Composition with improved low-temperature flexibility and elasticity

A composition and elastic technology, applied in the manufacture of door seal plastic sleeves for refrigerated products, refrigerated products, PVC composition field, can solve unacceptable, expensive, and unmanufactured problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The product of the present invention can be prepared by the conventional preparation method used in this area, and the specific preparation method is as follows:

[0034] First, put all the raw materials except the modifier into a high-speed mixer for pre-mixing until the temperature rises to 110°C, and the material is in a semi-plasticized state; then, move the mixed semi-plasticized material into a low-speed mixer In the mixer, add the modifier, cool to 50°C at the same time, and continue to stir for 2-3 minutes; send the mixed material into the single-screw extruder for granulation; add the plastic granules to another The final processing takes place in an extruder capable of making refrigerator weather strip profiles to obtain the final product.

[0035] The main advantages of the present invention are:

[0036] Compared with conventional PVC compositions containing NBR, the PVC composition of the present invention has much better hardness change rate and low tempe...

Embodiment 1

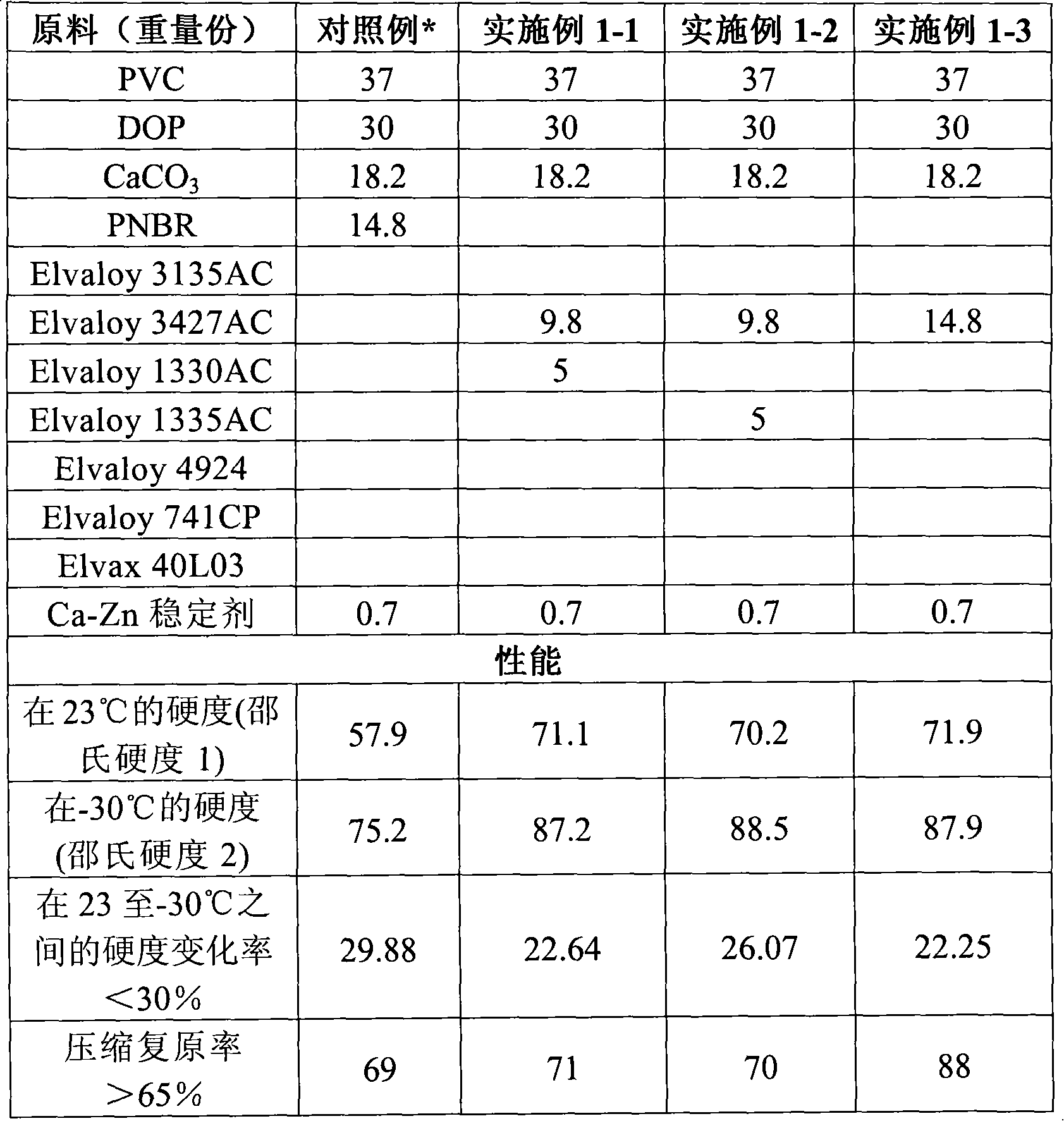

[0039] Example 1: Preparation and performance test of door seal plastic sleeve sample

[0040] preparation:

[0041] 1. Mixing: According to the following table 2, the corresponding raw materials listed in the following table 1 are blended in a Brabender (Brabender) mixer (manufactured by Brabender, Germany), and the mixing temperature is 150 ° C. Blending time was 5-8 minutes.

[0042] 2. Preparation of the sample: The blended material taken out of the Brabender mixer was placed in a mold and pressed into tablets with a hot press (process conditions: 15Mpa, 150°C, 8 minutes). According to the needs of experimental testing, different punching knives are selected to cut the pressed sheet into required samples for the next step of testing.

[0043] Table 1

[0044] raw material

Manufacturer Chemical Name

pvc

Tianjin Bohai Chemical Co., Ltd. PVC SG-3 type

DOP

Nanjing Jinling Petrochemical Bis(2-ethylhexyl)phthalate

CaCO 3

Cha...

Embodiment 2

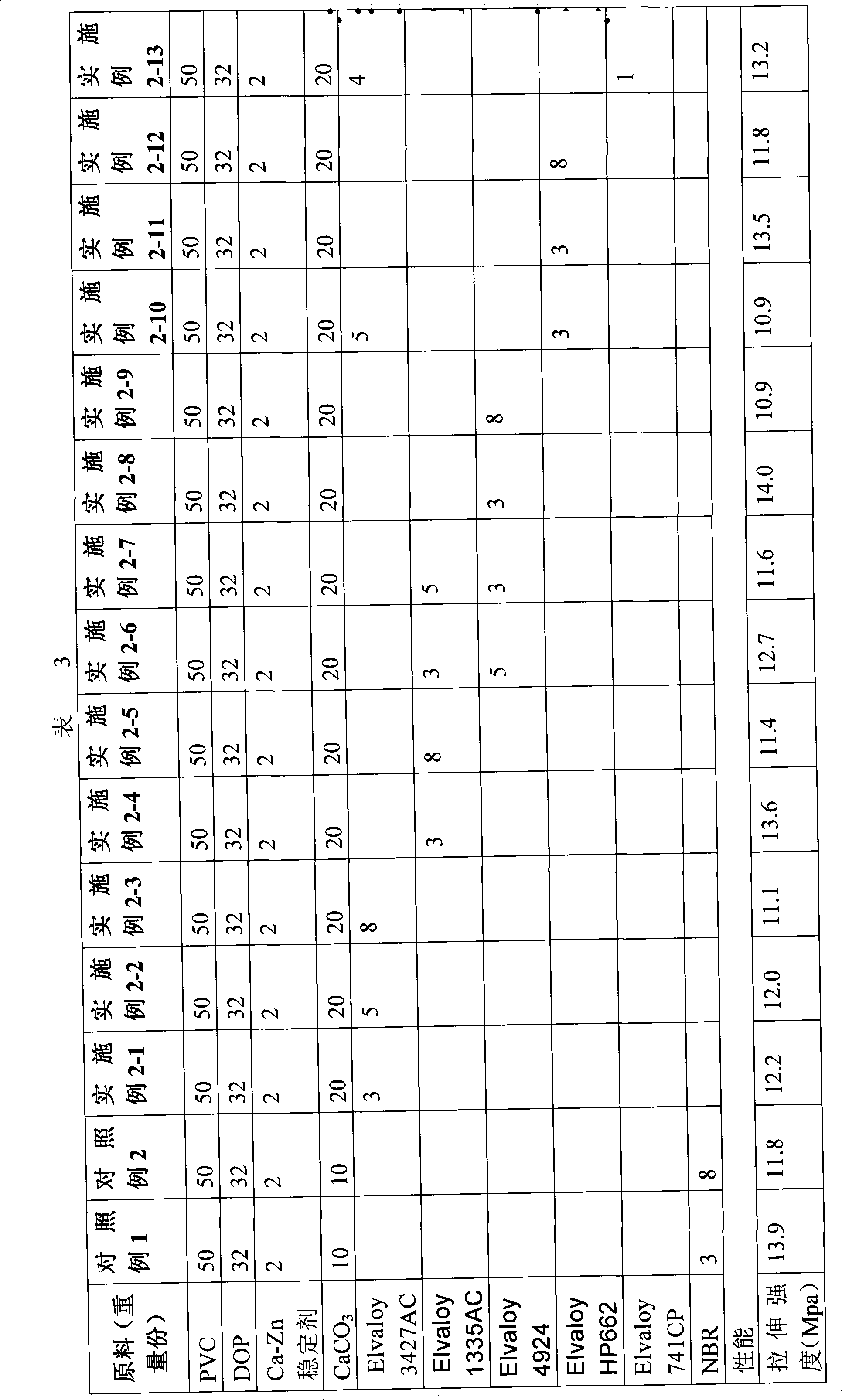

[0056] Example 2: Preparation and performance test of door seal plastic sleeve sample

[0057] preparation:

[0058] 1. Mixing: According to the following table 3, the corresponding raw materials listed in the above table 1 were blended in a Brabender mixer, the mixing temperature was 150°C, and the blending time was 5-8 minutes.

[0059] 2. Preparation of the sample: The blended material taken out of the Brabender mixer was placed in a mold and pressed into tablets with a hot press (process conditions: 15Mpa, 150°C, 8 minutes). According to the needs of experimental testing, different punching knives are selected to cut the pressed sheet into required samples for the next step of testing.

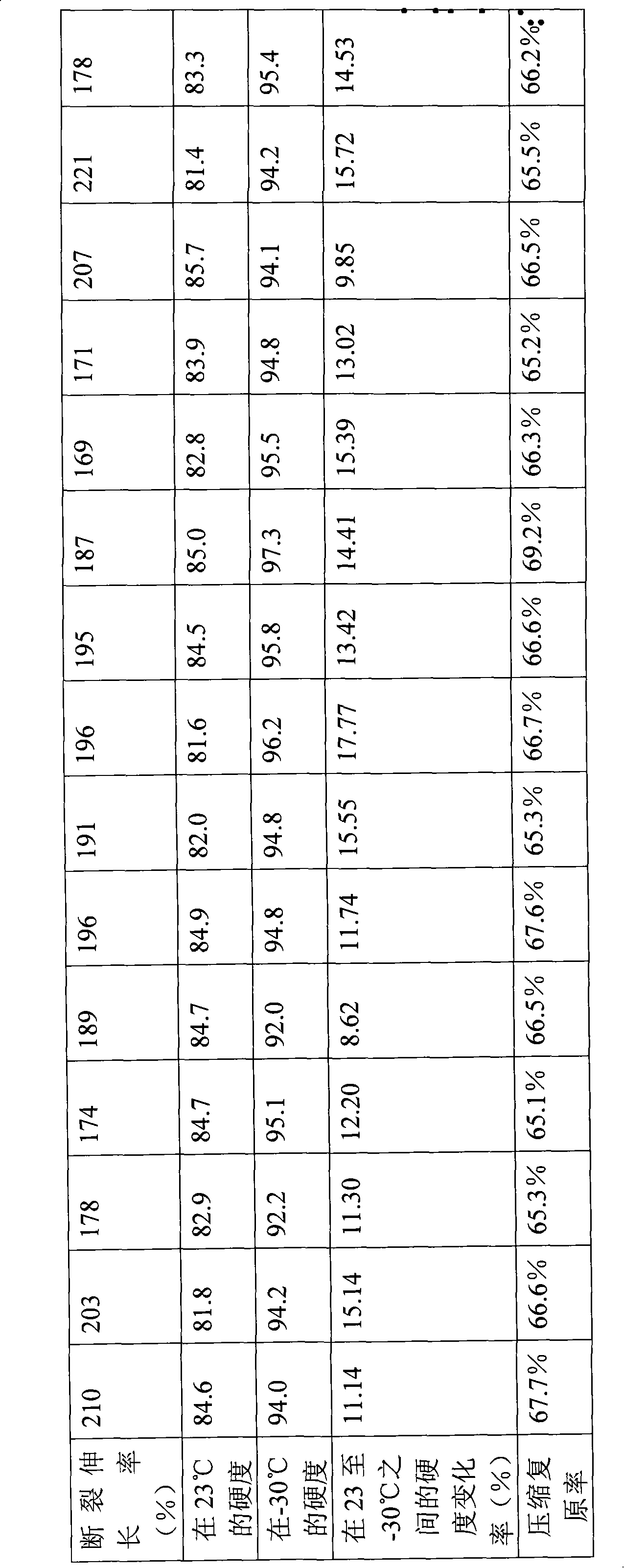

[0060] Performance Testing:

[0061] 1. Plastic tensile property test: according to ISO 527-2.

[0062] 2. Plastic Shore Hardness Test: According to GB / T2411-1980.

[0063] Hardness change rate:

[0064] Shore hardness 1 test temperature: 23-26 ℃; 15 seconds reading.

[0065] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com