Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Equivalent mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-region in-situ reaction preparation method for high strength fiber-reinforced ceramic matrix composite material

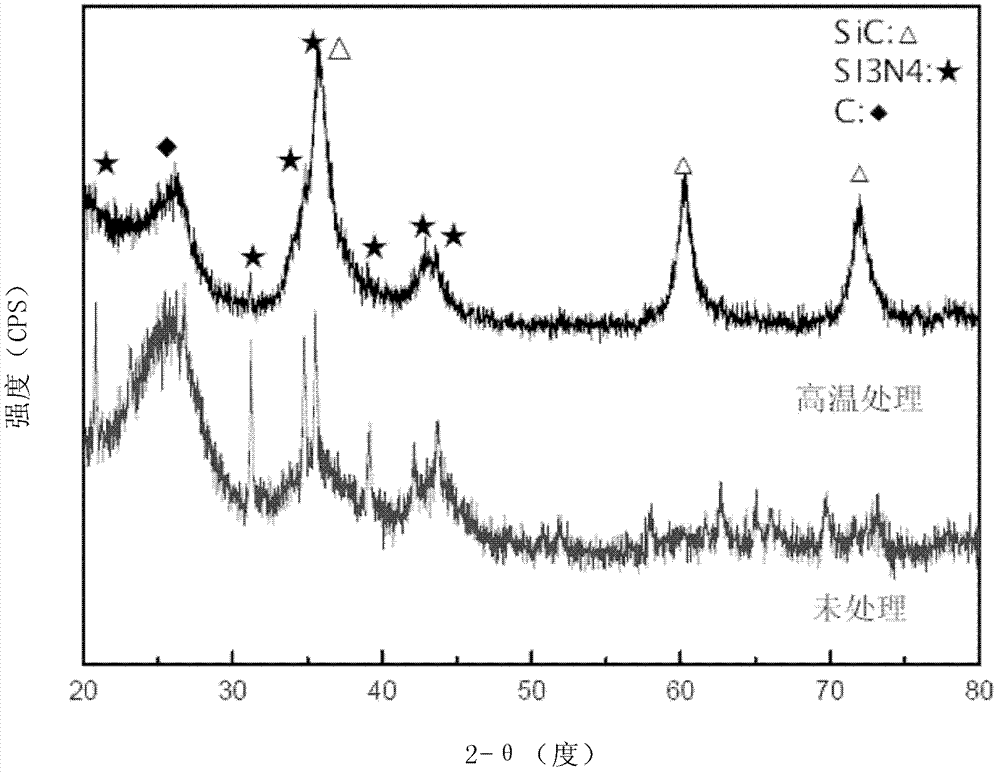

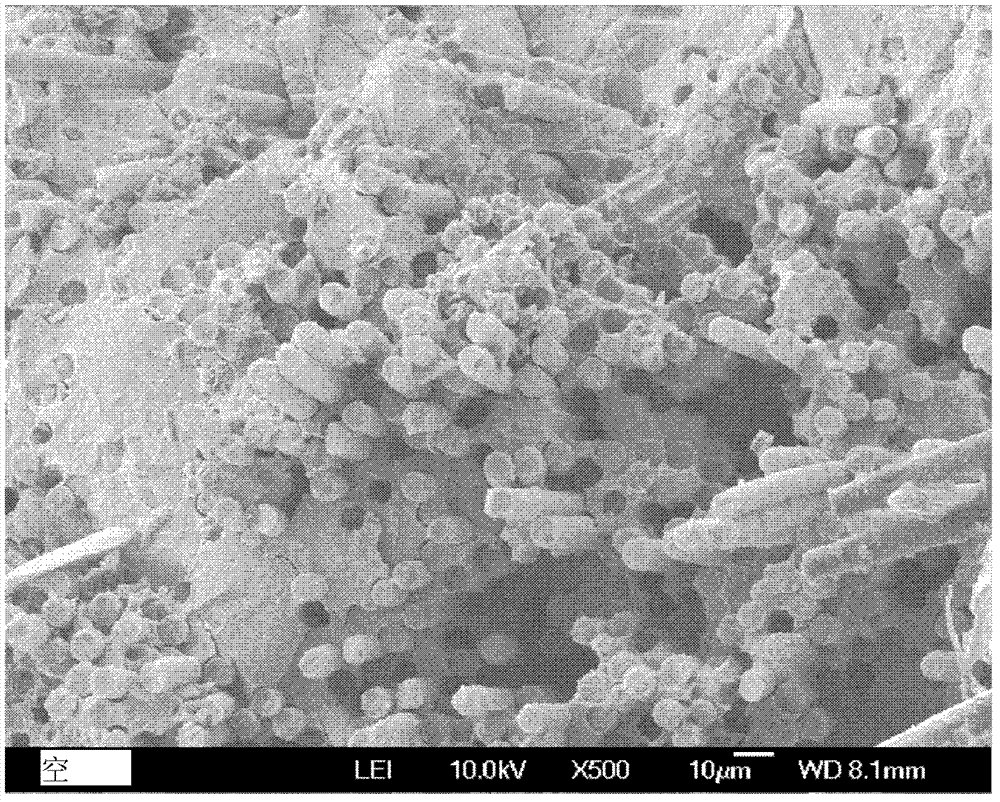

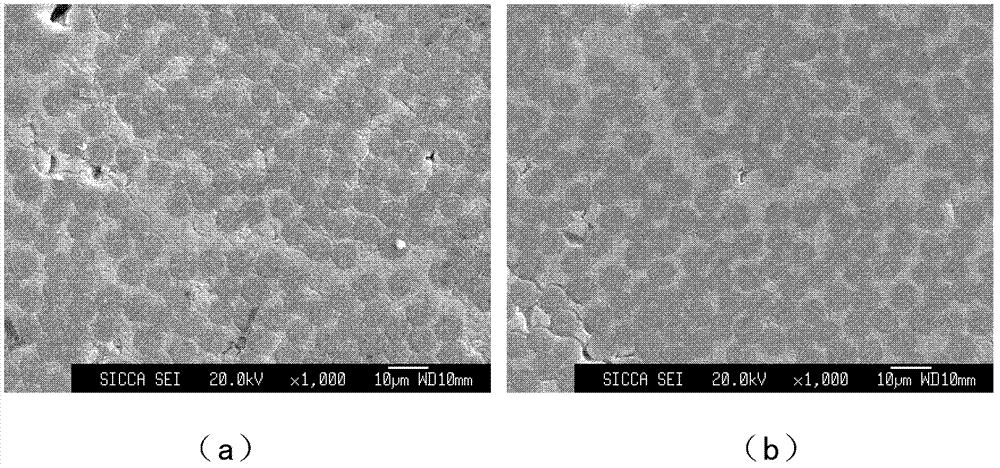

ActiveCN103086731AImprove mechanical propertiesEquivalent mechanical propertiesMaterial nanotechnologyMetallurgyInterface layer

The invention relates to a micro-region in-situ reaction preparation method for a high strength fiber-reinforced ceramic matrix composite material. The method comprises the following steps: (1) depositing an interface layer on the surface of a composite material fiber preform so as to protect fiber reinforcement body, wherein the interface layer comprises a PyC interface, a BN interface, a SiC interface, and a composite interface of the PyC interface, the BN interface and the SiC interface, and a thickness of the interface layer is 10-2000 nm; (2) introducing a Si3N4 ceramic phase to pores of the composite material fiber preform to obtain a composite material pre-molding body; and (3) carrying out a densification treatment on the composite material pre-molding body to obtain the high strength fiber-reinforced ceramic matrix composite material, wherein the densification treatment comprises a high temperature treatment with a temperature of 1200-2300 DEG C, such that the Si3N4 and a carbon-containing phase in the composite material are subjected to a micro-region in-situ reaction through mutual diffusion so as to form the SiC phase.

Owner:嘉兴睿创新材料有限公司

Corrosion-resistant twisted steel and production method thereof

The invention discloses corrosion-resistant twisted steel and a production method thereof. The twisted steel comprises the following components (weight percentage): basic components, a selective component and remain iron and impurities, wherein the basic components comprise carbon (C) 0.18-0.25%, silicon 0.40-0.80%, manganese (Mn) 0.30-1.00%, phosphorus (P) 0.02-0.04%, sulfur (S)<=0.01%, chromium(Cr) 0.45-1.00% and copper (Cu) 0.05-0.20%, and the selective component is the combination of any one or more than two components of vanadium (V) 0.01-0.05%, niobium (Nb) 0.01-0.04%, nickel (Ni) 0.01-0.20%, titanium (Ti) 0.01-0.05% and boron (B) 5-30ppm. The production process comprises electric furnace or converter smelting, refining out of the furnace, square blank continuous casting, hot rolling, cold bed air cooling, multiple length shearing and an end-flattening procedure which are performed sequentially, the corrosion service life of the corrosion-resistant twisted steel is more than 1.5 times that of a conventional steel product, and production cost, mechanical property, welding performance, processing performance and the like are identical with the conventional product.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

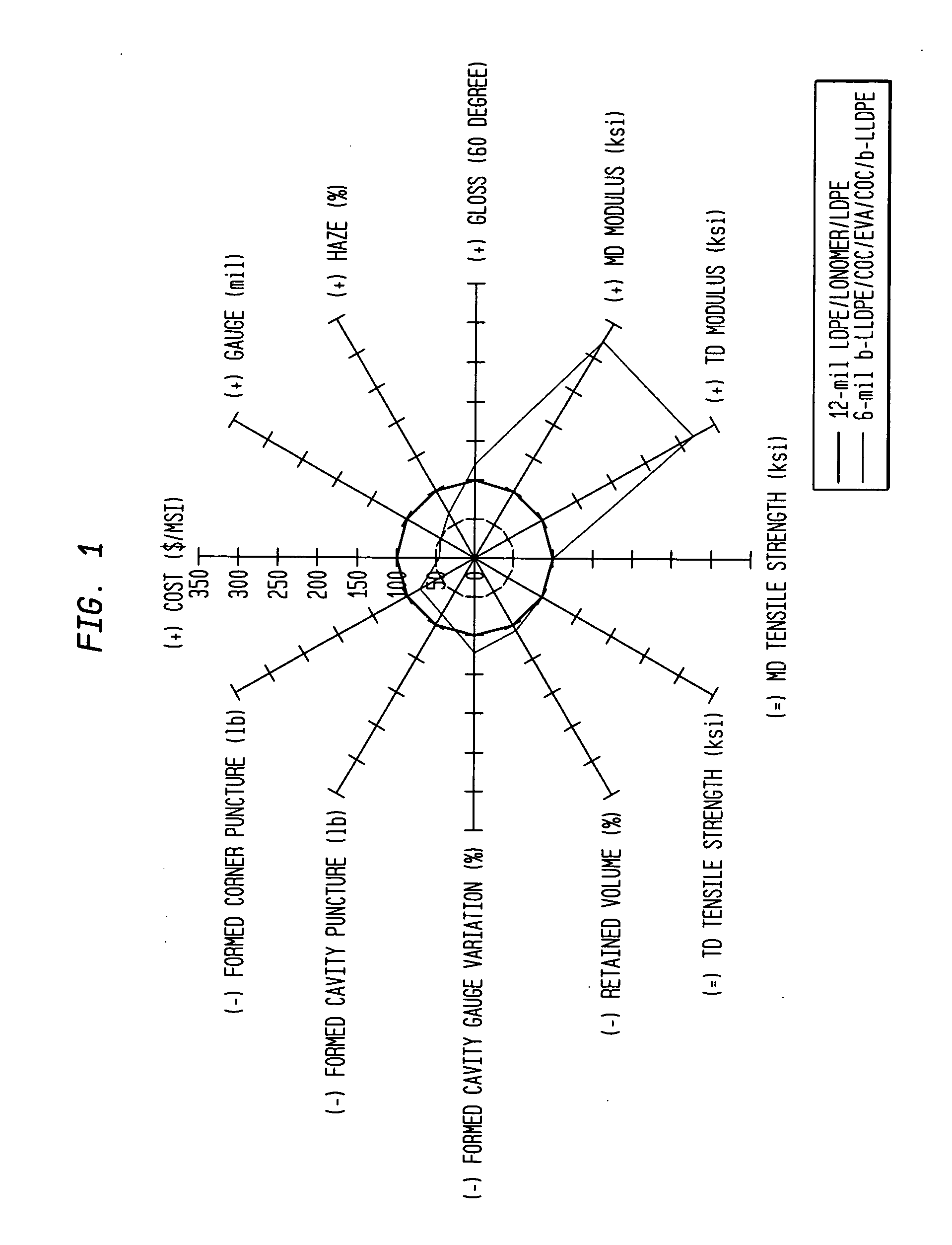

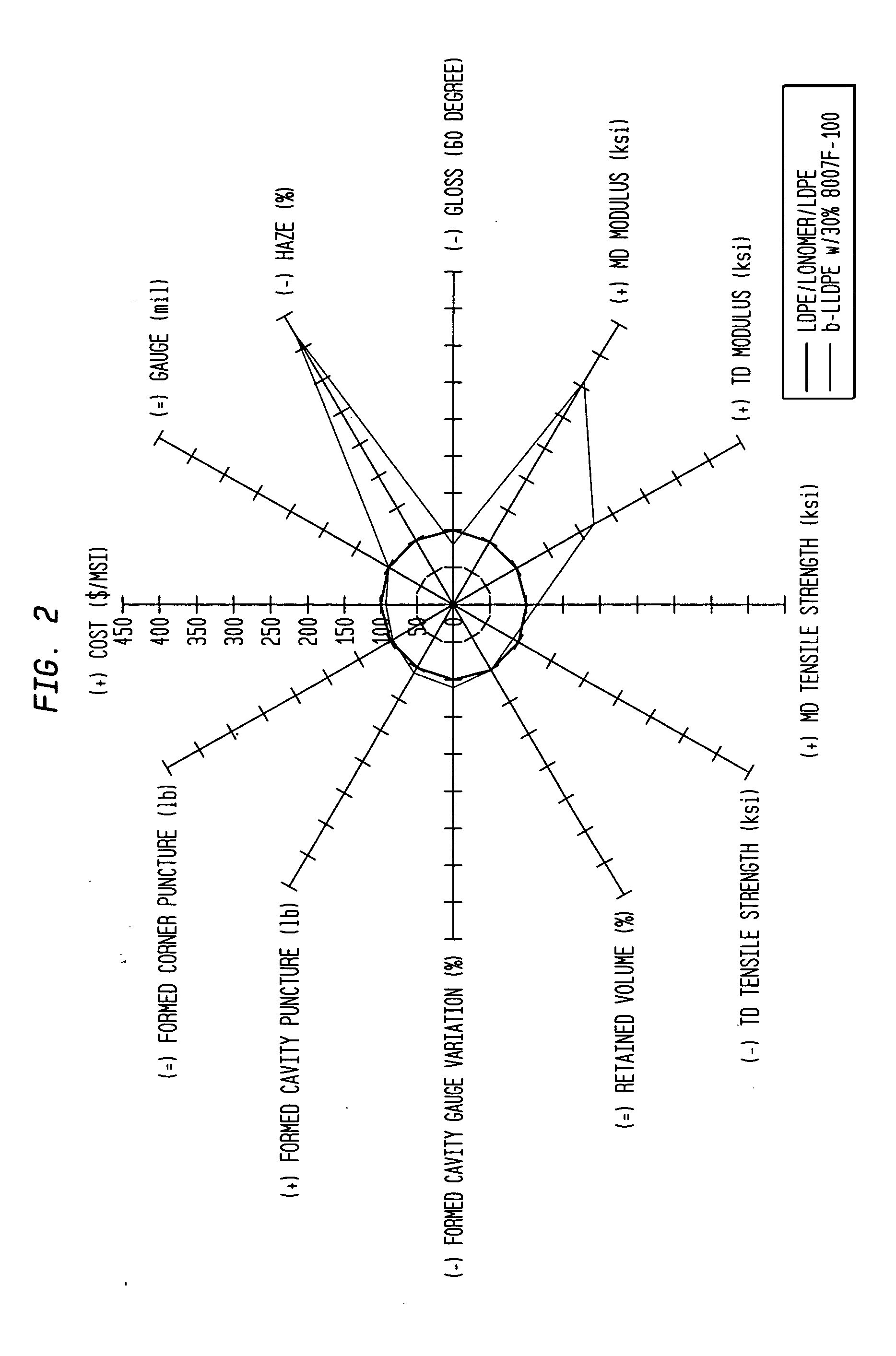

Thermoformed articles from sheet incorporating cycloolefin copolymer

ActiveUS20080311370A1High stiffness and tensile strengthLow variationSynthetic resin layered productsThin material handlingDuctilityCyclic Olefins

Thermoformed articles include cycloolefin / ethylene copolymer and LLDPE. The articles are formed with an areal draw ratio of 1.5 and greater and exhibit unexpectedly elevated stiffness along with ductility suitable for forming deep-draw parts. Multilayer sheet is used for achieving a desired set of properties.

Owner:TOPAS ADVANCED POLYMERS

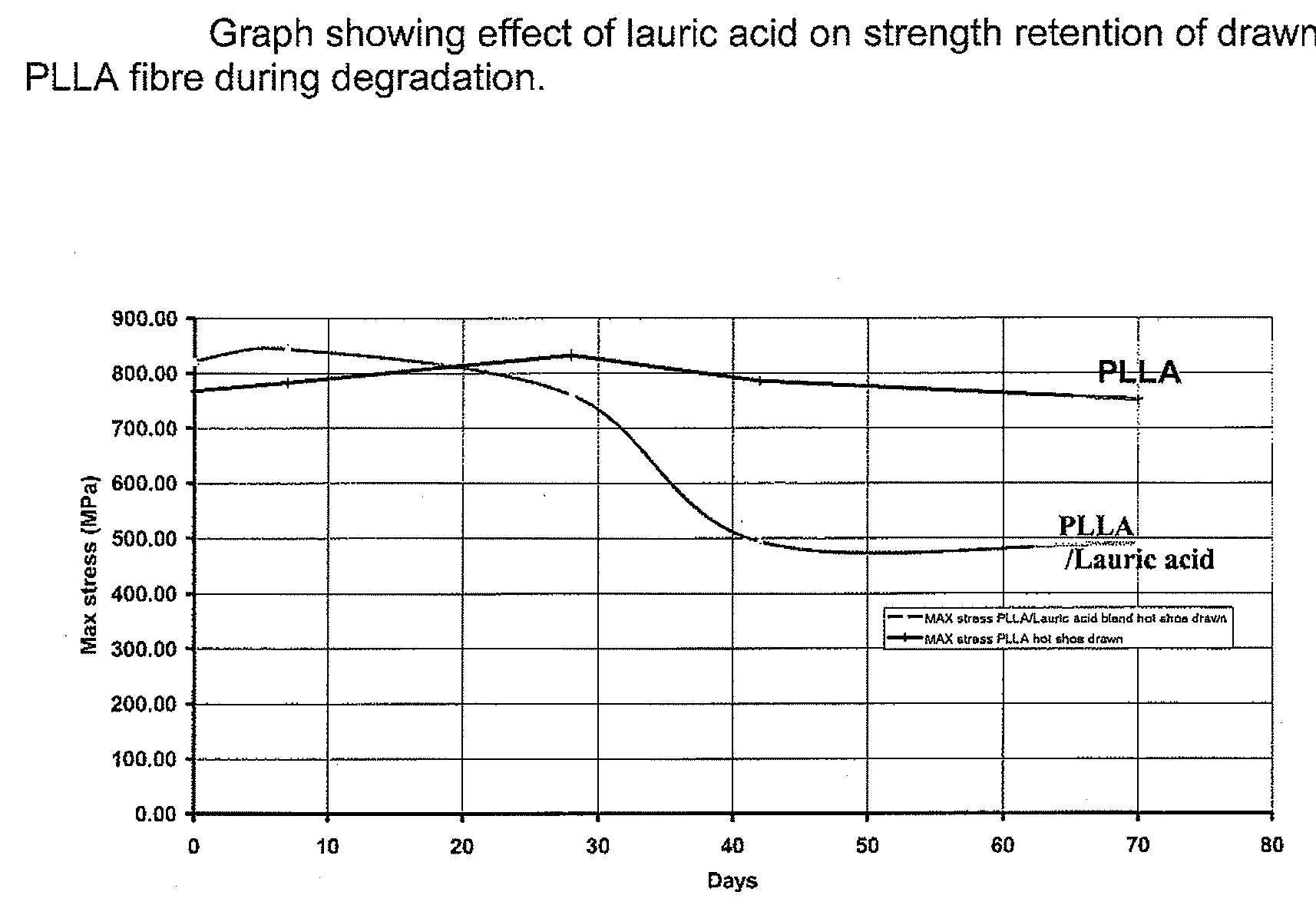

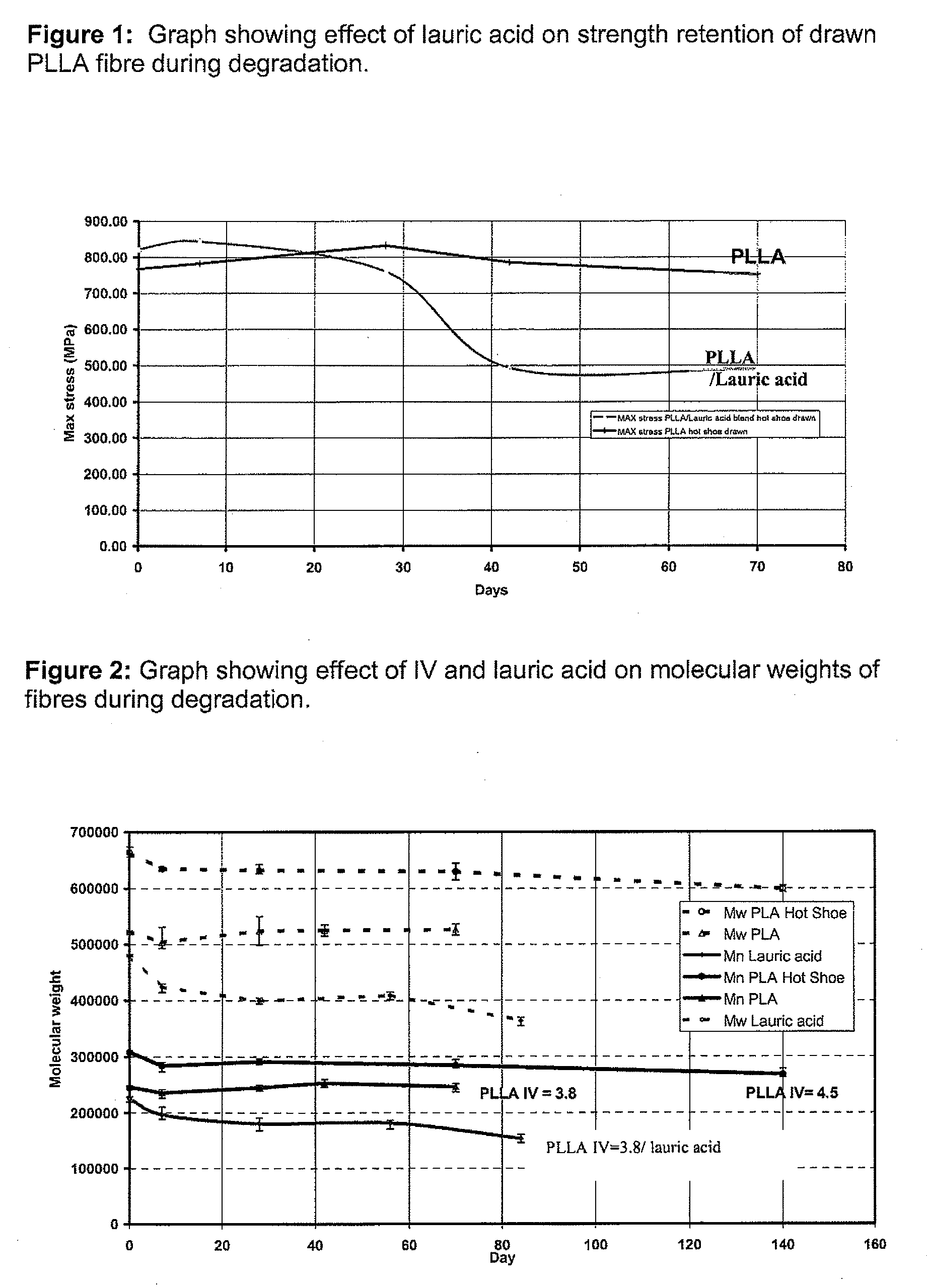

High Strength Devices and Composites

InactiveUS20080305144A1Promote degradationIncrease drawSuture equipmentsSurgical adhesivesHuman bodyPolymer science

An oriented implantable, biodegradable device is disclosed. The oriented implantable, biodegradable device is formed from a homogeneous polymer blend comprising a polylactic acid in admixture, in an amount of not more than 10% by weight of the polymer blend, with an additive which both plasticises polymer draw and is a degradation accelerant. The polymer comprised within the blend may be a uniaxial, biaxial or triaxial orientation. Also disclosed is a composite thereof, processes for the preparation thereof, and The implantable biodegradable device may be used as a high strength trauma fixation device suitable for implantation into the human or animal body. As examples, the high strength trauma fixation device may take the form of plates, screws, pins, rods, anchors or scaffolds.

Owner:SMITH & NEPHEW INC

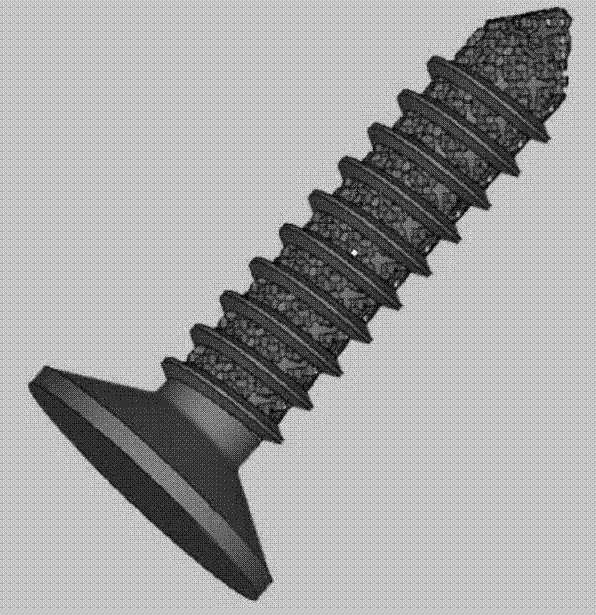

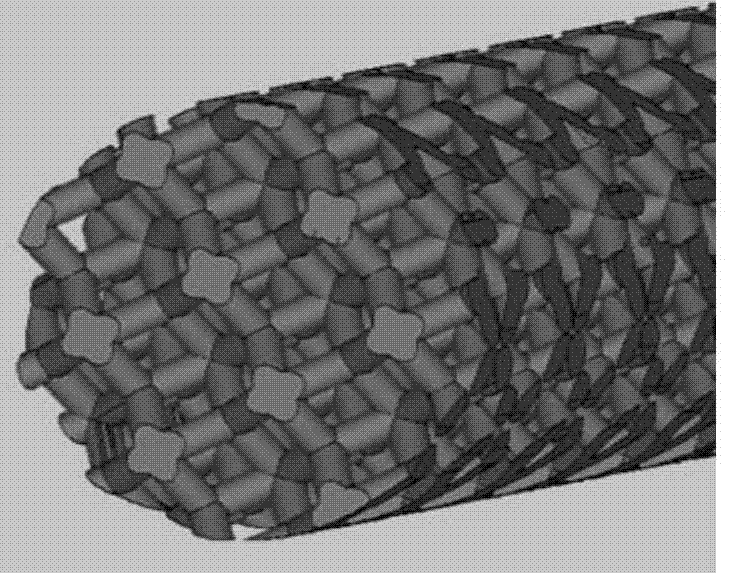

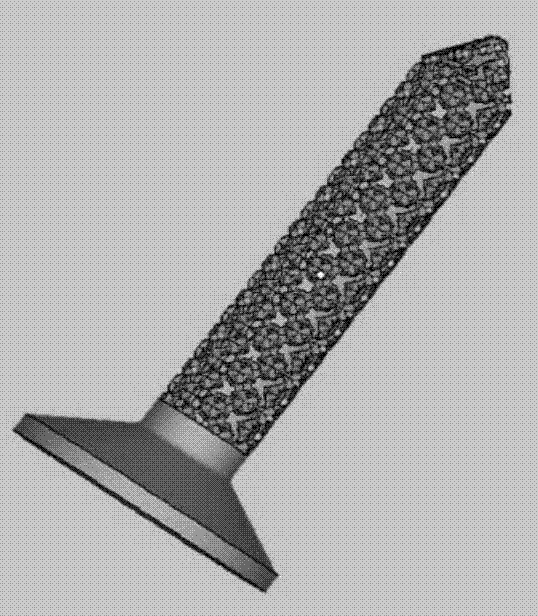

Bone screw of three-dimensional through porous structure

InactiveCN104758042AGood biocompatibilityEquivalent mechanical propertiesPharmaceutical delivery mechanismCoatingsBone tissueBone screws

The invention discloses a bone screw of a three-dimensional through porous structure. The porous bone screw comprises a screw head, a screw body and a screw cap. The screw body comprises a porous network composed of the three-dimensional through porous structure. The porous bone screw is made of medical materials which can be implanted into a human body, the three-dimensional through porous structure of the porous bone screw provides more space for the growth of bone cells, the combination between the implanted screw and the bone tissues of the human body is promoted, and the anchoring can be firm.

Owner:吴志宏

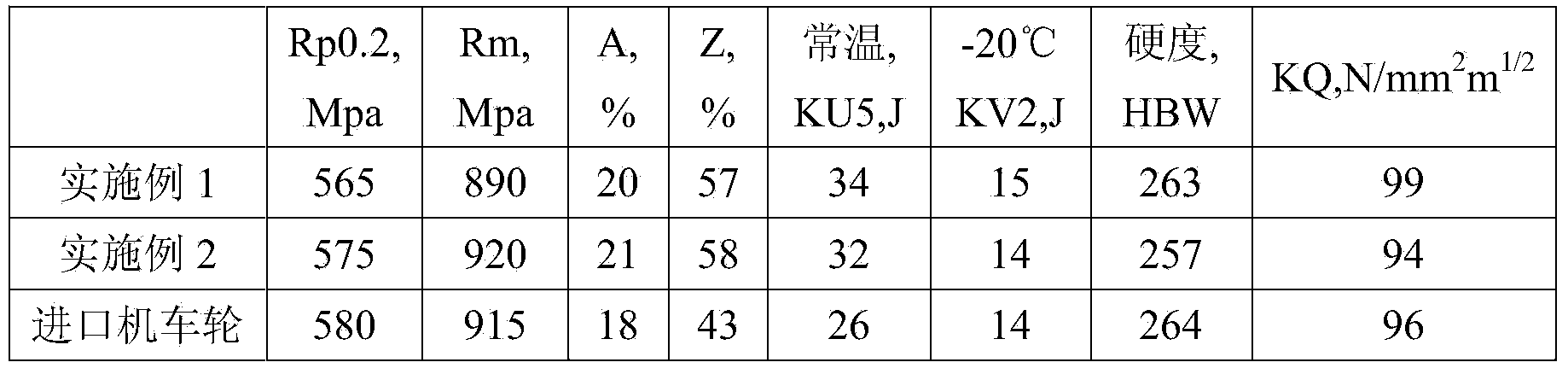

Wheel steel applicable to railway wagon and wheel preparation method

ActiveCN103643123AActual operation is goodEquivalent mechanical propertiesFurnace typesHeat treatment furnacesTruckHeat treated

The invention discloses wheel steel for a railway wagon. The wheel steel comprises the following chemical components in percentage by weight: 0.46-0.55% of C, 0.20-0.37% of Si, 0.70-0.85% of Mn, 0.24-0.32% of Cr, 0.020-0.040% of Als, less than or equal to 0.008% of P, less than or equal to 0.008% of S and the balance of Fe and inevitable impurity elements. The invention also discloses a method for preparing wheels by using high-carbon and low-alloy wheel steel for a railway wagon; and the method comprises a heat treatment process; and the heat treatment process comprises the following steps: holding the temperature at 860-880 DEG C for 3-3.5 hours, discharging the wheel steel out of a furnace and cooling the wheel steel with air to room temperature, then holding the temperature at 840-860 DEG C for 4 hours, spraying water to cool a wheel hub for 400 seconds, then holding the temperature at 480-500 DEG C for 5 hours, discharging the wheel out of the furnace and cooling the wheel with air.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

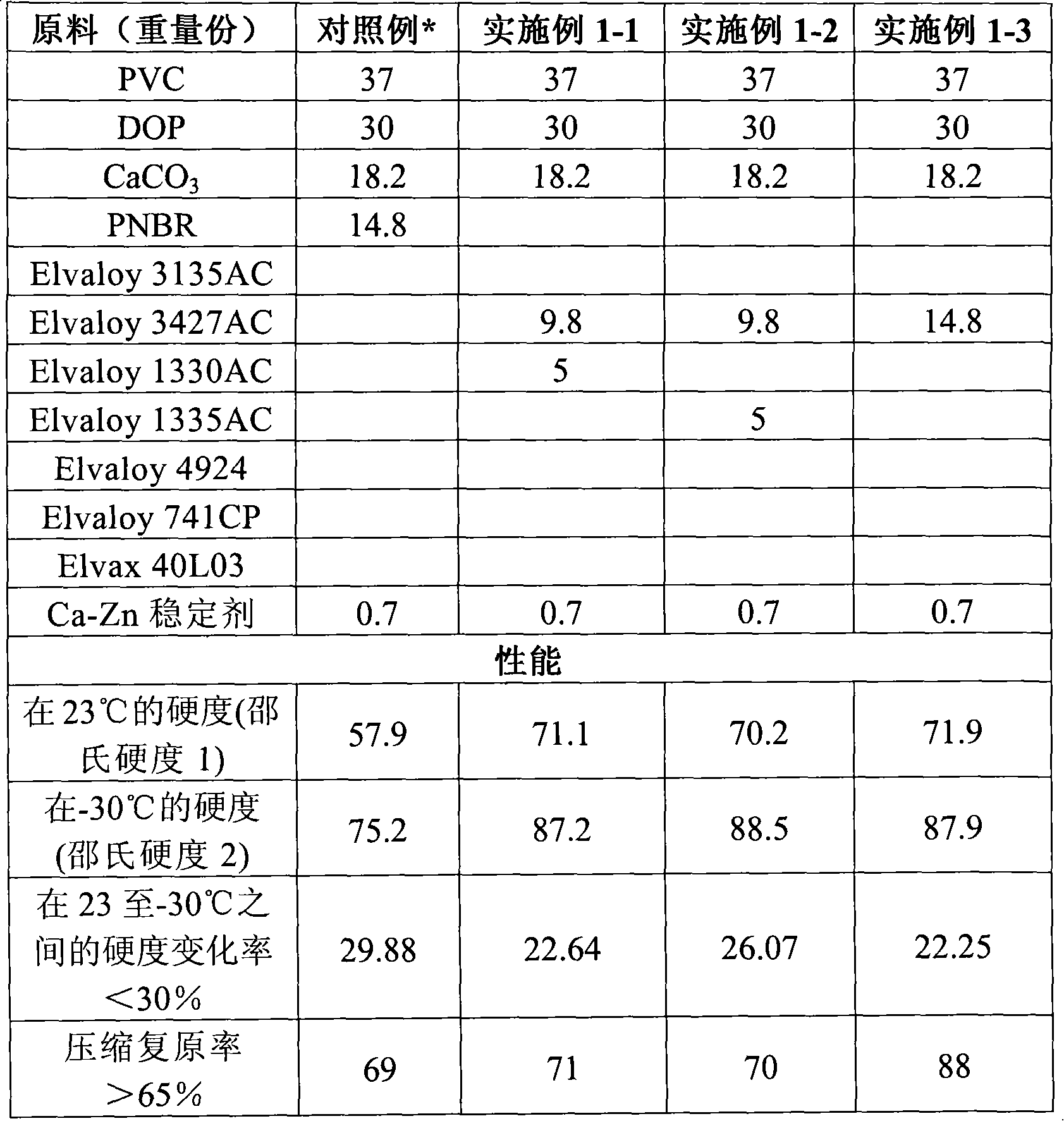

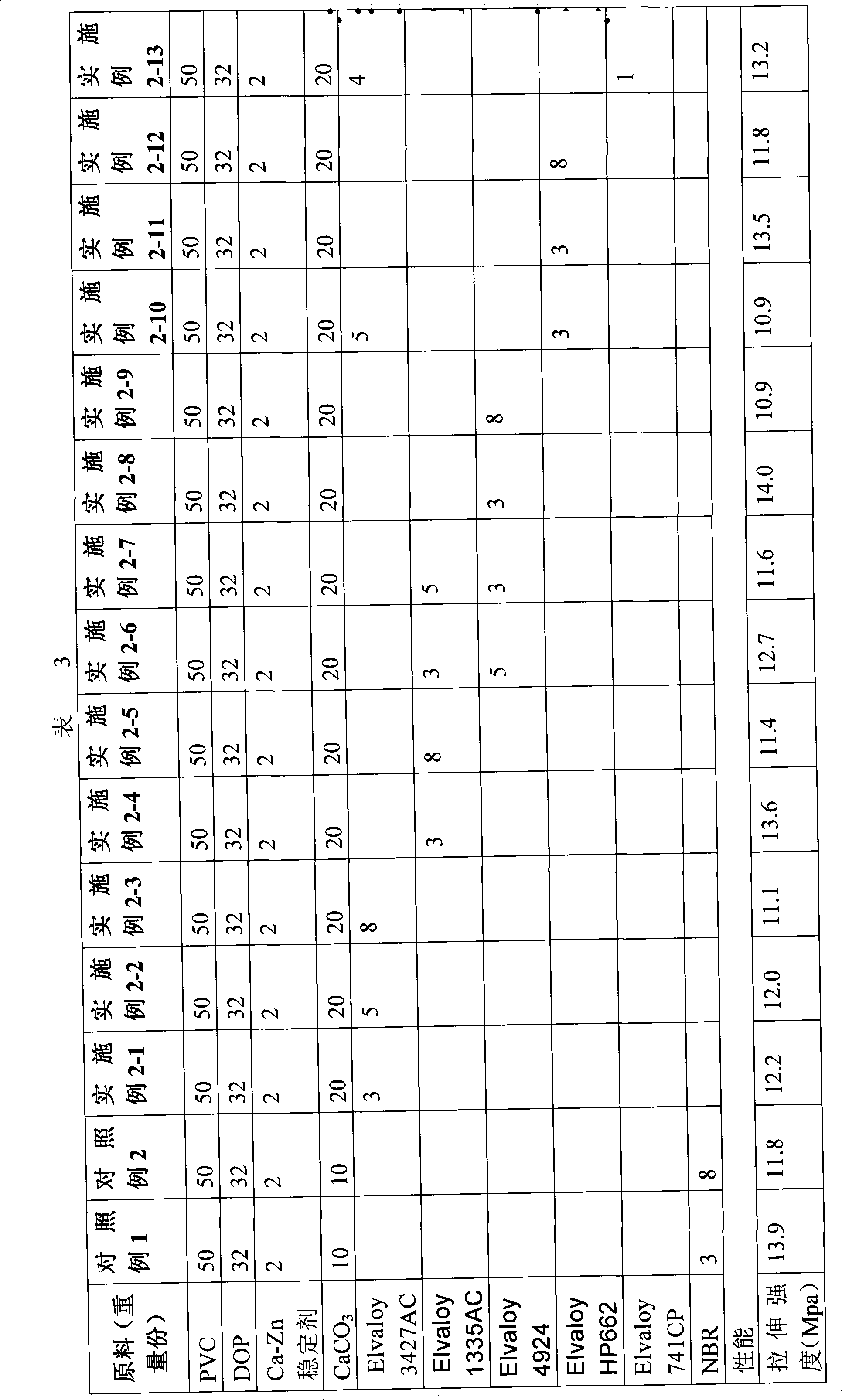

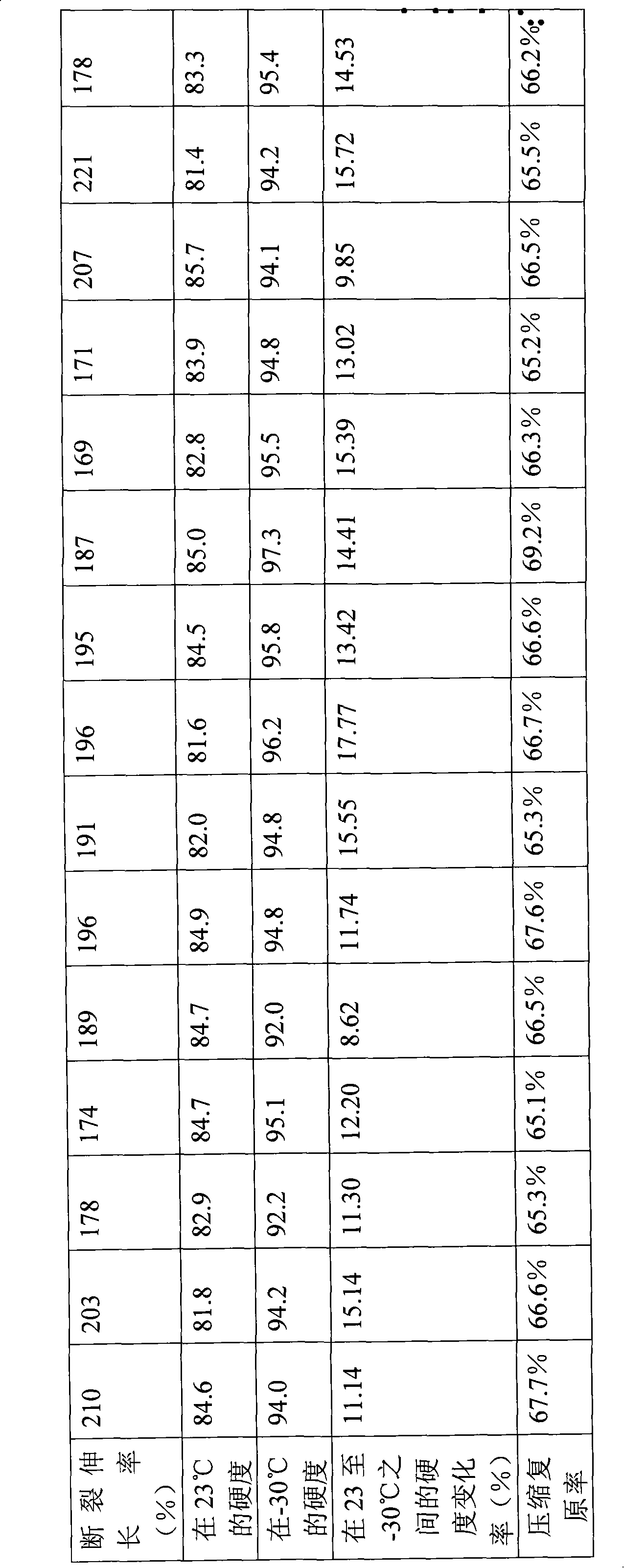

Composition with improved low-temperature flexibility and elasticity

InactiveCN101613508AEasy to manufactureHigh hardnessDomestic cooling apparatusLighting and heating apparatusVinyl acetateEngineering

The invention provides a composition with improved low-temperature flexibility and elasticity, comprising the components in parts by weight: 30-50 parts of polyvinyl chloride, 20-35 parts of plasticizing agent and 1-15 parts of modifying agent, wherein the modifying agent is selected from an ethane / acrylic ester multipolymer or trimer and an ethane / vinyl acetate multipolymer or trimer. The invention also relates to an application of the composition for manufacturing a door-seal plastic sleeve of refrigerated products and refrigerated products containing the composition.

Owner:EI DU PONT DE NEMOURS & CO

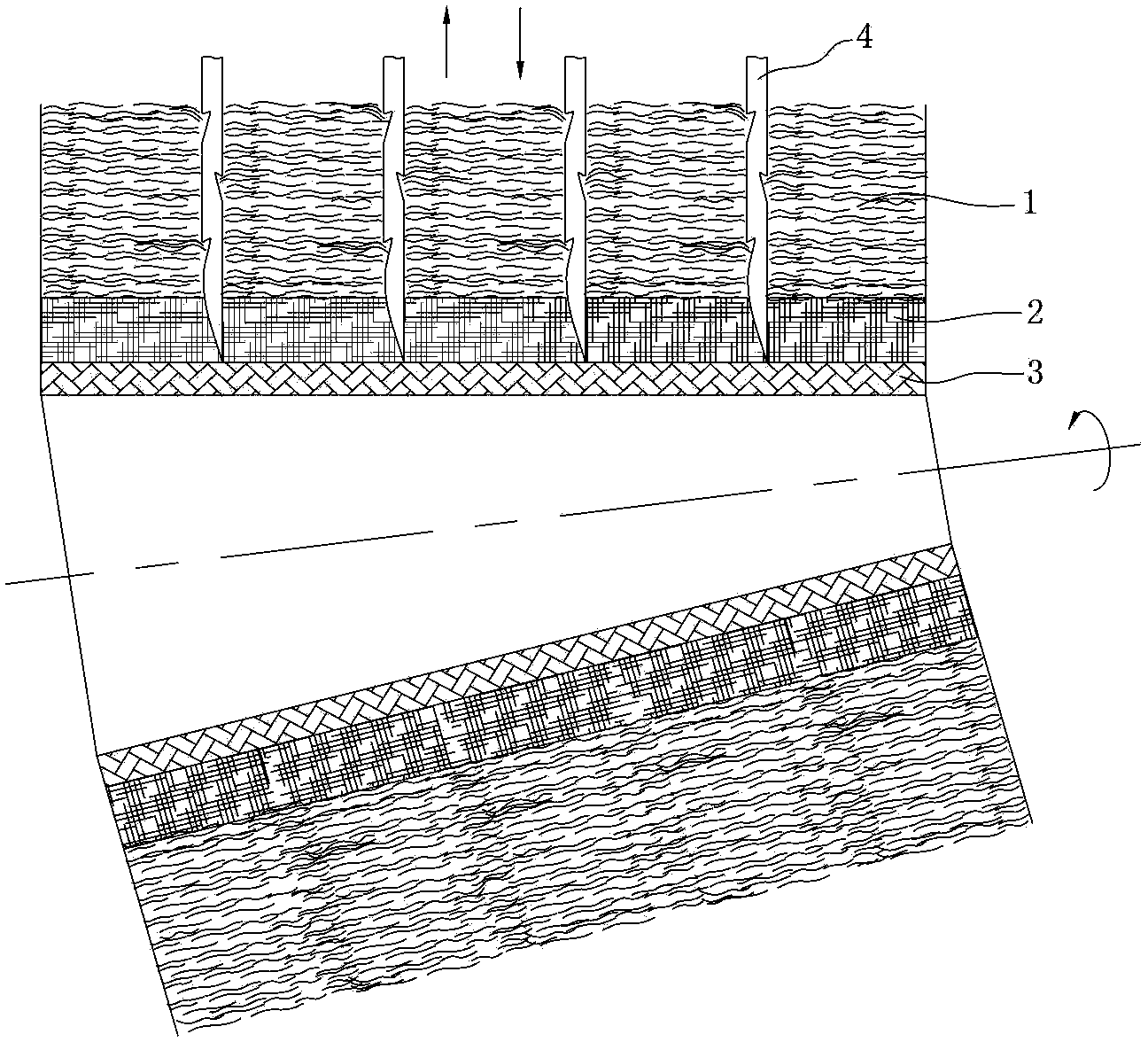

Coated sand for sand prevention in oil well and preparation method of coated sand

ActiveCN105542739AGood film formingImprove liquidityDrilling compositionLow temperature curingMethyl cellulose

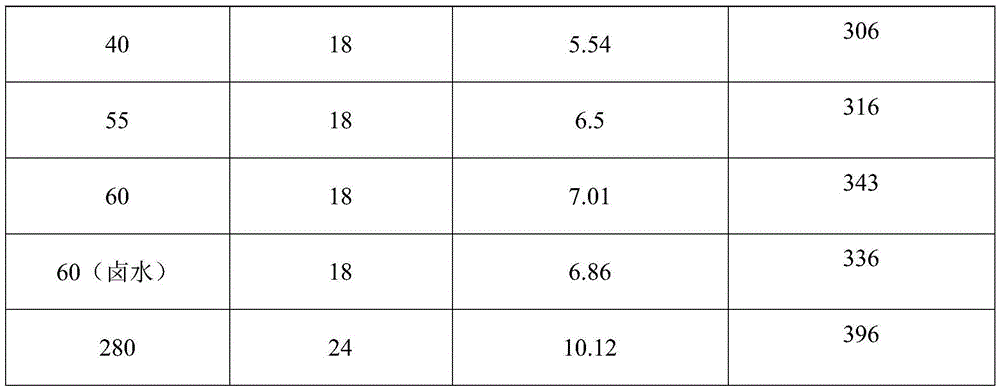

The invention discloses coated sand for sand prevention in an oil well and a preparation method of coated sand. The coated sand comprises A-type coated sand and B-type coated sand and is characterized in that the A-type coated sand is obtained by wrapping quartz sand with organosilicon-modified epoxy resin, a ketimine curing agent and external isolating agent hydroxy methyl cellulose in sequence; B-type coated sand is obtained by wrapping the surface of the quartz sand with cycloaliphatic epoxide resin, an amine curing agent and external isolating agent hydroxy methyl cellulose in sequence. The coated sand disclosed by the invention comprises the A-type coated sand and B-type coated sand, and a co-synergistic effect is generated after the A-type coated sand and the B-type coated sand are mixed, so that the requirements for low-temperature curing and high-temperature mining are met simultaneously. The coated sand disclosed by the invention meets the actual application requirements, gives consideration to low-temperature curing (a minimum temperature of 40 DEG C) to form higher strength, simultaneously is good in permeability, can stably work in a high temperature-resistant environment (about 280 DEG C), is wide in research and development scope of application, can be suitable for not only heavy oil wells, but also middle and low-temperature oil wells and water wells and is lower in comprehensive cost.

Owner:济南蓝昆新材料科技有限公司

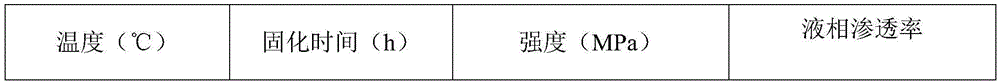

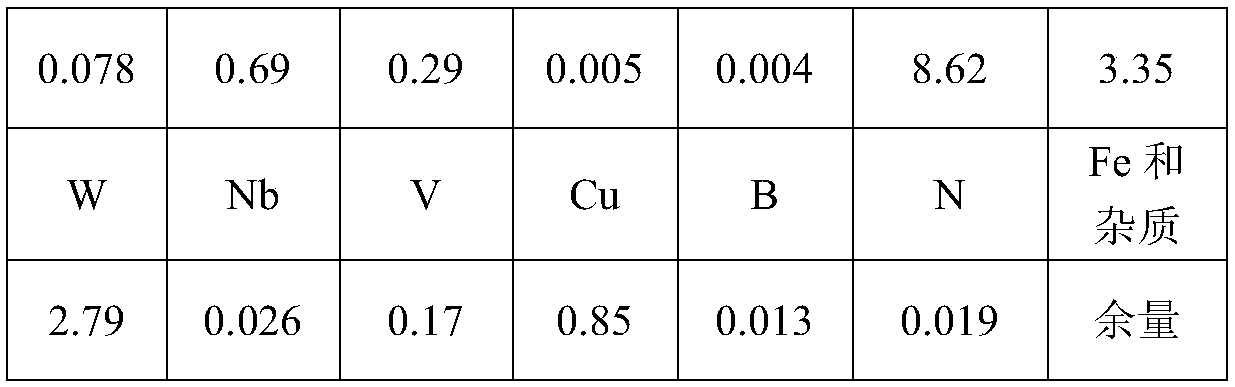

Coating transition type heat resistance steel welding rod for 650 DEG C ultra-supercritical thermal power generating unit

InactiveCN108188614AGood workmanshipStable arc burningWelding/cutting media/materialsSoldering mediaSlagHeat resistance

The invention provides a coating transition type heat resistance steel welding rod for a 650 DEG C ultra-supercritical thermal power generating unit. A CaO-CaF2-SiO2 slag system formula is adopted, atrace of alloy elements are added, the main components of deposited metal are 9%Cr-3%W-3%Co, and the welding technology performance is good. Under the heat treatment condition of 100 DEG C x 1h+780 DEG C x 3h, the tensile strength Rm of the deposited metal is larger than or equal to 680 MPa, and the normal temperature KV2 is larger than or equal to 50 J; and the tensile strength Rm of a welding connector of the deposited metal is larger than or equal to 680 MPa, the normal temperature KV2 is larger than or equal to 50 J, and the low-alloy steel electric welding rod is suitable for the 650 DEGC steam temperature ultra-supercritical thermal power generating unit.

Owner:KUSN GINTUNE WELDING

Optimal controlled rolling method adopting ultra-fast cooling to control Austenite structure

At present, an ultra-fast cooling technology is mainly applied to cooling of steel after two-stage controlled rolling. The invention discloses an optimal controlled rolling method adopting ultra-fast cooling to control an Austenite structure and belongs to the technical field of metallurgy. According to the method, the steel can be completely rolled in a steel billet Austenite recrystallization zone, rolling temperature and pass reduction rate can be simultaneously precisely controlled, an ultra-fast cooling system is immediately adopted to cool the rolled steel to a phase transition point after rolling, and then different cooling paths are adopted according to needs to control the phase transition of the steel. According to the method disclosed by the invention, the ultra-fast cooling is adopted, so that coarsening of the small re-crystallized Austenite structure can be effectively inhibited, and the refining effects of dynamic recrystallization and sub-dynamic recrystallization against the Austenite structure in a high-temperature rolling process can be retained. The product manufactured by the method disclosed by the invention and the steel manufactured by the two-stage controlled rolling process have equivalent mechanical properties, so that the rolling time is simultaneously reduced by 2-4min in comparison with the two-stage controlled rolling process at a waiting temperature and low-temperature atmosphere in the rolling process.

Owner:NORTHEASTERN UNIV

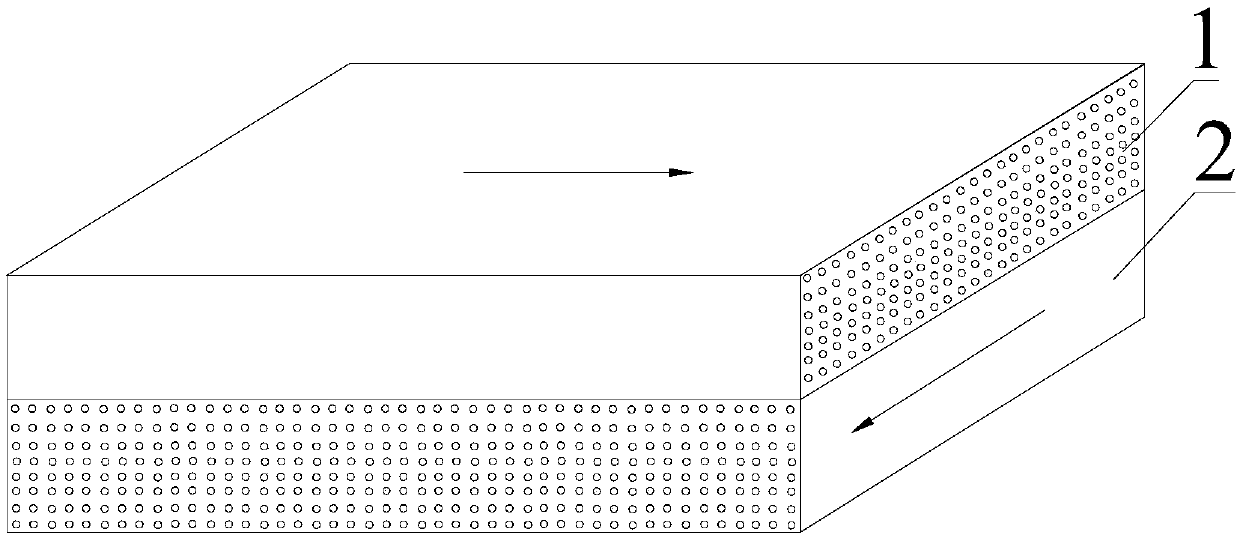

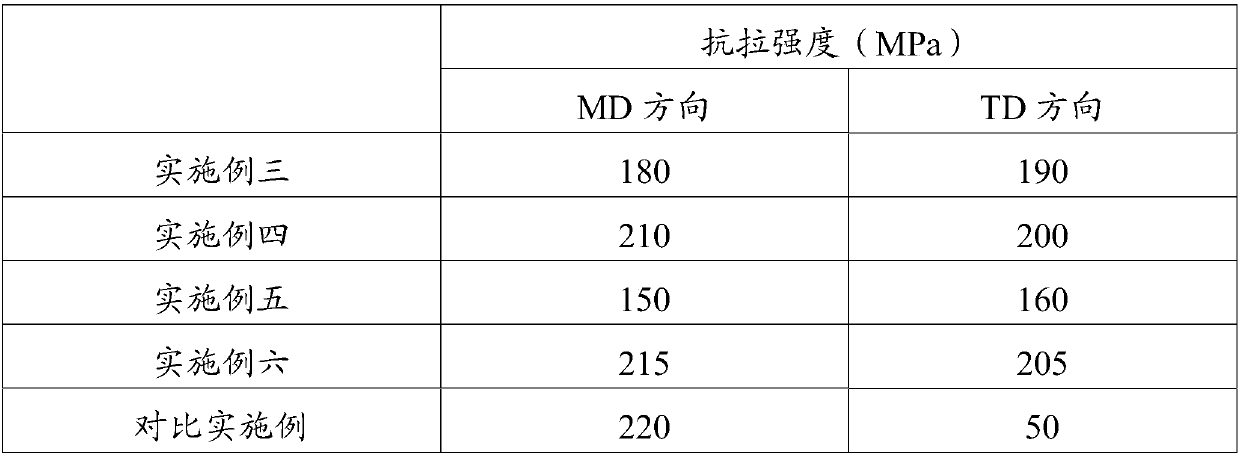

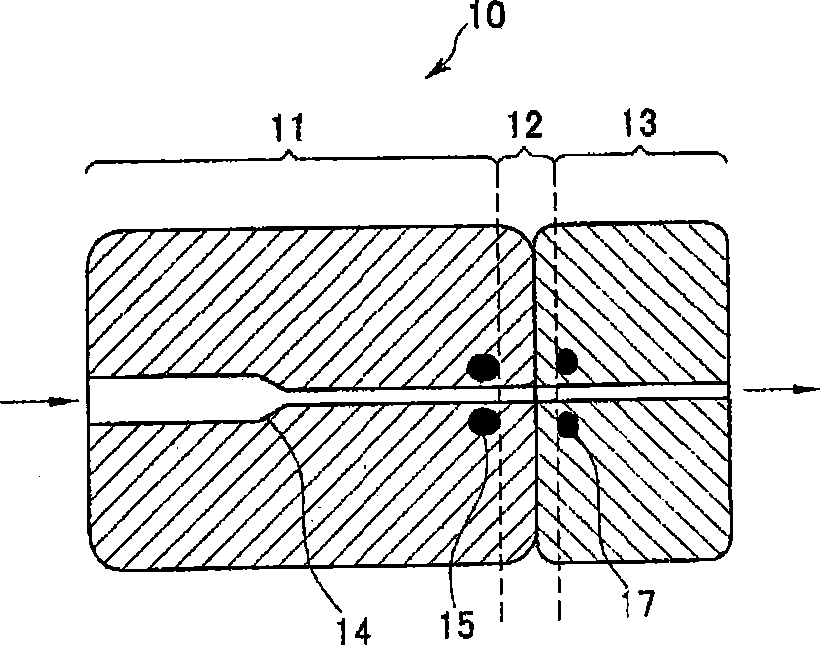

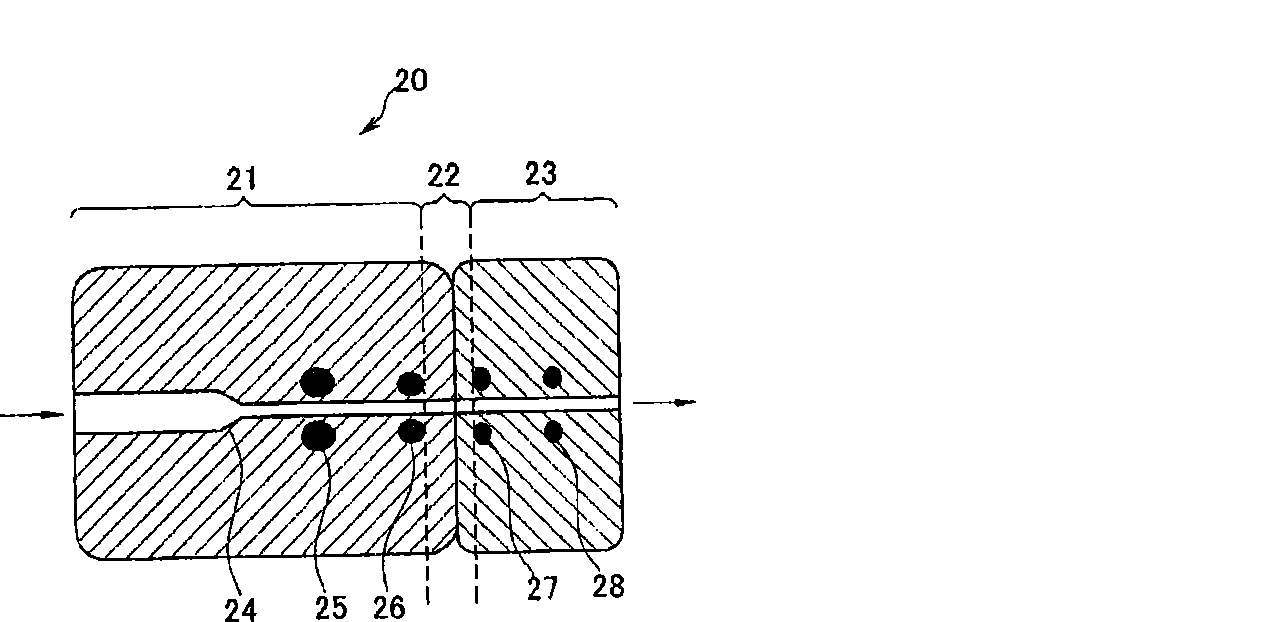

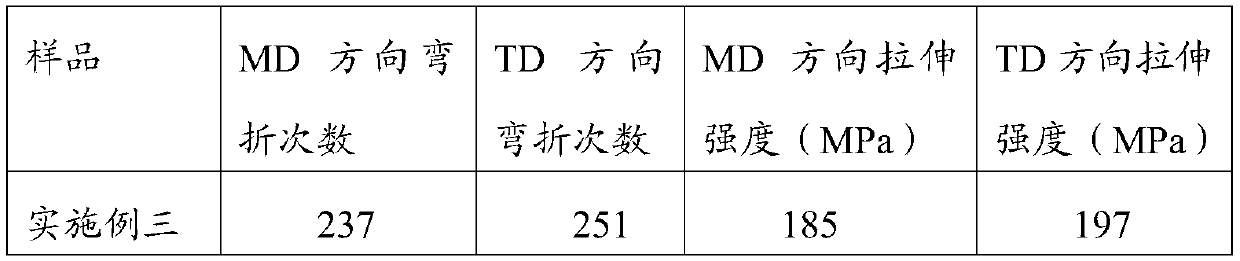

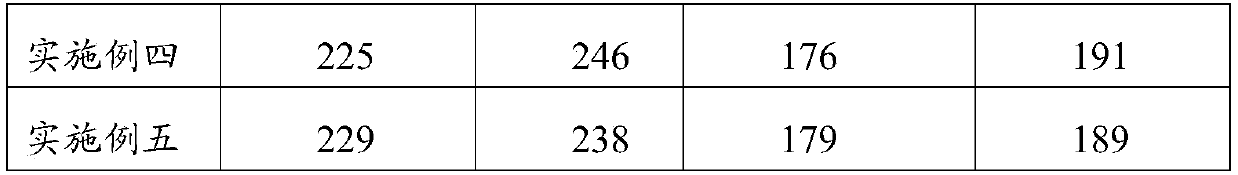

Liquid crystal polymer film and production method thereof

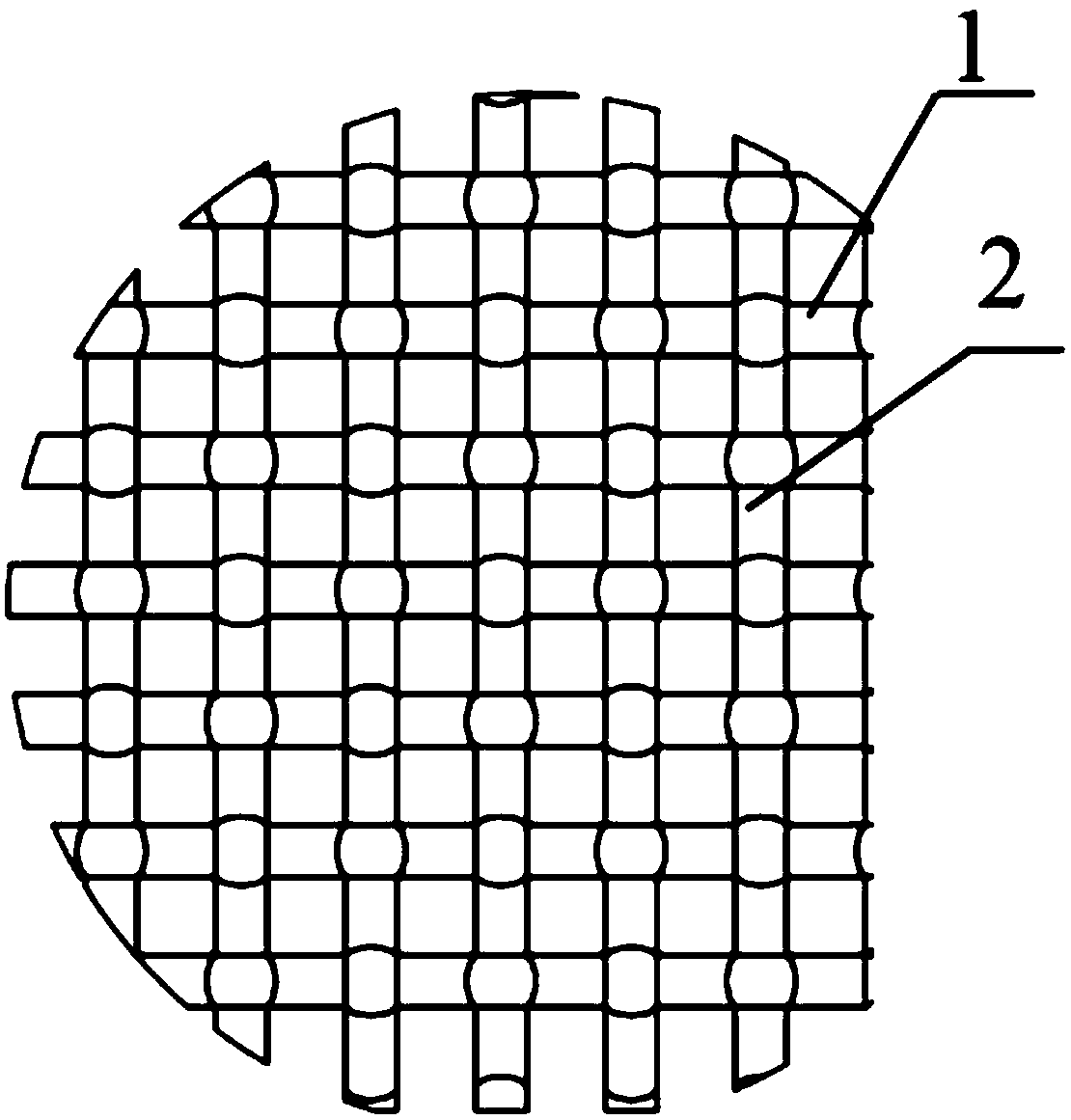

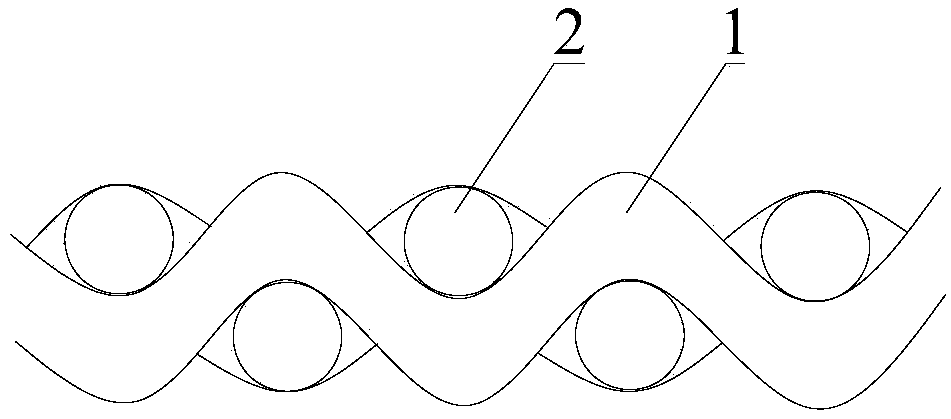

InactiveCN109651632AEquivalent mechanical propertiesThere will be no stratificationLiquid crystal compositionsPolymer scienceLiquid crystal

The invention discloses a liquid crystal polymer film and a production method thereof. The liquid crystal polymer film comprises at least two first orientation units and at least two second orientation units, the orientation directions of the first orientation units intersect with the orientation directions of the second orientations, the at least two first orientation units and the at least two second orientation units are arranged in a mesh woven structure, and the mesh woven structure is subjected to hot press molding to obtain the liquid crystal polymer film. The first orientation units and the second orientation units having different orientation directions are arranged in the mesh woven structure, the hot pressing molding is adopted to obtain the isotropic liquid crystal polymer filmwith same mechanical performances in an MD (machine direction) and in an TD (transverse direction), and the obtained film has no layering phenomenon in the thickness direction.

Owner:SHENZHEN SUNWAY COMM

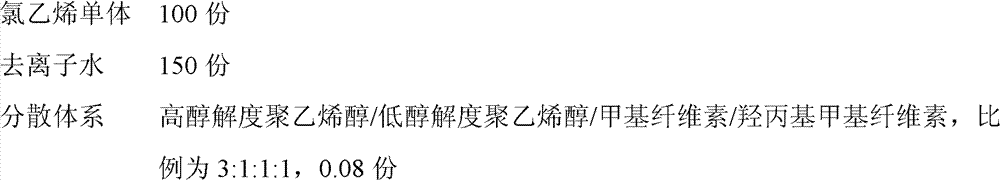

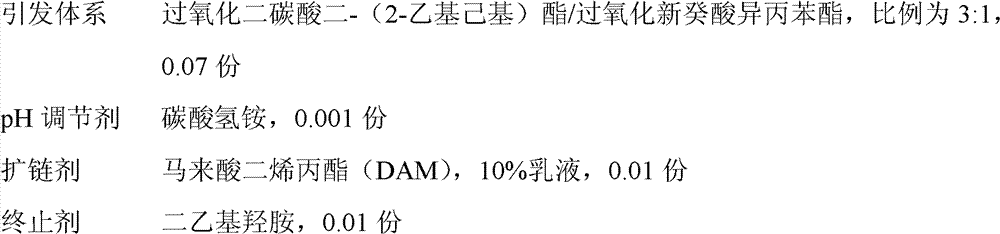

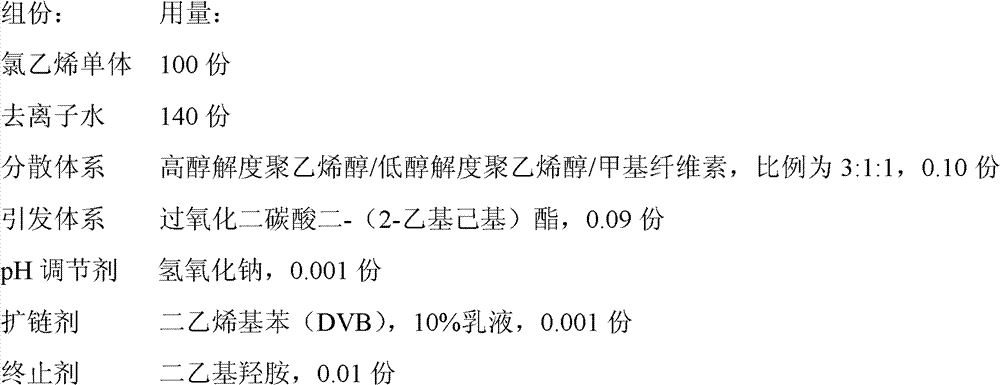

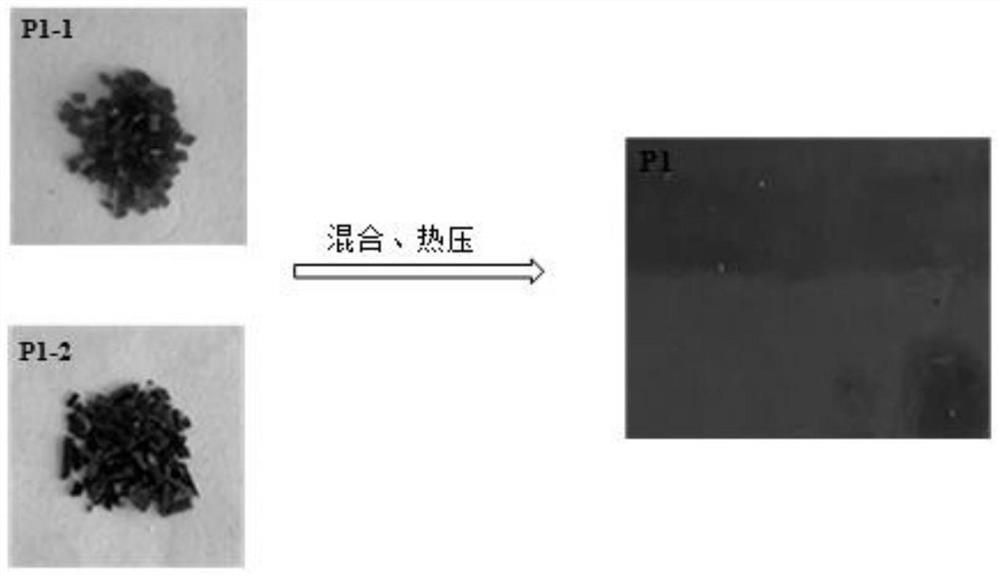

Polyvinyl chloride production method adding chain extender to match with later-stage heating process

The invention relates to a polyvinyl chloride production method adding a chain extender to match with a later-stage heating process. The production method is characterized in that during the polymerization reaction process, when the polymerization conversion rate achieves 50%-75%, the chain extender is added into a polymerization kettle by a high-pressure pump, the using quantity of the chain extender is 10-10000ppm of the total quantity of polyvinyl chloride, the material temperature in the polymerization kettle is simultaneously increased by 1-25 DEG C, and the temperature increasing speed is 0.2-3 DEG C / min. Polyvinyl chloride resin produced by adopting the production method disclosed by the invention has a larger molecular weight distribution width index than that of the resin with the same number-average molecular weight and further keeps the excellent processing performance of the resin produced by a pure polymerization later-stage heating process; and simultaneously, the impact strength and tensile strength of a simply supported girder gap of a product are higher than those of the resin produced by adopting the pure polymerization later-stage heating process and equivalent to those of the resin produced by a constant-temperature polymerization process, and good resin processing performance and great product mechanical performance are further realized.

Owner:CHINA PETROLEUM & CHEM CORP

Union melt welding process for steel Q420GJC for building structures

ActiveCN105499770AEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesPower flowEngineering

The invention discloses a union melt welding process for steel Q420GJC for building structures. Welding materials include a welding wire MCJ55GJ with a diameter being phi 4.0mm and a welding flux SJ101; a welding environment temperature is higher than or equal to -10 DEG C; a preheating temperature is 100-150 DEG C; multi-layer and multi-pass welding are adopted, and an interlayer temperature is not lower than the preheating temperature. Conditions of backing weld include that a welding current is 520-530A, a welding voltage is 28-30V, a welding speed is 34-35.5cm / min, and thermal input is 21.3-22.8KJ / cm. Conditions of filling weld include that a welding current is 530-540A, a welding voltage is 30-32V, a welding speed is 36-37cm / min, and thermal input is 22.5-23.8KJ / cm. Conditions of cosmetic weld include that a welding current is 535-545A, a welding voltage is 28-30V, a welding speed is 34-35cm / min, and thermal input is 22.4-23.8KJ / cm. By the union melt welding process, equality in mechanical property of welds and base materials can be realized so as to meet requirements on engineering welding quality, and a gap of union melt welding of the steel Q420GJC is filled.

Owner:鞍钢钢结构(营口)有限公司

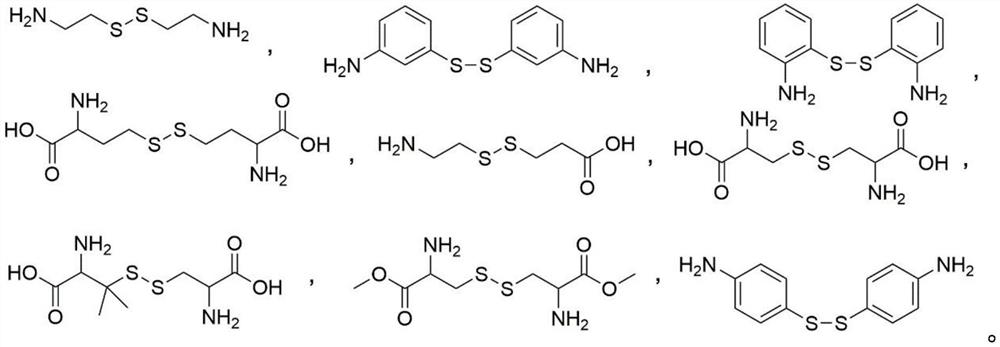

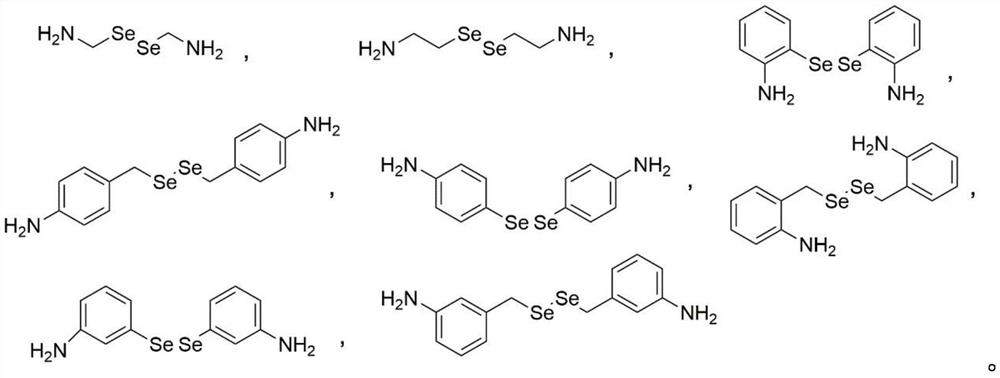

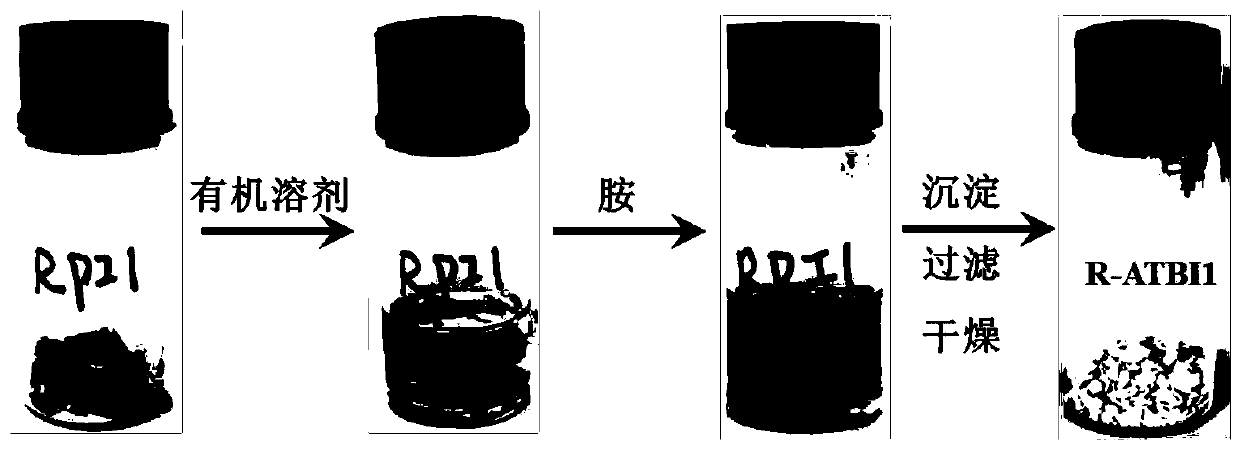

Epoxy thermosetting resin and preparation method thereof

PendingCN114350116AEquivalent mechanical propertiesAchieve hybridPlastic recyclingEpoxyPolymer science

The invention belongs to the technical field of polymer resin, and discloses epoxy thermosetting resin and a preparation method thereof. According to the preparation method, two different dynamic covalent bonds, namely S-S-and Se-Se-, are introduced into epoxy resin with different structures to prepare epoxy resin containing different structures and different cross-linking agents, and the-S-Se-cross-linked epoxy thermosetting resin composition is formed through high-temperature solid-phase fusion. The preparation method disclosed by the invention is simple, and the prepared epoxy thermosetting resin composition containing different structures has the same mechanical property as cross-linked epoxy resin with a single structure, so that not only is the mixing of the thermosetting epoxy resin with different structures realized, but also the composition has the functions of self-repairing, shape memory and the like.

Owner:江苏富琪森新材料有限公司

Gas shielded welding technology of steel Q420GJC for building structure

ActiveCN105598563AEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesEngineeringMechanical property

The invention provides a gas shielded welding technology of steel Q420GJC for a building structure. The technology comprises the steps that a welding material is prepared, wherein welding wires WH5-GJ with the diameter phi of 1.2 mm are prepared; the welding environment temperature is higher than or equal to minus 10 DEG C; the preheating temperature is 100 DEG C-150 DEG C; multi-layer and multi-pass welding is performed, and the interlayer temperature is no lower than the preheating temperature; weld joint priming is performed, wherein the welding current is 240-260 A, the welding voltage is 26-28 V, the welding speed is 30-32 cm / min, and heat input is performed at 9.4-10.2 KJ / cm; weld joint filling is performed, wherein the welding current is 280-300 A, the welding voltage is 28-30 V, the welding speed is 34-36 cm / min, and heat input is performed at 10.4-11.3 KJ / cm; weld joint capping is performed, wherein the welding current is 300-320 A, the welding voltage is 28-30 V, the welding speed is 36-38 cm / min, and heat input is performed at 10.5-11.4 KJ / cm. Q420GJC steel welding is performed by adopting the welding technology, the mechanical property same as that of base metal is obtained, the quality requirements of engineering welding are met, and a gap of gas shielded welding of the Q420GJC steel is filled.

Owner:鞍钢钢结构(营口)有限公司

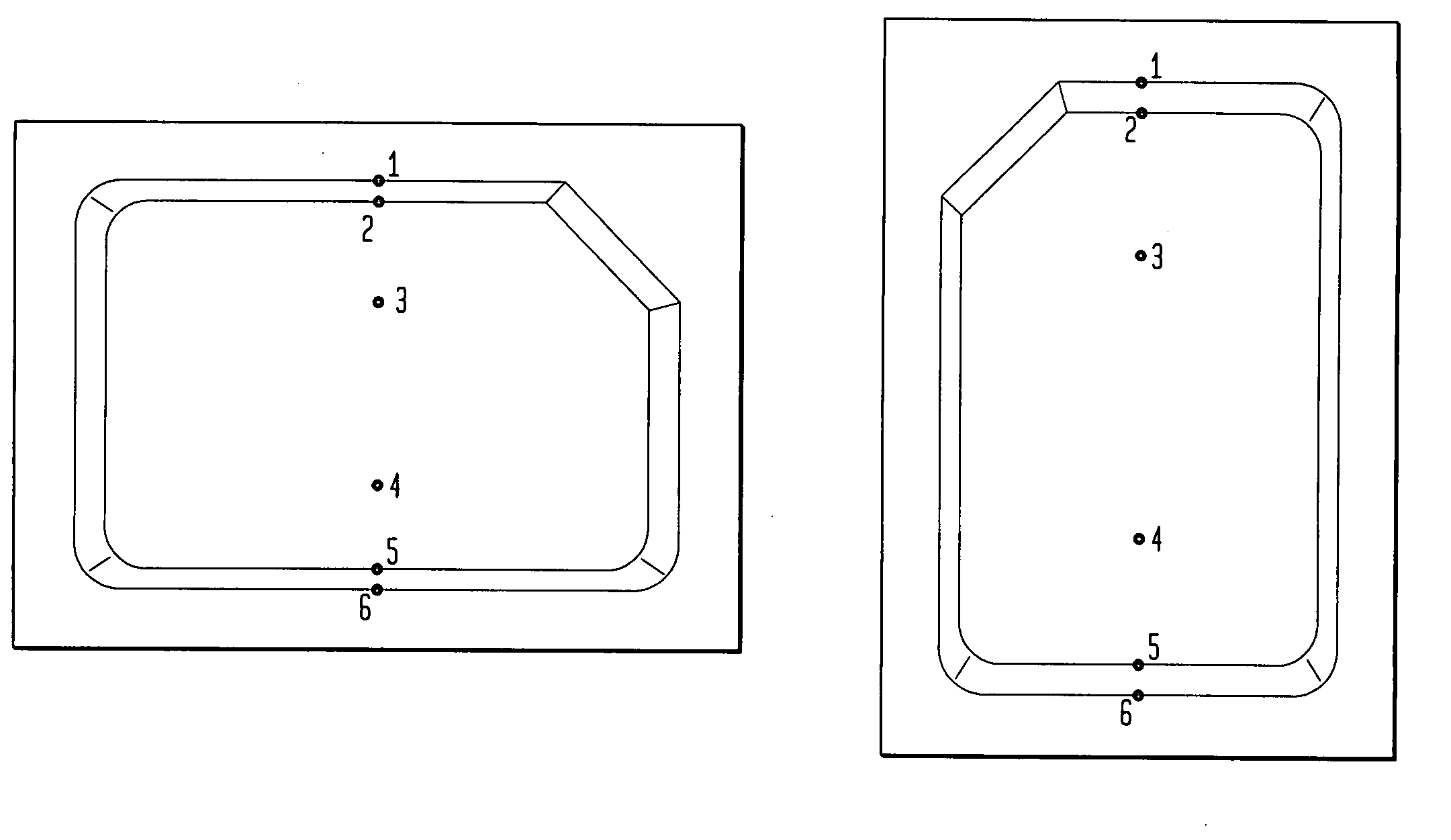

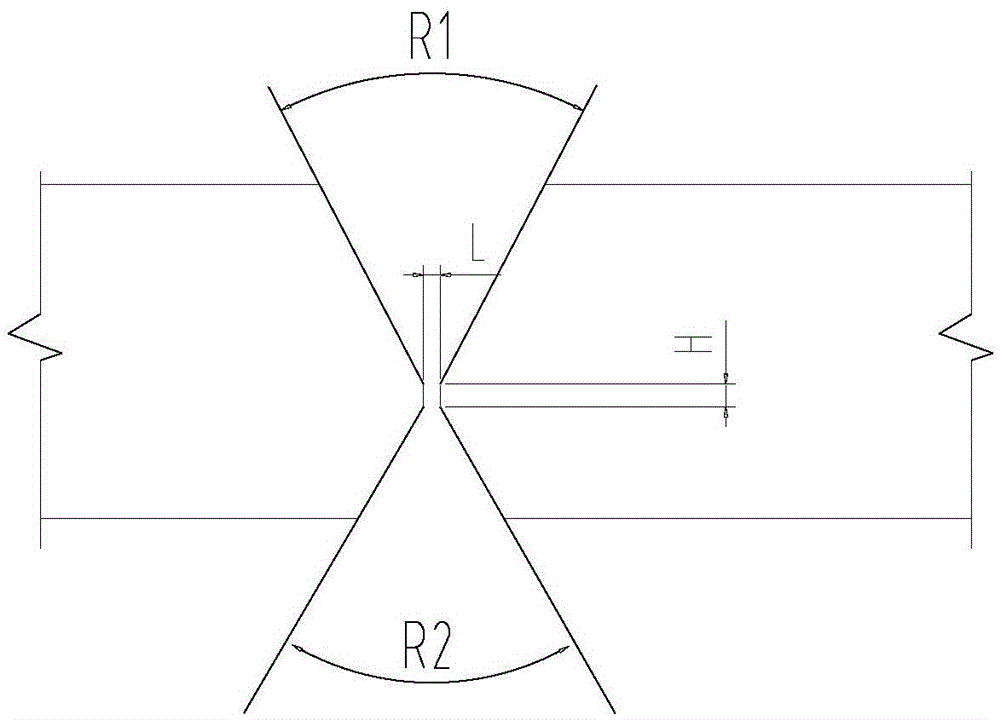

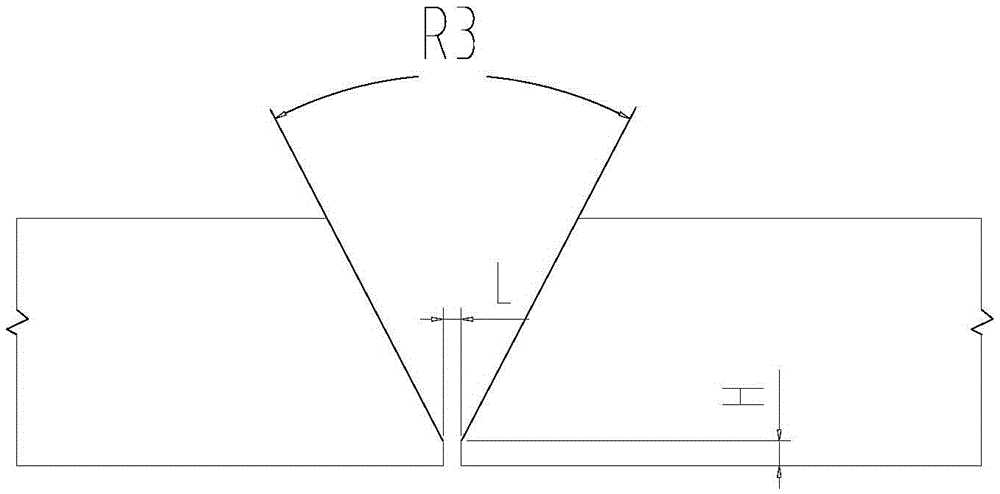

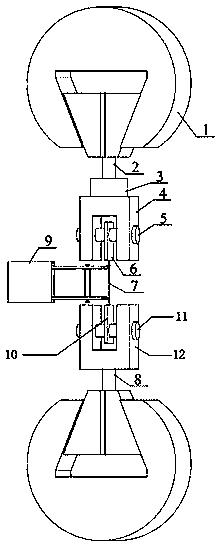

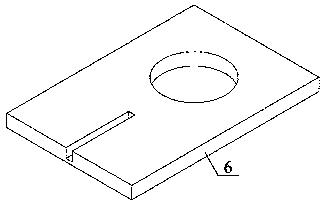

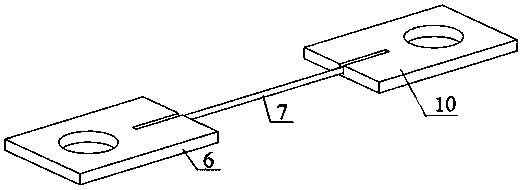

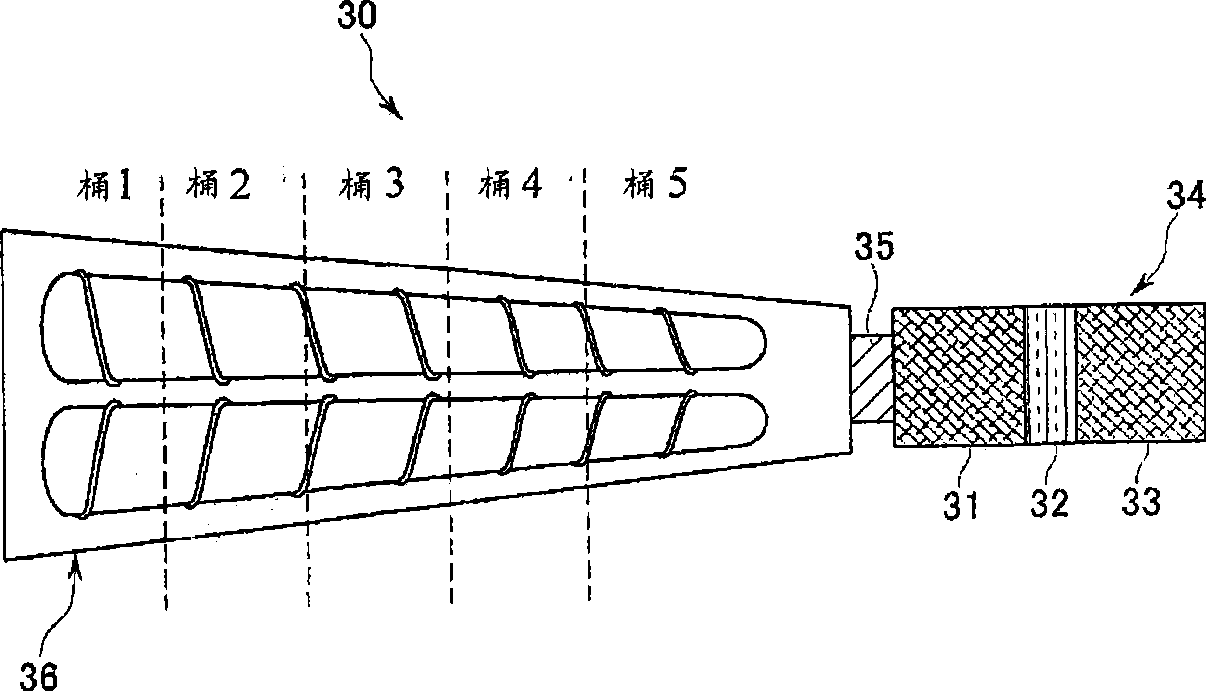

Testing device and method for the mechanical properties of inner yarn of ceramic matrix composite material

ActiveCN109827839AAvoid premature fractureEasy to disassemblePreparing sample for investigationMaterial strength using tensile/compressive forcesYarnData acquisition

The invention provides a testing device for the mechanical properties of an inner yarn of a ceramic matrix composite material. The device comprises test machine chunks, an upper round bar, a force sensor, U-shaped clamp blocks, pins, reinforcing pieces, a fibre bundle with a base body, a lower round bar and an extensometer. There are two test machine chunks respectively clamp the upper round bar and the lower round bar; the upper round bar is connected with the U-shaped clamp blocks through the force sensor, and the lower round bar is connected with the U-shaped clamp blocks; there are two U-shaped clamp blocks which are connected with the reinforcing pieces through the pins; there are two reinforcing pieces respectively connected with the two ends of the fibre bundle with a base body; theforce sensor and the extensometer are connected with a data collection system through data lines. The testing method based on the device comprises the steps of: preparing the fibre bundle with the base body, fixedly installing the fibre bundle with the base body on the testing device, the pull-up test is performed on the test machine, and the force sensor and the extensometer are employed to measure and obtain the mechanical properties such as elastic modulus and strength of the fiber bundle with the base body.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

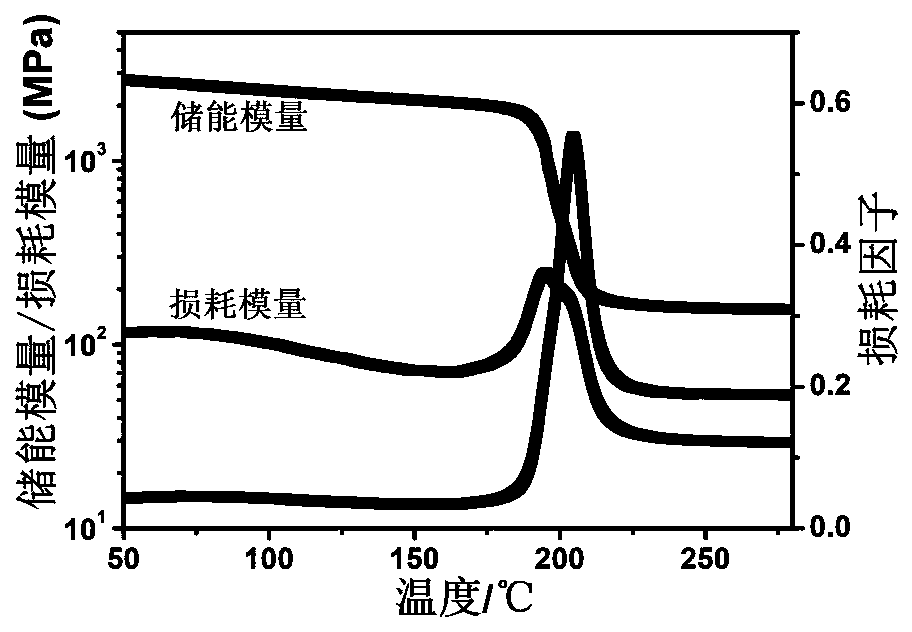

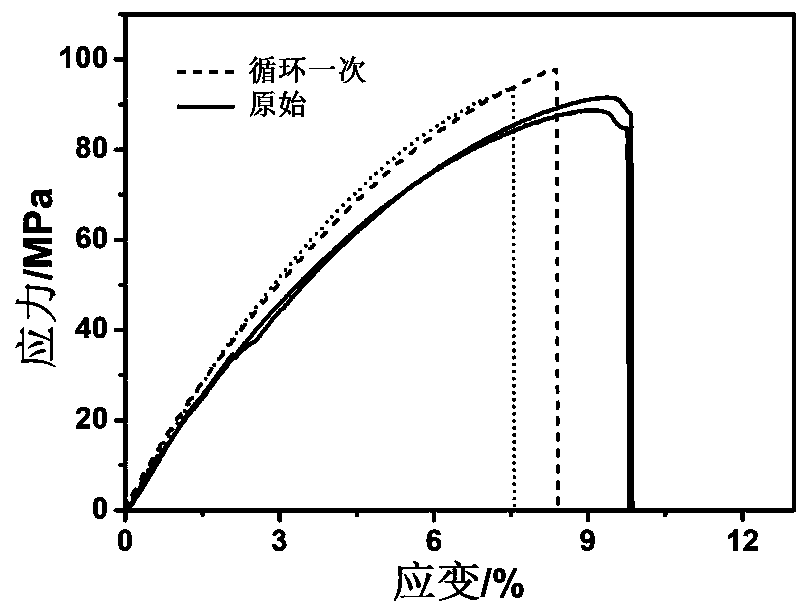

Preparation method of thermosetting polyimide

The invention belongs to the technical field of macromolecular materials, and particularly relates to a preparation method of recyclable thermosetting polyimide. The preparation method of recyclable thermosetting polyimide includes the steps that firstly, an amine end capping method is adopted to obtain polyimide oligomers with active reaction amino groups, and then a cross-linking agent containing multiple aldehyde groups is adopted to conduct cross-linking condensation to obtain thermosetting polyimide. Thermosetting polyimide prepared through the preparation method maintains excellent performance of polyimide and can be recycled and reprocessed; not only can thermosetting polyimide prepared through the preparation method be decomposed and recycled, but also recycled monomers still can be recycled again, a material obtained after the recycled monomers are polymerized again still has the same mechanical performance as the raw material, and the preparation method is mainly applied to recycling and the like of composite materials; the vitrification transformation temperature of thermosetting polyimide prepared through the preparation method is greater than 200 DEG C, and thermosetting polyimide can be applied to severe environments such as high-temperature environments.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of swimming bladder bioprosthetic valve material and preservation method thereof

InactiveCN110755688AImprove stabilityImprove anti-calcification propertiesTissue regenerationProsthesisSwim bladderBiology

The invention discloses a preparation method of a swimming bladder bioprosthetic valve material and a preservation method thereof. The preparation method comprises the following steps: a, cutting anddecellularizing swimming bladders; b, carrying out cross-linking immobilization on the decellularized swimming bladders by adopting glutaraldehyde; c, carrying out cross-linking post-treatment by adopting a polyphenol glycosaminoglycan enzyme inhibitor or carrying out cross-linking post-treatment by adopting a polyphenol compound and ferric chloride; and d, after rinsing, preserving by adopting anantibacterial solvent or preserving after dehydrating and drying by adopting an alcoholic solution. According to the swimming bladder bioprosthetic valve material prepared by the invention, the stability and the anti-calcification performance of glycosaminoglycan are improved, and the swimming bladder bioprosthetic valve material is the novel bioprosthetic valve material with an application prospect.

Owner:SICHUAN UNIV

Liquid crystal polymer film and manufacture method

InactiveCN109664563AEquivalent mechanical propertiesEasy to prepareTransportation and packagingSynthetic resin layered productsPolymer scienceFlexible circuits

The invention discloses a liquid crystal polymer film and a manufacture method. The liquid crystal polymer film comprises first oriented films and second oriented films, wherein the first oriented films and the second oriented films are in sequentially staggered and laminated arrangement; the orientation directions of the first oriented films and the adjacent second oriented films intersect with each other, and the first oriented films and the second oriented films are subjected to hot press molding to obtain the liquid crystal polymer film. The liquid crystal polymer film has considerable mechanical properties in the MD direction and the TD direction, thereby being applicable to manufacture of flexible circuit boards; the manufacture method of the liquid crystal polymer film is simple, the manufacture cost is low, and the liquid crystal polymer film is easy to produce in a large scale.

Owner:SHENZHEN SUNWAY COMM

Fabric punched felt complex and preparation method thereof

ActiveCN103879076AEquivalent mechanical propertiesImprove mechanical propertiesGlass/slag layered productsNatural mineral layered productsIntensity changeEngineering

The invention provides a fabric punched felt complex and a preparation method thereof. The preparation method comprises the following steps: compounding a continuous functional fiber fabric layer and a continuous functional fiber bulked yarn crude fabric layer together so as to obtain integrated fabric; then compounding a chopped functional fiber punched felt layer with the continuous functional fiber bulked yarn crude fabric layer of the integrated fabric through needling so as to obtain the fabric punched felt complex. The fabric punched felt complex has a light and high strength structure with stepped intensity changes. The weight of the fabric punched felt complex is 30% lighter than that of complete fabric with a same volume, while the mechanical performance of the fabric punched felt complex is equal to that of complete fabric with a same volume, and is better than that of complete chopped fiber punched felt. At the same time the fiber raw material is saved by 30% or more, moreover the preparation technology is simple, and the production period is short.

Owner:HUNAN JIUHUA CARBON HI TECH

Manufacturing method of optical cable strengthening piece

InactiveCN103407176AEquivalent mechanical propertiesGood flexibilityFibre mechanical structuresYarnGlass fiber

The invention relates to a manufacturing method of an optical cable strengthening piece, and belongs to the technical field of composite material processing. The manufacturing method is characterized in that a strengthening fiber is a glass fiber or a para-position aramid fiber, and a resin is a thermoplastic resin. The manufacturing method comprises the steps of putting yarns, soaking by a coupling agent, preheating and drying the fiber, coating the resin, cooling, drying and rolling the resin and the like. The optical cable strengthening piece prepared by the invention has the advantages that the flexibility is greatly improved, the production speed is rapid, the benefits are high, the cost is low, a fiber disconnecting condition is avoided, and the manufacturing method of the optical cable strengthening piece can be used on a large scale.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

High thermal conductivity and high strength carbon-based composite material and preparation method thereof

The invention provides a high thermal conductivity and high strength carbon-based composite material and a preparation method thereof and belongs to the technical field of manufacturing of carbon materials. The high thermal conductivity and high strength carbon-based composite material comprises at least two layers of carbon / carbon composite material plates which are laminated, and two adjacent layers of the carbon / carbon composite material plates are adhered by a silicon adhesive. As for the high thermal conductivity and high strength carbon-based composite material provided by the invention,the thermal conductivity is more than 450W / mK, the tensile strength and the compressive strength are more than 250MPa respectively, and the bending strength is more than 200MPa. Compared with an aluminum alloy material which is currently used for a heat dissipation panel of a spacecraft thermal control system, the mechanical performances of the material are comparable, but the mass is lighter andthe thermal conductivity is much higher than that of the aluminum alloy. Thus, the high thermal conductivity and high strength carbon-based composite material is expected to be widely applied in thefields of spacecraft thermal control, thermal management of electronic devices and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Microcellular foam of thermoplastic resin prepared with die having improved cooling property and method for preparing the same

The present invention relates to a microcellular foam of a thermoplastic resin and a method for preparing the same, and more particularly to a microcellular foam comprising a skin layer having a porosity of below 5% and a core layer having a porosity of at least 5%, wherein the thickness of the skin layer accounts for 5 to 50% of the entire foam, and a method for preparing the same. The microcellular foam of the present invention is advantageous in that it has a thicker skin layer and smaller and uniform micropores in the core layer, compared with conventional microcellular foams, while having mechanical properties comparable to those of conventional non-foamed sheets.

Owner:LG CHEM LTD

Large-specification Ti2AlNb alloy ring piece and manufacturing method thereof

ActiveCN112275966AReduce rolling forceAvoid pollutionFurnace typesEngine componentsTemperature controlAlloy

The invention relates to the technical field of forge piece manufacturing processes, in particular to a large-specification Ti2AlNb alloy ring piece and a manufacturing method thereof. The manufacturing method of the large-specification Ti2AlNb alloy ring piece comprises the following steps that after a Ti2AlNb alloy ring blank is subjected to heat preservation treatment at the beta transformationtemperature of a Ti2AlNb alloy or above, one-time rolling forming with the deformation larger than 45% is carried out, and then temperature control cooling is carried out. According to the manufacturing method, after the Ti2AlNb alloy ring blank is subjected to heat preservation treatment at at the beta transformation temperature of the Ti2AlNb alloy or above, it is guaranteed that no B2 straightgrain boundary influencing the plasticity of the alloy exists in a microstructure of the rolled alloy in a large-deformation one-time rolling forming mode. Meanwhile, the one-time rolling forming mode with large deformation is adopted, the temperature control cooling mode is combined, precipitation of a second phase alpha phase on the B2 grain boundary is limited, and therefore the situation thatplasticity is reduced due to brittle fracture of the alloy along grains is avoided.

Owner:BEIJING CISRI GAONA TECH +1

Preparation method of composite zirconia ceramic backboard

ActiveCN108821767ACompact structureThe process is simple and controllableRelative energyHot pressing

The invention discloses a preparation method of a composite zirconia ceramic backboard. The method comprises steps as follows: composite zirconia granulation powder is poured into a backboard mold andsubjected to dry-pressing molding, an obtained model is subjected to degreasing, high-temperature roasting and flash burning, and a backboard sintered body can be prepared. The preparation method ofthe composite zirconia ceramic backboard is combined with high-pressed sintering and flash burning technologies, the temperature of the high-temperature roasting of the method is lower than that of the high-pressed sintering technology by 500-700 DEG C, the total time for high-temperature roasting does not exceed two minutes, and the obtained backboard sintered body not only has mechanical properties equivalent to those of a product obtained with the high-pressed sintering technology, but also has the characteristics of being compact in structure and free of microscopic hole defects; besides,the method further has the advantages of simple and controllable process, efficient preparation and relative energy conservation, and is suitable for industrial production.

Owner:苏州山人纳米科技有限公司

Alloy zinc bar preparation method

The invention discloses an alloy zinc bar preparation method which includes the steps: smelting copper, titanium and zinc in an industrial furnace; gradually adding zinc ingot until component requirements are met; adding refining agents, mixing and refining; keeping temperature for melted liquid after refining, and controlling the temperature within a range from 450 DEG C to 500 DEG C; squeezing out alloy zinc bars by the aid of a pressurized mode. The weight percentage of the copper is 0.1-2%, the weight percentage of the titanium is 0.05-0.1%, and the balance being zinc. The alloy zinc bars prepared by the method can be drawn into different lengths, diameters and shapes according to requirements, mechanical properties and corrosion resistance of the alloy zinc bars are equivalent to those of brass bars, and cost is greatly reduced.

Owner:NANTONG XINXIANG ZINC IND

3D printing nozzle and forming method of liquid crystal polymer film

PendingCN109648850AAchieve transformationGood orientation3D object support structuresFlat articlesSpray nozzleEngineering

The invention discloses a 3D printing nozzle and a forming method of a liquid crystal polymer film. The 3D printing nozzle comprises a shell and further comprises an inner core. The inner core is located in the shell. The central axis of the inner core coincides with the central axis of the shell. The inner core is rotatably arranged relative to the shell. The inner core of the spray nozzle is rotatably arranged relative to the shell. When a melt is subjected to mixing and plastifying, the forming pressing can be increased, and a raw material is transformed well from zero dimension to three dimension. When the liquid crystal polymer film is formed through the spray nozzle, the problem of orientation of the liquid crystal polymer film on a 2D plane can be improved remarkably, and the mechanical properties of the obtained liquid crystal polymer film in all directions are equivalent.

Owner:SHENZHEN SUNWAY COMM

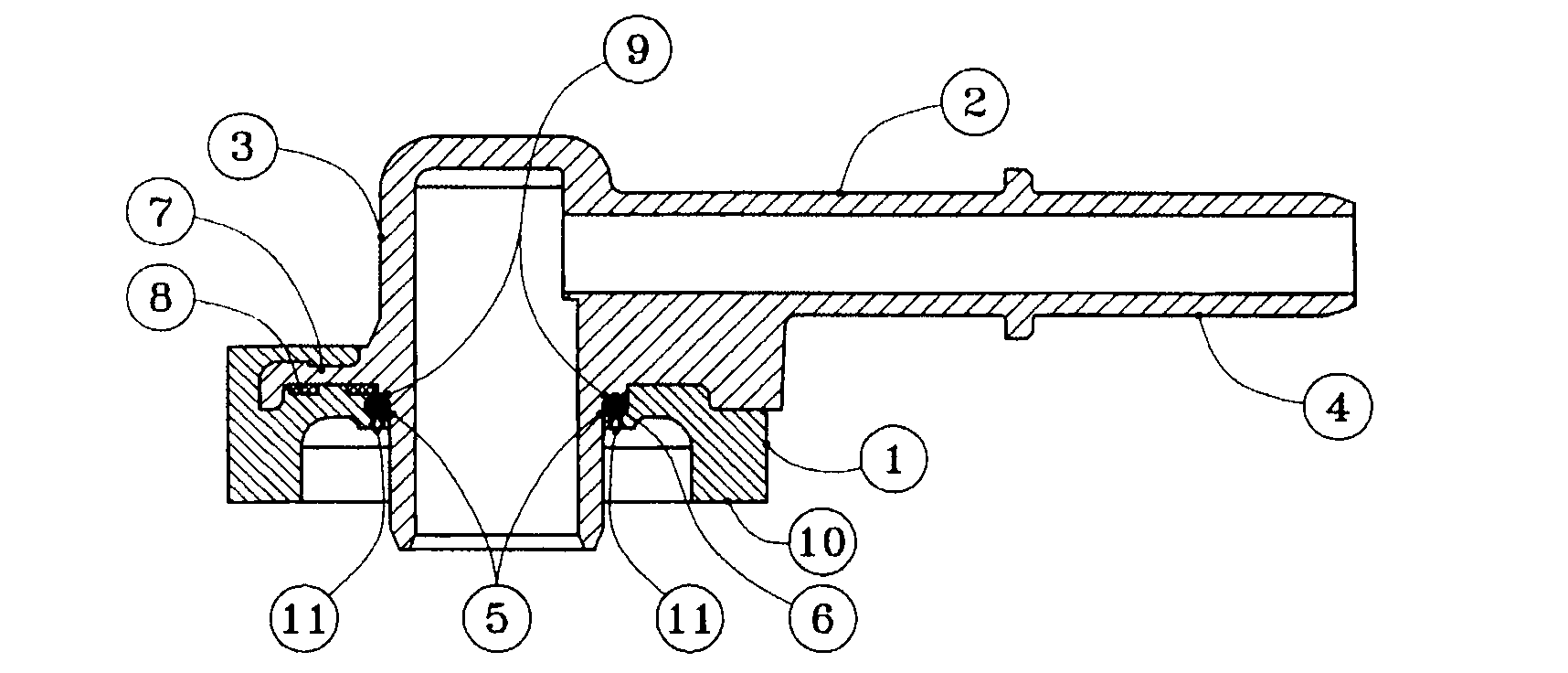

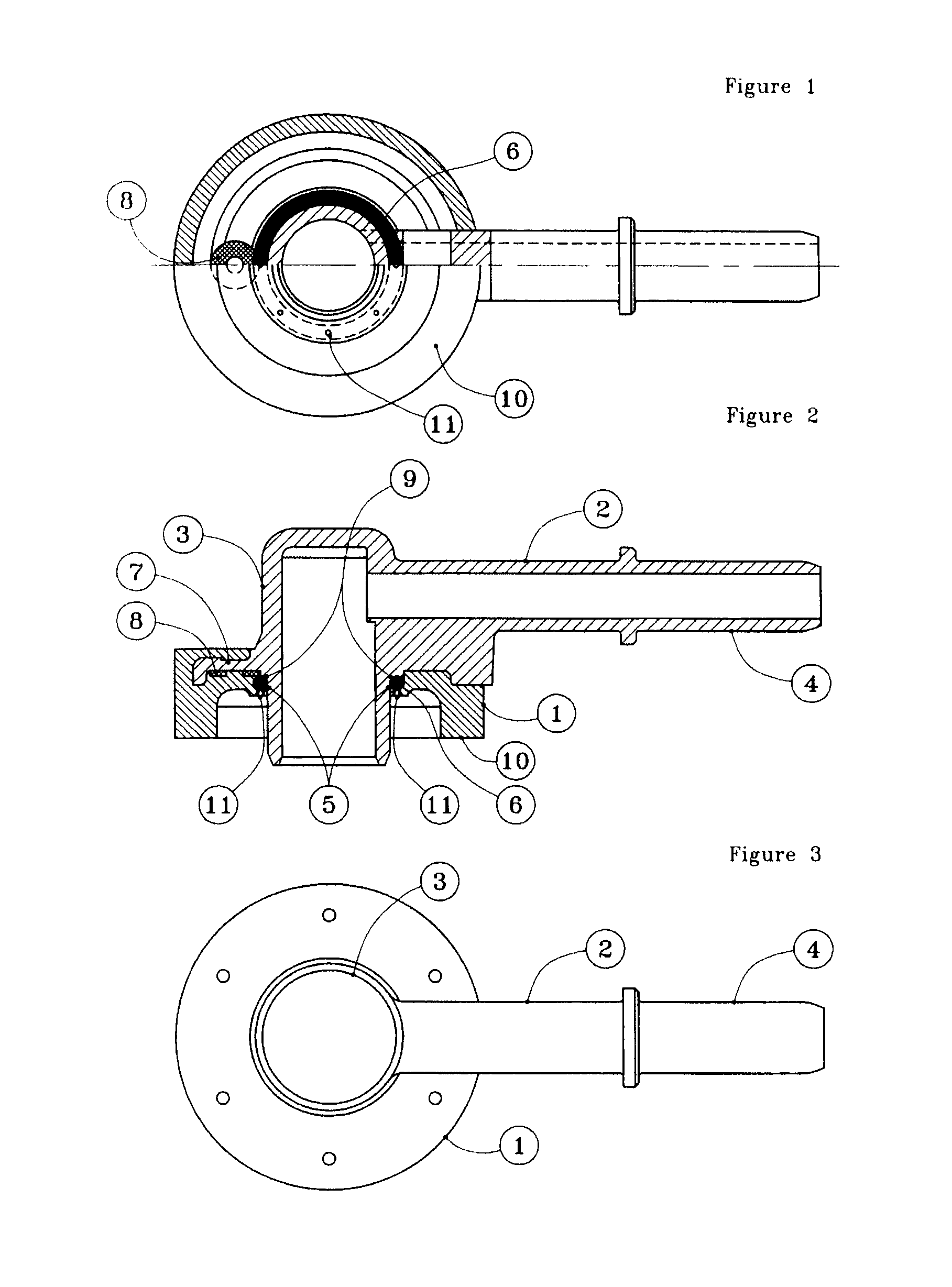

System for supplying an internal combustion engine and method of manufacturing a tank comprised in the system

InactiveUS20090295026A1Reduce manufacturing costImprove mechanical propertiesCeramic shaping apparatusCoatingsExternal combustion engineEngineering

System for supplying an internal combustion engine with a liquid fuel, comprising a tank, a pipe for the circulation of hot fuel between the engine and the tank and at least one sealed composite junction conduit for joining the pipe to the tank. The composite junction conduit comprises at least two hollow components each based on a different plastic, the said components being mechanically attached to each other and in communication with each other and include, between them, an overmoulded seal.

Owner:INERGY AUTO SYST RES SA

High damping titan alloy of multicomponent alloy

The invention discloses a high damping titanium alloy of a multi-element alloy. The alloy is manufactured into an electrode by adopting sponge titanium, electrolytic nickel, oxygen-free copper, metal zirconium and less rare earth yttrium in a pressing way according to the designed components. The electrode is melted into the high damping titanium alloy of a multi-element alloy by a normal vacuum induction furnace; the components of the high damping titanium alloy include: 25 to 30 percent of Ni; 25 to 30 percent of Cu; 1 to 5 percent of Zr; 0.01 to 0.20 percent of Y; the rest is Ti and unavoidable impurities. The damping performance of the invention is more than 2 times than the optimized performance that can be achieved by the existing damping alloy of a Ti-Ni-Cu-Y system; besides, the mechanical property is equivalent; the production mode thereof is to adopt the normal production mode and is easily carried out.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparing method of alloy magnesium rod

InactiveCN109666808AEquivalent mechanical propertiesCorrosion resistance is equivalentIngotMechanical property

The invention discloses a preparing method of an alloy magnesium rod. The preparing method comprises following steps that copper, sodium and magnesium are added into an industrial furnace to be smelted; a magnesium ingot is added step by step until the component need is achieved, the mass percent of the copper is 0.1 to 2%, the mass percent of the sodium is 0.05 to 0.1%, and the balance is magnesium; a refining agent is added, and stirring refining is carried out; the refined alloy melt is subjected to heat preservation, and the temperature is controlled to range from 450 to 500 DEG C; and through pressurized extrusion, the alloy magnesium rod is obtained. The alloy magnesium rod obtained through the preparing method can be drawn into different lengths, diameters and shapes according to needs, the mechanical property, and corrosion resistance of the magnesium rod are equivalent to those of the brass rod, and the cost is greatly reduced.

Owner:王磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com