Steel sheet for soft nitriding and process for producing same

A manufacturing method and soft nitriding technology, which are applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of long time required for nitriding, and achieve the effects of excellent fatigue resistance and reduction of manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

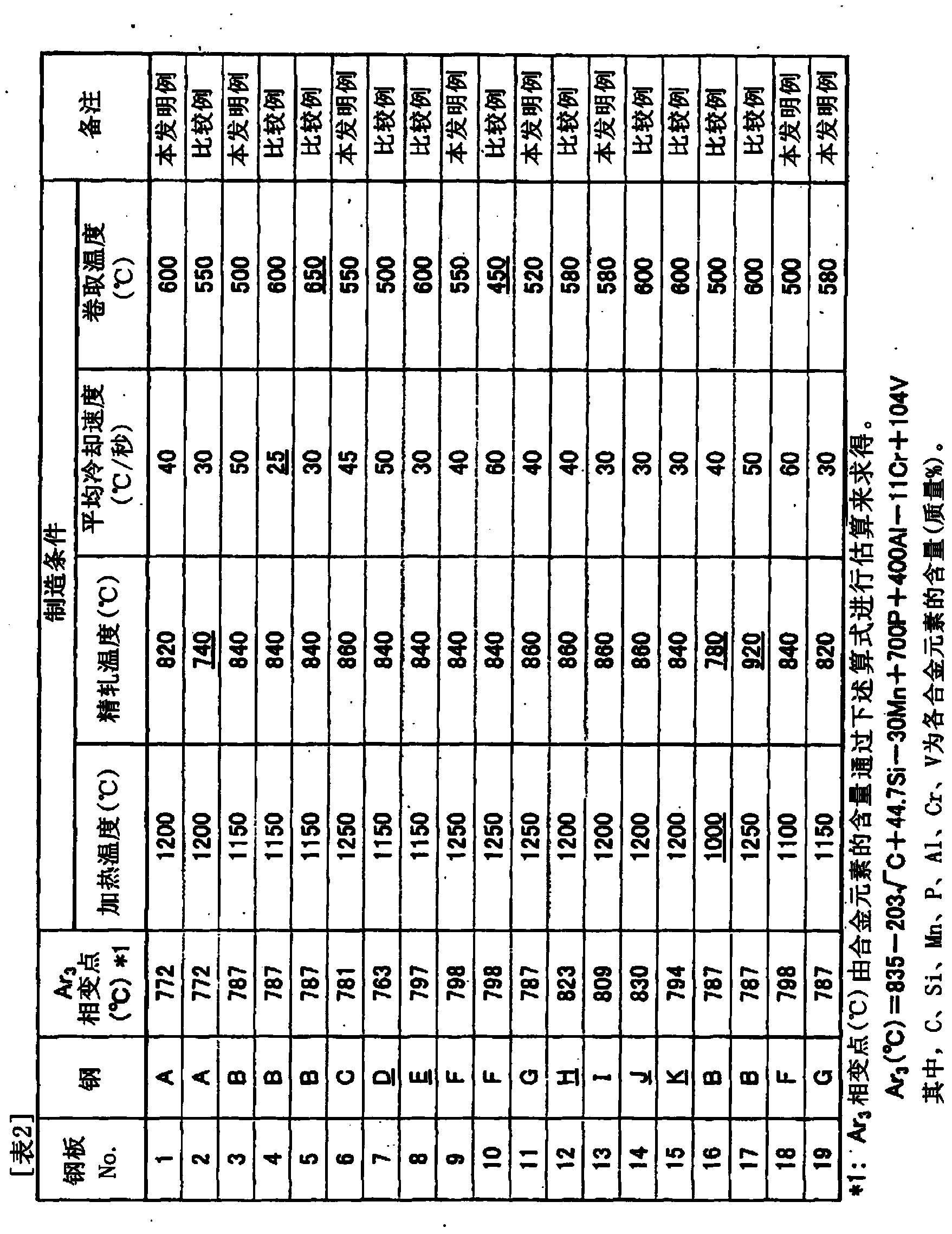

[0101] Steel containing the chemical components shown in Table 1 was melted, ingot-cast and billet-rolled to form steel sheets. After these steel sheets were heated, rough rolling and finish rolling were performed, and immediately after finishing rolling, cooling and coiling were performed to obtain hot-rolled steel sheets with a thickness of 3.2 mm. In addition, the heating temperature, finish rolling temperature, average cooling rate from the finish rolling temperature to the coiling temperature, and the coiling temperature of the above-mentioned steel sheets are shown in Table 2.

[0102]

[0103]

[0104] The hot-rolled steel sheet obtained above was pickled to remove scale, and temper rolling with an elongation of 0.5% was performed. Then, test pieces were cut out from the temper-rolled steel sheets and used for the following evaluations.

[0105] (i) Solid solution V amount

[0106] Regarding the solid-solution V content, a test piece was cut from the 1 / 4 position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com