Durable high-modulus asphalt mixture based on hard asphalt particles

A technology of asphalt mixture and hard asphalt, which is applied in the field of road paving materials, can solve the problems that affect the popularization and application of high modulus asphalt mixture, and the overall cost is high, so as to improve the shear and compression resistance, prolong the service life and maintain Good cycle and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

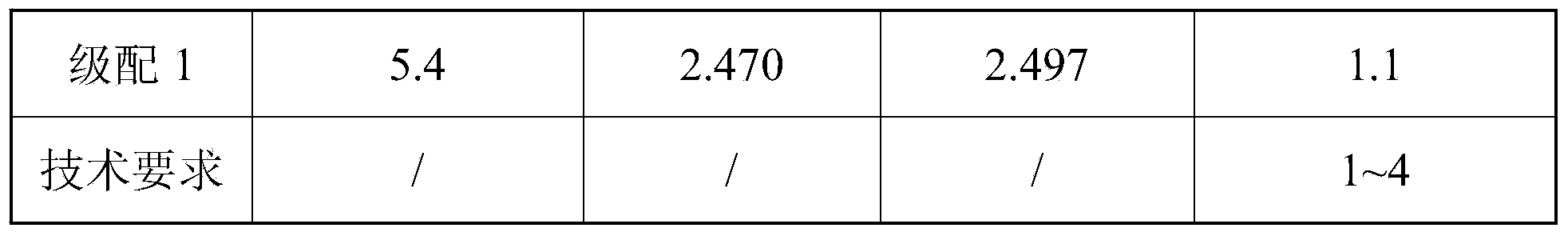

[0021] The asphalt mixture in this example is mainly composed of 100 parts by mass of mineral material and 5.4 parts by mass of asphalt. Asphalt particles = 7:3), mineral materials include limestone aggregate and limestone powder, limestone aggregate and limestone powder account for 96.5% and 3.5% of the mineral mass respectively, limestone aggregates are divided according to aggregate particle size There are four groups of aggregates: the particle size of the first group: 10-15mm; the particle size of the second group: 5-10mm; the particle size of the third group: 3-5mm; the particle size of the fourth group: 0~3mm, the percentages of the mass of the above four groups of aggregates in the total mass of mineral materials are: 30%, 19%, 14.5%, 33%, the effective density of the total mineral material ρ G =2.702g / cm 3 , and its gradation is shown in Table 1.

[0022] Table 1 Grading table

[0023]

[0024] Put the mineral material configured according to the above gradation...

Embodiment 2

[0059] The asphalt mixture in this example is mainly composed of 100 parts by mass of mineral material and 5.5 parts by mass of asphalt. The asphalt is composed of two components. The petroleum asphalt is obtained by compounding Sinopec No. 70 road petroleum asphalt and hard asphalt particles. No. 15 asphalt, the mineral materials include limestone aggregate and limestone powder, the quality of limestone aggregate and limestone powder accounted for 97% and 3.0% of the mineral material respectively, limestone aggregate is divided into four groups of aggregates according to the aggregate particle size : The particle size of the first group of aggregates: 10-15mm; the particle size of the second group: 5-10mm; the particle size of the third group: 3-5mm; the particle size of the fourth group: 0-3mm, the above The percentages of the mass of the four groups of aggregates in the total mass of mineral materials are: 38%, 15%, 8%, and 36%, and the effective density of the total mineral...

Embodiment 3

[0096] The asphalt mixture in this example is mainly composed of 100 parts by mass of mineral material and 5.6 parts by mass of asphalt. Asphalt particles = 7:3), mineral materials include limestone aggregate and limestone powder, limestone aggregate and limestone powder account for 96% and 4% of the mineral material, limestone aggregates are divided according to aggregate particle size There are four groups of aggregates: the particle size of the first group: 10-15mm; the particle size of the second group: 5-10mm; the particle size of the third group: 3-5mm; the particle size of the fourth group: 0-3mm, the percentages of the mass of the above four groups of aggregates in the total mass of mineral materials are as follows: 36%, 15%, 13%, 33%, the effective density of the total mineral material ρ G =2.709g / cm 3 , and its gradation is shown in Table 17.

[0097] Table 17 Grading table

[0098]

[0099] Put the mineral material configured according to the above gradation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com