High-elastic foamed shoe insole material, and preparation method and application thereof

A high-resilience, foam molding technology, applied in the field of shoe manufacturing, can solve the problems of poor wearing experience, poor softness, high density, etc., achieve the best wearing and running experience, realize personalized customization, efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The embodiment of the present invention provides a method for preparing the high resilience foamed shoe midsole material as described above, which includes the following steps:

[0054] Melt and knead each component in the thermoplastic resin composite material, extrude or grind to obtain a printing material, and print it by a 3D printer to obtain a shoe sole blank;

[0055] The shoe sole blank is immersed in a high-pressure fluid atmosphere to balance, then the pressure is quickly released, dried and aged to obtain a high resilience foamed shoe midsole material.

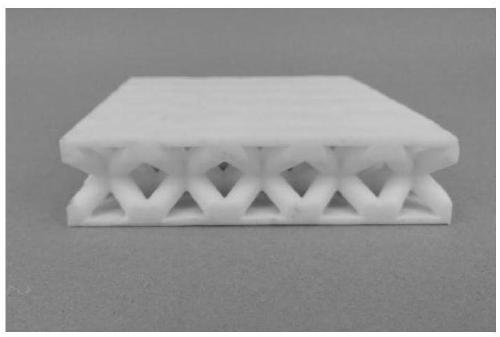

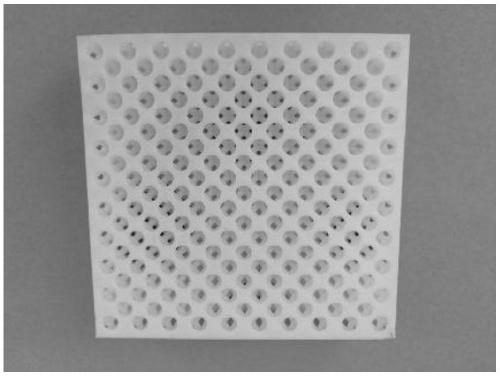

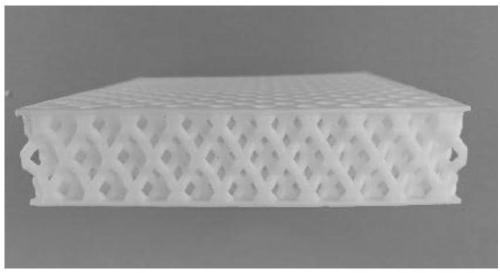

[0056] See Figure 4 , Figure 4 These are the front and back side views of the foamed 3D structure of the injection molded shoe midsole in some embodiments of the present invention.

[0057] In the embodiment of the present invention, each component in the thermoplastic resin composite material is weighed in parts by weight. In some embodiments of the present invention, the weighed thermoplastic elastomer composit...

Embodiment 1

[0069] In the embodiment of the present invention, the thermoplastic polyurethane composite material includes the following components in parts by mass:

[0070] Thermoplastic polyurethane: 100 parts;

[0071] Compatibilizer: 2 parts;

[0072] Antioxidant: 0.3 parts;

[0073] Nucleating agent: 5 parts;

[0074] Stearic acid: 0.5 parts;

[0075] Cell stabilizer: 0.5 parts.

[0076] Among them, the compatibilizer is maleic anhydride; the antioxidant is AT-10; the nucleating agent is nano titanium dioxide; and the cell stabilizer is polyisobutyl methacrylate.

[0077] Weigh the components in the thermoplastic polyurethane composite material in parts by weight; dry and stir the weighed thermoplastic polyurethane composite material, then add it to the barrel of the twin-screw extruder for melt mixing , The printed wire is produced by extrusion, and 3D printing is used to obtain the initial blank of the 3D structure of the thermoplastic elastomer composite (unfoamed, with a size smaller than th...

Embodiment 2

[0079] In the embodiment of the present invention, the thermoplastic polyurethane composite material includes the following components in parts by mass:

[0080] Thermoplastic polyurethane: 85 parts;

[0081] Nylon elastomer: 15 parts;

[0082] Compatibilizer: 2 parts;

[0083] Antioxidant: 0.3 parts;

[0084] Nucleating agent: 5 parts;

[0085] Stearic acid: 0.5 parts;

[0086] Cell stabilizer: 0.5 parts.

[0087] Among them, the compatibilizer is maleic anhydride; the antioxidant is AT-10; the nucleating agent is nano titanium dioxide; and the cell stabilizer is polyisobutyl methacrylate.

[0088] Weigh the components in the thermoplastic polyurethane composite material in parts by weight; dry and stir the weighed thermoplastic polyurethane composite material, then add it to the barrel of the twin-screw extruder for melt mixing , The printed wire is produced by extrusion, and 3D printing is used to obtain the initial blank of the 3D structure of the thermoplastic elastomer composite (unf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com