Epoxy thermosetting resin and preparation method thereof

A technology of epoxy thermosetting and epoxy resin, applied in the field of polymer resin, to achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of epoxy thermosetting resin, comprises the following steps:

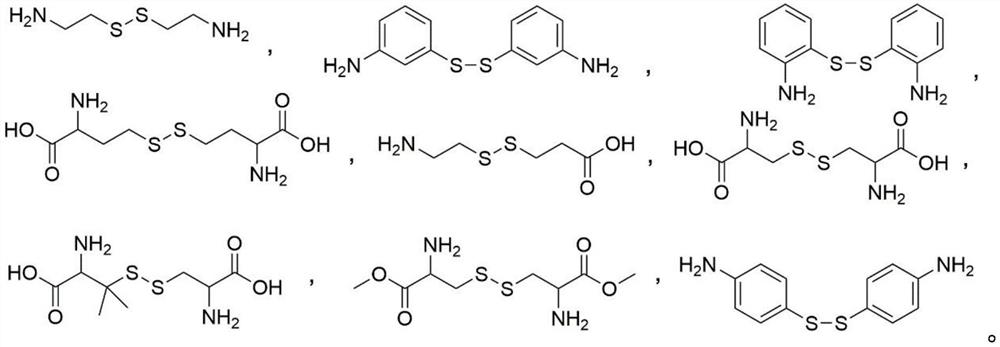

[0027] (1) Mix the epoxy resin and the disulfide-containing amine compound, add the solvent and let it stand in the mold. After the solvent evaporates, let it stand at 110-130°C for 10-14 hours to obtain the disulfide bond exchange-dynamic epoxy network;

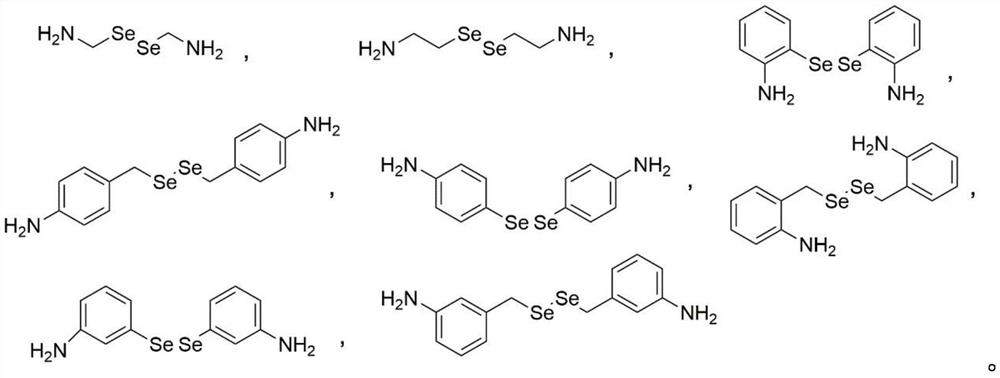

[0028] (2) Mix the epoxy resin and the amine compound containing diselenide, add the solvent and let it stand in the mold. After the solvent evaporates, let it stand at 110-130°C for 10-14 hours to obtain the diselenide bond exchange-dynamic epoxy network;

[0029] (3) Disulfide bond exchange-dynamic epoxy network and diselenide bond exchange-dynamic epoxy network are mixed and hot pressed to obtain epoxy thermosetting resin;

[0030] Wherein, step (1) and step (2) have no order limitation.

[0031] In the present invention, the epoxy resin in step (1) and step (2) is independently preferably ethylene ...

Embodiment 1

[0047] The present embodiment provides a kind of epoxy thermosetting resin, and its preparation method comprises the following steps:

[0048](1) Mix 8mmol of bisphenol F diglycidyl ether and 4mmol of cystamine, add 5mL of tetrahydrofuran, stir evenly, place in a 50mm*50mm*2mm polytetrafluoroethylene film, and wait for the solvent to evaporate to dryness, at 120°C After standing for 12 hours, a disulfide bond exchange-dynamic epoxy network was obtained, denoted as P1-1;

[0049] Mix 8mmol of bisphenol A diglycidyl ether and 4mmol of selenocystamine, add 5mL of tetrahydrofuran, stir evenly, place in a 50mm*50mm*2mm polytetrafluoroethylene film, and wait for the solvent to evaporate to dryness. Set for 12h to obtain diselenium bond exchange-dynamic epoxy network, denoted as P1-2;

[0050] The reaction process is as follows:

[0051]

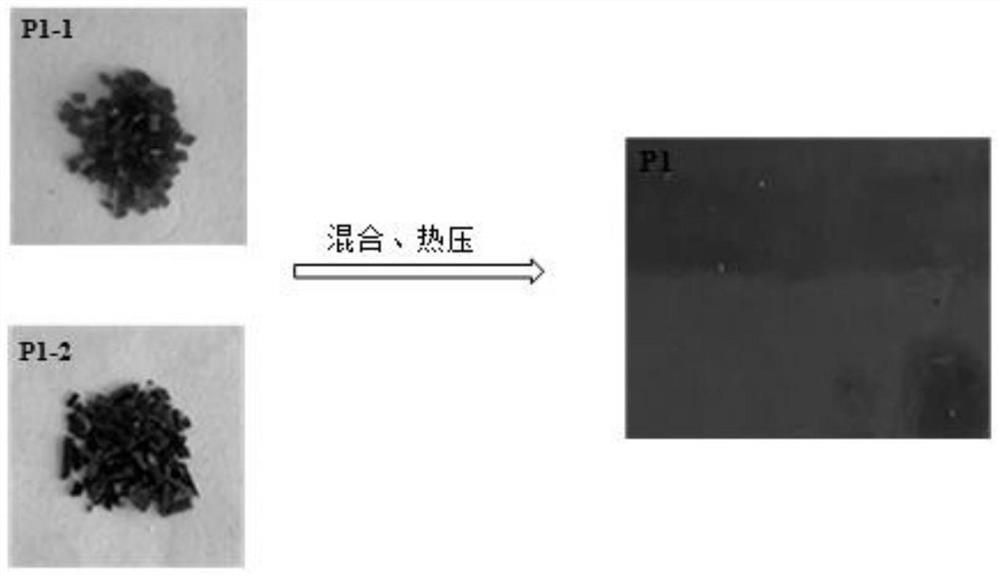

[0052] (2) The schematic flow chart of preparing P1 by hot pressing P1-1 and P1-2 prepared in step (1) is as follows figure 1 Shown: Cut 0.5...

Embodiment 2

[0056] The present embodiment provides a kind of epoxy thermosetting resin, and its preparation method comprises the following steps:

[0057] (1) Mix 4mmol of poly(ethylene glycol) diglycidyl ether and 2mmol of 2,2'-dithiodianiline, add 6mL of dichloromethane, stir well and place in a 50mm*50mm*2mm polytetrafluoroethylene In the film tool, after the solvent evaporates, let it stand at 120°C for 10 hours to obtain a disulfide bond exchange-dynamic epoxy network, which is denoted as P2-1;

[0058] Mix 4mmol of bisphenol F diglycidyl ether and 2mmol of bis(2-aminophenyl) diselenide, add 6mL of dichloromethane, stir evenly, place in a 50mm*50mm*2mm polytetrafluoroethylene film, wait for the solvent After evaporating to dryness, let it stand at 120°C for 10 hours to obtain a diselenide bond exchange-dynamic epoxy network, denoted as P2-2;

[0059] The reaction process is as follows:

[0060]

[0061] (2) Shred 0.5g of P2-1 and 0.5g of P2-2, mix them, and heat-press for 16 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com