Processing technology for spring made of titanium alloy wire with special-shaped section

A technology of titanium alloy wire and special-shaped section, applied in the field of metal material processing, can solve the problems of reduced service life, poor corrosion resistance, easy to be corroded, etc., and achieve the effects of increased service life, high fatigue life, and not easy to corrode failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, titanium alloy wire with special-shaped cross-section is prepared by forging, precision forging, hot drawing, and cold swaging. The specific process is as follows:

[0029] (1) Heat a titanium alloy ingot with a diameter of φ220mm at 1160°C, heat it for 4.5 hours, and then forge the alloy ingot into a φ85mm billet (the forging deformation is 85%) through the forging blanking process;

[0030] (2) Turn the surface of the forged billet to φ80mm, heat it at 1020°C for 2 hours, and then precision forge the alloy billet into a φ30mm forged rod (the precision forging deformation is about 86%);

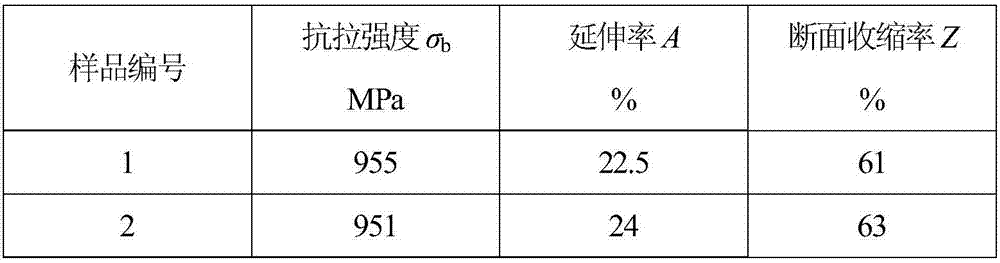

[0031] (3) Polish the surface of the forged rod to φ28mm, heat it at 840°C for 40 minutes, and then pass the hot drawing process. The deformation of the hot drawing pass is between 11% and 15%, and prepare a rod with a diameter of φ12mm. The tensile properties of the as-drawn rods at room temperature are shown in Table 1.

[0032] Table 1 Tensile properties of hot...

Embodiment 2

[0038] In this embodiment, titanium alloy wire with special-shaped cross-section is prepared by forging, precision forging, hot drawing, and cold swaging. The specific process is as follows:

[0039] (1) Make a titanium alloy ingot with a diameter of φ220mm at 1170°C, heat it for 3.5 hours, and then forge the alloy ingot into a φ95mm billet (the forging deformation is 81%) through the forging blanking process;

[0040] (2) Turn the surface of the forged billet to φ89mm, heat it at 1030°C for 2.5 hours, and then precision forge the alloy billet into a φ35mm forged rod (the precision forging deformation is about 85%);

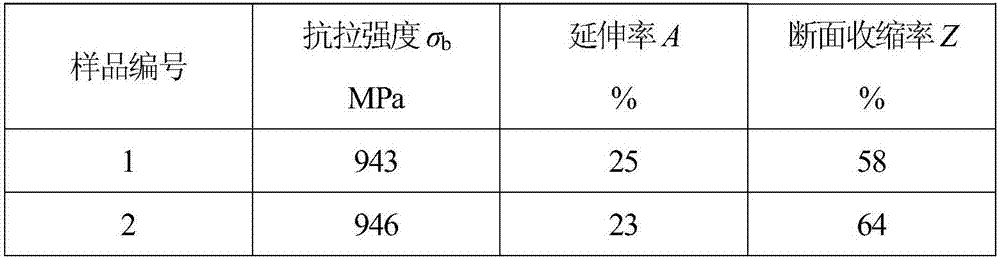

[0041] (3) Polish the surface of the forged bar to φ33mm, heat it at 860°C for 50 minutes, and then use the hot drawing process. The deformation of the hot drawing pass is between 11% and 15%, and prepare a φ15mm bar. The room temperature tensile properties of the as-drawn rods are shown in Table 3.

[0042] Table 3 Tensile properties of hot-drawn rods at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com