Si killed steel wire material having excellent fatigue property and spring

A silicon-killed steel, fatigue-resistant technology, applied in the direction of metal rolling, can solve the problems of fatigue strength, difficulty, inability to make full use of various component differences and compounding, etc., to promote the miniaturization of inclusions and fatigue resistance characteristics excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0044] It is known that a wire rod having a large deformation ratio during hot rolling is useful because inclusions are stretched and split during hot rolling to make them finer. Under such circumstances, the present inventors considered the changes in the shape of inclusions caused by heating and hot rolling after solidification, and selected the composition and shape of each inclusion for improving the fatigue resistance of the spring from various research angle. As a result, it was found that by appropriately controlling the concentrations of Sr, Al, Si, Mg, and Ca, the deformation of oxide-based inclusions during hot rolling is significantly promoted and easily miniaturized.

[0045] It has also been known that the addition of small amounts of alkaline earth metal elements such as Sr, Mg, and Ca is effective for improving the characteristics of springs (for example, the aforementioned Patent Document 3), but it has been found that it is not necessary to add only a small am...

no. 2 approach

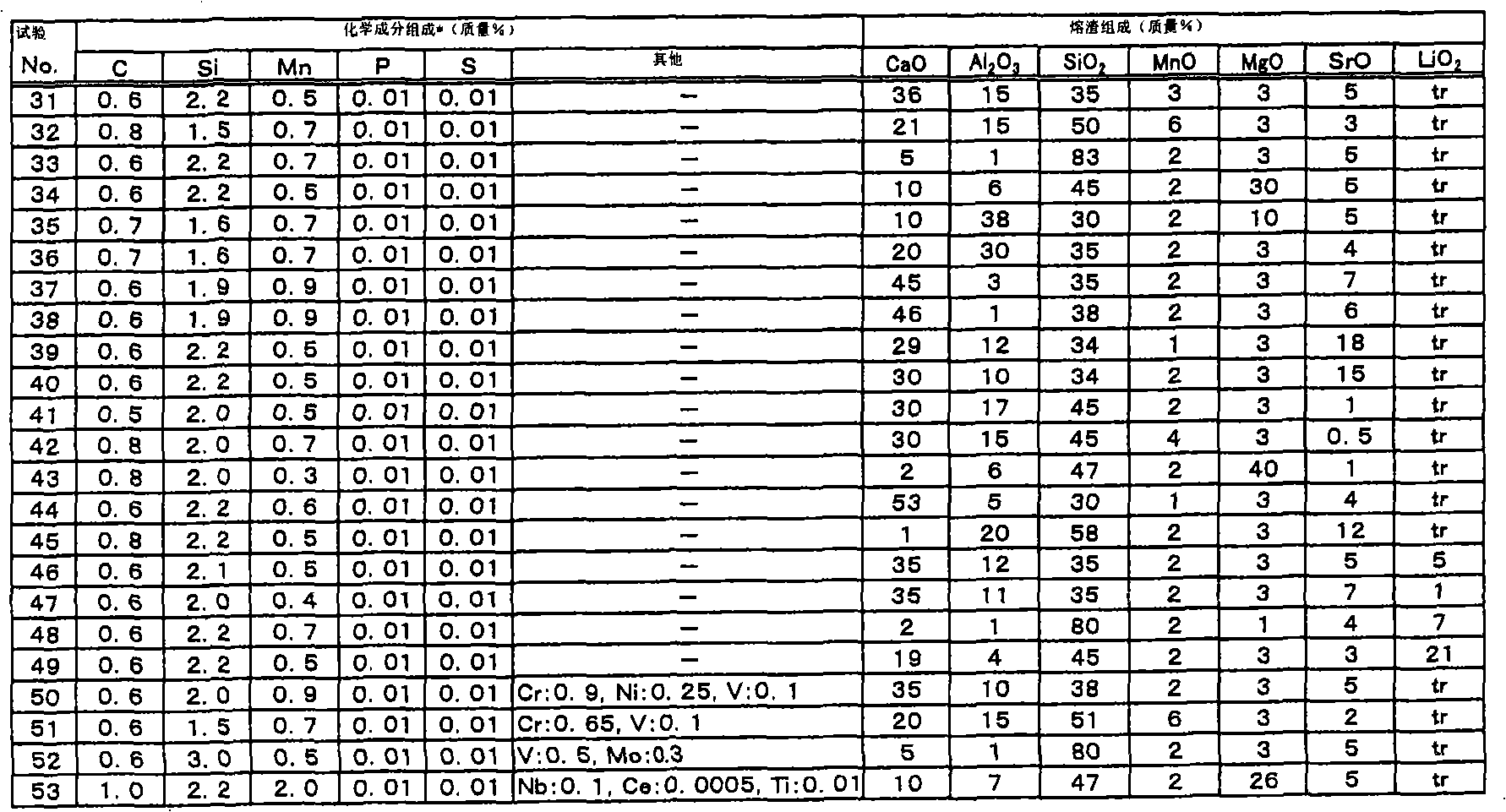

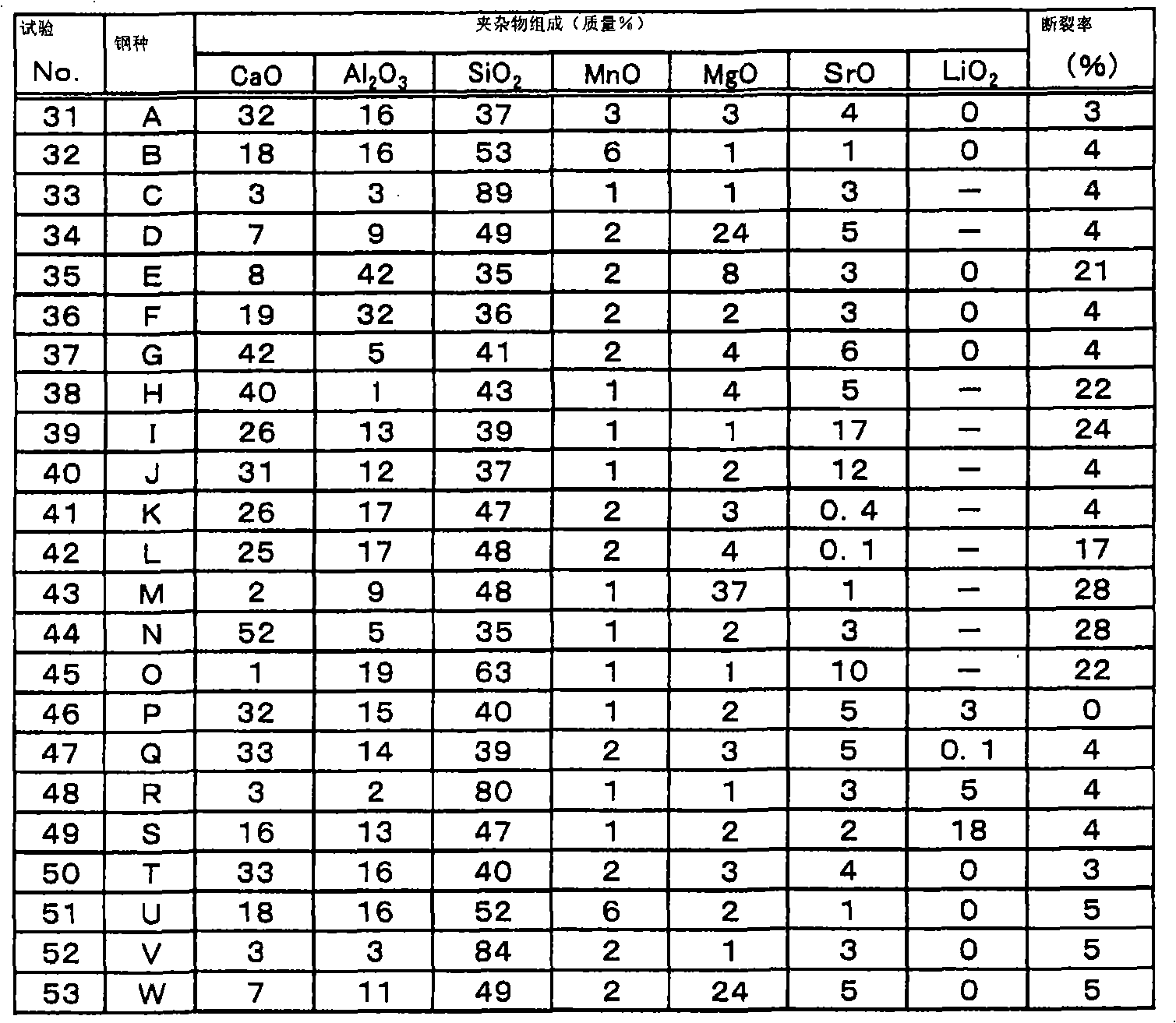

[0060]Based on the research results of the present inventors, it has also been found that if SrO, Al 2 o 3 , SiO 2 , MgO, CaO, and MnO concentrations, and if the ratio of each oxide component in the oxide-based inclusions is appropriate, the deformation of the oxide-based inclusions during hot rolling will be significantly promoted and the micronization will be facilitated.

[0061] Conventionally, it has also been known that appropriate ratios of oxides in the oxide-based inclusion system are effective in improving the properties of steel (for example, the aforementioned Patent Documents 1 to 3, 5 to 7), but the fatigue strength is not necessarily good. When these elements are contained in a balanced manner, it has been found that the fatigue resistance of the silicon-killed steel wire rod is significantly improved. For example, CaO-Al 2 o 3 -SiO 2 Three-component system inclusions, in the generally known ternary system phase diagram, although it can be seen that there i...

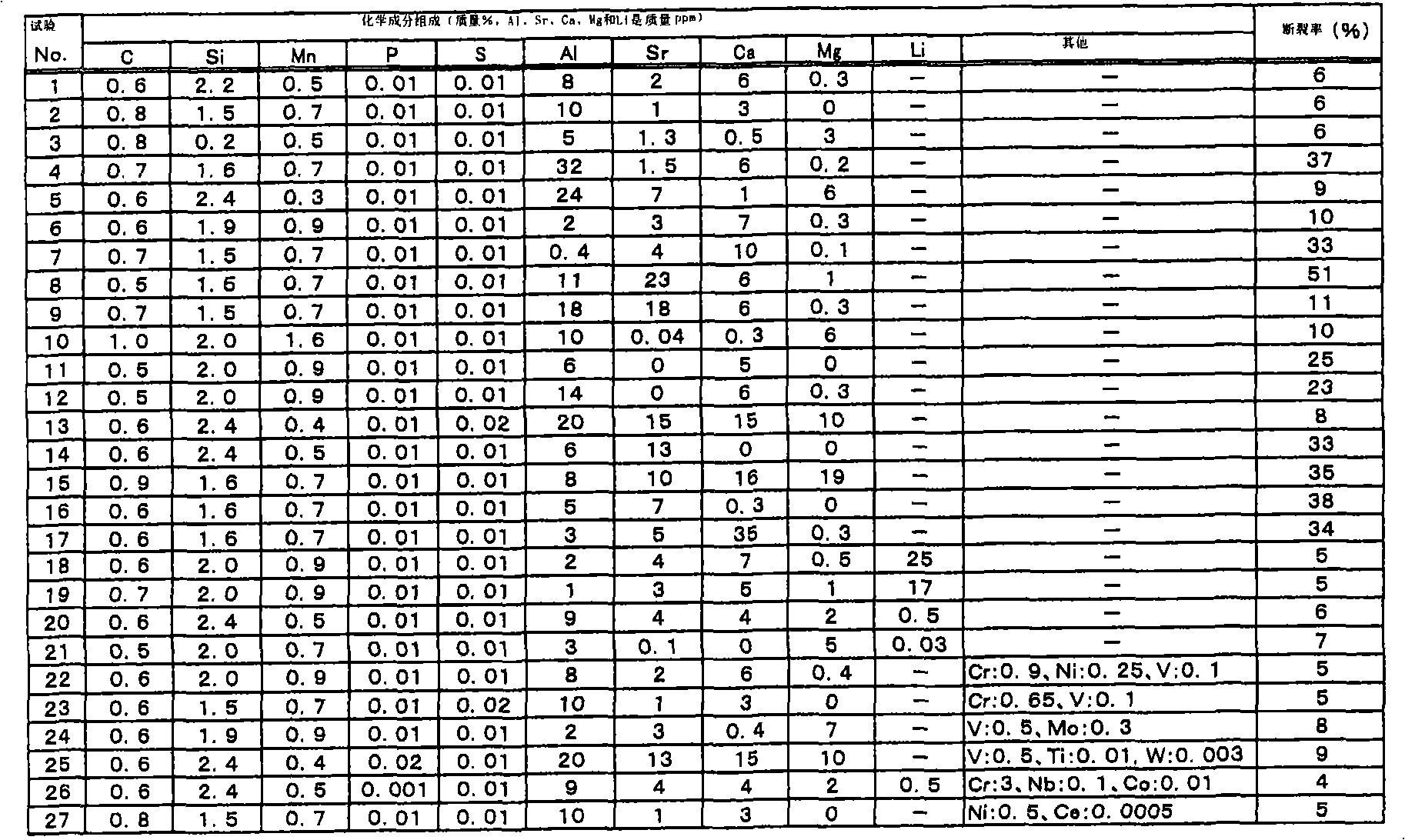

Embodiment 1

[0085] Experiments are implemented on a real machine (or laboratory level). That is, the actual machine is to tap the molten steel smelted in the converter into the ladle (the laboratory is to smelt 500kg of molten steel, which simulates the molten steel tapped from the converter), add various additives to adjust the composition, and implement Electrode heating and argon bubbling are performed to perform molten steel treatment (slag refining). In addition, after adjusting other components, Ca, Mg, Ce, Ba, Li, etc. were added as necessary during the molten steel treatment, and kept for 5 minutes or more. The obtained steel ingot was forged and hot-rolled to obtain a wire rod having a diameter of 8.0 mm.

[0086] For each of the obtained steel wire rods, the contents of Sr and Li in the steel were measured by the following method, and an evaluation test simulating a rotational bending fatigue test of a valve spring was performed.

[0087] (Contents of Sr and Li in steel)

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com