Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Meet welding quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic welding method of flow production line for hydraulic support grid box type structure members

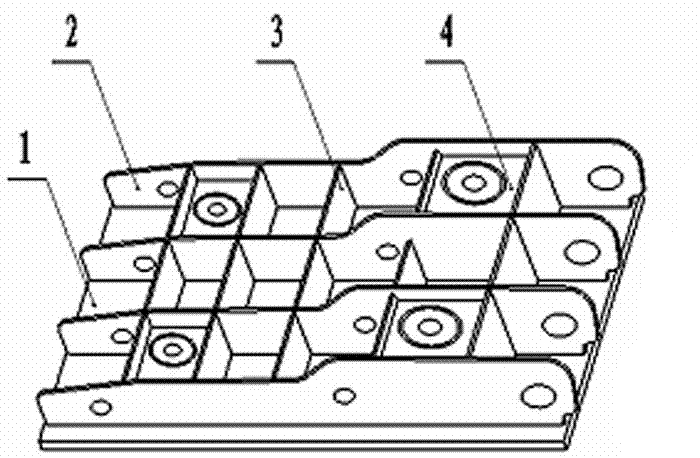

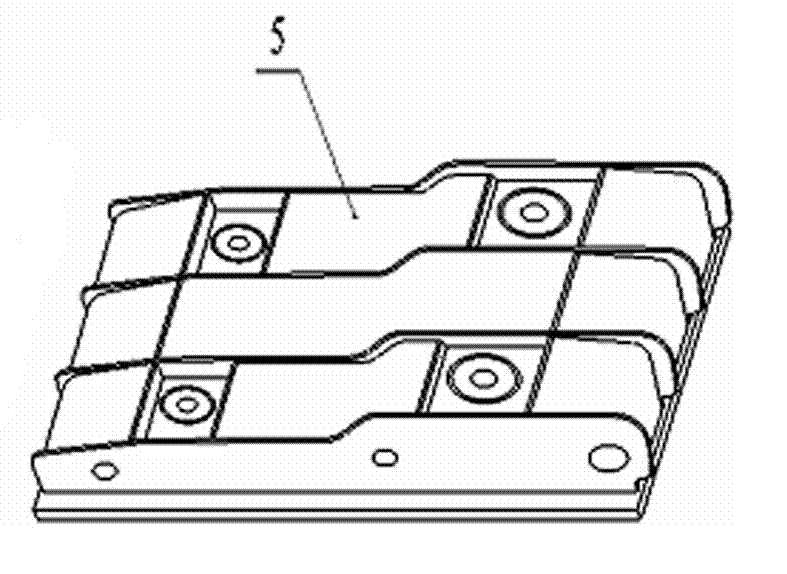

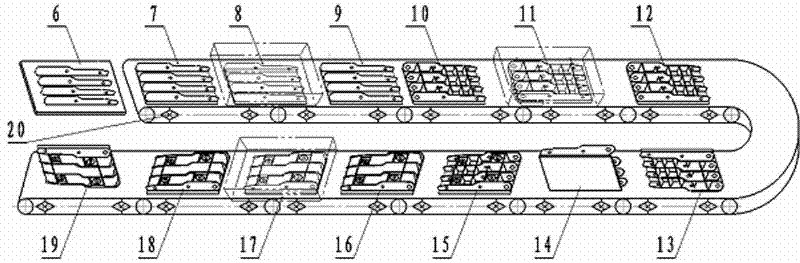

ActiveCN102441720ASolve the deformationResolve integrityWelding accessoriesFlat jointProduction line

The invention relates to the field of welding fabrication of hydraulic support structure members, particularly to an automatic welding method of a flow production line for hydraulic support grid box type structure members, which solves the problem that the traditional manual welding method cannot guarantee the welding forming quality and workpieces cannot be completely and automatically welded due to deformation caused by a unit type automatic robot due to thick plate welding thermal cycle. The automatic welding method comprises the following concrete steps of: cutting and forming the grid box type structure members; automatically counting and assembling bottom plates and main rib plates; preheating the counted and assembled bottom plates and main rib plates; automatically welding the main rib plates; automatically counting and assembling separation plates; preheating the counted and assembled separation plates; automatically welding the flat joints of the separation plates; automatically welding the left vertical joints of the separation plates; automatically welding the right vertical joints of the separation plates; counting and assembling function parts; counting and assembling cover plates; automatically welding the flat joints of the cover plates; automatically welding the arc joints of the cover plates; and circulating the above steps. The method provided by the invention is reasonable and simple in process, strong in operability and high production efficiency, and can guarantee the welding quality.

Owner:SHANXI PINGYANG IND MACHINERY

Surfacing welding method for abraded large roll shaft

ActiveCN105382378AReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

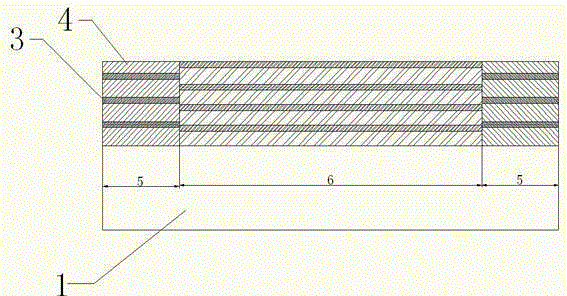

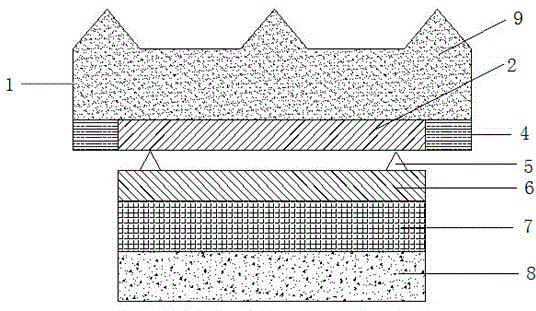

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508AReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

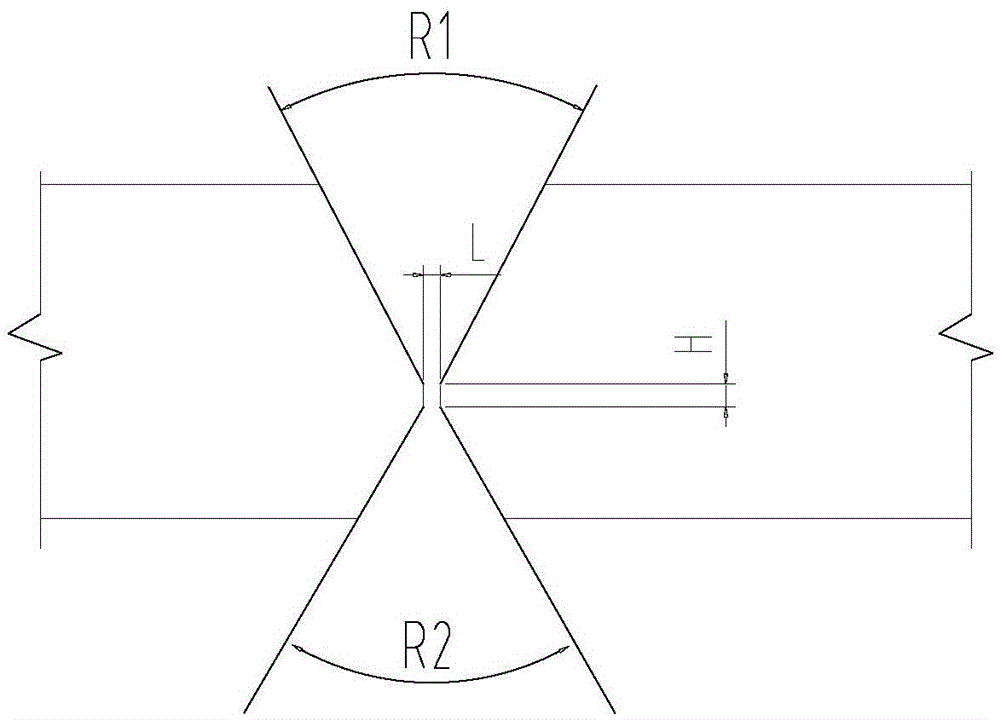

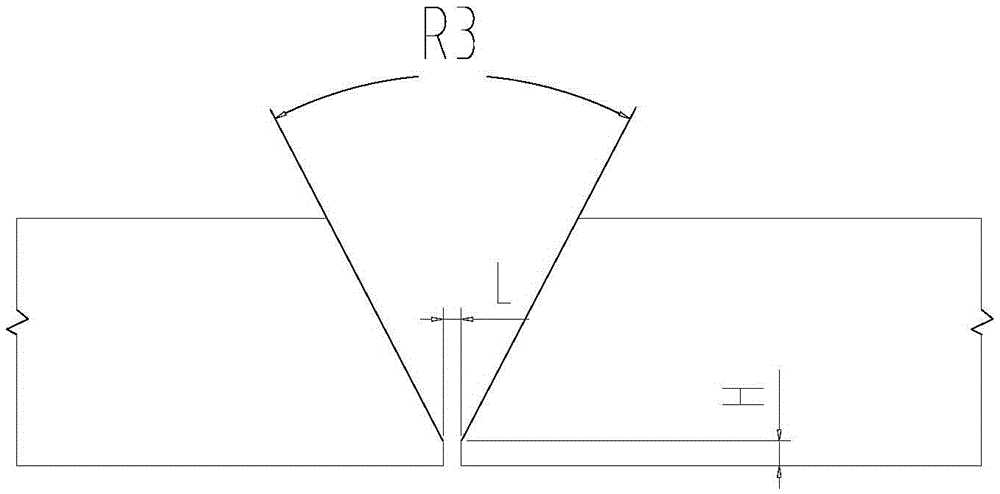

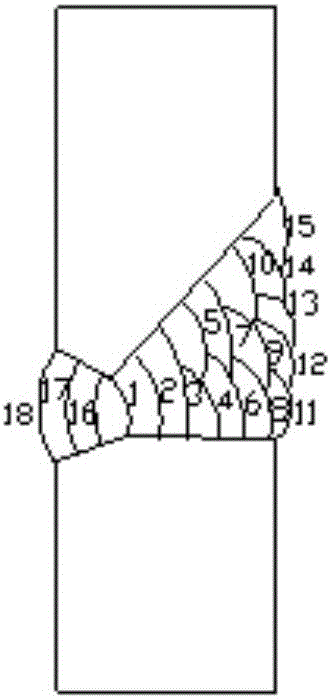

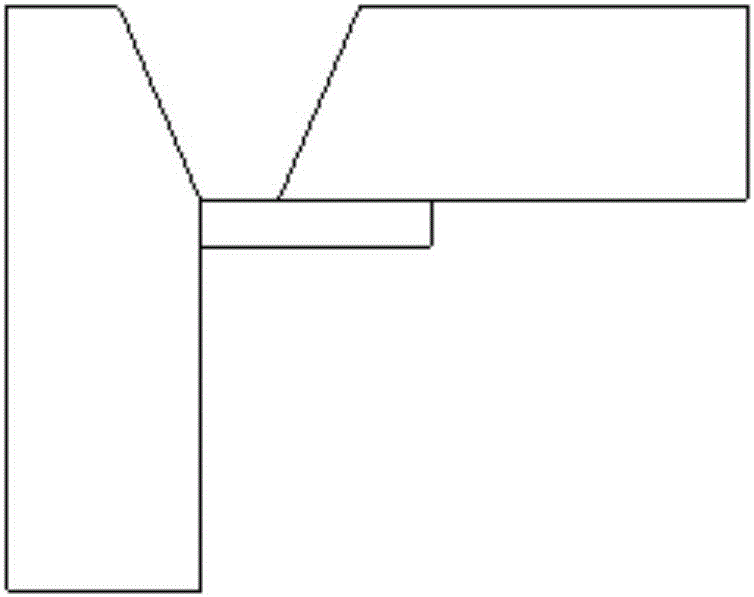

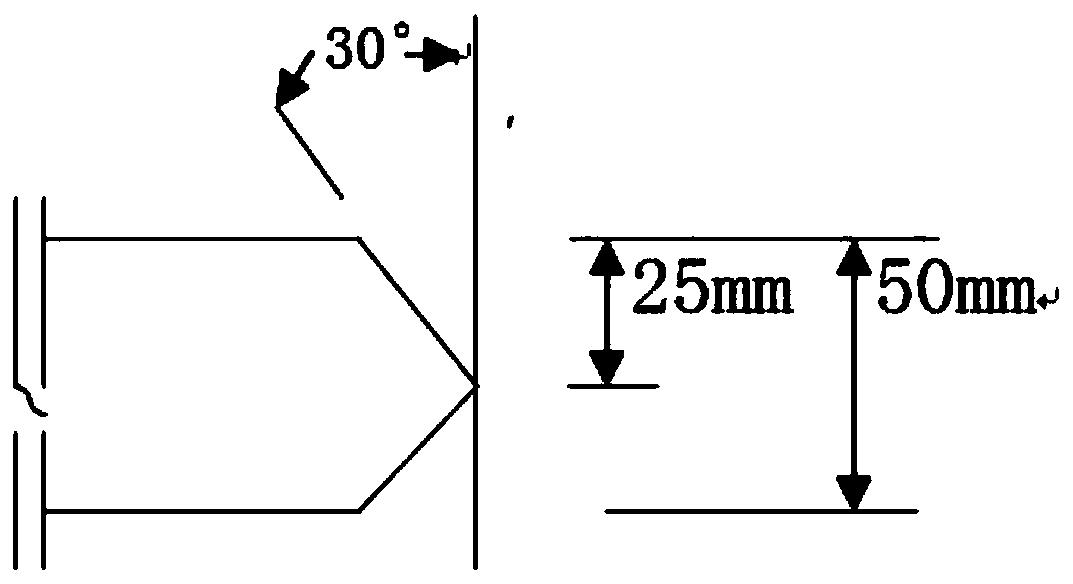

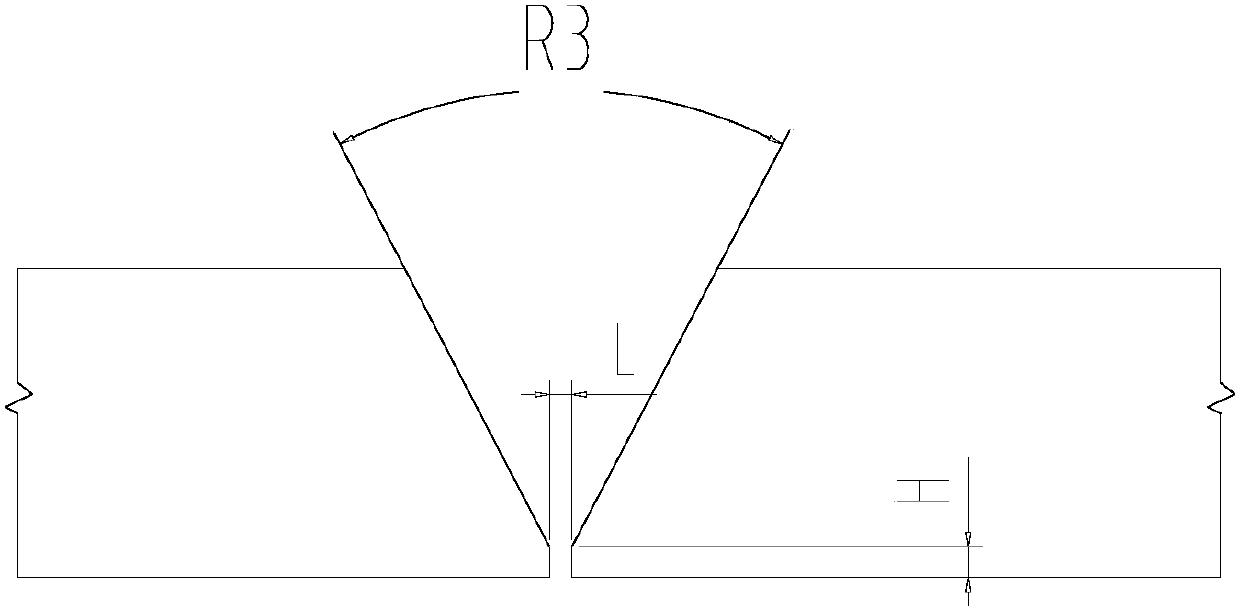

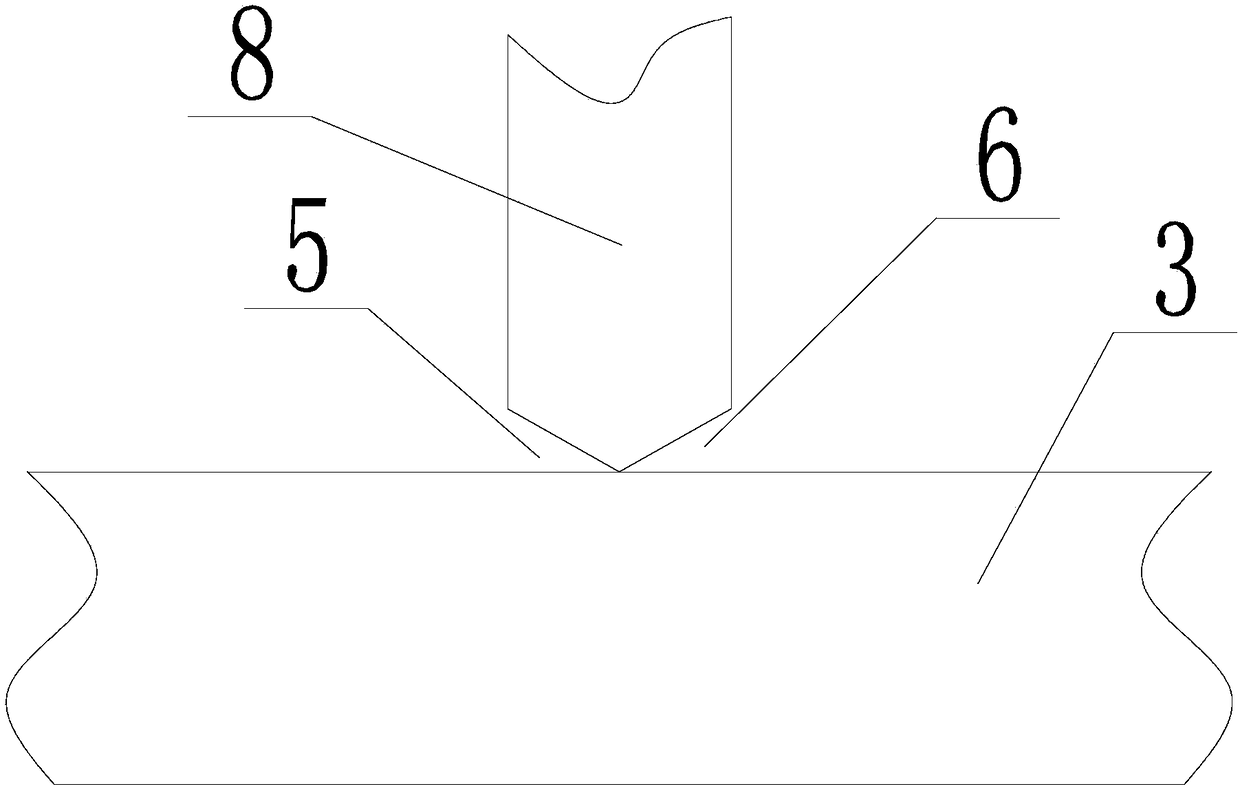

Process for molding I-steel main welding seam non-back chipping full-penetration I-level component

InactiveCN104227182AGuaranteed quality levelReduce production cost inputWelding/cutting auxillary devicesAuxillary welding devicesEngineeringEnergy conservation

The invention discloses a process for molding an I-steel main welding seam non-back chipping full-penetration I-level component and relates to a molding process of light thin-walled I-steel. The process comprises the following steps of preparing a plate, testing welding processing property on the plate, blanking and cutting a flange plate to form a technical beveled edge, cutting or shearing and leveling a technical triangular stiffening plate, positioning and performing full-length welding (single side and singe surface) on the technical triangular stiffening plate, performing submerged-arc door welding on the I-steel, performing ultrasonic (UT) flaw inspection on a main welding seam of an I-steel web, transferring the qualified I-steel component after inspection to the next procedure. When the I-steel is welded, the quality grade of the welding seam can be guaranteed to meet the requirement of full-penetration welding I grade, the deformation of the I-steel is small, back chipping on the opposite surface of a weld bead is not required, backing, filling and surface covering operations which are sequentially performed on the opposite surface of the weld bead are not required, the production cost is relatively low, the production efficiency is relatively high, and the requirements of advanced technology, energy conservation and environment friendliness on construction are met.

Owner:湖北源盛钢构有限公司

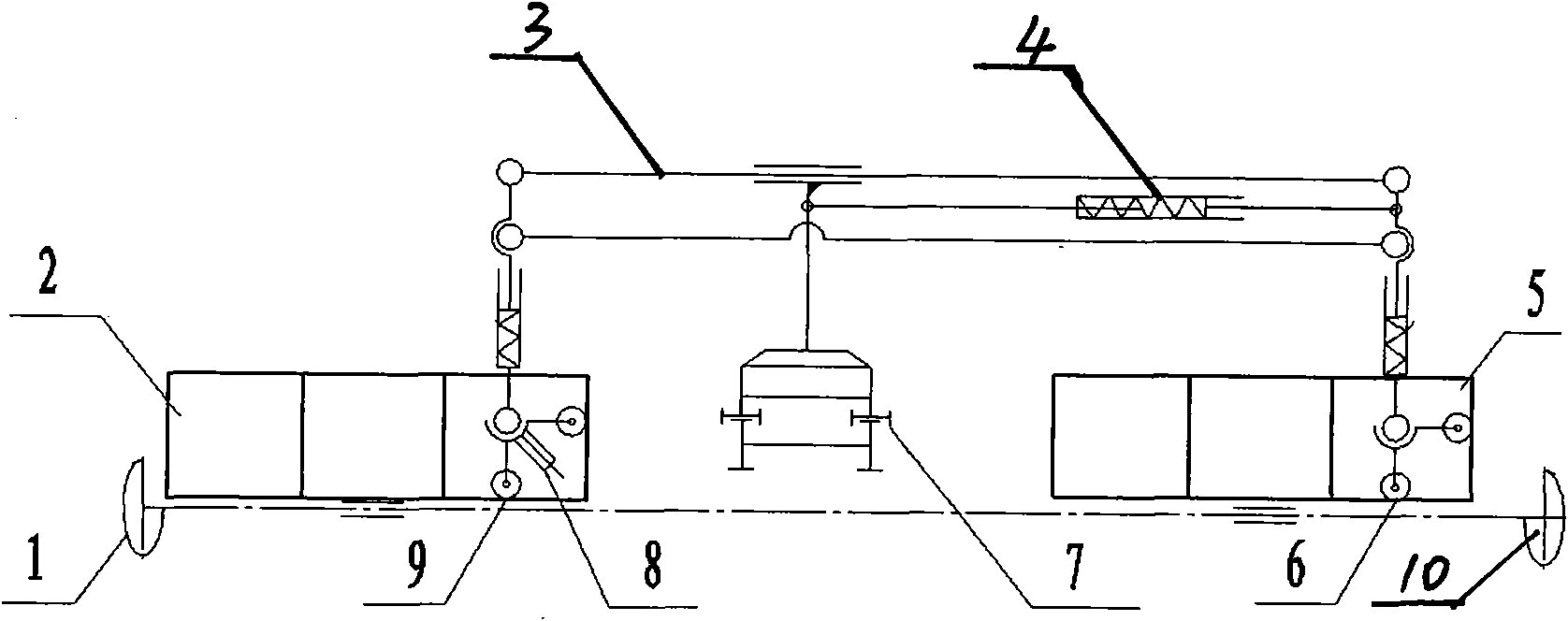

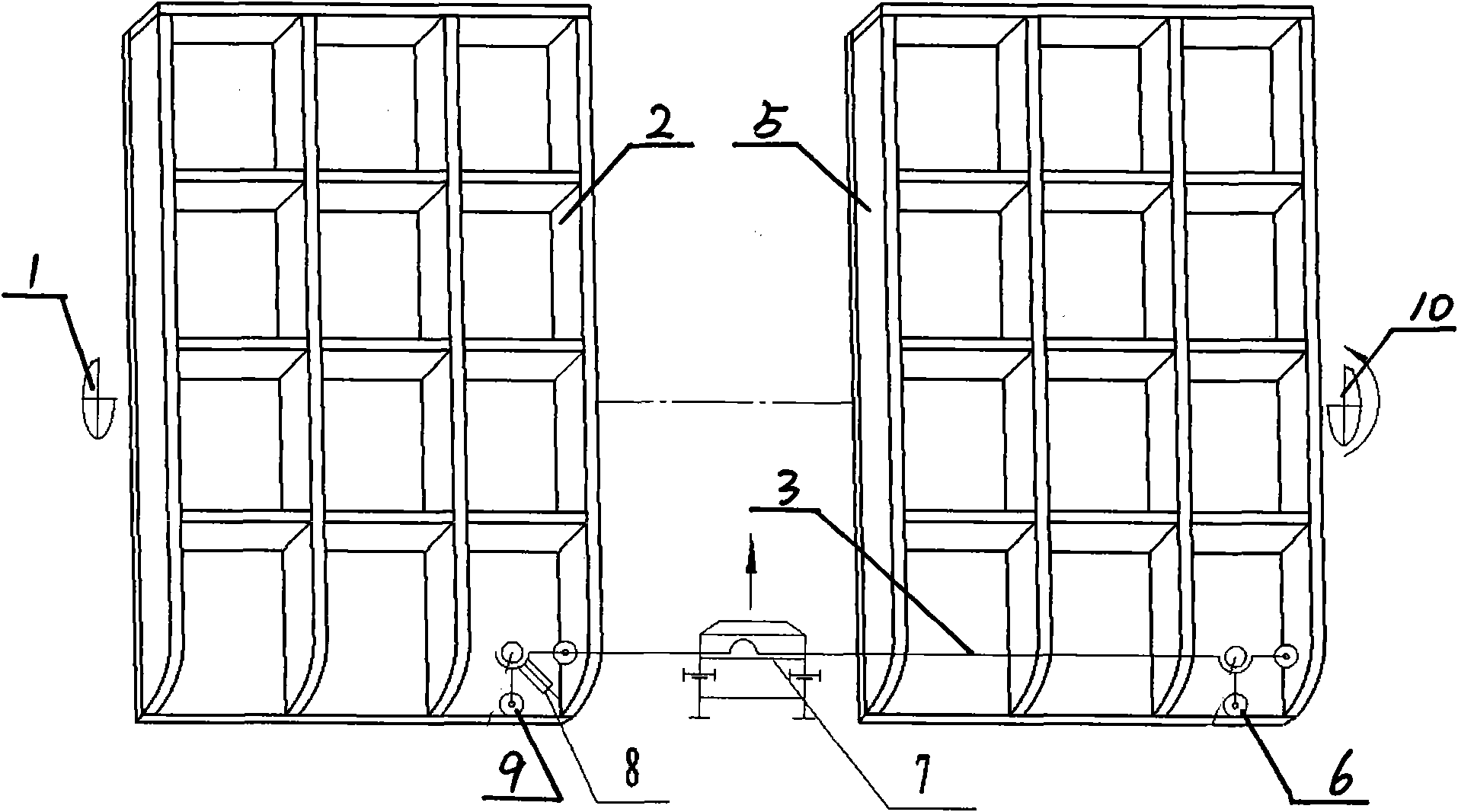

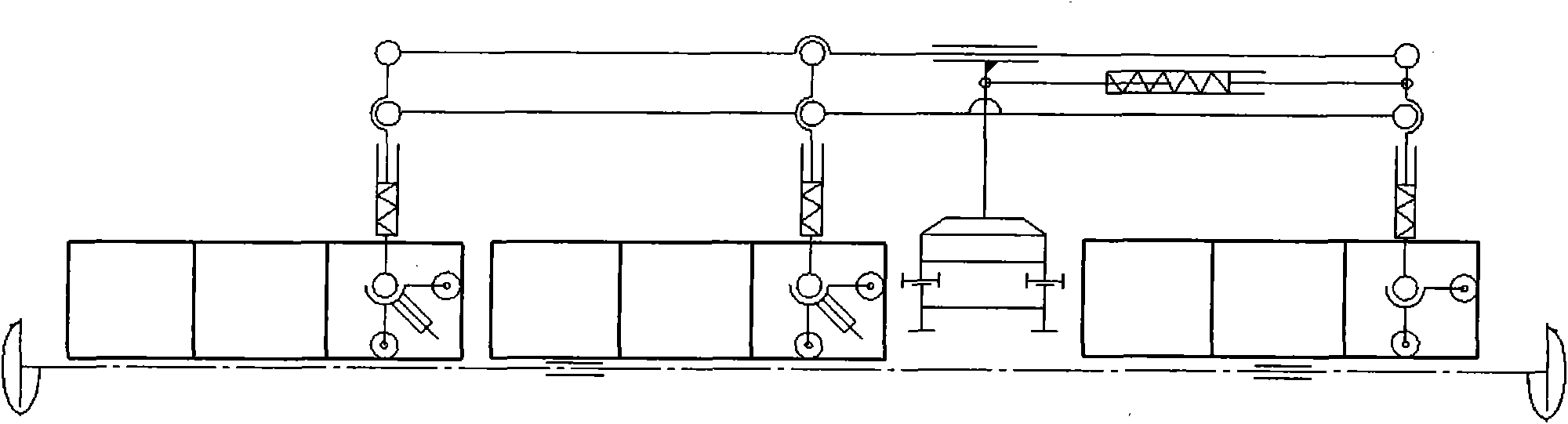

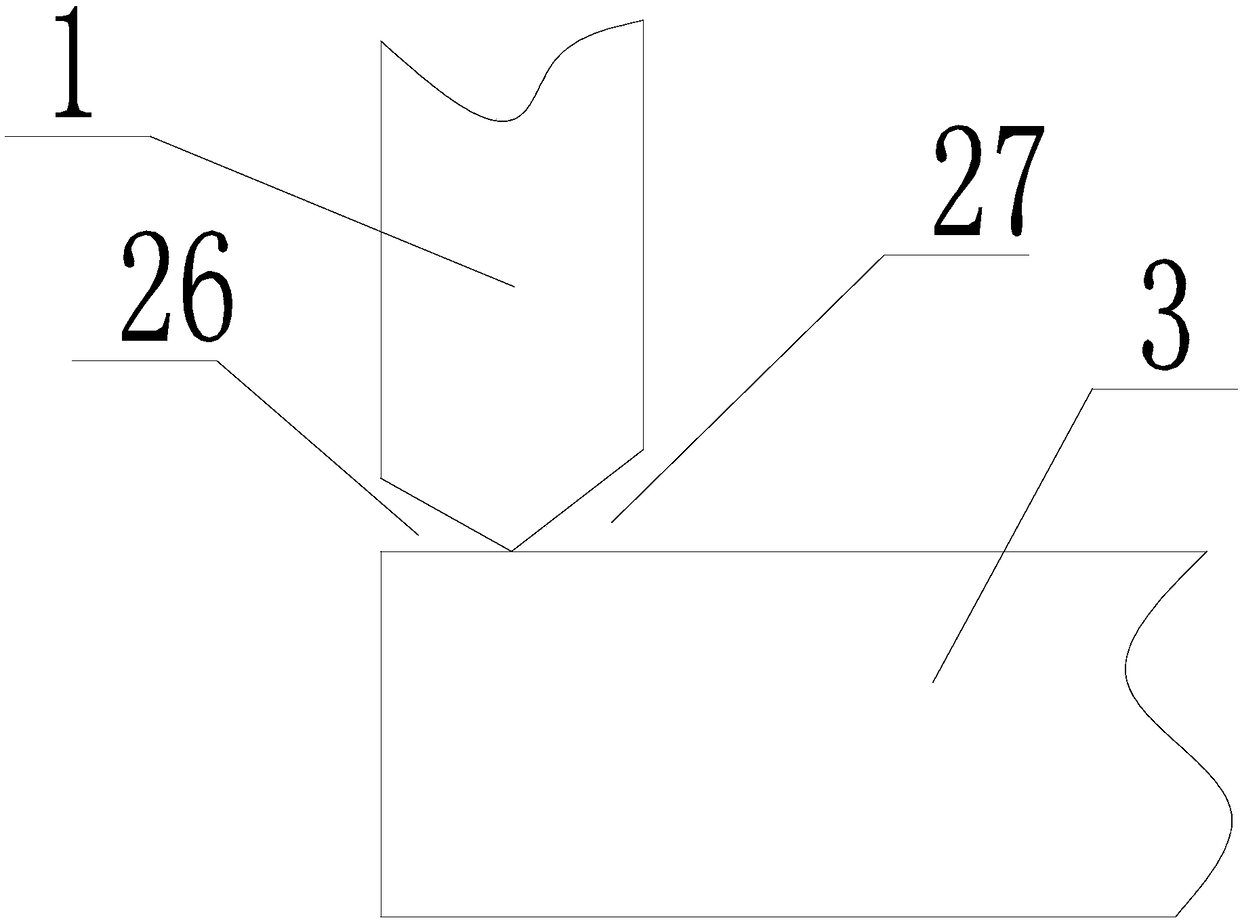

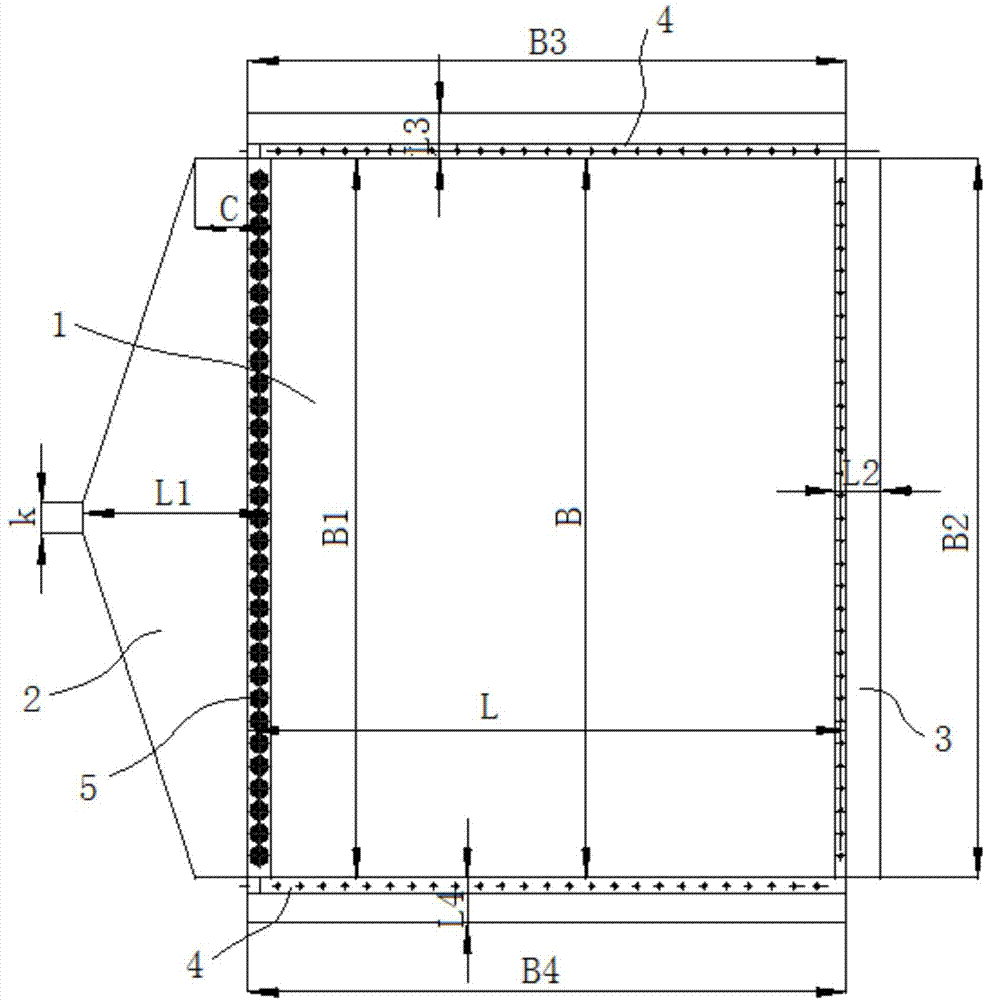

Mutual tack welding method for hydraulic support grid box type structure

InactiveCN101596633ALow implementation costReasonable workmanshipWelding/cutting auxillary devicesArc welding apparatusEngineeringCorner angle

The invention relates to the hydraulic support structural member welding processing field, in particular to a mutual tack welding method for hydraulic support grid box type structure. The invention solves the problems that the existing hydraulic support grid box type structure is processed by manual welding, welding fabrication quality can not be ensured, and the cost of welding by automatic robot is too high; and the method includes the following steps: (1) sorting and mounting welding fabrication grid box type structure; (2) respectively placing two grid box structures on two positioners between which a tack welding position is arranged; (3) realizing positioning of a tack welding device and the two grid box type structures; (4) adjusting arc starting position of a welding gun and arc starting; (5) starting a synchronous shifting device and welding the welding position by the welding gun; (6) controlling the two positioners to turn on the corner and carrying out corner transition welding by the welding gun; (7) welding the welding position in another direction after the welding of the welding position is completed. The technology is reasonable and concise, feasibility is high, welding quality can be ensured, production efficiency is high, and implementation cost is relatively low.

Owner:SHANXI PINGYANG IND MACHINERY

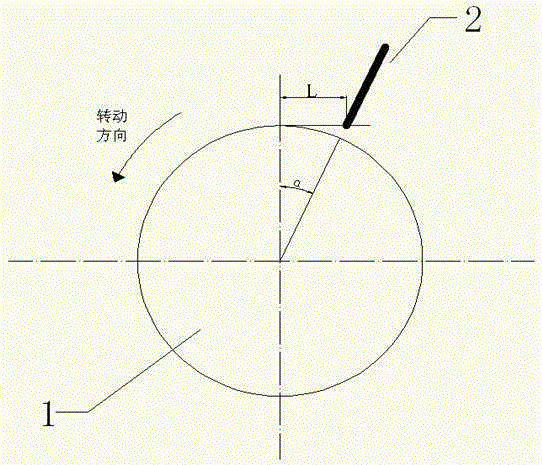

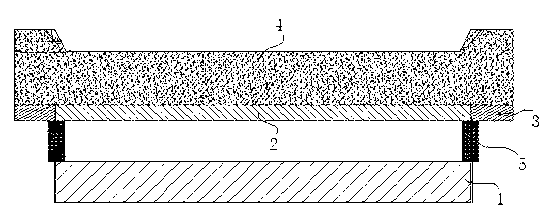

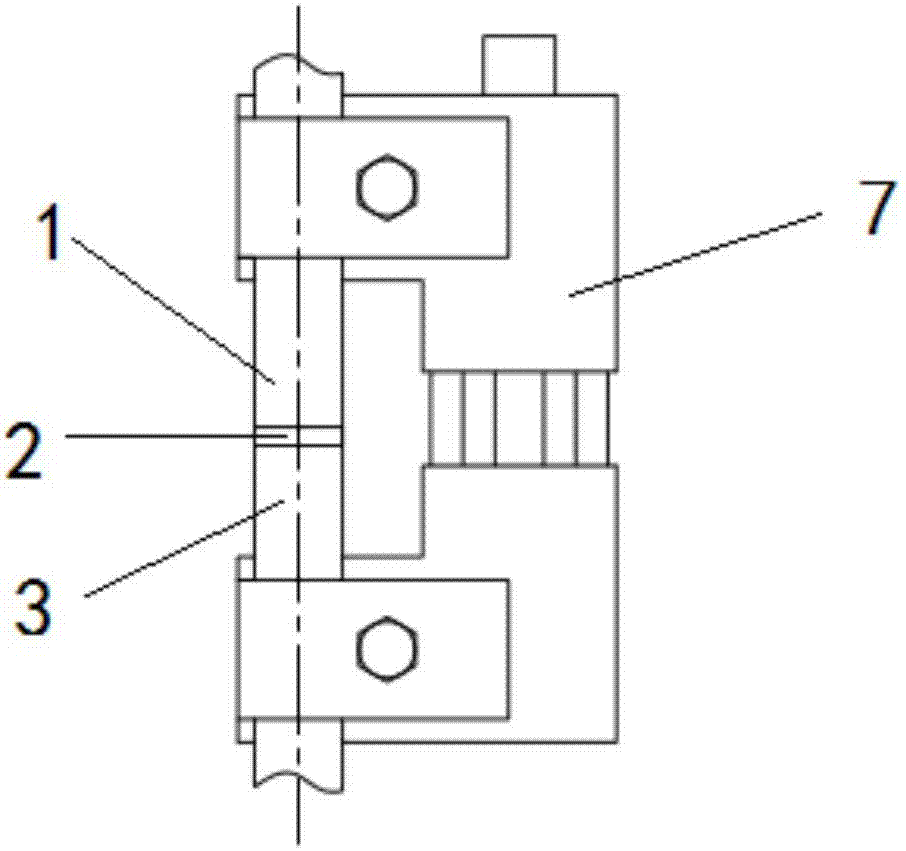

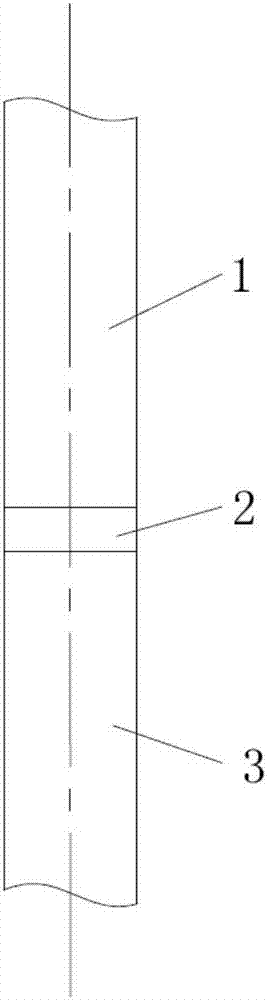

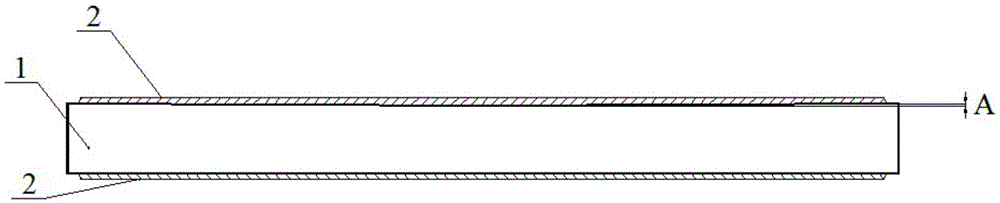

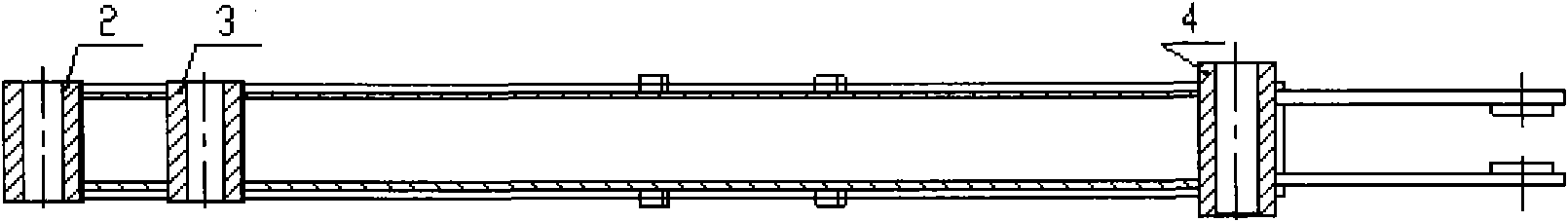

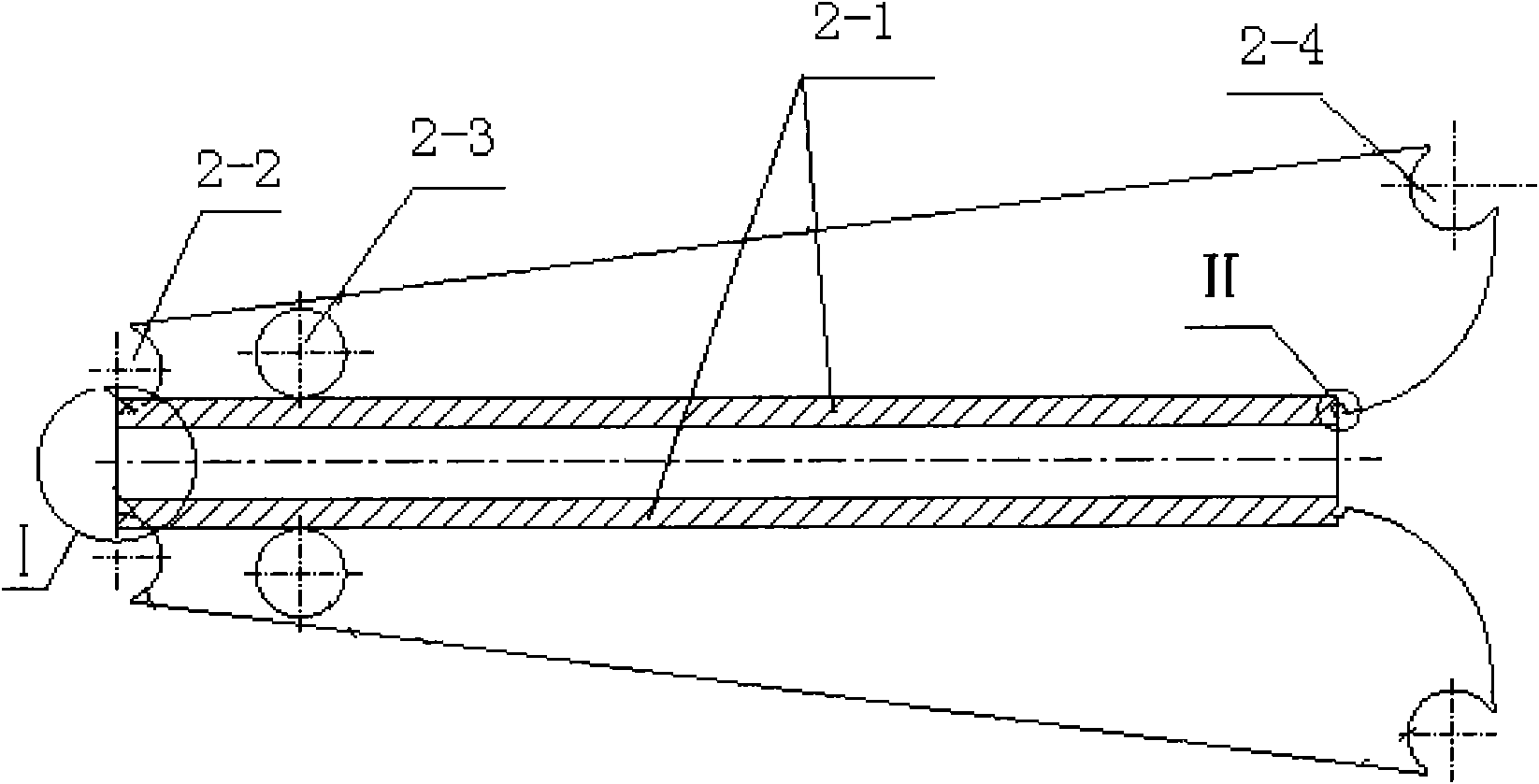

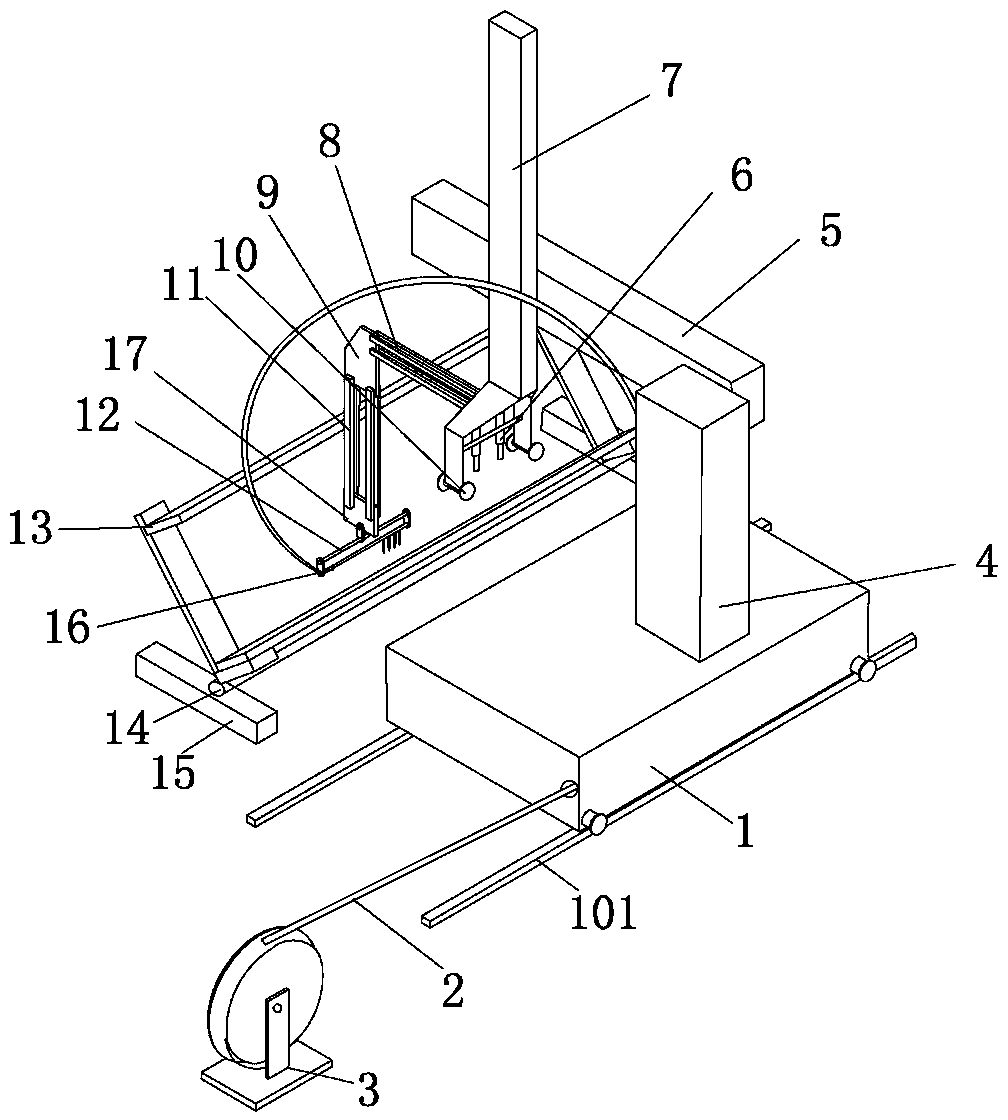

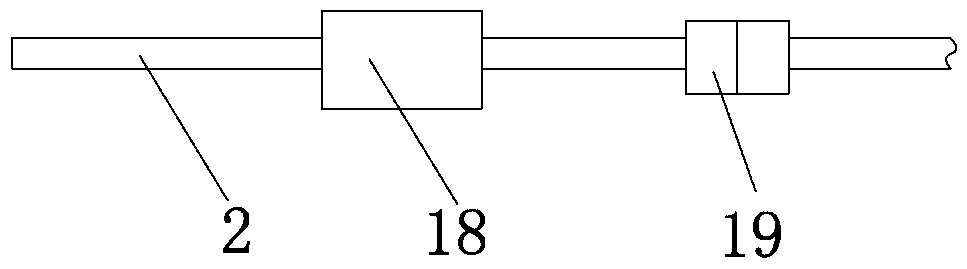

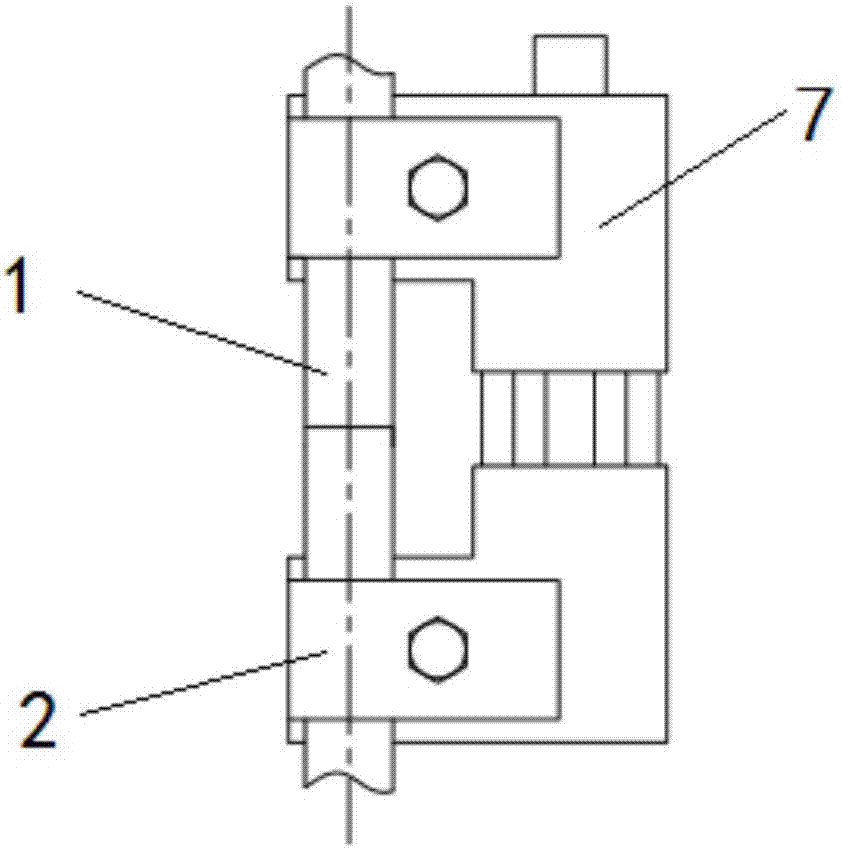

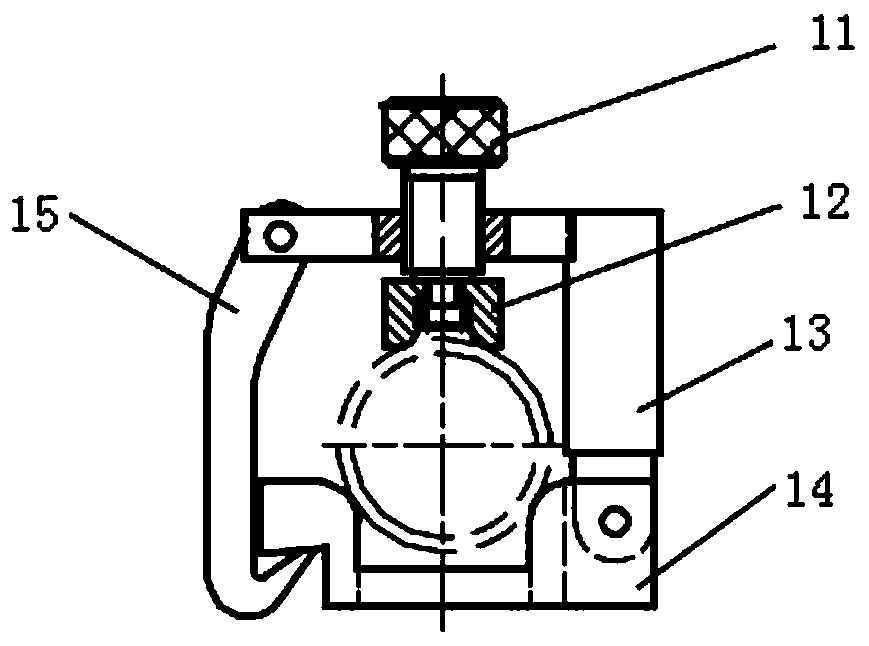

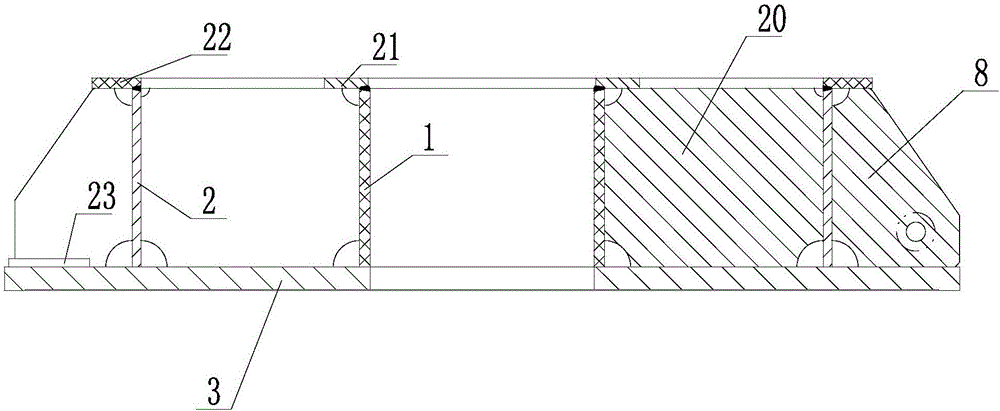

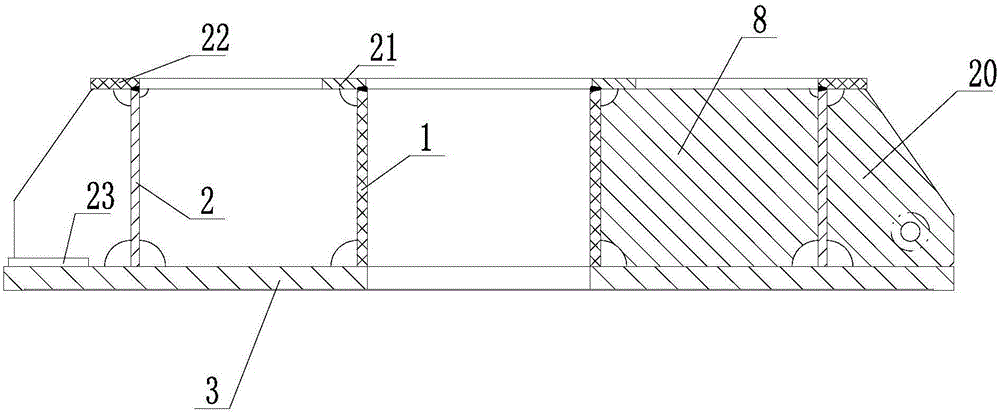

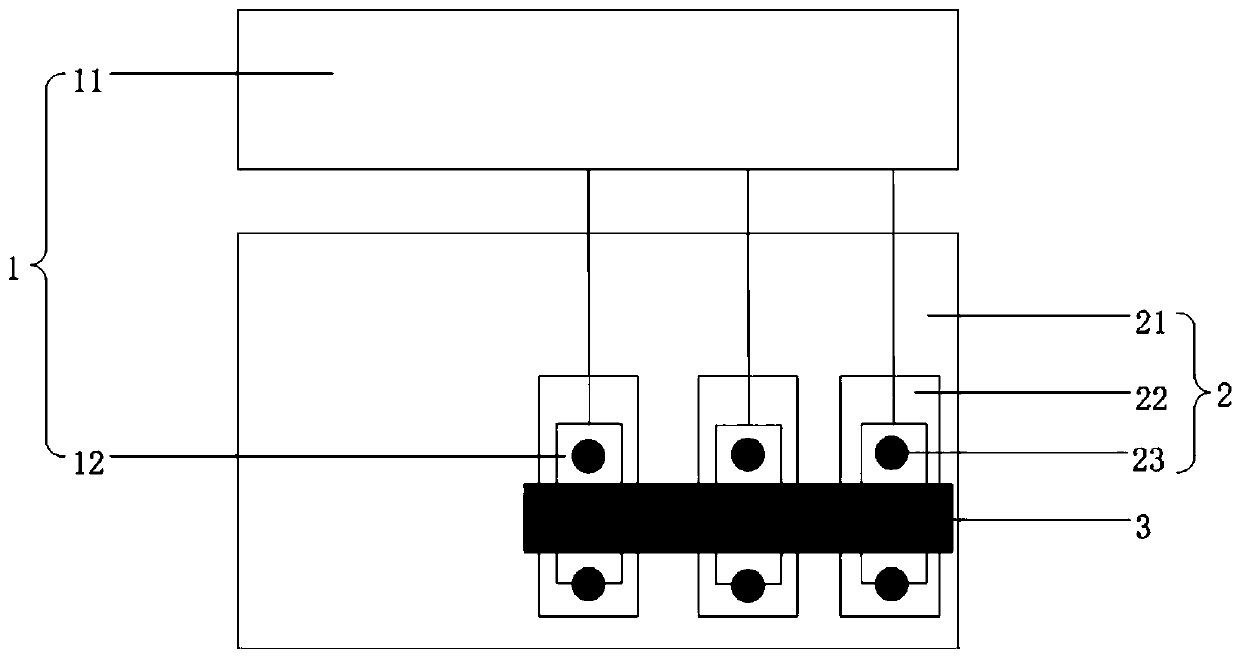

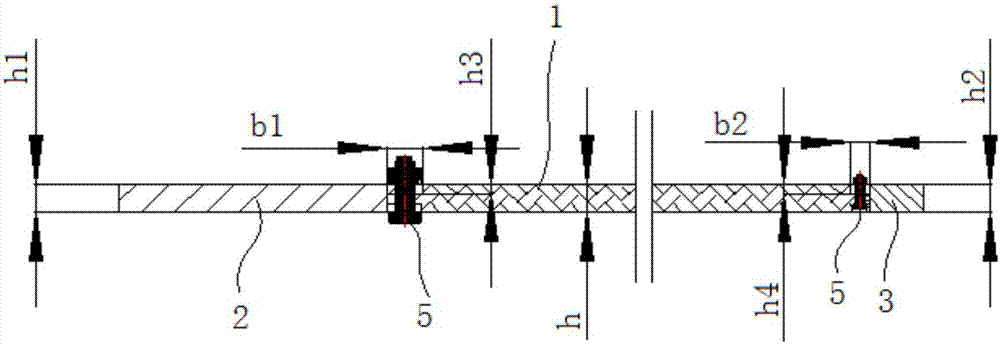

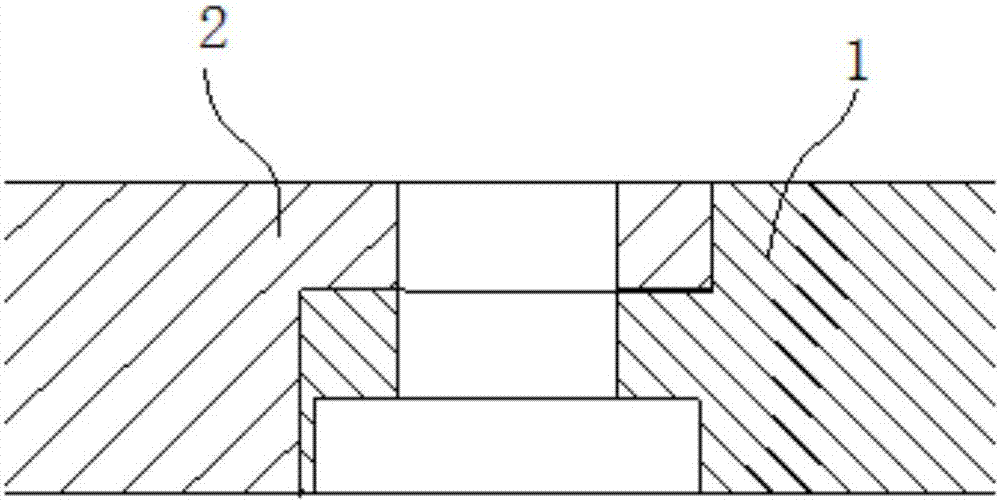

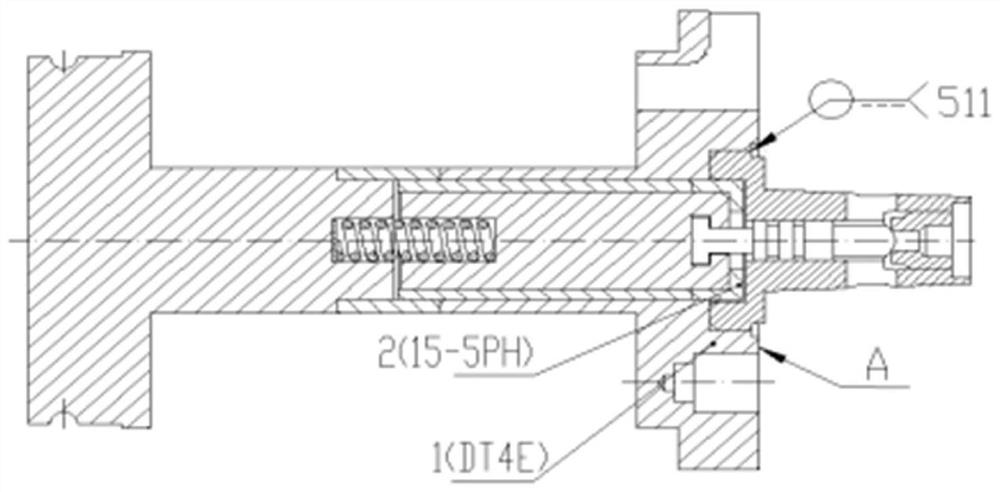

Low-alloy steel heat exchange pipe butt joint automatic welding process for filling molten rings

ActiveCN106944723AGuaranteed performanceGuarantee welding qualityArc welding apparatusHeat exchange apparatusButt jointFilling materials

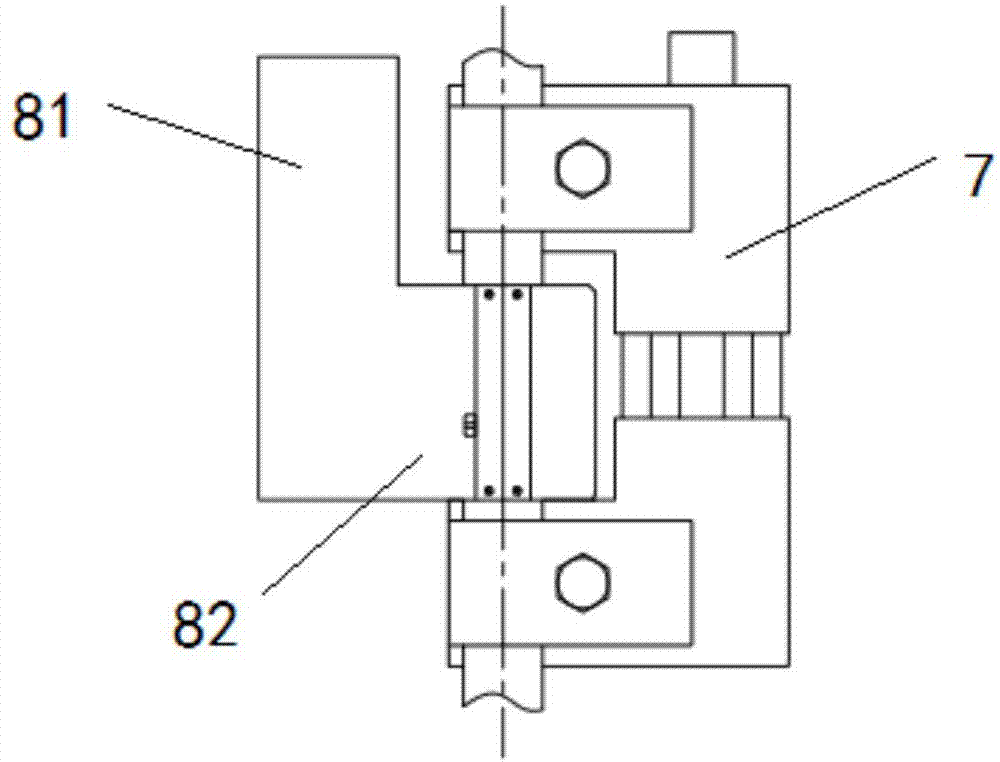

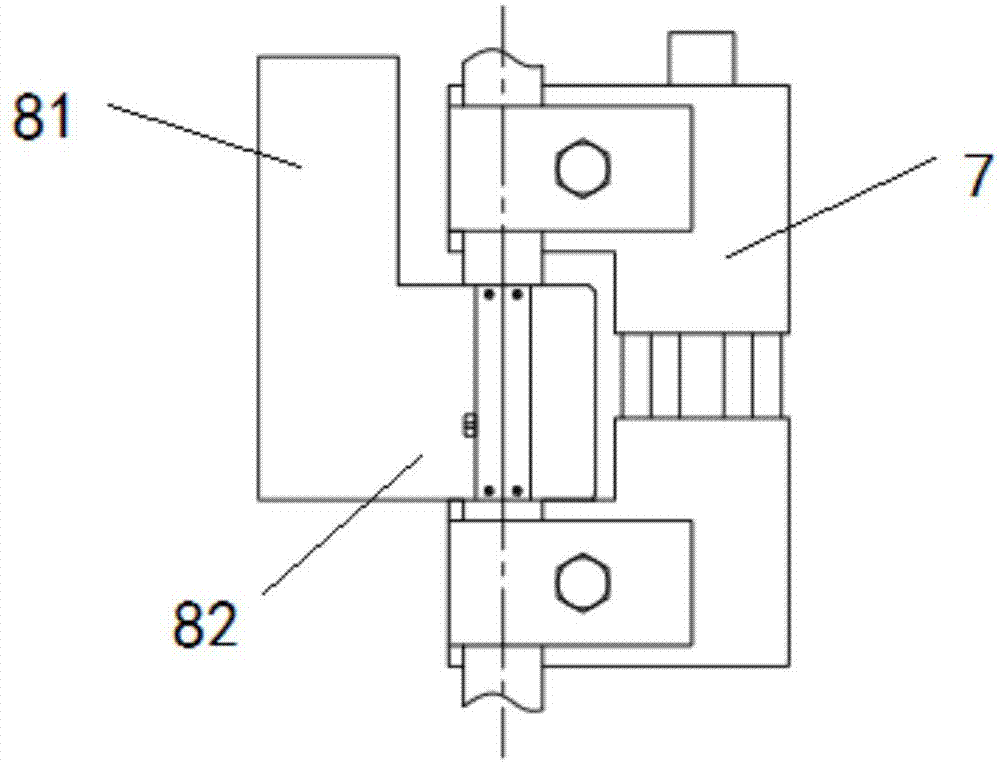

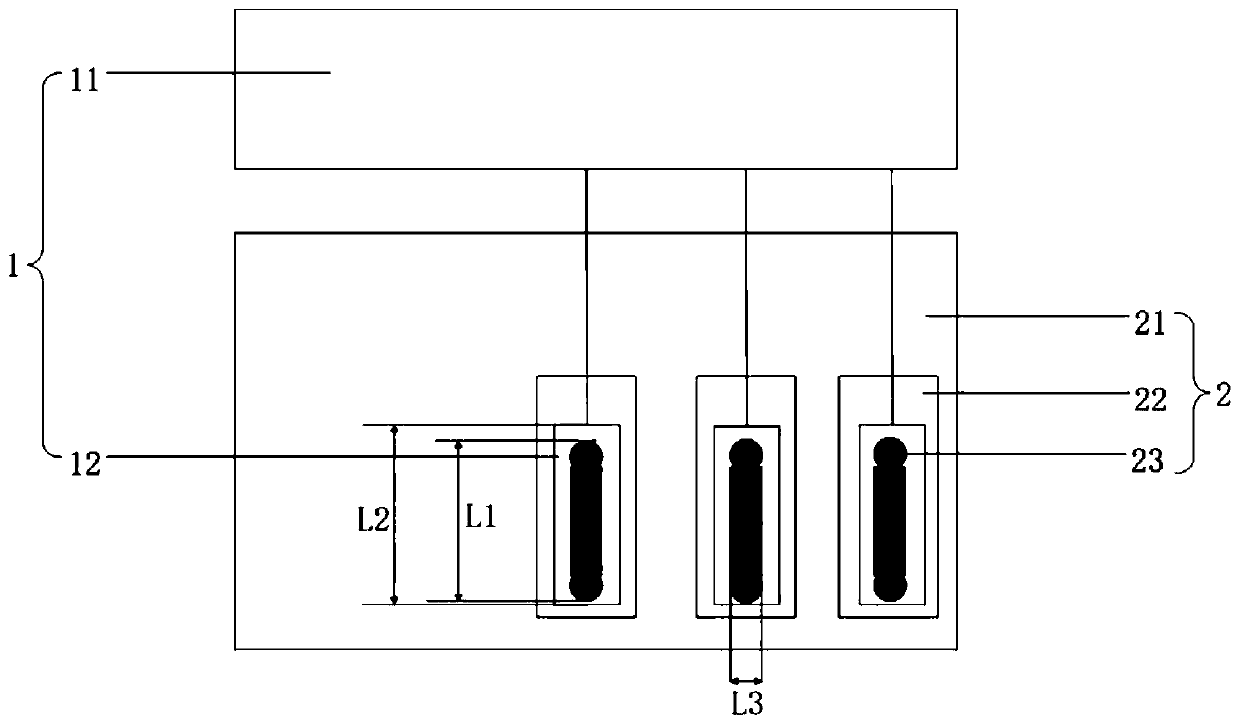

The invention discloses a low-alloy steel heat exchange pipe butt joint automatic welding process. The process adopts the molten rings machined by IN521 materials as filling materials for butt joint of low-alloy steel heat exchange pipes; the axles of a heat exchange pipe I (1) and a heat exchange pipe II (3) are vertically fixed; a tool (7) is adopted to assemble the heat exchange pipes and the molten rings (2) to guarantee coaxiality; a welding machine head is matched and clamped with the tool (7) to control the positions of a tungsten electrode and the molten rings (2); and according to welding parameters and operation requirements of the process, a rotating center of the welding machine head drives the tungsten electrode to rotate around the molten rings (2) for automatic welding. The welding process is stable in welding process, and can effectively control the welding line quality and the welding line formation; and the performances of joints for heat exchange pipe butt joint meet the product requirements.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

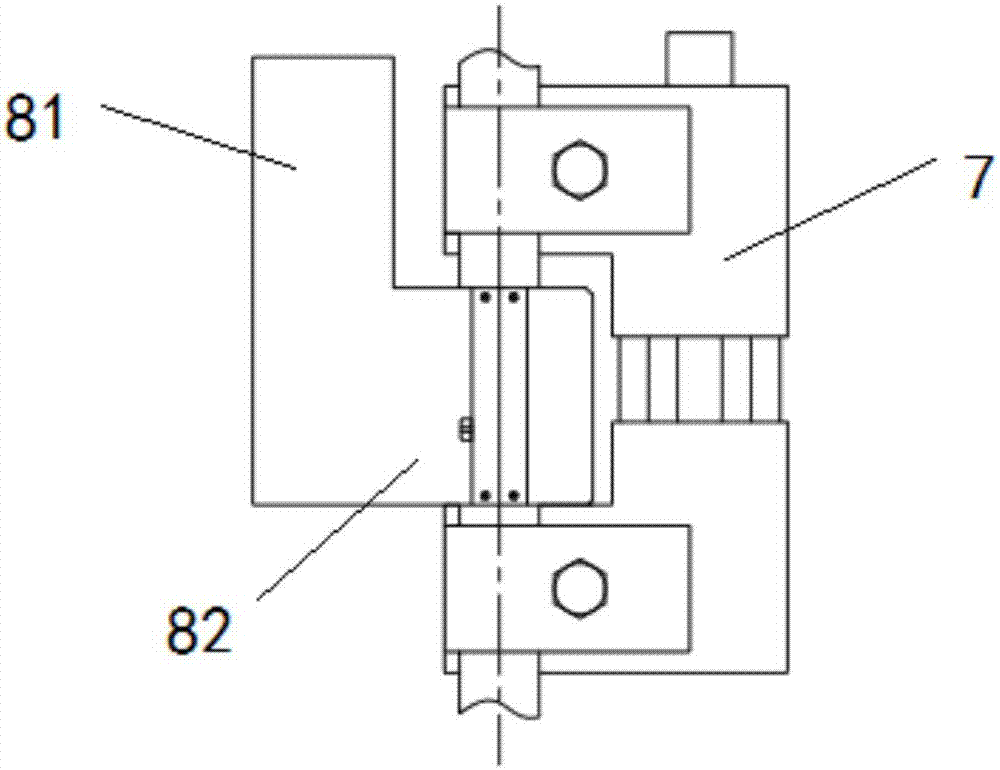

Automatic welding technology for nickel base alloy heat exchange pipe butt joint

ActiveCN106975826AGuaranteed performanceGuarantee welding qualityArc welding apparatusButt jointAlloy

The invention discloses an automatic welding technology for nickel base alloy heat exchange pipe butt joint. The technology comprises the following steps that a heat exchange pipe I (1), a heat exchange pipe II (3) and a melting ring (2) are assembled; welding equipment is installed and debugged; and welding process parameters are set, and welding is conducted. According to the automatic welding technology for nickel base alloy heat exchange pipe butt joint, the heat exchange pipes are fixed in the mode that the axes are vertical, tools (7) are adopted to assemble the heat exchange pipes and the melting ring to guarantee coaxiality of the heat exchange pipes and the melting ring; and a welding machine head of the welding equipment is matched with the tools (7) for clamping, the positions of a tungsten electrode and the melting ring are controlled, and automatic welding is conducted according to the set welding parameters and the operation requirements. The welding technology is stable in welding process and is implemented in small space with the minimum pipe wall interval being 41 mm, the quality of butt joint welding lines between the nickel base alloy heat exchange pipes can be effectively controlled, the situation that the double sides of the formed welding lines between the nickel base alloy heat exchange pipes do not sink can be controlled, meanwhile, the double sides of the formed welding lines do not exceed the surfaces of the heat exchange pipes by 0.45 mm, the magnitude of the pigging diameter phi is guaranteed, and the property of a heat exchange pipe butt joint connector meets the product requirements.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

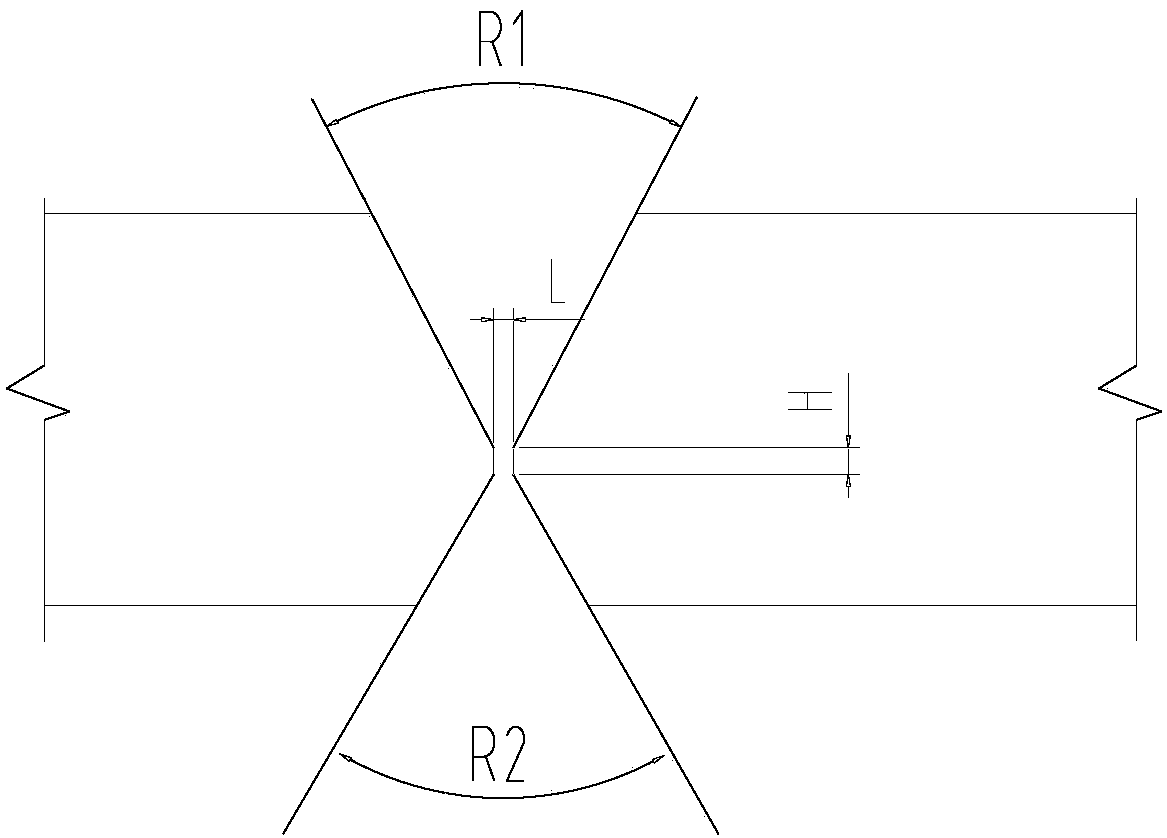

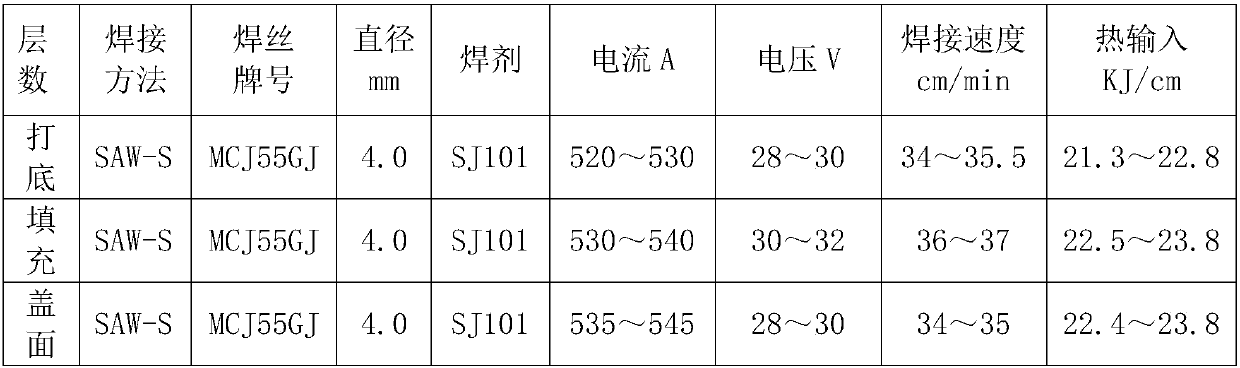

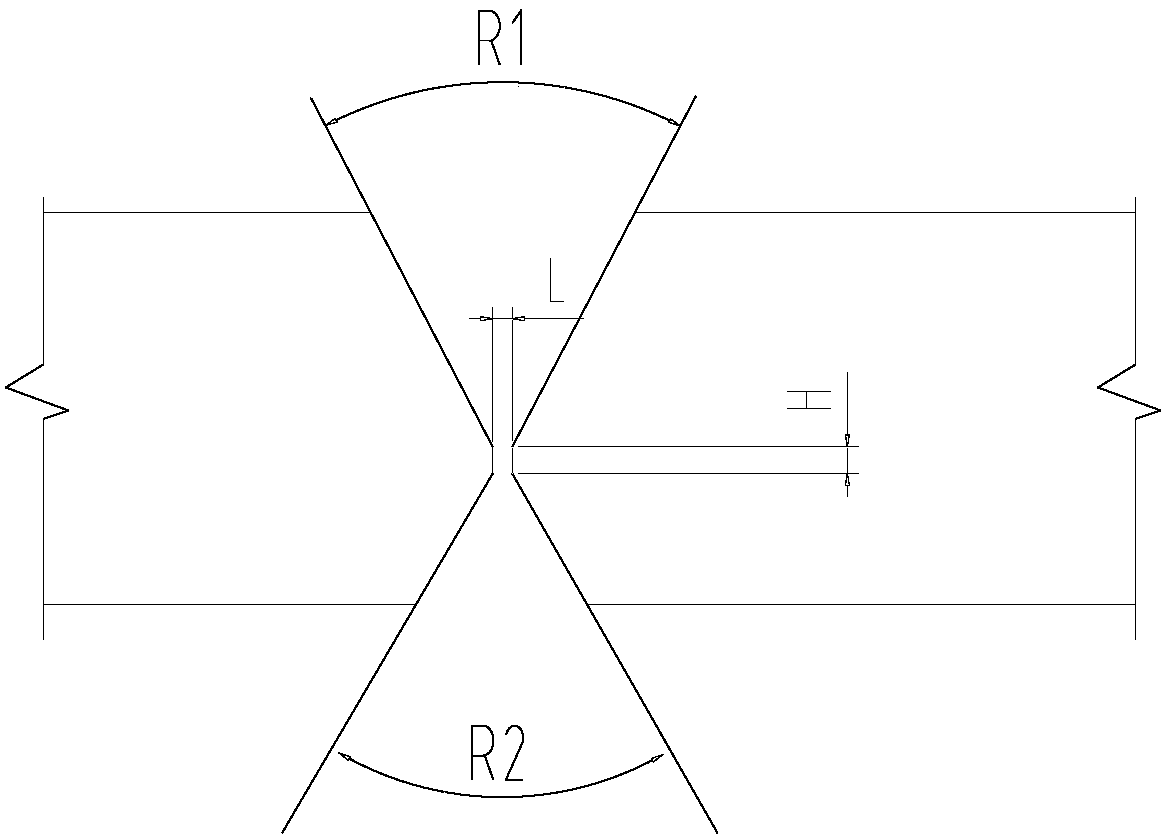

Union melt welding process for steel Q420GJC for building structures

ActiveCN105499770AEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesPower flowEngineering

The invention discloses a union melt welding process for steel Q420GJC for building structures. Welding materials include a welding wire MCJ55GJ with a diameter being phi 4.0mm and a welding flux SJ101; a welding environment temperature is higher than or equal to -10 DEG C; a preheating temperature is 100-150 DEG C; multi-layer and multi-pass welding are adopted, and an interlayer temperature is not lower than the preheating temperature. Conditions of backing weld include that a welding current is 520-530A, a welding voltage is 28-30V, a welding speed is 34-35.5cm / min, and thermal input is 21.3-22.8KJ / cm. Conditions of filling weld include that a welding current is 530-540A, a welding voltage is 30-32V, a welding speed is 36-37cm / min, and thermal input is 22.5-23.8KJ / cm. Conditions of cosmetic weld include that a welding current is 535-545A, a welding voltage is 28-30V, a welding speed is 34-35cm / min, and thermal input is 22.4-23.8KJ / cm. By the union melt welding process, equality in mechanical property of welds and base materials can be realized so as to meet requirements on engineering welding quality, and a gap of union melt welding of the steel Q420GJC is filled.

Owner:鞍钢钢结构(营口)有限公司

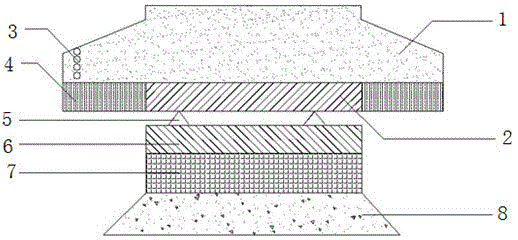

Surfacing welding technology for large-area anti-corrosion layers of tube plate

InactiveCN105478964ASmall amount of deformationReduce welding distortionArc welding apparatusEngineeringSecondary side

The invention discloses a surfacing welding technology for large-area anti-corrosion layers of a tube plate. The technology includes the steps that the tube plate is assembled and positioned, and the portion to-be-welded is cleared; welding equipment is installed and debugged, and welding technological parameters are input; straight welding pass surfacing welding is carried out at the primary side of the tube plate, after one layer is formed through surfacing welding, the tube plate is turned over by 180 degrees, and straight welding pass surfacing welding is carried out at the secondary side of the tube plate; welding operation is repeated until the anti-corrosion layers of the specific thickness are formed at the two sides of the tube plate. According to the welding technology, the deformation of the tube plate can be as low as 1 mm or below after the welding technology is completed, the welding process is stable, weld joints are formed uniformly, fusion between layer passes is good, and the requirement for welding quality of nuclear island main equipment can be met.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

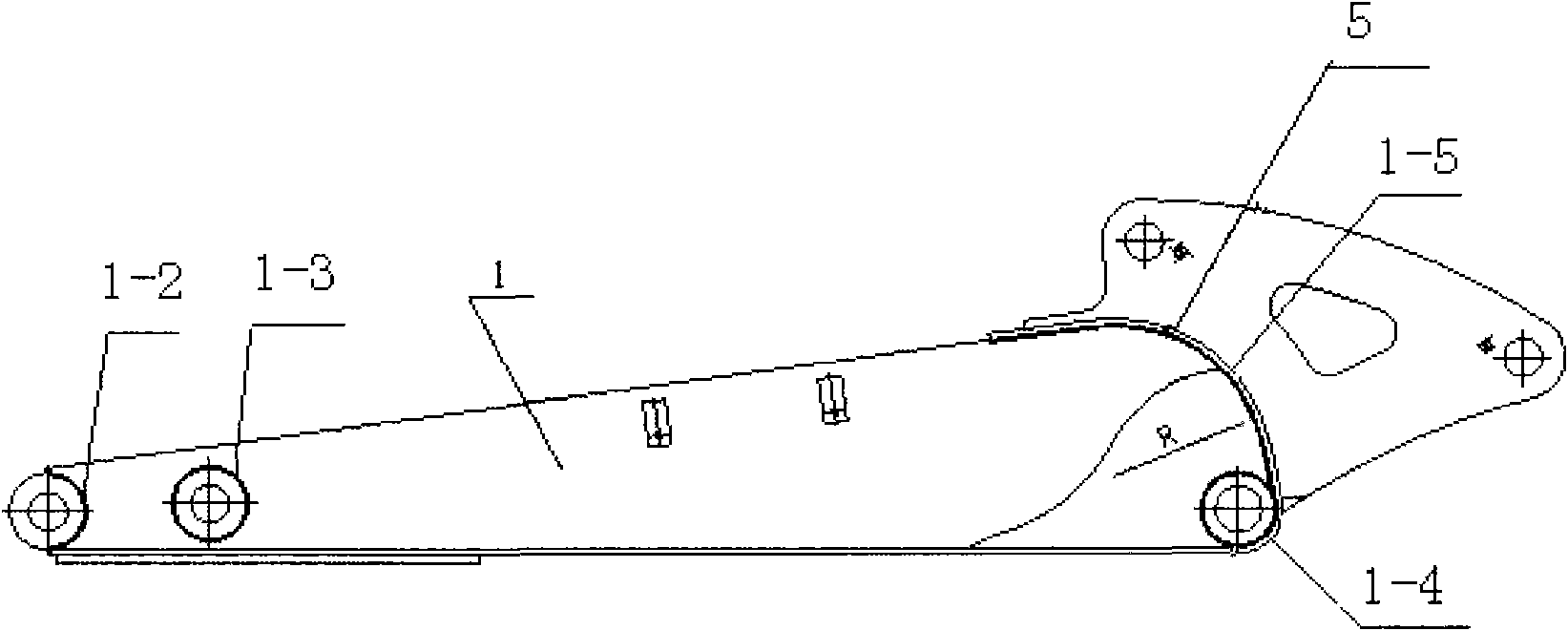

Bucket rod slot plate forming method of 6-ton digging machine

The invention relates to a bucket rod slot plate forming method of a 6-ton digging machine. The method comprises the following steps: calculating the press bending unfolding length l of a bucket rod slot plate according to a metal plate material press bending process design specification standard; and determining the positions of three shaft holes on the bucket rod slot plate by a geometrograph method through adding the straight line length to the circular arc unfolding length l. The invention is characterized in that the minimum bending edge height h is preserved at the first axial hole; the center position of the circular arc R of the bucket rod slot plate needs to be downwards moved by a distance K between 1.5 and 2 mm; a transverse crack-resistance slot is formed at the end part of the circular arc R of the bucket rod slot plate; a gas flame cutting method, a plasma cutting method, a precision plasma cutting method or a laser cutting method are adopted for baiting; the materials are bended and formed after being cut; and finally, the circular arc at the first axial hole is positioned and cut. The invention has the advantages that the size after the press bending is precise, in addition, no cracking condition occurs, and the welding quality requirement is met. The reasonable cutting methods are reasonably selected according to the requirements, and high quality and high speed of the manufacture of the press bending forming parts can be reached.

Owner:龙工(上海)机械制造有限公司 +2

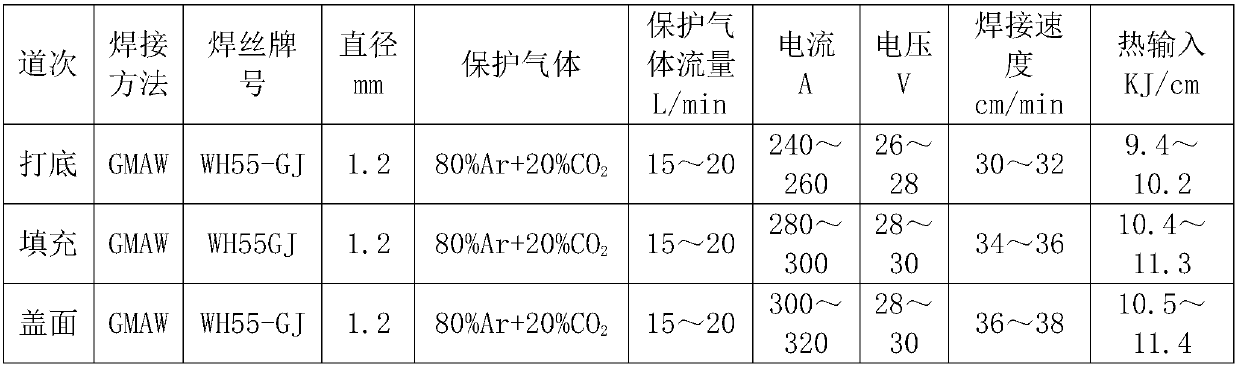

Gas shielded welding technology of steel Q420GJC for building structure

ActiveCN105598563AEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesEngineeringMechanical property

The invention provides a gas shielded welding technology of steel Q420GJC for a building structure. The technology comprises the steps that a welding material is prepared, wherein welding wires WH5-GJ with the diameter phi of 1.2 mm are prepared; the welding environment temperature is higher than or equal to minus 10 DEG C; the preheating temperature is 100 DEG C-150 DEG C; multi-layer and multi-pass welding is performed, and the interlayer temperature is no lower than the preheating temperature; weld joint priming is performed, wherein the welding current is 240-260 A, the welding voltage is 26-28 V, the welding speed is 30-32 cm / min, and heat input is performed at 9.4-10.2 KJ / cm; weld joint filling is performed, wherein the welding current is 280-300 A, the welding voltage is 28-30 V, the welding speed is 34-36 cm / min, and heat input is performed at 10.4-11.3 KJ / cm; weld joint capping is performed, wherein the welding current is 300-320 A, the welding voltage is 28-30 V, the welding speed is 36-38 cm / min, and heat input is performed at 10.5-11.4 KJ / cm. Q420GJC steel welding is performed by adopting the welding technology, the mechanical property same as that of base metal is obtained, the quality requirements of engineering welding are met, and a gap of gas shielded welding of the Q420GJC steel is filled.

Owner:鞍钢钢结构(营口)有限公司

Explosive welding method of metal clad plate of super-thick shroud plate

InactiveCN104096962AGuarantee welding qualityMeet welding quality requirementsMetal working apparatusNon-electric welding apparatusBond interfaceEngineering

The invention discloses an explosive welding method of a metal clad plate of a super-thick shroud plate. The explosive welding method comprises the following steps of 1) pretreating substrate and shroud plate blanks; 2) arranging an extension plate at the periphery of the shroud plate; 3) arranging a substrate and the shroud plate; 4) laying main charge and auxiliary charge; 5) producing and arranging a priming device; 6) carrying out explosive welding. According to the explosive welding method, the welded rate of the clad plate welded through the process reaches 100%, the bonding strength of a welding surface conforms to a strength rule of duplex metal solid phase metallurgical bonding, a bonding interface of the welding surface is in a shape like a micro-wave with excellent quality, the impurity content of the interface is not higher than the corresponding impurity content of raw materials, and the welding quality requirements on the clad plate are completely met.

Owner:王晖 +2

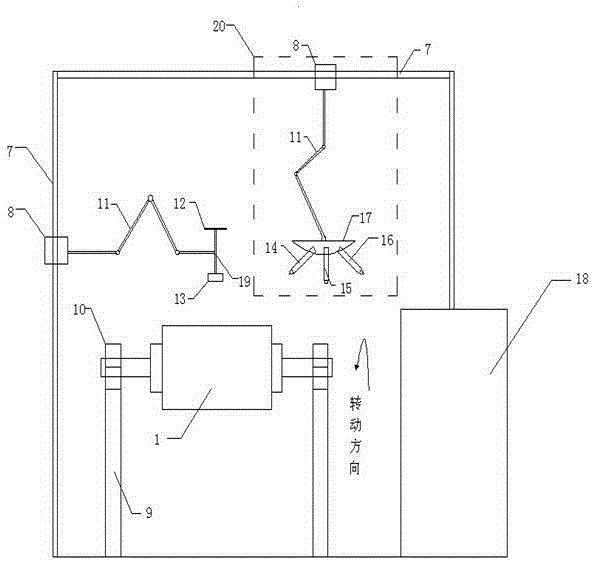

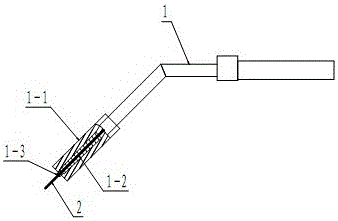

Preheating welding equipment

InactiveCN108705187AAdapt to welding preheating requirementsEasy to manageWelding accessoriesTorchHigh intensity

The invention relates to preheating welding equipment. The preheating welding equipment comprises an arc welding machine and a movable platform. The arc welding machine is arranged on the movable platform. The arc welding machine and the movable platform are connected through a connecting arm. The connecting arm is further connected with a multi-head heating torch. The arc welding machine and themulti-head heating torch are arranged in the same axial direction, and the multi-head heating torch is connected with an air linkage pipe. The preheating welding equipment has the beneficial effects that the arc welding machine and the multi-head heating torch are arranged in the same axial direction, high efficiency and safety can be achieved, management is convenient, input is little, the preheating welding equipment can conduct synchronous construction with welding, the high-strength steel welding preheating requirement is met, and accordingly the welding technology and welding quality requirements are met.

Owner:SHANGHAI COSCO KAWASAKI HEAVY IND STEEL STRUCTURE

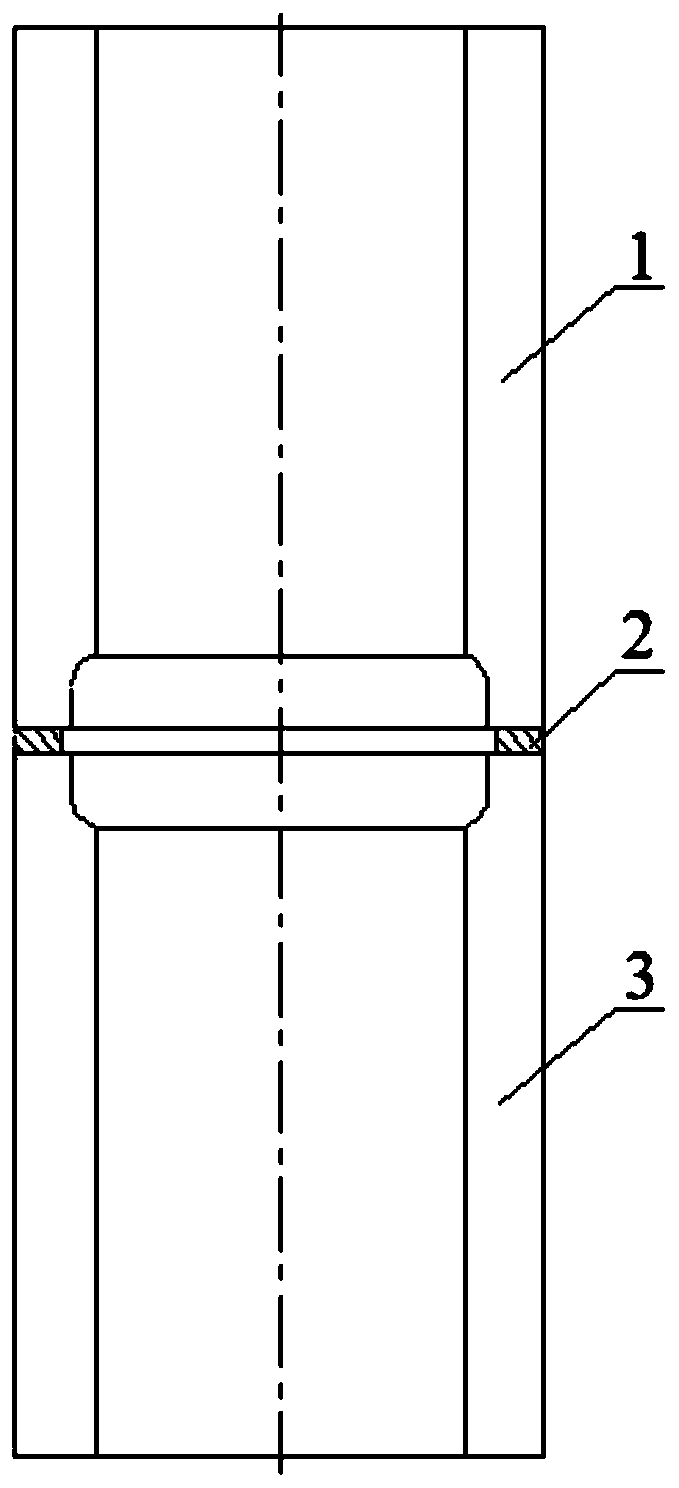

Filling-material-free low-alloy steel heat-exchange pipe butt-joint automatic welding technique

ActiveCN107052536AGuarantee welding qualityFully formedArc welding apparatusWelding/soldering/cutting articlesButt jointFilling materials

The invention provides a low-alloy steel heat-exchange pipe butt-joint automatic welding technique. The technique comprises the following steps that a first heat exchange pipe (1) and a second heat exchange pipe (2) are assembled; welding equipment is mounted and debugged; and welding technological parameters are arranged, and welding treatment is conducted. The low-alloy steel heat-exchange pipe butt-joint automatic welding technique is free of a filling material, a tool (7) is adopted for assembly of the heat exchange pipes, and the coaxial effect is ensured; and a welding machine head and the tool (7) are matched for clamping, and the positions of a tungsten electrode and the heat exchange pipes are controlled; and according to the welding parameters and the operating requirements of the technique, the rotation center of the welding machine head drives the tungsten electrode to rotate to conduct self-melting automatic welding, the welding process is stable, the welding seam quality and welding seam forming can be effectively controlled, and the performance of a heat exchange pipe butt-joint connector meet the requirement of a product.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

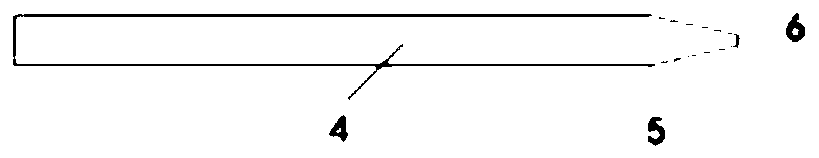

Automatic superposition pulse single-pass welding system and method for stainless steel pipe abutting connection

ActiveCN110508909AGuarantee welding qualityFully formedMetal working apparatusTubular articlesSpot weldingMaterials science

The invention provides an automatic superposition pulse single-pass welding system and method for stainless steel pipe abutting connection. The system comprises a stainless steel abutting connection pipe and a TIG welding machine. The method comprises the steps that during welding, the end parts of a casing and connecting piece and the inner diameter of a melting ring are machined and cleaned; thecasing, the connecting piece and the melting ring are assembled, and spot welding is carried out; after the welding equipment is installed and debugged, welding parameters are set, and welding is carried out. According to the automatic superposition pulse single-pass welding system and method for the stainless steel pipe abutting connection, under the condition that the electric heater of a voltage stabilizer is dense, the distance between the pipes is small and the welding operation space is small, effective welding between the casing of an electric heater and the connecting piece can be effectively realized; and a workpiece and a tungsten electrode are prevented from being in an overheated state for long time, so that the welding process is stable, and good weld forming and welding quality can be obtained.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

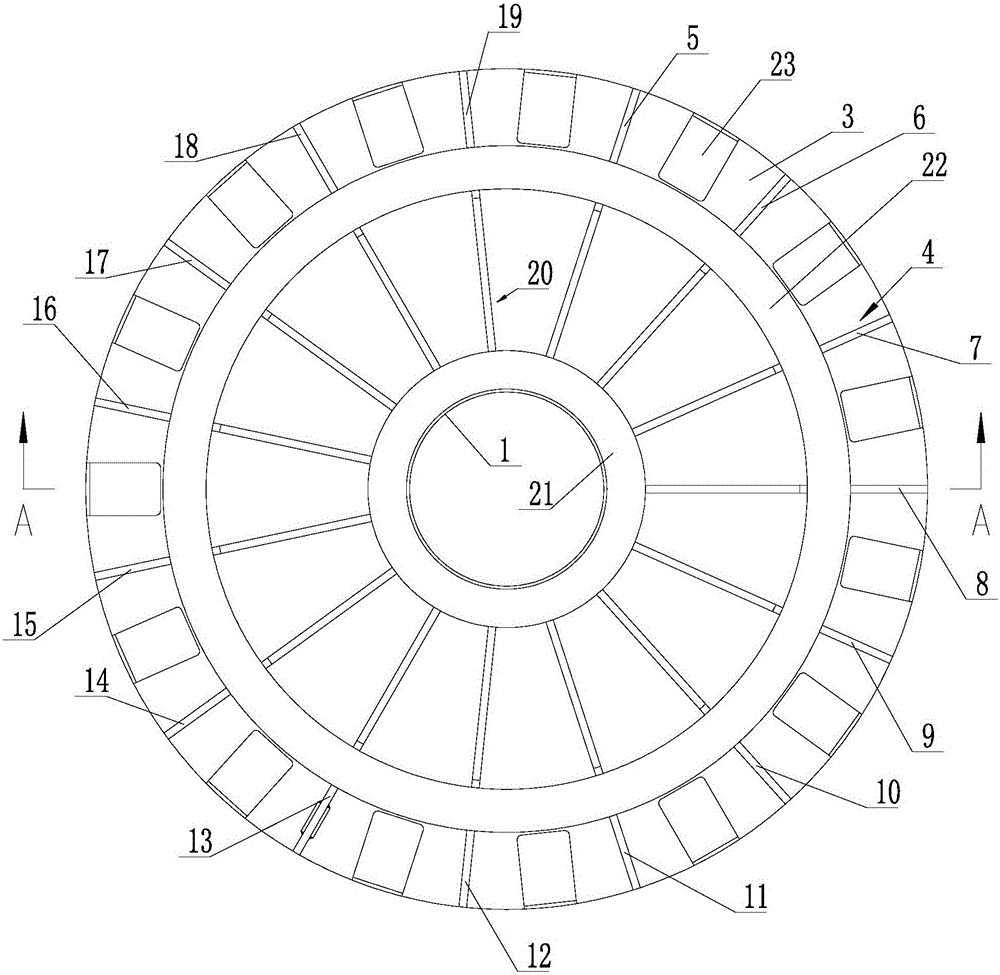

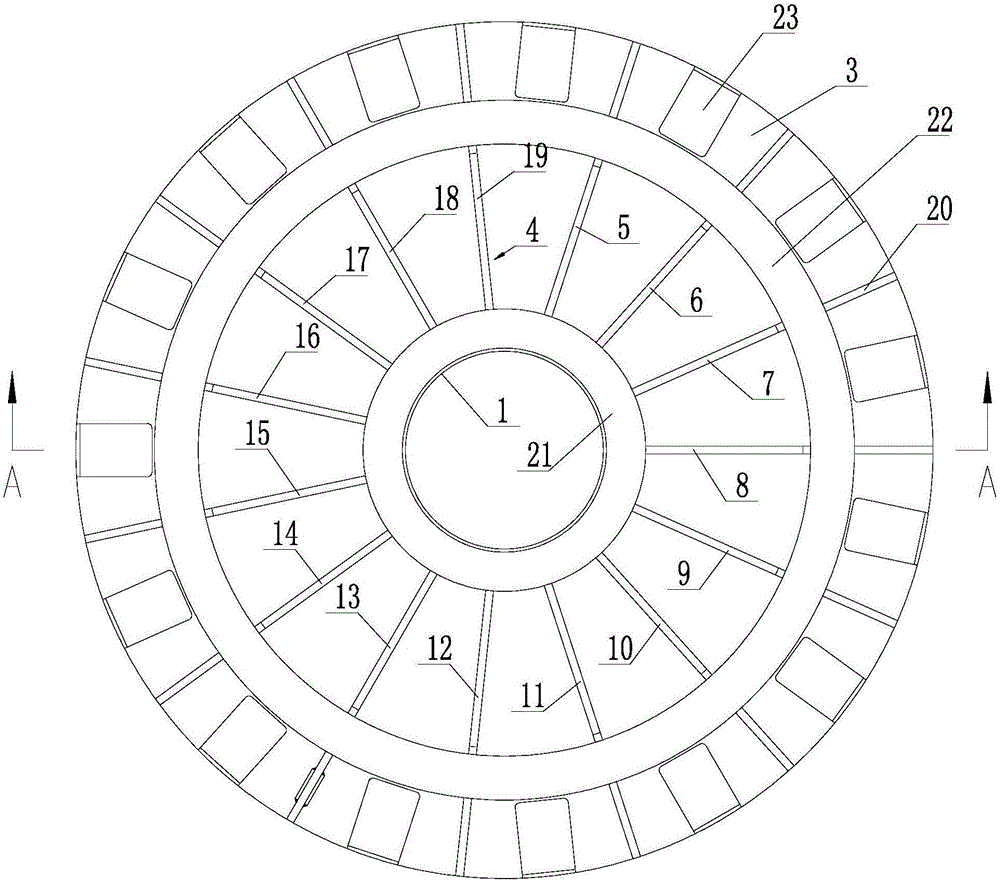

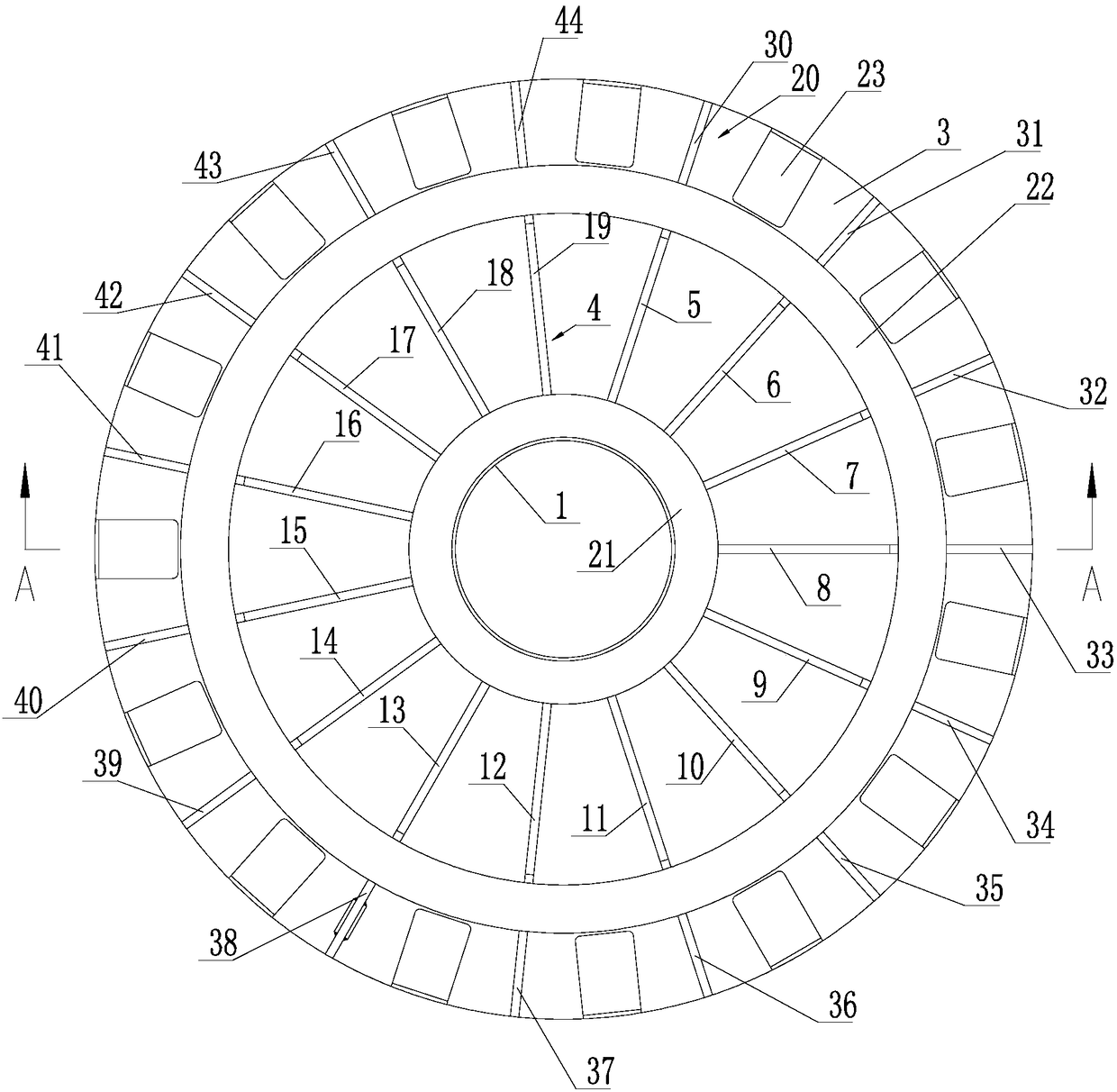

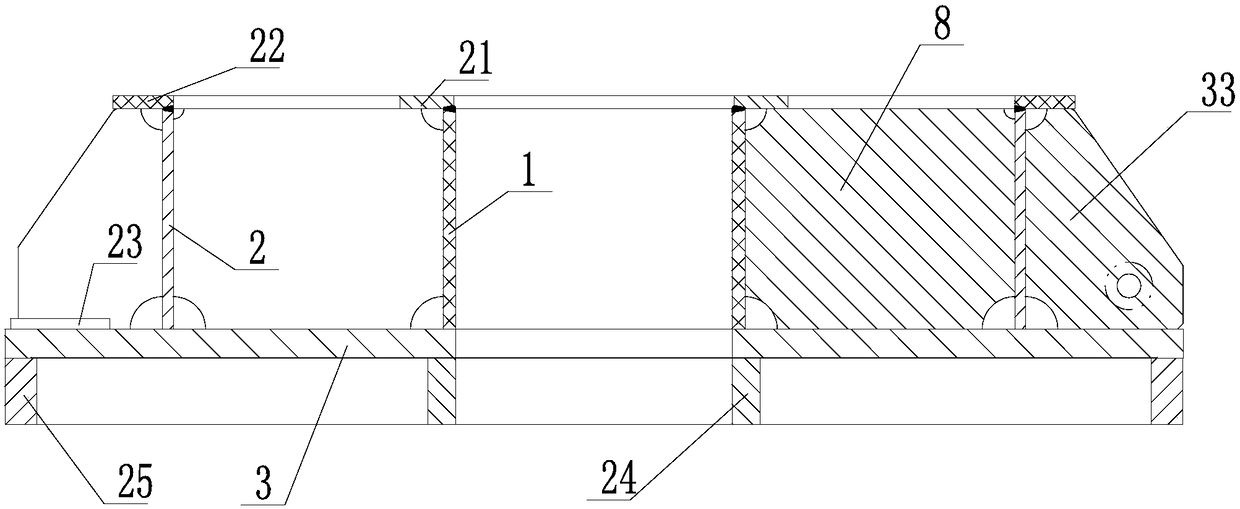

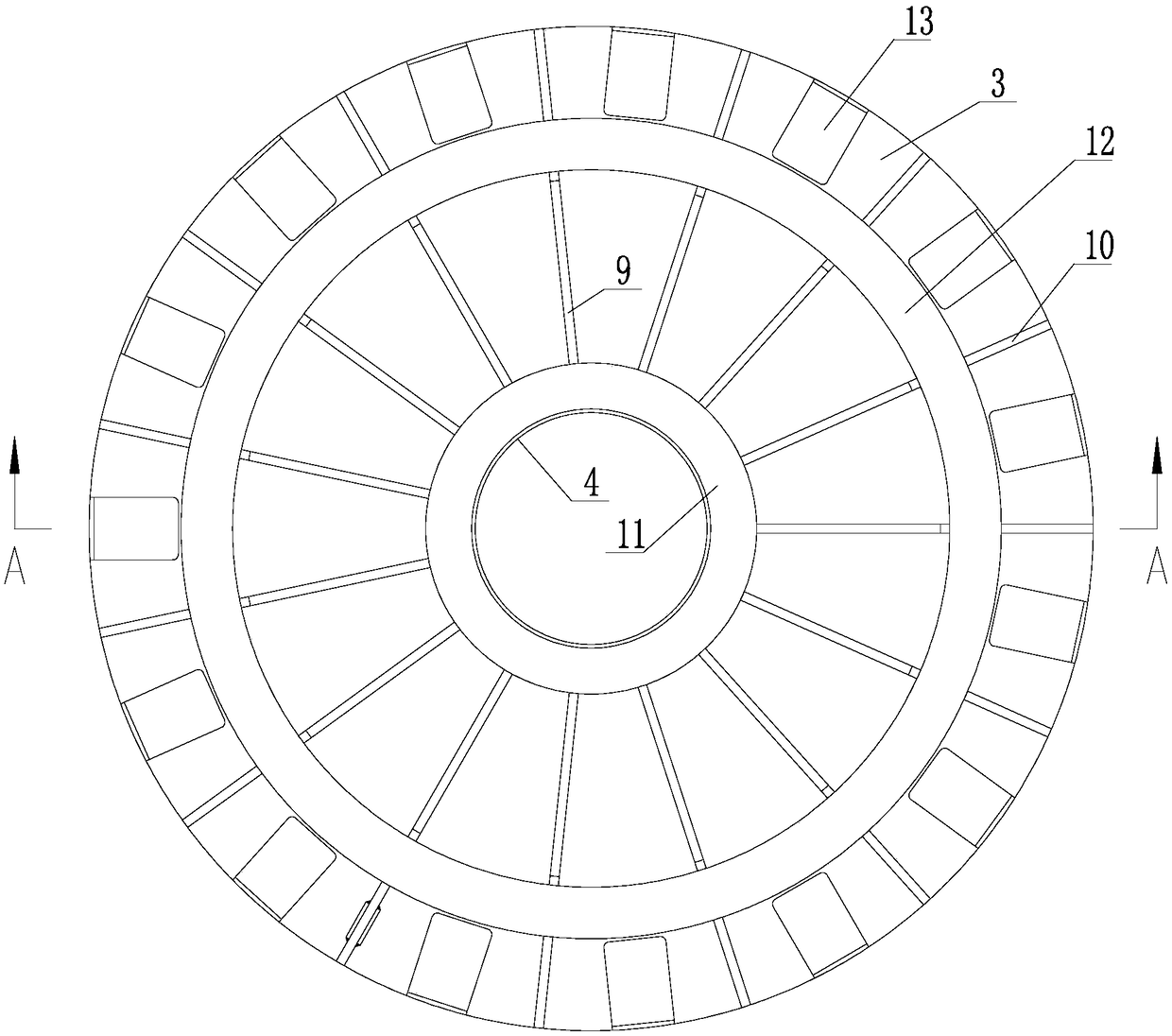

Method for welding outer rib plates in base of lower reactor core vessel of high-temperature gas-cooled reactor

ActiveCN106271155AMeet welding quality requirementsExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNuclear power

The invention discloses a method for welding outer rib plates in a base of a lower reactor core vessel of a high-temperature gas-cooled reactor. With the method, the maximum deformation of a bottom plate can be controlled to be smaller than or equal to 9.6 mm. After an outer barrel and the bottom plate are welded and the 15 outer rib plates are evenly distributed between the bottom plate and the outer barrel, to-be-welded parts are preheated to be at 205 DEG C or higher, positioned welding is performed on the outer barrel and the outer rib plates as well as the bottom plate and the outer rib plates after preheating, and then the outer rib plates and the bottom plate are welded after the outer rib plates and the outer barrel are welded firstly with a multilayer multi-pass welding method. The method has the advantages as follows: with the method, the maximum deformation of the bottom plate can be controlled to be smaller than or equal to 9.6 mm, firm welding can be realized, welding quality requirements in the aspect of nuclear power can be met, and the service life of the base is prolonged.

Owner:SUZHOU HAILU HEAVY IND

Welding method of Q460GJC steel used for architectural structure

InactiveCN106270928AAvoid cold cracksAvoid it happening againArc welding apparatusWelding/soldering/cutting articlesRoom temperatureEngineering

The invention relates to a welding method of Q460GJC steel used for an architectural structure. The welding method comprises the steps that a plate blank which is 3-40 mm thick is welded at the room temperature of -10-0 DEG C through automatic submerged-arc welding or CO2+Ar gas shielded welding, specifically, (1) preheating is conducted before welding so that cold cracks can be prevented from being produced at the joint portion; (2) a reasonable groove mode and a welding method are put forward according to the joint mode and the thickness of the plate blank; (3) an appropriate welding material is selected and used according to the joint mode, the groove mode and the welding method; and (4) corresponding appropriate welding process parameters are presented. Making of the technical scheme of the welding method is based on a welding procedure qualification test, and the welding method has sufficient objectivity and reasonability; and the Q460GJC steel is welded through the technical scheme, a welded joint has mechanical properties equivalent to a parent material and meets the welding quality requirements of engineering.

Owner:鞍钢钢结构(营口)有限公司

Laser welding method for ultrahigh strength armor steel

InactiveCN108672929AOvercoming extreme cold hardeningMeet performance requirementsLaser beam welding apparatusEngineeringToughness

The invention discloses a laser welding method for ultrahigh strength armor steel. The laser welding method comprises the following steps that step 1, preparation before welding is carried out; step 2, two to-be-welded workpieces are installed on a tool fixture; and step 3, a welding line between the two to-be-welded workpieces is welded, wherein welding parameters are that laser power is 2500-2700W, the welding speed is 600mm / min, pure argon gas protection is needed, the welding environment temperature is no less than 15 DEG C, the welded position preheating temperature is between 50 DEG C-100DEG C, and the wind speed of the welded area is limited below 1m / s, otherwise a wind blocking device is needed. The cooling speed of a connector is decelerated, brittleness of the connector is reduced, shaping toughness is improved, cold crack is avoided, and usability requirements of the connector to a vehicle are guaranteed.

Owner:内蒙古第一机械集团股份有限公司

Submerged arc automatic welding process for high-strength steel Q460GJD for building structure

ActiveCN109967839AIncrease productivityStable qualityWelding/cutting media/materialsSoldering mediaProduction ratePower flow

The invention relates to a submerged arc automatic welding process for high-strength steel Q460GJD for a building structure. The maximum plate thickness of the structure steel Q460GJD is 50 mm, the welding material adopts CHW-SG+CHF102A, the diameter of a welding wire is 4.0 mm, strict roasting is performed before a welding flux is used, an X-shaped groove is selected according to the thickness ofa base material, the pre-welding preheating temperature is 110-140 DEG C, multi-layer multi-pass welding process is adopted, the interlayer temperature is 150-200 DEG C, and is higher than the preheating temperature, in the case of the welding parameters, the welding current is 620 + / - 10 A, the welding voltage is 32 + / - 2 V, the welding speed is 40 + / - 1 cm / min, the linear energy is 27.5-32 KJ / cm. Through verification, a structure steel welded product produced through the submerged arc automatic welding process for the high-strength steel Q460GJD for the building structure can completely obtain the good welding comprehensive performance, moreover, the effect of being equivalent to the performance of the base material is achieved, the GB / T 19879-2015 standard and construction structure engineering steel standard requirement is completely met, the linear energy is increased, the productivity is improved, and the welding quality is stable and reliable.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Protection method of explosive welding

PendingCN108213685ASolve the problem of environmental pollutionReduce the amount of explosives usedNon-electric welding apparatusEngineeringExplosion welding

The invention discloses a protection method of explosive welding. Two different metal plates are superposed, an explosive layer is paved on a metal compound plate, and explosive explodes to obtain a metal compound plate. A protection material layer covers the explosive surface, and a protection material comprises a porous gauze material. An adsorber is arranged on the porous gauze material, the explosive explosion noise is remarkably attenuated, the explosive energy is fully utilized, thus, the problem that the energy utilization rate of explosive used for explosive welding is low is solved, and meanwhile, the problem of environment pollution during explosive welding construction is solved. By means of the protection material, the explosive use amount can be decreased by 40-60%, and the explosion noise can be decreased by 50-80%.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508BReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

A kind of submerged arc automatic welding process of steel q420gjc for building structure

ActiveCN105499770BEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesPower flowEngineering

The invention discloses a union melt welding process for steel Q420GJC for building structures. Welding materials include a welding wire MCJ55GJ with a diameter being phi 4.0mm and a welding flux SJ101; a welding environment temperature is higher than or equal to -10 DEG C; a preheating temperature is 100-150 DEG C; multi-layer and multi-pass welding are adopted, and an interlayer temperature is not lower than the preheating temperature. Conditions of backing weld include that a welding current is 520-530A, a welding voltage is 28-30V, a welding speed is 34-35.5cm / min, and thermal input is 21.3-22.8KJ / cm. Conditions of filling weld include that a welding current is 530-540A, a welding voltage is 30-32V, a welding speed is 36-37cm / min, and thermal input is 22.5-23.8KJ / cm. Conditions of cosmetic weld include that a welding current is 535-545A, a welding voltage is 28-30V, a welding speed is 34-35cm / min, and thermal input is 22.4-23.8KJ / cm. By the union melt welding process, equality in mechanical property of welds and base materials can be realized so as to meet requirements on engineering welding quality, and a gap of union melt welding of the steel Q420GJC is filled.

Owner:鞍钢钢结构(营口)有限公司

A gas shielded welding process for steel q420gjc used in building structures

ActiveCN105598563BEquivalent mechanical propertiesMeet welding quality requirementsArc welding apparatusWelding/soldering/cutting articlesEngineeringMechanical property

The invention provides a gas shielded welding technology of steel Q420GJC for a building structure. The technology comprises the steps that a welding material is prepared, wherein welding wires WH5-GJ with the diameter phi of 1.2 mm are prepared; the welding environment temperature is higher than or equal to minus 10 DEG C; the preheating temperature is 100 DEG C-150 DEG C; multi-layer and multi-pass welding is performed, and the interlayer temperature is no lower than the preheating temperature; weld joint priming is performed, wherein the welding current is 240-260 A, the welding voltage is 26-28 V, the welding speed is 30-32 cm / min, and heat input is performed at 9.4-10.2 KJ / cm; weld joint filling is performed, wherein the welding current is 280-300 A, the welding voltage is 28-30 V, the welding speed is 34-36 cm / min, and heat input is performed at 10.4-11.3 KJ / cm; weld joint capping is performed, wherein the welding current is 300-320 A, the welding voltage is 28-30 V, the welding speed is 36-38 cm / min, and heat input is performed at 10.5-11.4 KJ / cm. Q420GJC steel welding is performed by adopting the welding technology, the mechanical property same as that of base metal is obtained, the quality requirements of engineering welding are met, and a gap of gas shielded welding of the Q420GJC steel is filled.

Owner:鞍钢钢结构(营口)有限公司

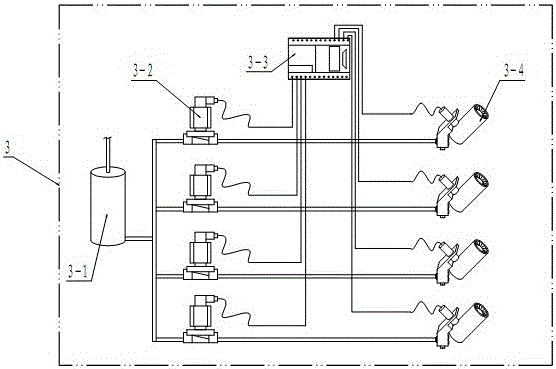

A co2 gas shielded welding torch nozzle anti-blocking treatment system

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

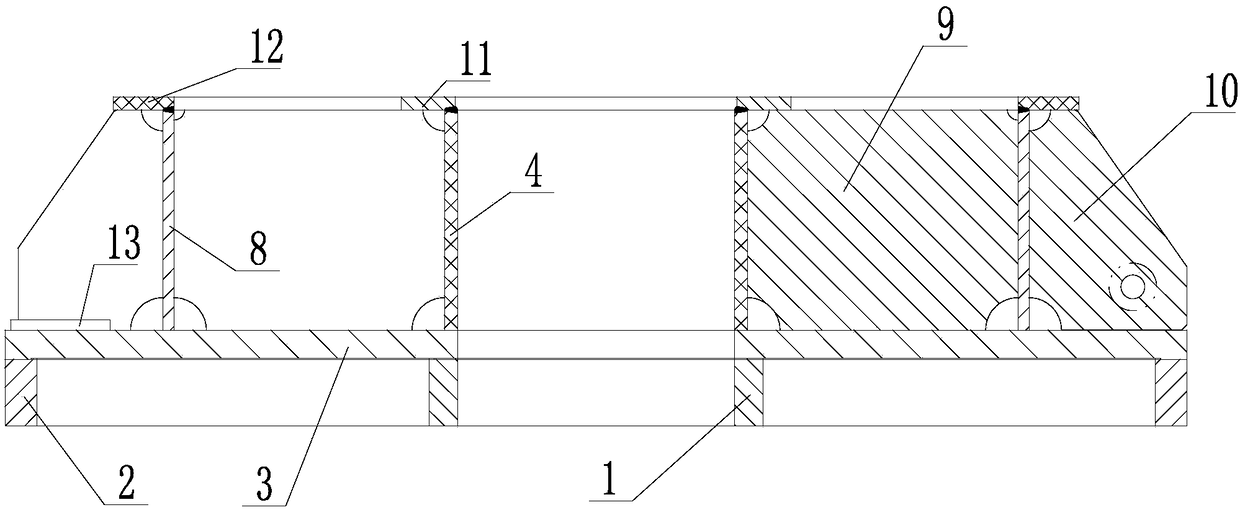

Welding method of inner rib plates in lower reactor core shell base in high temperature gas cooled reactor

ActiveCN106270921AMeet welding quality requirementsExtended service lifeWelding accessoriesNuclear engineeringNuclear power

The invention discloses a welding method of inner rib plates in a lower reactor core shell base in a high temperature gas cooled reactor, which can control maximum deformation of a baseplate to be not higher than 9.6 mm. After an inner cylinder, an outer cylinder and the baseplate are welded, and 15 inner rib plates are uniformly distributed between the inner cylinder and the outer cylinder, parts needing to be welded are preheated to above 205 DEG C; after the preheating is finished, the positioning welding is performed for the outer cylinder and the inner rib plates, and the inner cylinder and the inner rib plates; then, the multi-layer and multi-way welding method is adopted to weld the inner rib plates and the outer cylinder; and finally, the inner rib plates and the baseplate are welded. The welding method has the following advantages: the method can control the maximum deformation of the baseplate to be not higher than 9.6 mm, is firm in welding, satisfies the welding quality requirements on the nuclear power aspect, and prolongs the service life of the base.

Owner:SUZHOU HAILU HEAVY IND

Flexible circuit board for display panel, assembly thereof, and soldering method thereof

InactiveCN110430667AIncrease the areaImprove yieldPrinted circuit assemblingElectrical connection printed elementsComing outFlexible circuits

The invention provides a flexible circuit board for a display panel, an assembly thereof, and a soldering method thereof. The flexible circuit board assembly comprises a flexible circuit board and a backlight module electrically connected with the flexible circuit board by soldering, wherein the flexible circuit board includes a flexible circuit board body; a pad is arranged on the flexible circuit board body; a tin passing groove is arranged in the pad; the backlight module comprises a backlight module body and a pin disposed on the backlight module body, and the pin is electrically connectedto the pad by tin melted from the tin passing groove. The tin coming-out area in the case of hot pressure welding is increased, the open circuit risk is thus reduced, the welding quality requirementsare met, the product yield is increased, manpower and material resources are reduced, and the manufacturing cost is further reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Welding method of core shell base under metal reactor internals in high temperature gas-cooled reactor nuclear power plant

ActiveCN106270974BMeet welding quality requirementsExtended service lifeArc welding apparatusNuclear powerNuclear engineering

The invention discloses a method for welding reactor core shell base under a metal reactor internal in a high temperature gas cooled reactor nuclear power plant. It can be ensured that the maximum deformation of a bottom plate is controlled to be smaller than or equal to 9.6 mm. After an inner cylinder, an outer cylinder and the bottom plate are welded and fifteen inner rib plates are evenly distributed between the inner cylinder and the outer cylinder, to-be-welded parts are preheated till the temperature is 205 DEG C or above, positioning welding is conducted between the outer cylinder and the inner rib plates and between the inner cylinder and the inner rib plates after preheating is completed, and then by means of a multi-layer multi-way welding method, the inner rib plates and the outer cylinder are welded, the inner rib plates and the bottom plate are welded and then outer rib plates are welded. The method has the advantages that it can be ensured that the maximum deformation of the bottom plate is controlled to be smaller than or equal to 9.6 mm, welding is firm, the requirement for welding quality on the aspect of nuclear power is met, and the service life of the base is prolonged.

Owner:SUZHOU HAILU HEAVY IND

Base plate and doubling plate expansion method in explosion welding of large-thickness oxygen-free copper doubling plate

ActiveCN107042357AReliable weldingIncrease profitNon-electric welding apparatusBond interfaceBoundary effects

The invention discloses a base plate and doubling plate expansion method in explosion welding of a large-thickness oxygen-free copper doubling plate. The expansion method comprises the steps that (1) continuation plates are additionally arranged on a base plate and a doubling plate correspondingly; (2) the dimensions of the continuation plates are determined based on calculation of the thicknesses of the base plate and the doubling plate and adopted-explosive parameters; (3) the doubling plate and the continuation plates are connected through bolts; and the connecting mode between the base plate and the continuation plates is determined according to the material of the base plate, wherein, the thickness h of the oxygen-free copper doubling plate is larger than or equal to 15 mm, and the thickness of the base plate is larger than or equal to 1.0 h. According to the base plate and doubling plate expansion method in explosion welding of the large-thickness oxygen-free copper doubling plate, the strength and the quantity calculating formula for the bolts are determined, quantification is realized, blindness eliminating is facilitated, the method of controlling the detonating end to be not welded together and the boundary effect of the detonating end is determined, and reliable welding of the four edges of a composite plate is guaranteed. The welding ratio of the composite plate welded through the process is up to 90%, the utilization ratios of the base plate and the doubling plate are greatly improved, the bonding strength of the welding surface is in accordance with the strength law of bimetal solid-phase metallurgy combination, the bonding interface of the composite plate is in excellent minute wave shape, and the welding quality requirement of the composite plate is completely met.

Owner:南京镭辉新材料有限公司 +2

Welding method of outer cylinder and bottom plate in base of lower core shell of high temperature gas-cooled reactor

ActiveCN106271157BMeet welding quality requirementsExtended service lifeWelding apparatusNuclear powerEngineering

The invention discloses a method for welding an outer cylinder in a reactor core vessel base and a base plate in a high-temperature gas cooled reactor. By the adoption of the method, the maximum deformation of the base plate can be controlled to be 9.6 mm or below. An inner cylinder tool and an outer cylinder tool are placed on a site, then the base plate is placed on the inner cylinder tool and the outer cylinder tool, welding portions are preheated, the welding portion of the outer cylinder is divided into eight welding areas: a, b, c, d, e, f, g and h with the same arc length in the circumferential direction clockwise, positioned welding is conducted after preheating, and then a multi-layer multi-pass welding method is adopted. The multi-layer multi-pass welding method specifically comprises the steps of three-layer welding of an internal groove, three-layer welding of an external groove, welding of the fourth layer and the fifth layer of the internal groove, welding of the fourth layer and the fifth layer of the external groove, complete welding of the internal groove, and complete welding of the external groove. The method has the advantages that the maximum deformation of the base plate can be controlled to be 9.6 mm or below, welding is firm, the requirement of the nuclear power field for welding quality is met, and the service life of the base is prolonged.

Owner:SUZHOU HAILU HEAVY IND

Vacuum electron beam welding method for end face of dissimilar metal electromagnetic valve assembly

ActiveCN113909663AMeet welding quality requirementsMeet performance requirementsElectron beam welding apparatusVacuum electronicsElectromagnetic valve

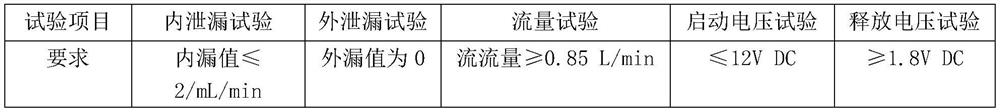

The invention discloses a vacuum electron beam welding method for the end face of a dissimilar metal electromagnetic valve assembly. The vacuum electron beam welding method comprises the following steps of soaking and drying, demagnetization, positioned welding, seal welding, welding, bench work, heat treatment, washing and inspection. According to the method, quality inspection including macroscopic defect inspection, organization inspection, penetration inspection and the like is carried out on a welded joint of a part subjected to vacuum electron beam welding on the end face of the electromagnetic valve assembly, and the welding quality requirements are all met; and element tests including airtight performance tests, hydraulic performance tests and the like of the electromagnetic valve assembly are carried out, performance verification of an electromagnetic valve product is completed, and the performance requirements of the product are met.

Owner:GUIZHOU HONGLIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com