High-strength structural steel material having excellent fatigue crack propagation inhibitory characteristics and manufacturing method therefor

A technology of fatigue crack propagation and manufacturing method, applied in the field of structural steel and its manufacturing, can solve problems such as inability to achieve accurate temperature, and achieve the effects of suppressing fatigue crack growth, improving fatigue resistance, and ensuring fatigue crack growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

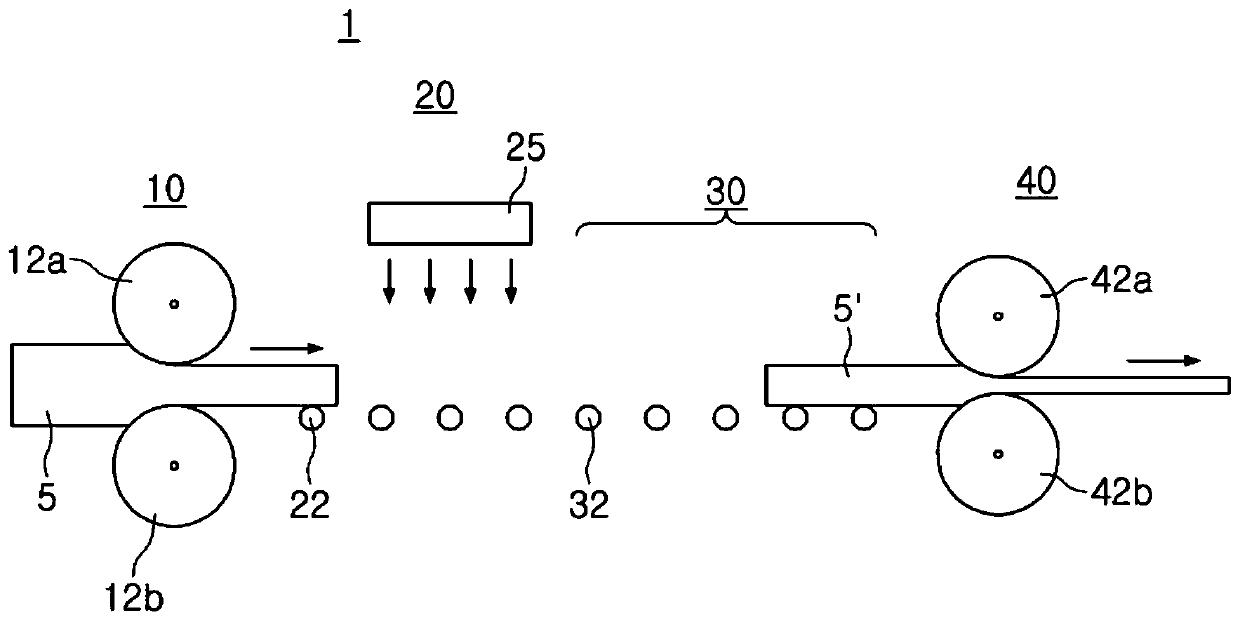

Image

Examples

Embodiment Construction

[0103] The present invention will be described in more detail below by way of examples. However, it should be noted that the examples described below are merely examples for embodying the present invention, and are not intended to limit the scope of rights of the present invention.

[0104] Slabs having the composition of Table 1 below were produced, and Table 2 is the calculation result of the phase transition temperature of each slab.

[0105] 【Table 1】

[0106]

[0107] 【Table 2】

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com