3D printing nozzle and forming method of liquid crystal polymer film

A liquid crystal polymer, 3D printing technology, applied in the direction of 3D object support structure, coating device, additive manufacturing, etc., can solve the problems of high cost, long production cycle, complicated process, etc., to increase the molding pressure and improve the orientation problem Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

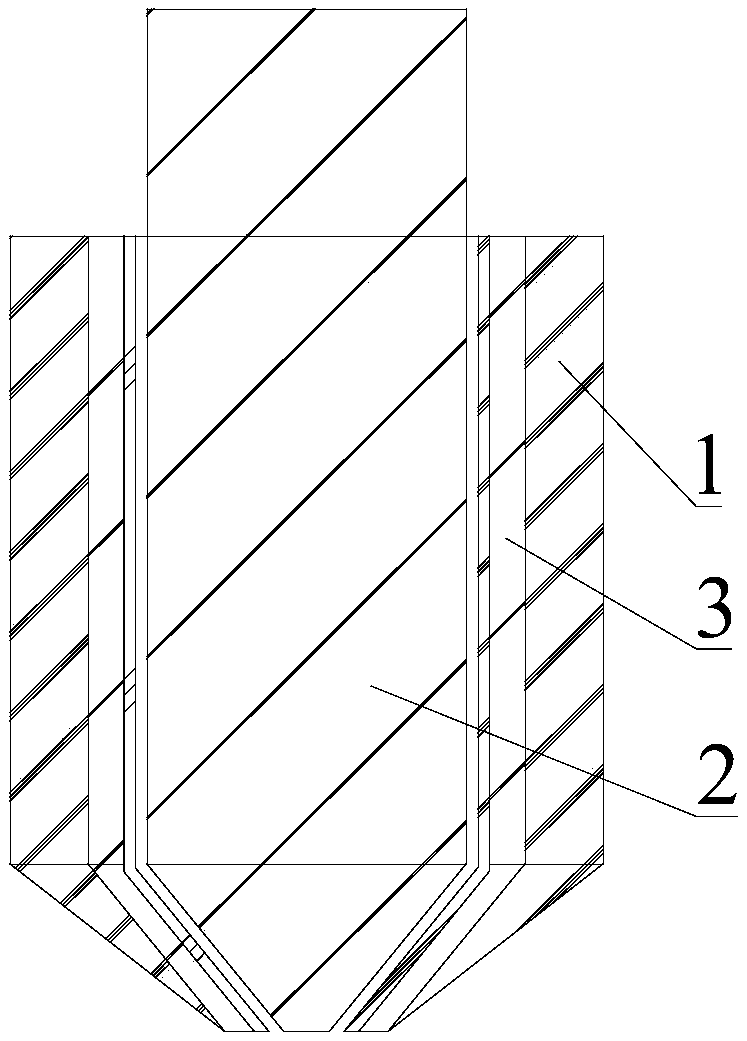

[0037] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0038] A 3D printing nozzle, comprising an outer shell 1 and an inner core 2, the inner core 2 is located in the outer shell 1, the central axis of the inner core 2 coincides with the central axis of the outer shell 1, and the inner core 2 It is rotatably arranged relative to the outer shell 1, that is, the inner core 2 can rotate around its central axis. The outer surface of the inner core 2 is provided with a helix, preferably, the angle between the helix and the center line of the inner core 2 is 40-50°, more preferably the helix and the The included angle between the centerlines of the inner cores 2 is 45°. The inner surface of the housing 1 is provided with a thermal insulation layer 3, preferably the material of the thermal insulation layer 3 is an airgel ceramic composite material, specifically, a commercial airgel thermal insulation blanket can be used, the model is CTB650, The thermal con...

Embodiment 2

[0040] Embodiment 2 of the present invention is a method for forming a liquid crystal polymer film, which is formed by 3D printing with the 3D printing nozzle described in Embodiment 1. The forming process of the liquid crystal polymer film specifically includes:

[0041] 1. Heat treatment of raw materials used to form liquid crystal polymer films. In this embodiment, heat treatment is performed on the raw material under vacuum condition, the temperature of the heat treatment is 140-160° C., and the time of the heat treatment is 4-18 hours. The raw materials used can be LCP resins synthesized by copolymerization between polyphenyl ring rigid molecular monomers, introduction of naphthalene rings into the molecular structure, and use of aliphatic segments in the molecular chain. The melting point of the resin is in the range of 250-380°C. In the present embodiment, the density of the raw material used is 1.3~1.5g / cm 3 .

[0042] 2. Extrude the heat-treated raw materials to ob...

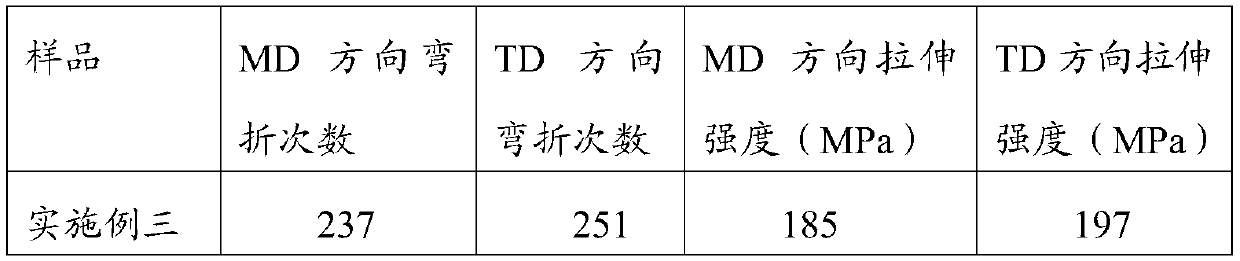

Embodiment 3

[0051] Embodiment 3 of the present invention is a method for forming a liquid crystal polymer film, which differs from Embodiment 2 in that:

[0052] The temperature of the heat treatment is 150° C., and the time of the heat treatment is 12 hours. The temperature of the annealing treatment is 220° C., and the time is 60 minutes. The obtained liquid crystal polymer film had a thickness of 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com