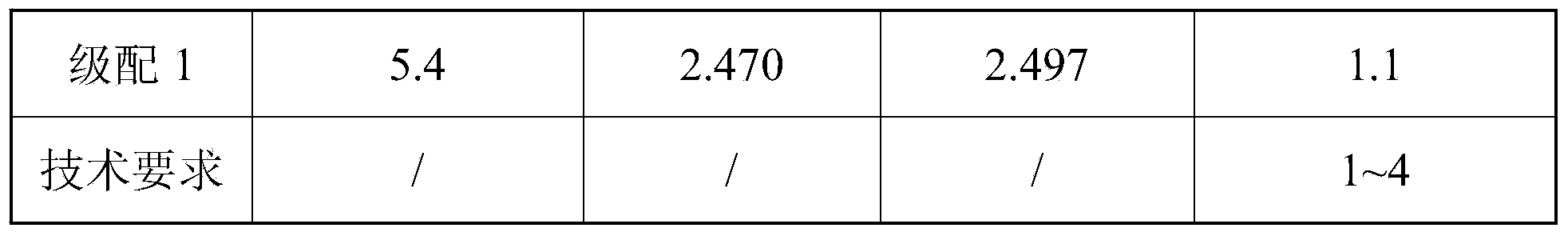

Durable high-modulus asphalt mixture based on hard asphalt particles

InactiveCN103588424AImprove high temperature performanceImprove shear resistanceAdhesive cementRoad surface

The invention discloses a durable high-modulus asphalt mixture based on hard asphalt particles. The asphalt mixture comprises 100 parts by mass of mineral aggregate and 5.3-5.7 parts by mass of asphalt, wherein the mineral aggregate comprises a limestone aggregate accounting for 96-98% of the total mass of the mineral aggregate, and limestone mineral powder accounting for 2-4% of the total mass of the mineral aggregate; and the asphalt is a compound of number 70 road petroleum asphalt and the hard asphalt particles. The asphalt mixture improves the gradation of the mineral aggregate, so that a coarse aggregate forms a good skeleton structure, and the shear property and the compressive property of the mixture are improved; and the property of asphalt adhesive cement in the mixture is improved by adding an appropriate amount of mineral powder, so that the surface of the mineral aggregate has appropriate asphalt membrane thickness. Therefore, the mixture is good in high temperature property, easy to compact, and excellent in fatigue resistance and durability; the capacity of a pavement for resisting damage of a track and the like can be improved if the mixture is used in a road middle surface course; the construction cost can be lowered; and the service life and the maintenance cycle of the pavement can be prolonged.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

High-strength high-flexibility CuNiSn alloy material and preparation method thereof

InactiveCN106435260AExcellent fatigue resistanceExcellent fatigue resistance Cu-Ni-Sn alloy has excellent strengthSolution treatmentElastic component

The invention provides a high-strength high-flexibility CuNiSn alloy material and a preparation method thereof. The high-strength high-flexibility CuNiSn alloy material comprises, by weight, 8.5-10.5% of Ni, 1.8-2.8% of Sn, 0.5-1.0% of Co, 0.005-0.01% of B, 0.01-0.05% of V, 0.1-0.5% of P, and the balance Cu. The alloy material is obtained through the processing treatment steps of smelting, casting, solution annealing, surface milling, rough rolling, intermediate annealing, acid pickling, intermediate rolling, secondary solution treatment, finish rolling, ageing heat treatment and the like. The tensile strength of the alloy material reaches up to 1230 MPa. Under the condition of the stress ratio being -1 and the number of circulation cycles being 107, the fatigue strength of the alloy is not less than 400 MPa. When the insertion and extraction force is greater than or equal to 1.5N, the number of insertion and extraction times is 41000-43000. Cracks occur after 46000 times of insertion and extraction, the use requirement for high-frequency and high-current elastic components can be met.

Owner:NINGBO XINGYE SHENGTAI GROUP

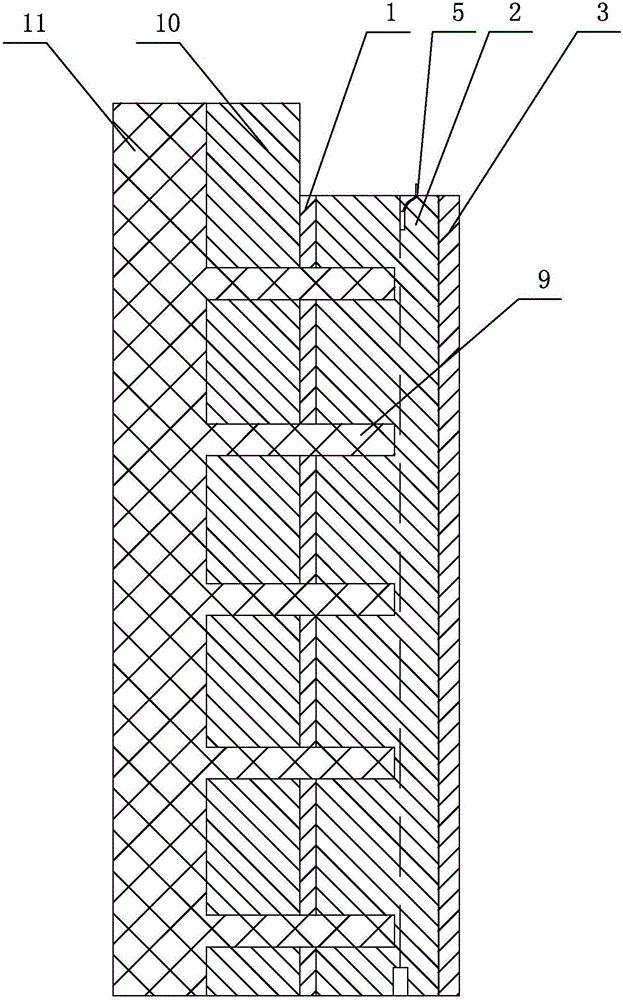

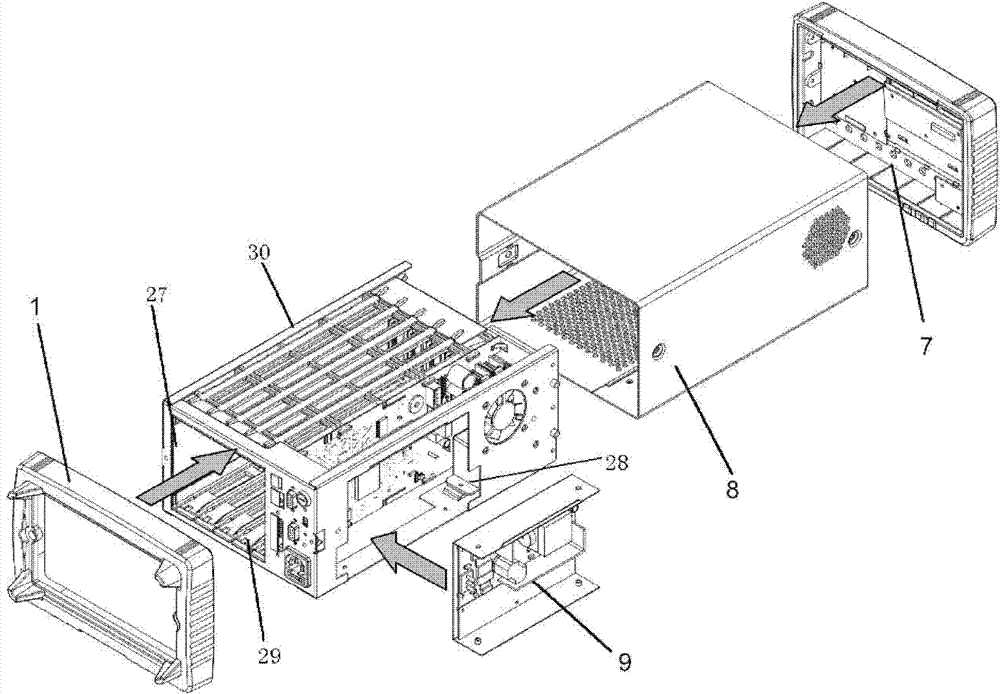

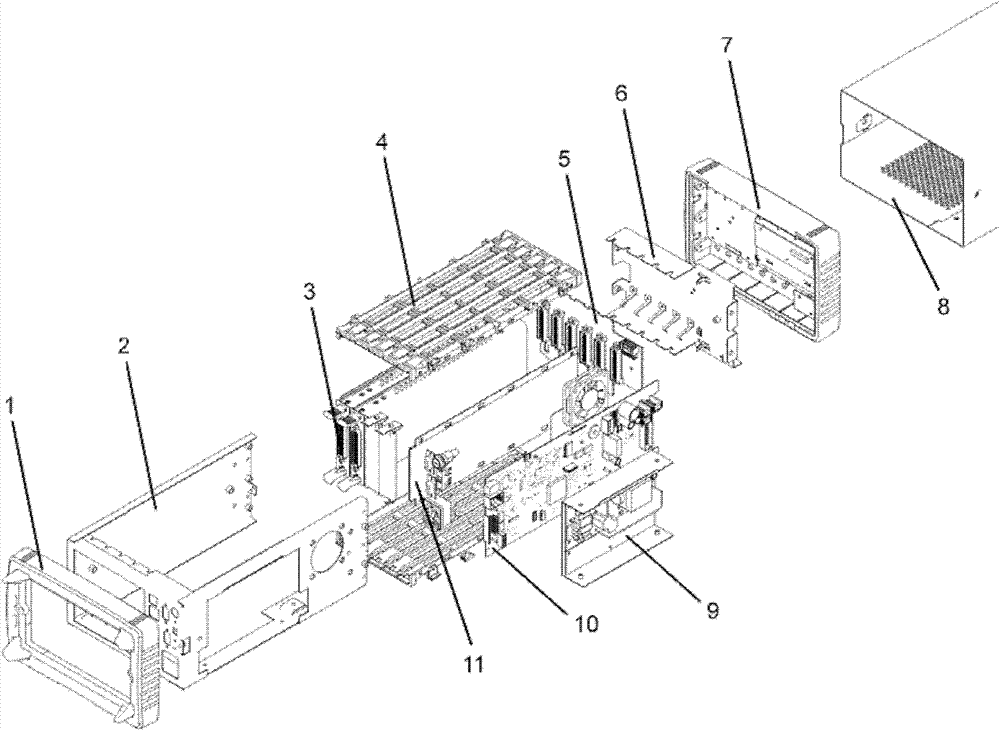

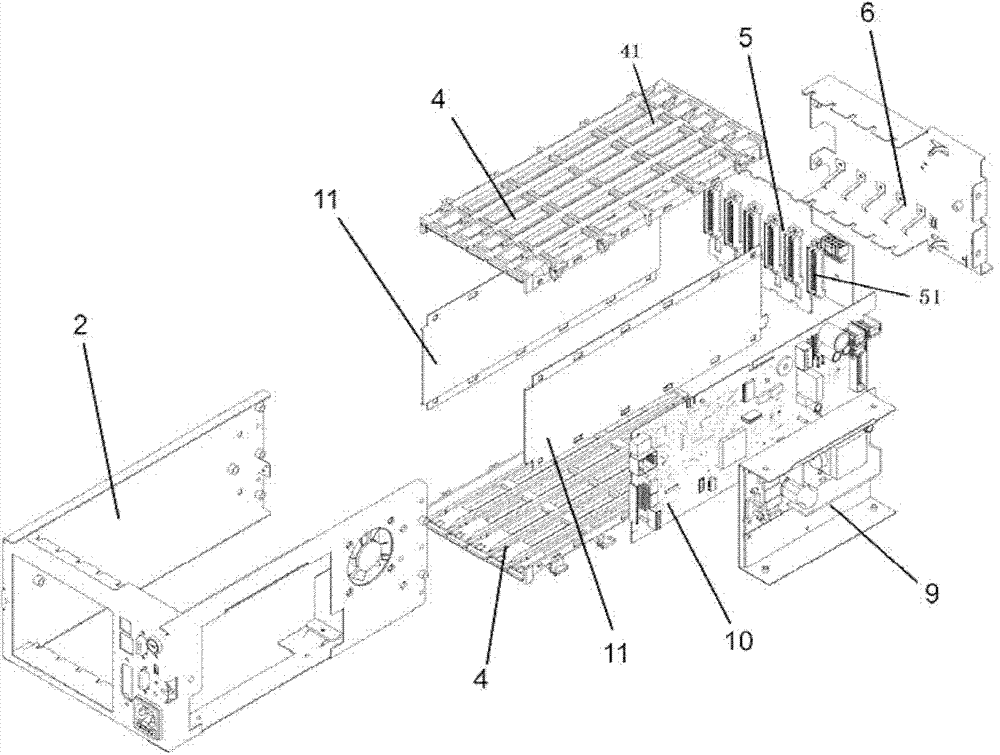

Chassis with bus structure

ActiveCN102770002AAvoid assemblyAvoid connectivitySupport structure mountingSelf lockingEmbedded system

The invention relates to a chassis with a bus structure. The chassis comprises a sleeve, an instrument frame and a main control panel, wherein the instrument frame is arranged in the sleeve; a module card entrance is arranged at the rear end wall of the instrument frame; a power-supply module socket is arranged on the side wall of the instrument frame; a module card guide rail and the main control panel are arranged in the instrument frame; the main control panel is arranged on the side wall of the module card guide rail and is connected with the power-supply module which is arranged on the power-supply module socket; the instrument frame is fixedly connected by inserting a front frame and a rear frame; a bus rear panel is longitudinally arranged in the front frame; the module card is inserted into the module card guide rail through the module card entrance and is socketed with the bus rear panel; and the module card guide rail is connected with the rear frame and the front frame respectively in a clamping and hooking way. According to the chassis with the bus structure, the design difficult point of an instrument in a compact space is solved, as the internal main structures and the main control panel are all assembled by self-locking structure assembles such as plugging, clamping and hooking, the chassis is high in assembling efficiency, compact in structure and high in installation reliability.

Owner:RIGOL

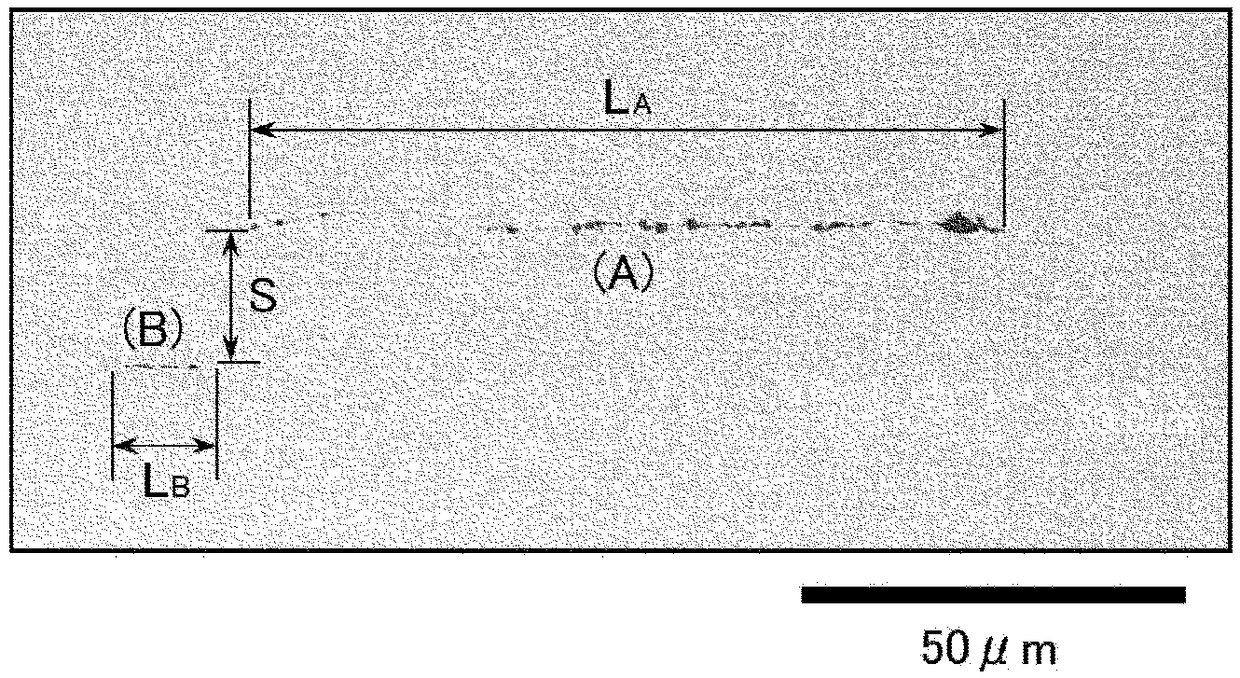

High-strength stainless steel sheet having excellent fatigue characteristics, and method for manufacturing same

ActiveCN108368573AExcellent fatigue resistanceHelp miniaturizationFurnace typesProcess efficiency improvementSheet steelNon-metallic inclusions

To realize a thin plate material having a distribution state of nonmetallic inclusions effective at improving fatigue resistance characteristics in a type of stainless steel having a high Si content in which deformation-induced martensite is generated. A thin steel plate comprising, in terms of mass%, 0.010-0.200% C, over 2.00% and no more than 4.00% Si, 0.01-3.00% Mn, 3.00% to less than 10.00% Ni, 11.00-20.00% Cr, 0.010-0.200% N, 0-3.00% Mo, 0-1.00% Cu, 0-0.008% Ti, and 0-0.008% Al, the remainder being Fe and unavoidable impurities, the distance between particles in a rolling direction being20 [mu]m or less, the distance between particles in a plate thickness direction being 10 [mu]m or less, and the number density of nonmetallic inclusions having a length in the rolling direction of 40[mu]m or greater being 3.0 inclusions / mm2 or less in an L cross-section.

Owner:NIPPON STEEL STAINLESS STEEL CORP

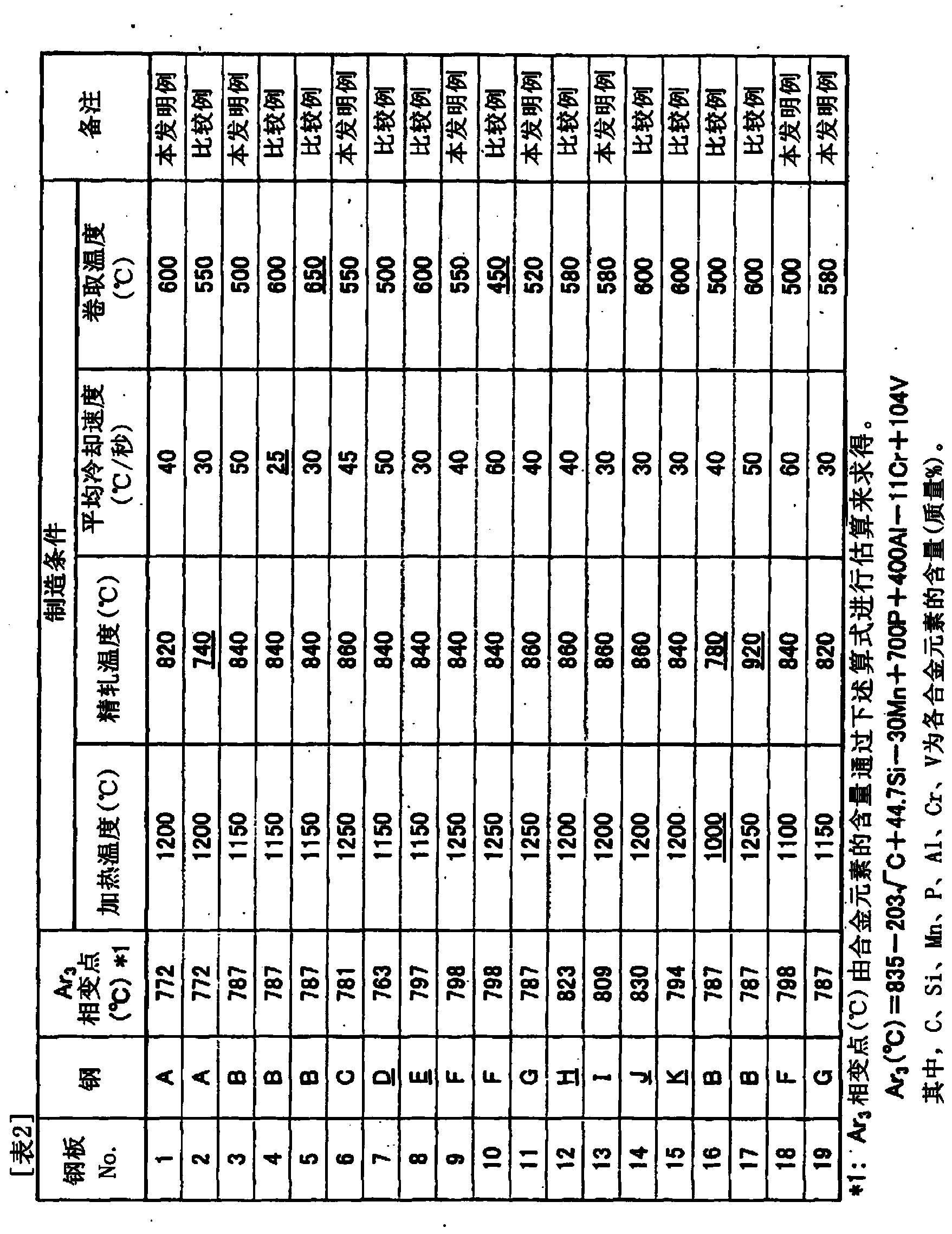

Hot-rolled steel sheet

ActiveCN106715742AImprove surface propertiesExcellent fatigue resistanceFurnace typesHeat treatment furnacesPearliteMass content

A hot-rolled steel sheet that contains prescribed components, that satisfies formula (1) with regard to added amount of Cr and Al, and that has a metallographic structure that has a volume fraction of ferrite of more than 90% but 98% or less, a volume fraction of martensite of 2% or more but less than 10%, and a volume fraction of less than 1% of a remainder structure that comprises one or more substance from among pearlite, bainite, and retained austenite, the ferrite having an average circle-equivalent diameter of 4 [mu]m or more and a maximum circle-equivalent diameter of 30 [mu]m or less, and the martensite having an average circle-equivalent diameter of 10 [mu]m or less and a maximum circle-equivalent diameter of 20 [mu]m or less. Formula (1): [Cr] x 5 + [Al] >= 0.50. In formula (1), [Cr] is Cr content (mass%), and [Al] is Al content (mass%).

Owner:NIPPON STEEL CORP

Lattice type derrick of electric transmission line

A lattice type derrick of an electric transmission line is formed by connecting a suspension base, a standard knot and a pulley in sequence. The two ends of the standard knot are provided with conical end joints. The standard knot and the end joints are formed by a plurality of joint bodies. Each joint body is made of carbon fiber reinforced resin matrix composite materials, and the adjacent joint bodies are connected through a flange. Each joint body of the standard knot comprises four vertical main pipes which are distributed in a rectangular mode and inclined pipes arranged between every two adjacent main pipes. Each end joint body comprises four main pipes which are distributed in a conical mode and inclined pipes between every two adjacent main pipes. Each flange comprises a rectangular base and inserting pipes arranged in the four corners of the rectangular base, and the main pipes of the standard knot and the main pipes of the end joints are inserted into the inserting pipes respectively to be bonded through glue. The derrick is made of the carbon fiber reinforced resin matrix composite materials and is high in strength and light in weight.

Owner:STATE GRID CORP OF CHINA +3

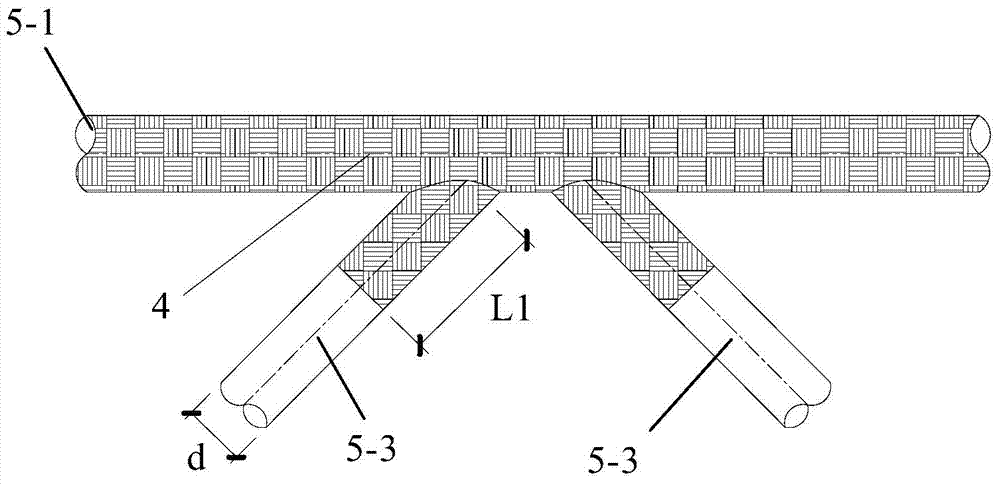

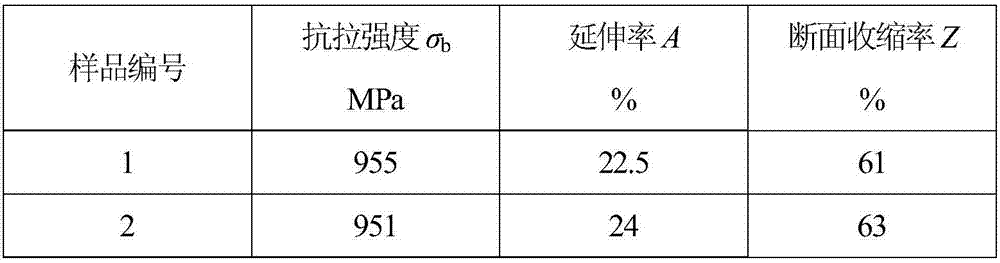

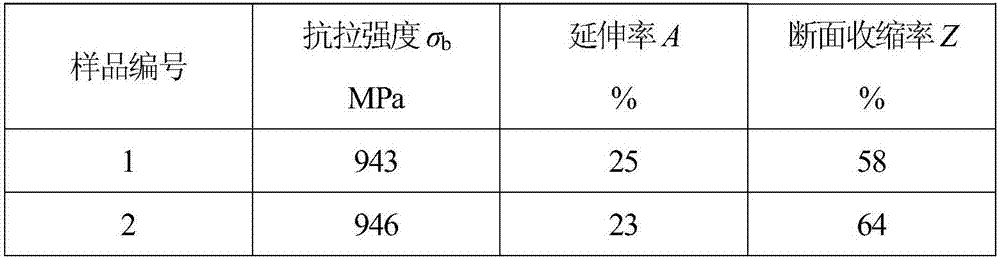

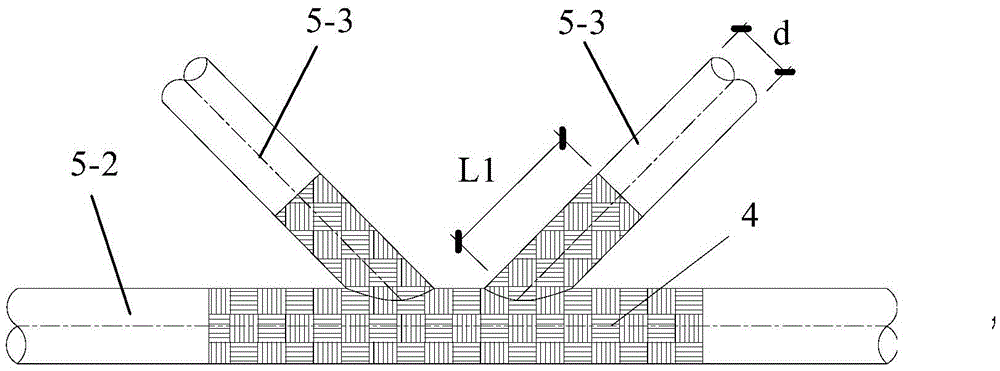

CFRP cloth reinforcing structure of steel truss bridge steel tube tubular joints

InactiveCN104233964ASimple structureReasonable designTruss-type bridgeBridge erection/assemblyAdhesive glueEngineering

The invention discloses a CFRP cloth reinforcing structure of steel truss bridge steel tube tubular joints. The CFRP cloth reinforcing structure comprises a GFRP cloth covering layer covering the outer side of the tubular joints and CFRP cloth covering layers covering the outer side of the GFRP cloth covering layer, and the inner surface and the outer surface of the GFRP cloth covering layer and the inner surfaces and the outer surfaces of the CFRP cloth covering layers are coated with adhesive glue coatings. The number of the CFRP cloth covering layers is one or more than one, the CFRP cloth covering layers coat the outer side of the GFRP cloth covering layer from inside to outside, the GFRP cloth covering layer and the tubular joints required to be reinforced are adhered through adhesive glue, the CFRP cloth covering layers and the GFRP cloth covering layer are adhered through adhesive glue, and the adjacent CFRP cloth covering layers are adhered through adhesive glue. The CFRP cloth reinforcing structure is simple, reasonable in design, convenient to construct and good in reinforcing effect, and the problems that an existing tubular joint reinforcing method is complex in actual operation and poor in reinforcing effect, and the strength and stability of the bridge structure are influenced can be effectively solved.

Owner:CHANGAN UNIV

Processing technology for spring made of titanium alloy wire with special-shaped section

ActiveCN107234192AExcellent corrosion resistanceExcellent fatigue resistanceIngotMaterials processing

The invention relates to a processing technology for a spring made of a titanium alloy wire with a special-shaped section and belongs to the field of metal material processing. Titanium alloy components include the following elements in percentage by mass: 2-4 of Al, 8-11 of V, 4-8 of Cr, 4-8 of Mo, 3.5-6 of Zr and the balance of Ti. The spring is wound by using the titanium alloy wire with the special-shaped section, the titanium alloy wire with the special-shaped section, which is used for winding the spring, is prepared by using processes of ingot forging and cogging, finish forging, hot drawing and cold rotary forging, and the section of the wire can be shaped like a square, a rectangle, a regular hexagon and a regular octagon. Compared with a steel spring, the titanium alloy spring has favorable corrosion resistance and fatigue resistance and is stable in performance and obviously prolonged in life when being used in environments such as sea and other corrosive environments. In addition, the titanium alloy is relatively low in density which accounts for about 60% of that of steel, and therefore, a weight reducing effect can also be achieved if the steel spring is replaced with the titanium alloy spring.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Single column type derrick of electric transmission line

ActiveCN103726711AIncreased anisotropySmall coefficient of thermal expansionTowersCarbon fibersResin matrix

A single column type derrick of an electric transmission line is formed by connecting a suspension base, a standard knot and a pulley in sequence. The two ends of the standard knot are provided with conical end joints. The standard knot and the end joints are formed by a plurality of circular pipe joint bodies. Each joint body is formed by winding carbon fiber reinforced resin matrix composite materials, and the adjacent joint bodies are connected through a flange. Each flange comprises a core pipe with the side wall provided with a groove and a tubular inner plate arranged on the top of the core pipe, wherein bolt holes are formed inside the groove in the circumferential direction, a boss is arranged between the inner plate and the core pipe, the inner plate is sleeved with the joint bodies, the inner plate and the joint bodies are bonded together through glue, and the end of each joint body abuts against the corresponding boss. The derrick is made of the carbon fiber reinforced resin matrix composite materials and is high in strength and light in weight.

Owner:STATE GRID CORP OF CHINA +3

Steel member, hot-rolled steel sheet for said steel member and production methods therefor

ActiveCN110494582AExcellent fatigue resistanceFurnace typesMetal rolling arrangementsSolid solutionHeat treated

The purpose of the present invention is to provide a steel member with excellent fatigue resistance characteristics in the plastic strain range, a hot-rolled steel sheet as the material therefor and production methods therefor. A steel member, which contains 0.031-0.200 mass% Ti and in the structure of which at least 0.005 mass% of the Ti is precipitated as precipitates with a particle size of 20nm or less. A hot-rolled steel sheet for said steel member that contains 0.031-0.200 mass% Ti and in the structure of which at least 0.005 mass% of the Ti is present as Ti solid solution. A productionmethod for said steel member in which, after molding of the hot-rolled steel sheet, heat treatment is performed wherein the member is heated to a temperature greater than 550 DEG C and not exceeding1050 DEG C and then cooled at an average cooling rate of at least 10 DEG C / s for the temperature range of 550-400 DEG C. A production method for said hot-rolled steel sheet in which a steel slab containing 0.031-0200 mass% Ti is extracted under temperature conditions higher than the equilibrium solid solution temperature TTi determined from a specified formula, after which finish-rolling is completed at a temperature of at least TTi-400 DEG C, the sheet is cooled at an average cooling rate of at least 10 DEG C / s for the temperature range from TTi-400 DEG C to TTi-500 DEG C, and is coiled at atemperature of TTi-500 DEG C or less.

Owner:JFE STEEL CORP

CFRP cloth reinforced structure of steel pipe intersecting joints of steel truss bridge

InactiveCN104233964BSimple structureReasonable designTruss-type bridgeBridge erection/assemblyAdhesive glueEngineering

The invention discloses a CFRP cloth reinforcing structure of steel truss bridge steel tube tubular joints. The CFRP cloth reinforcing structure comprises a GFRP cloth covering layer covering the outer side of the tubular joints and CFRP cloth covering layers covering the outer side of the GFRP cloth covering layer, and the inner surface and the outer surface of the GFRP cloth covering layer and the inner surfaces and the outer surfaces of the CFRP cloth covering layers are coated with adhesive glue coatings. The number of the CFRP cloth covering layers is one or more than one, the CFRP cloth covering layers coat the outer side of the GFRP cloth covering layer from inside to outside, the GFRP cloth covering layer and the tubular joints required to be reinforced are adhered through adhesive glue, the CFRP cloth covering layers and the GFRP cloth covering layer are adhered through adhesive glue, and the adjacent CFRP cloth covering layers are adhered through adhesive glue. The CFRP cloth reinforcing structure is simple, reasonable in design, convenient to construct and good in reinforcing effect, and the problems that an existing tubular joint reinforcing method is complex in actual operation and poor in reinforcing effect, and the strength and stability of the bridge structure are influenced can be effectively solved.

Owner:CHANGAN UNIV

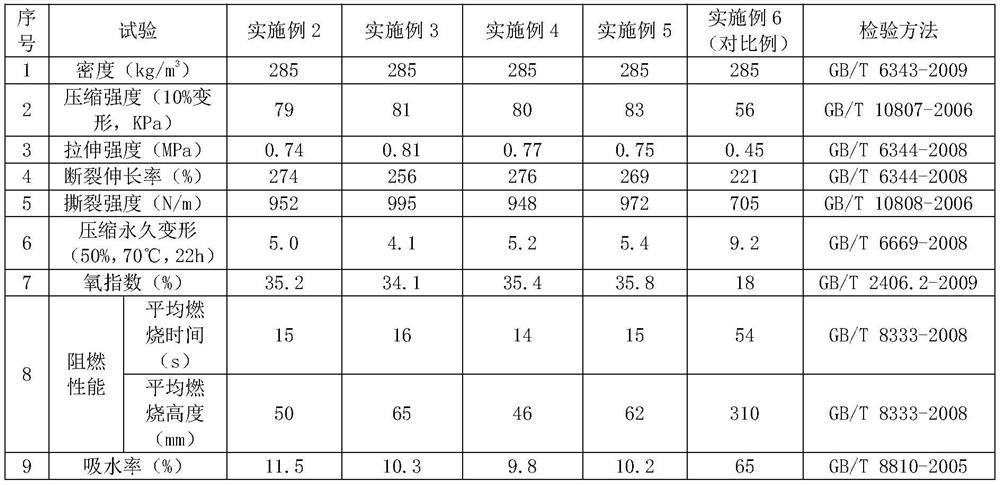

Polyurethane flexible foam material for railway curing ballast bed and preparation method thereof

The invention relates to a polyurethane flexible foam material for a railway curing ballast bed, and belongs to the technical field of curing ballast bed materials. The polyurethane flexible foam material comprises the following components in parts by mass: 100 parts of a material A and 86-91 parts of a material B, wherein the material A is prepared from the following materials in parts by mass: 100 parts of polyether polyol, 30-40 parts of bio-based polyol, 20-30 parts of a flame retardant, 4-8 parts of a small molecule chain extender, 1.75-2.75 parts of a foaming agent and 0.6-1.2 parts of a catalyst; the material B is prepared from the following materials in parts by mass: 57 to 63 parts of isocyanate and 37 to 43 parts of polyether polyol.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Steel sheet for soft nitriding and process for producing same

InactiveCN104411847AExcellent fatigue resistanceGood formabilitySolid state diffusion coatingFurnace typesSheet steelSolid solution

Provided is a steel sheet for soft nitriding which is excellent in terms of formability and fatigue resistance. The steel sheet for soft nitriding has a composition which contains, in terms of mass%, 0.05-0.10% C, up to 0.5% Si, 0.7-1.5% Mn, up to 0.05% P, up to 0.01% S, 0.01-0.06% Al, 0.5-1.5% Cr, 0.03-0.30% V, and up to 0.005% N and in which the ratio of the amount of V present as solid solution to the V content [(solid-solution V amount) / (V content)] exceeds 0.50, with the remainder comprising Fe and unavoidable impurities. The steel sheet has a composite structure which comprises ferrite and pearlite.

Owner:JFE STEEL CORP

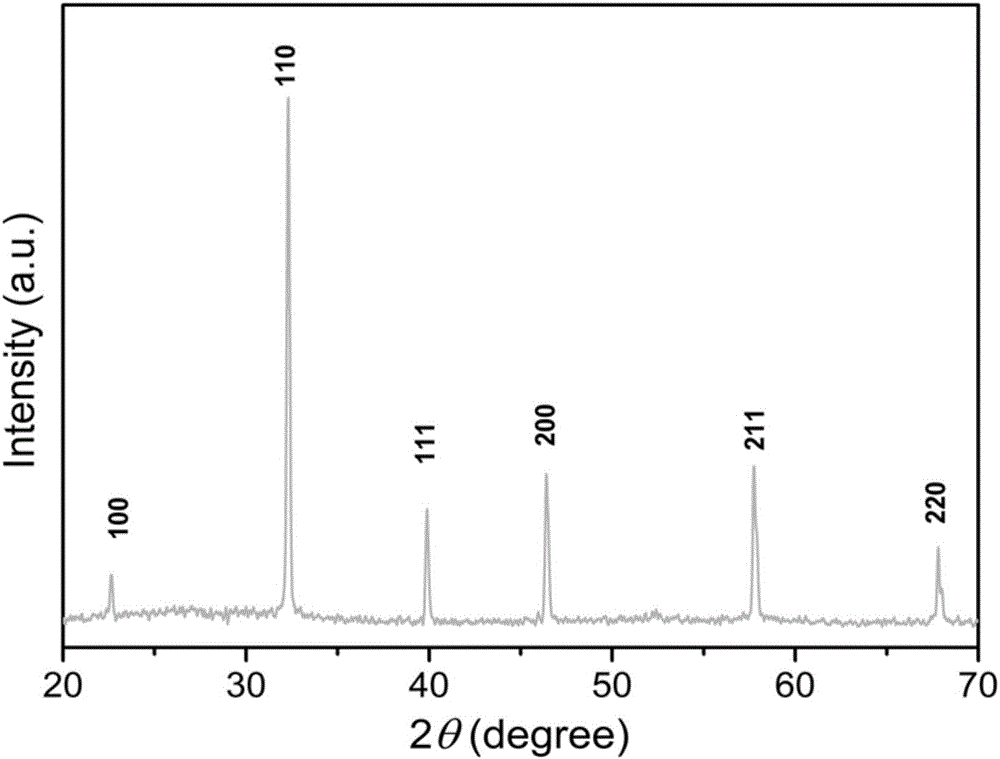

High electrostrictive strain lead-free piezoelectric material under low electric field driving and preparing method

ActiveCN106316389AExcellent fatigue resistanceStrain values are not attenuatedPiezoelectric/electrostrictive/magnetostrictive devicesRare-earth elementElectricity

The invention provides a high electrostrictive strain lead-free piezoelectric material under low electric field driving, of which chemical component conforms to a general chemical formula: (0.935-(i)*( / i))(BiO.5Na0.5)TiO3-0.065BaTi03-(i)( / i)A2BMn06, wherein A is a rare earth element, B is chosen from one or two of Ni and Co, value range of (i)*( / 1) is 0< (i)*( / i) is 0.015 or below. The invention further provides a preparing method of the high electrostrictive strain lead-free piezoelectric material under low electric field driving and an application thereof. The high electrostrictive strain lead-free piezoelectric material under low electric field driving can achieve high electrostrictive strain under low electric field driving, and meanwhile has excellent fatigue resistance property, and can be widely applied to aspects in a piezoelectric actuator, a displacement controller and the like.

Owner:LIAOCHENG UNIV

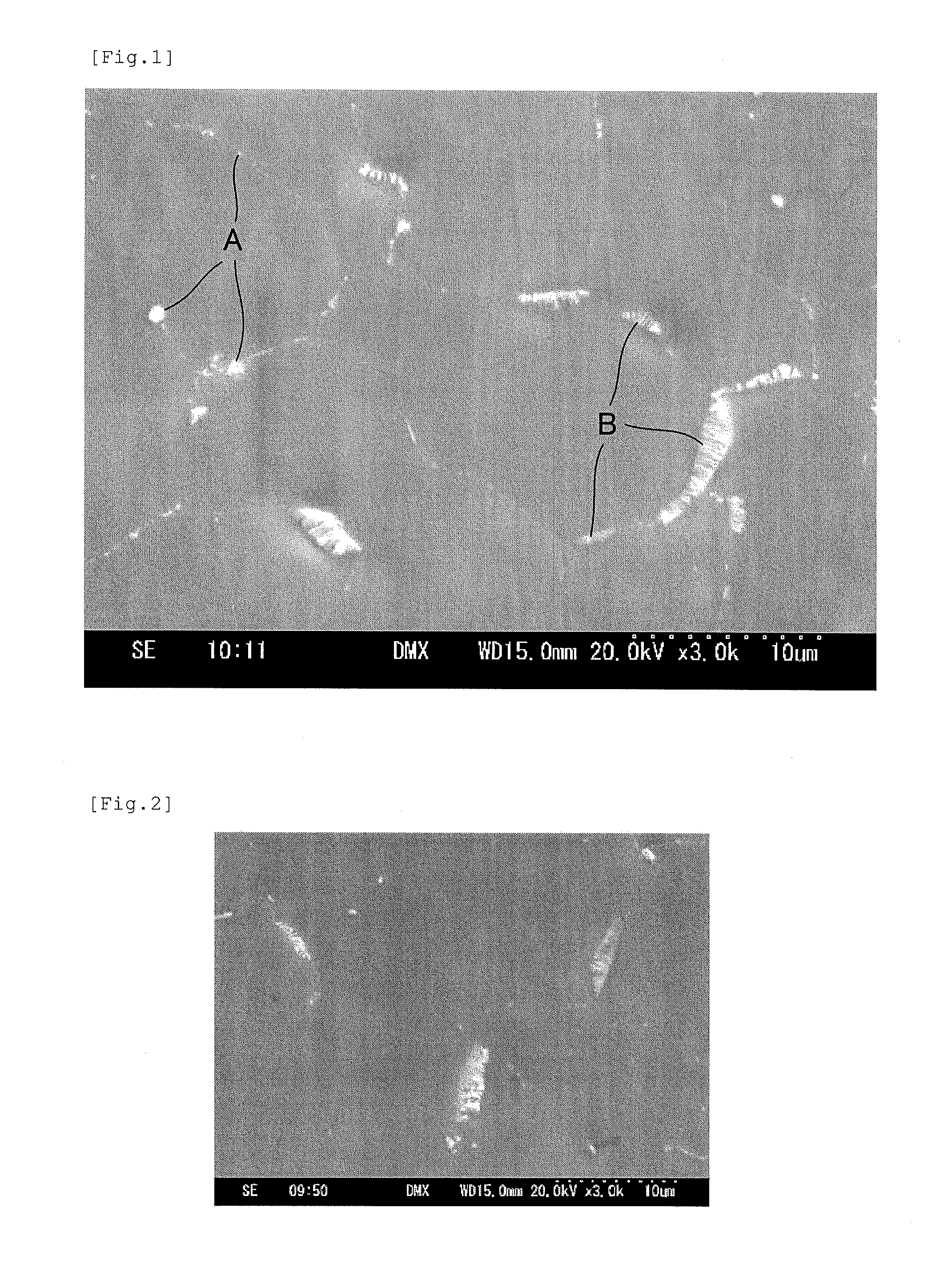

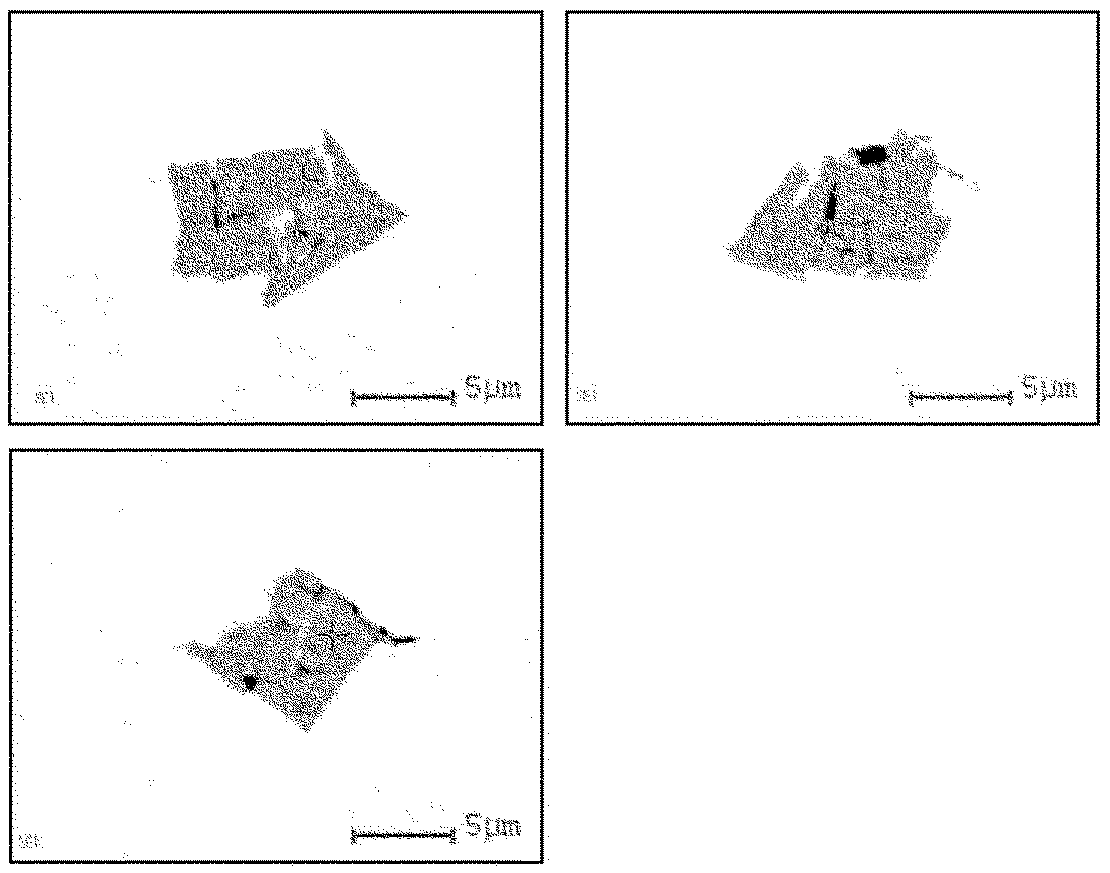

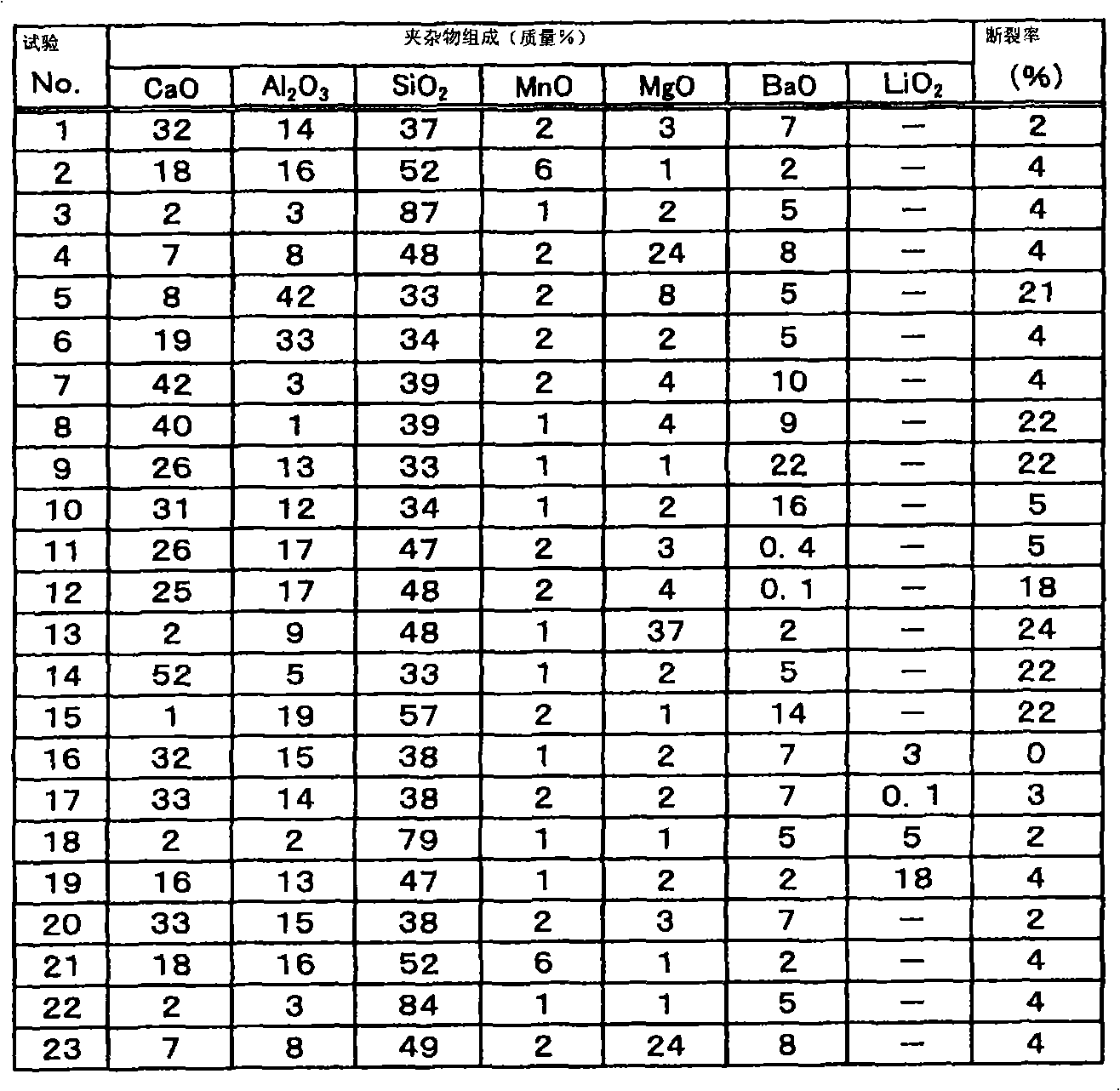

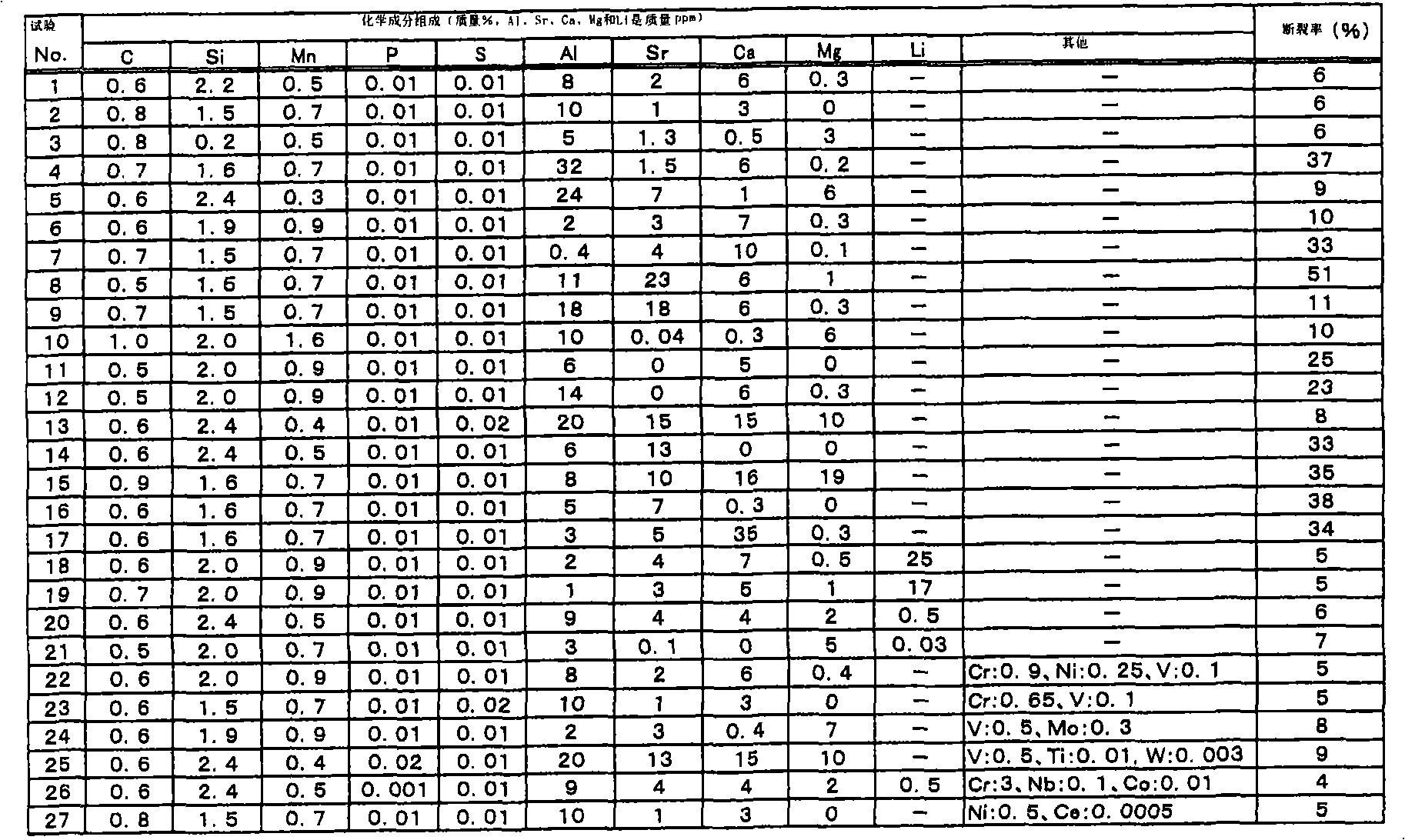

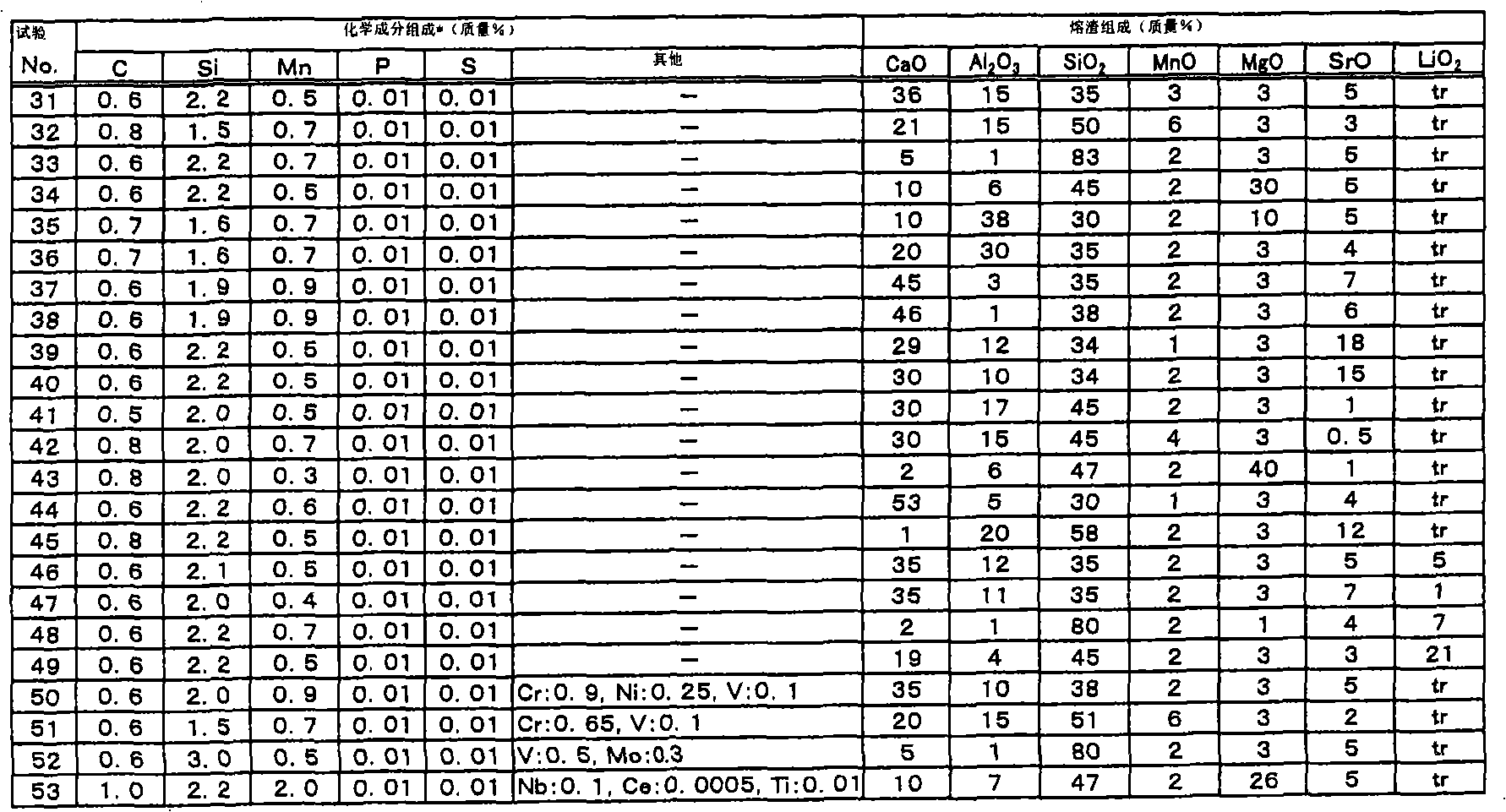

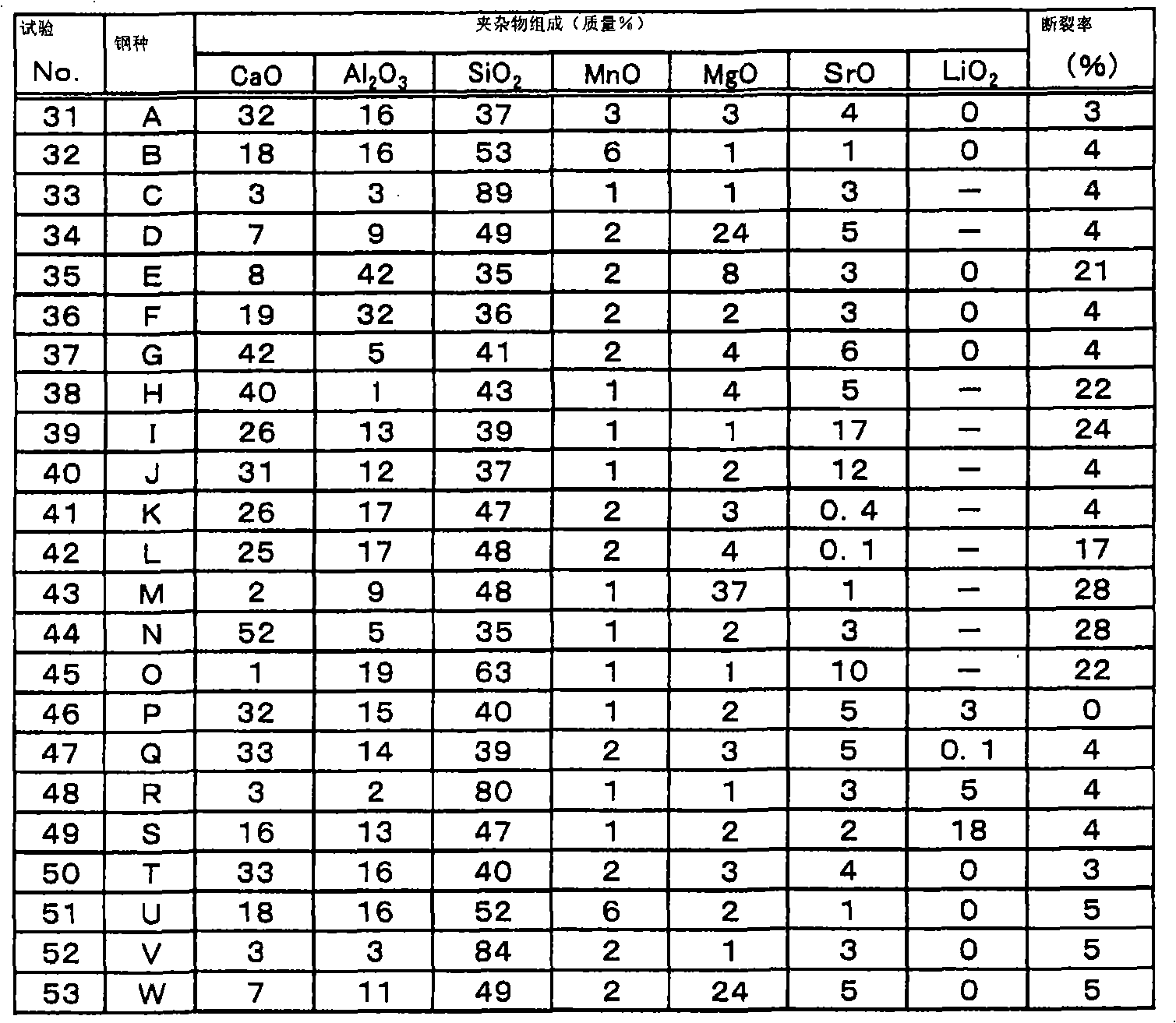

Silicon-killed steel wire material and spring

InactiveCN101553588AEasy to transformExcellent fatigue resistanceLow internal friction springsWire rodSilicon

A silicon-killed steel wire material which has been made suitable for obtaining a spring with excellent fatigue properties by regulating inclusions so as to be reduced in melting point and thereby facilitating deformation. Also provided is a spring having excellent fatigue properties which is obtained from the steel wire material. The silicon-killed steel wire material contains oxide inclusions which comprise 30-90% SiO2, 2-50% Al2O3, up to 35% (excluding 0%) MgO, up to 50% (excluding 0%) CaO, up to 20% (excluding 0%) MnO, and 0.2-20% BaO, provided that the total content of CaO and MgO is 3% or higher.

Owner:KOBE STEEL LTD

Si killed steel wire material having excellent fatigue property and spring

Disclosed is a Si killed steel wire material for producing a spring having an excellent fatigue property. Also disclosed is a spring having an excellent fatigue property, which is produced from the steel wire material. The Si killed wire material comprises 0.03 to 20 ppm (''ppm'' means ''ppm by mass'', hereinbelow) of Sr, 1 to 30 ppm of Al and 0.2 to 4% (''%'' means ''% by mass'', hereinbelow) of Si, and additionally comprises Mg and / or Ca in a total amount of 0.5 to 30 ppm. The Si killed wire material contains an oxide inclusion comprising 30 to 90% of SiO2, 2 to 50% of Al2O3, 35% or less (more than 0%) of MgO, 50% or less (more than 0%) of CaO, 20% or less (more than 0%) of MnO and 0.2 to 15% of SrO, wherein the total content of CaO and MgO is 3% or more. A spring formed from the steel wire material has an excellent fatigue property.

Owner:KOBE STEEL LTD

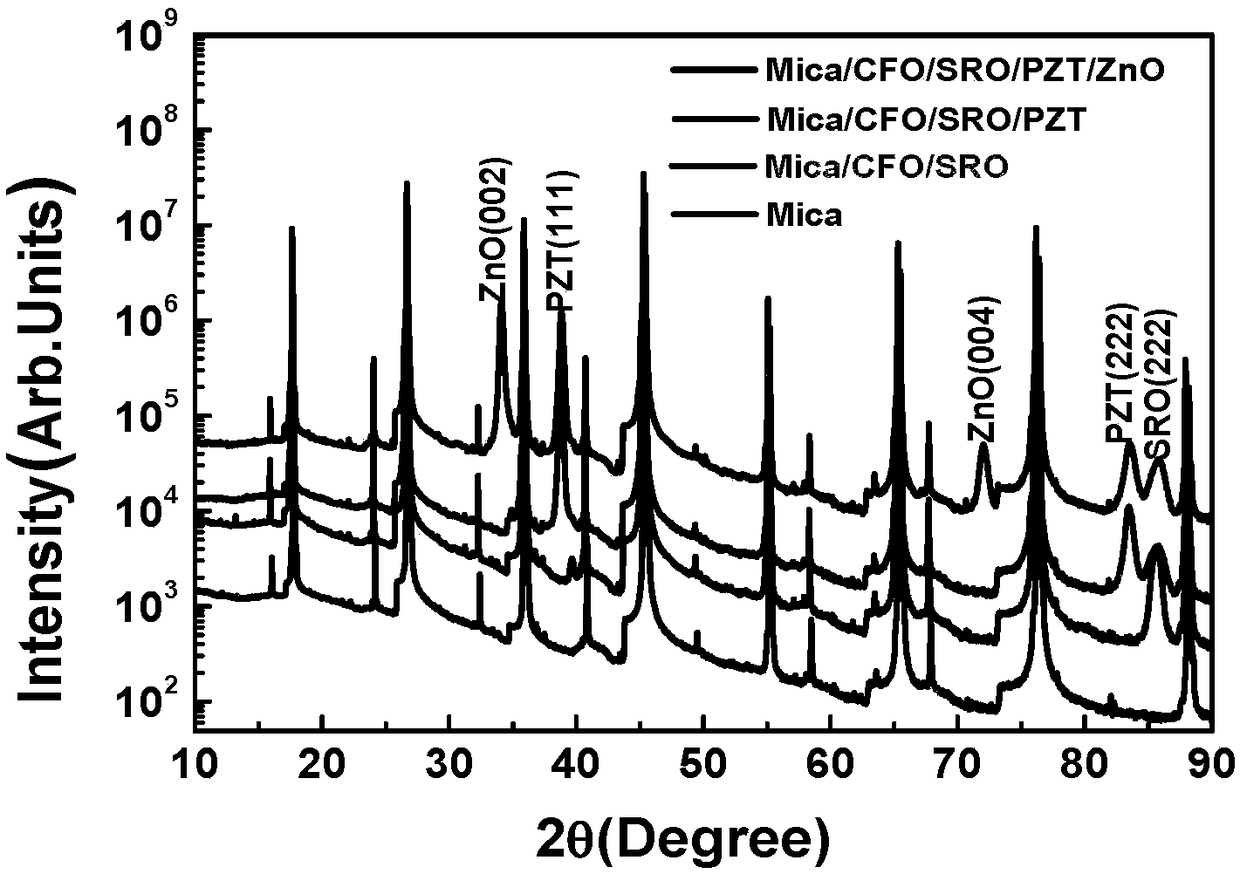

Flexible epitaxial ferroelectric-gate thin-film transistor and preparation method thereof

InactiveCN108550627AGood ferroelectric propertiesHigh remanent polarizationTransistorSemiconductor/solid-state device manufacturingGate dielectricFerroelectric thin films

The invention discloses a flexible epitaxial ferroelectric-gate thin-film transistor and a preparation method thereof. The transistor is composed of a flexible mica substrate, a buffer layer formed onthe substrate, a bottom gate electrode formed on the buffer layer, an epitaxial ferroelectric thin film layer formed on the bottom gate electrode, a channel layer formed on the epitaxial ferroelectric thin film layer, a source electrode formed on the channel layer, and a drain electrode being formed on the channel layer and being separated from the source electrode. According to the invention, the perovskite oxide SrRuO3 epitaxial film with metal conductivity is used as the bottom gate electrode and the perovskite oxide epitaxial ferroelectric film is used as a gate dielectric layer. The transistor has the excellent mechanical bending property and is resistant to bending with the 2-mm bending radius for repeated 1000 times; and the electrical property of the ferroelectric gate thin-film transistor is kept to be unchanged basically. The reading and writing speed is fast; and the high temperature-resistant performance is excellent; and after annealing at a temperature of 400 DEG C, theelectrical property of the transistor does not change obviously. Moreover, the preparation process is simple; the process is stable; and the manufacturing cycle is short.

Owner:XIANGTAN UNIV

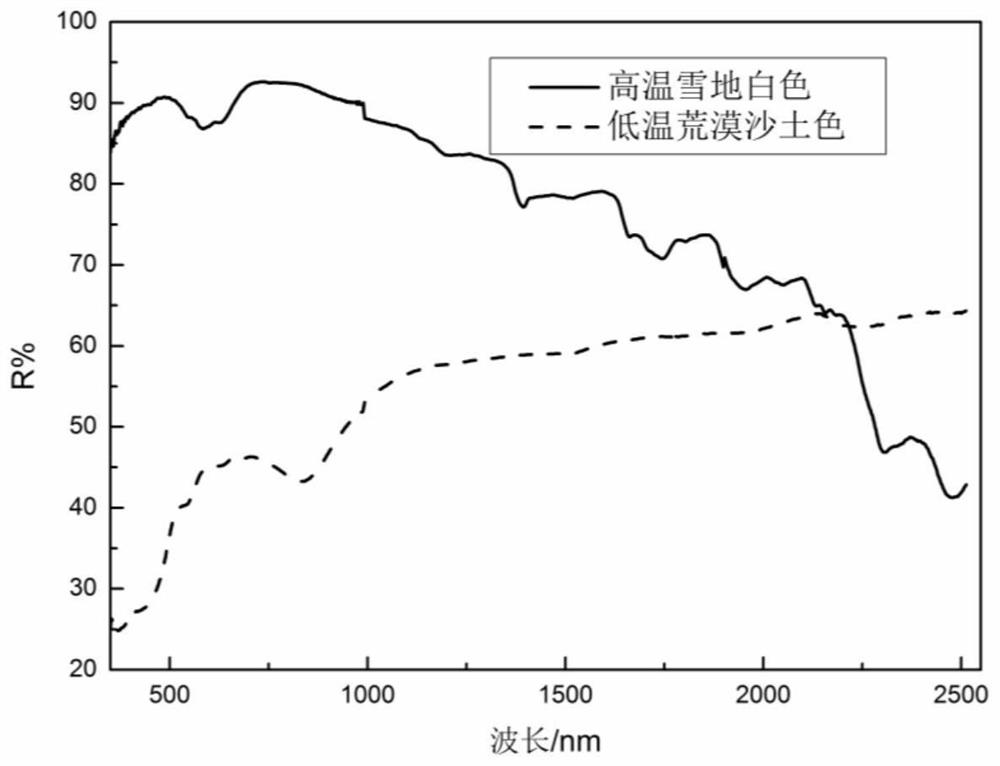

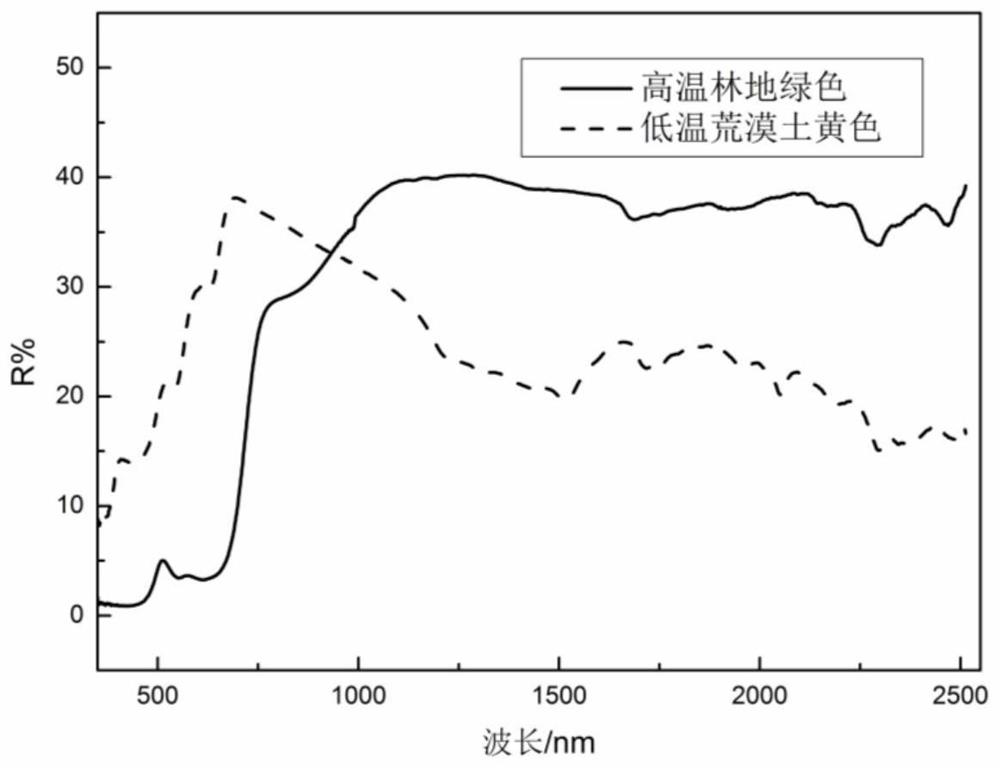

Novel self-adaptive camouflage coating as well as preparation method and application thereof

InactiveCN112745727AGood film-forming performanceImprove bonding fastnessPolyurea/polyurethane coatingsEpoxy resin coatingsPhysicsChemistry

The invention discloses a novel self-adaptive camouflage coating as well as a preparation method and application thereof. The self-adaptive camouflage coating comprises a component A and a component B in a mass ratio of 10: (1-10), the component A comprises an off-color material, a film-forming substance, a solvent, a pigment and an auxiliary agent in a mass ratio of (1-10): (30-60): (10-15): (20-50): (2-10); and the component B is a curing agent. The preparation method comprises two steps, namely, preparation of the component A and preparation of the self-adaptive camouflage coating. According to the self-adaptive camouflage coating provided by the invention, the binding strength of the camouflage coating and a substrate can be greatly improved, and the fatigue resistance and environmental adaptability of the camouflage coating are enhanced; and the preparation method provided by the invention is simple in process and suitable for mass production, the prepared self-adaptive camouflage coating can be applied to manufacturing of military protection, functional fibers, fabrics and clothes, and the prepared camouflage coating is excellent in fatigue resistance and high in environmental adaptability.

Owner:上海戎科特种装备有限公司

High-strength structural steel material having excellent fatigue crack propagation inhibitory characteristics and manufacturing method therefor

ActiveCN111542633AIncreased high-angle grain boundary fractionExcellent fatigue resistanceFurnace typesProcess efficiency improvementMaterials scienceBainite

A high-strength structural steel material having excellent fatigue crack propagation inhibitory characteristics according to an aspect of the present invention contains, by weight, 0.02-0.12% of C, 1.7-2.5% of Mn, 0.01-0.8% of Si, 0.005-0.5% of Al, and the balance Fe and unavoidable impurities, wherein a microstructure of the structural steel material is divided into a surface layer portion outside and a central portion inside along a thickness direction; the surface layer portion may comprise tempered bainite as a matrix structure, fresh martensite as a second structure, and austenite as a residual structure; and the central portion may comprise lath bainite.

Owner:浦项股份有限公司

Efficient low-noise reciprocating piston type refrigerator compressor and manufacturing process thereof

ActiveCN103925193AReduce reaction forceEasy to liftPositive displacement pump componentsPositive-displacement liquid enginesEnvironmental resistanceLow noise

The invention discloses an efficient low-noise reciprocating piston type refrigerator compressor. The efficient low-noise reciprocating piston type refrigerator compressor comprises an air suction valve slice, an exhaust valve slice and a valve plate, wherein the compressor operates back and forth in the manner that a motor drives a crankshaft and the crankshaft drives a piston, and a coating is arranged on the surface of either the air suction valve slice or the exhaust valve slice; or the surfaces of the air suction valve slice and the exhaust valve slice are respectively provided with a coating; the coatings are made of polytetrafluoroethylene or PEEK engineering plastics. In addition, the invention further relates to the manufacturing process of the refrigerator compressor. By means of the technical scheme, the noise of the valve slices of the compressor is largely lowered, fatigue strength is improved, the gas transmission coefficient of the compressor is increased, and therefore the refrigerating capacity is increased. The effect of eliminating the exhaust pulse of the compressor is good, and pressure loss is reduced, so that the gas transmission coefficient is increased. The noise of the compressor is lowered, the energy efficiency ratio of the compressor is improved, and the purposes of saving energy and protecting the environment are achieved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

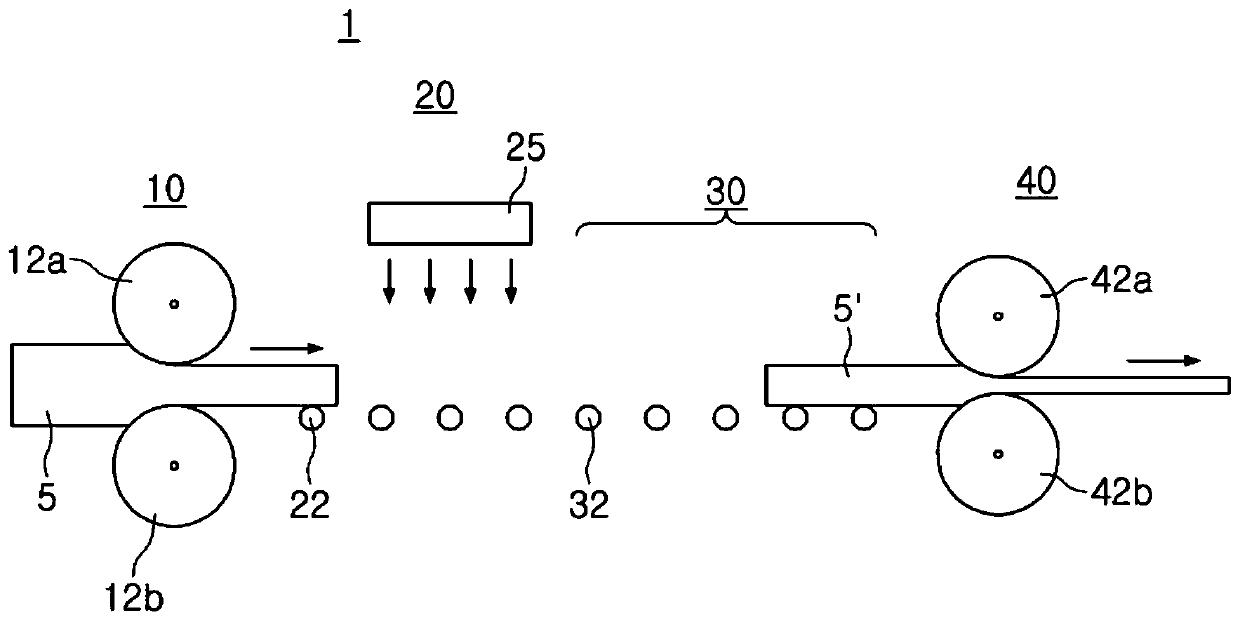

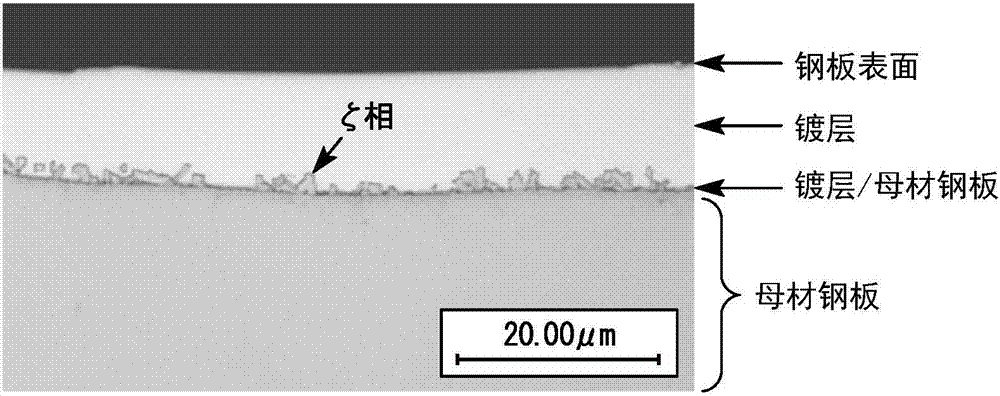

Hot-dip galvanized steel sheet

ActiveCN107109554AGood formabilityEasy to shapeHot-dipping/immersion processesFurnace typesSurface layerSheet steel

A hot-dip galvanized steel sheet comprising a base steel sheet and a hot-dip galvanizing layer, the hot-dip galvanized steel sheet having a hot-dip galvanizing layer in which columnar crystals comprising 5% or less of Fe, 1.0% or less of Al, and a Zeta phase are interposed in 20% or more of the entire interface of the plating layer and the steel sheet on the surface of a base steel sheet in which a ferrite phase constitutes 40%-97% and a hard structure constitutes a total of 3% or more in terms of volume ratio in a range of 1 / 8 thickness to 3 / 8 thickness from the surface of the base steel sheet, and the volume ratio of the hard structure in a surface layer range to a depth of 20 mum in the base steel sheet from the interface of the plating layer and the base steel sheet is 0.10-0.90 times the volume ratio of the hard structure in the range of 1 / 8 thickness to 3 / 8 thickness, the hot-dip galvanized steel sheet having a refined layer on the interface side of the base steel sheet, and the average thickness of the refined layer, the average grain size of a ferrite phase in the refined layer, and the maximum diameter of oxides included in the refined layer each being prescribed.

Owner:NIPPON STEEL CORP

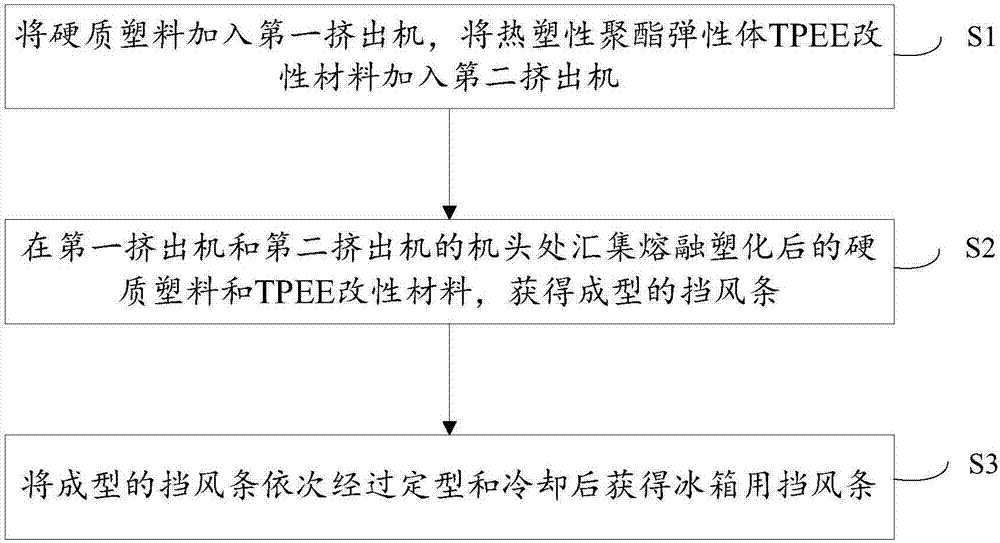

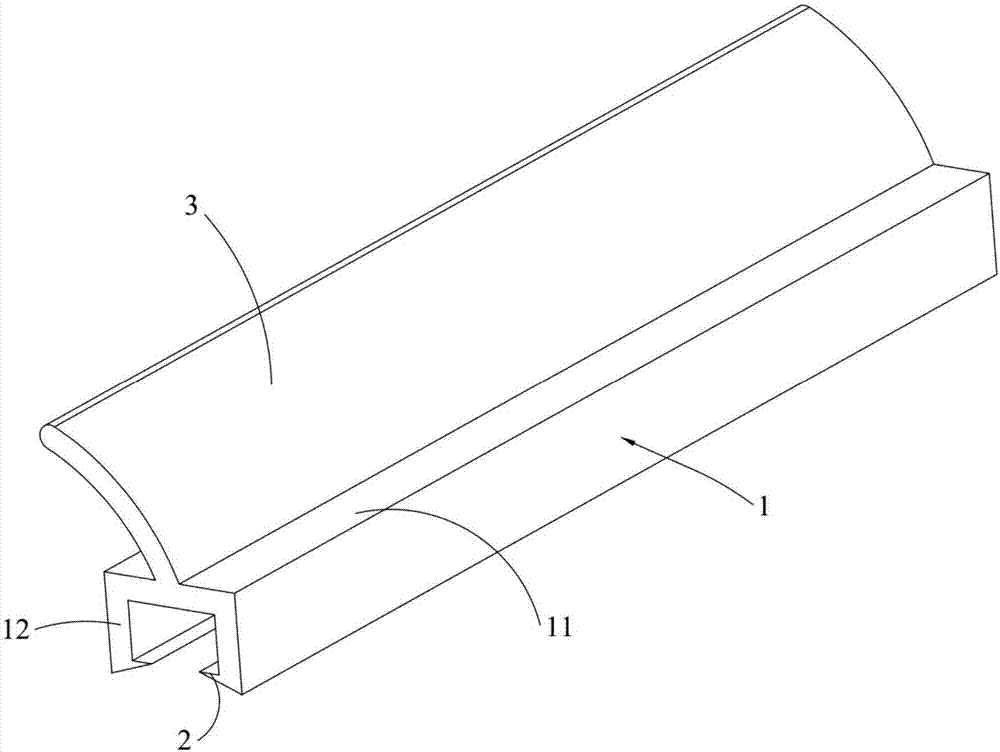

Refrigerator, wind blocking strip used for refrigerator and manufacturing method thereof

InactiveCN106926425AExcellent fatigue resistanceHigh resilienceDomestic cooling apparatusLighting and heating apparatusPolyesterEngineering

The invention discloses a refrigerator, a wind blocking strip used for the refrigerator and a manufacturing method thereof. The manufacturing method of the wind blocking strip used for the refrigerator comprises the steps that first, rigid plastic is added into a first extruding machine, a thermoplastic polyester elastomer (TPEE) modified material is added into a second extruding machine; second, the molten and plasticized rigid plastic and the TPEE modified material are collected at machine heads of the first extruding machine and the second extruding machine, and the formed wind blocking strip is obtained; and third, the formed wind blocking strip is shaped and cooled sequentially, and the wind blocking strip used for the refrigerator is obtained. A clamping groove is made of the rigid plastic, a folded edge is made of the TPEE modified material, and through different moulds and a certain process condition, the rigid plastic and the TPEE modified material are extruded together to be manufactured to be the wind blocking strip; because the TPEE modified material has the strength of engineering plastic and the elasticity of rubber, the friction resistant capacity and the elasticity and airtightness at the low temperature of the wind blocking strip are all improved, accordingly the service life of the wind blocking strip is prolonged, and the energy consumption of the refrigerator is reduced.

Owner:HEFEI HUALING CO LTD +2

Ethylene-acrylate rubber formula for turbocharging rubber pipes

The invention relates to an ethylene-acrylate rubber formula for turbocharging rubber pipes. The ethylene-acrylate rubber formula comprises, by weight, 25-50 parts of ethylene-acrylate rubber HT-OR, 50-75 parts of ethylene-acrylate rubber 5394, 1-3 parts of stearic acid, 1-3 parts of an anti-aging agent 445, 0.5-2 parts of an auxiliary agent 18D, 1-3 parts of an auxiliary agent VAM, 50-80 parts ofcarbon black N550, 10-40 parts of N990 carbon black, 10-30 parts of a plasticizer TP759, 1-4 parts of a cross-linking agent ACT55 and 1-2 parts of a cross-linking agent Diak No.1. A turbocharging pipe assembly prepared according to the formula is excellent in fatigue resistance and aging resistance and high in pulse frequency, the service life of the turbocharging pipe assembly under high-power extreme severe conditions is greatly prolonged, and safety and practicality of the HT-AEM turbocharging pipe assembly are improved.

Owner:WUXI NO 2 RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com