Welding method of core shell base under metal reactor internals in high temperature gas-cooled reactor nuclear power plant

A technology of high-temperature gas-cooled stacking and welding methods, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as welding difficulties, large hardening tendency, and control of the maximum deformation of the bottom plate, and meet welding quality requirements , Welding is firm, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

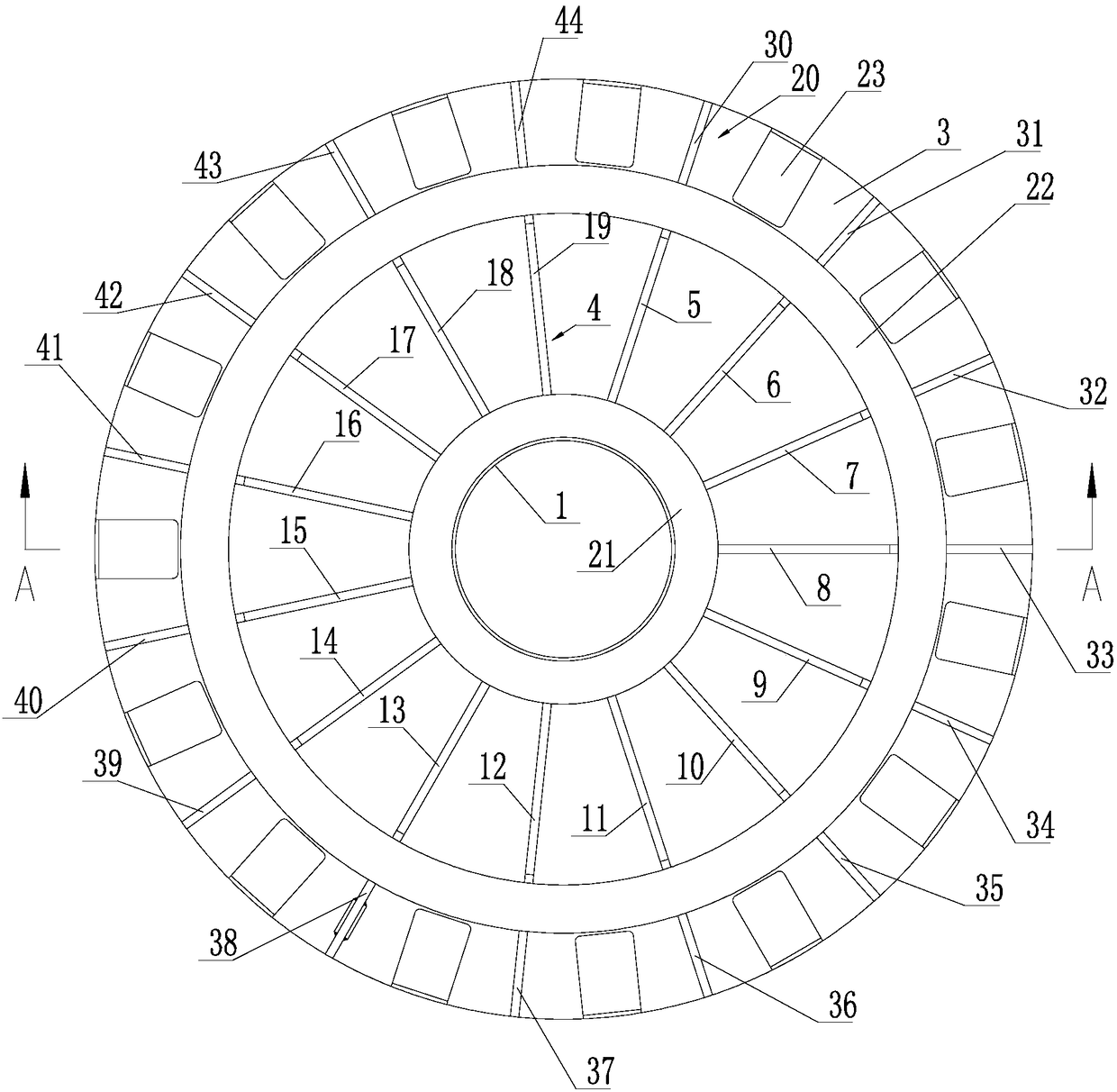

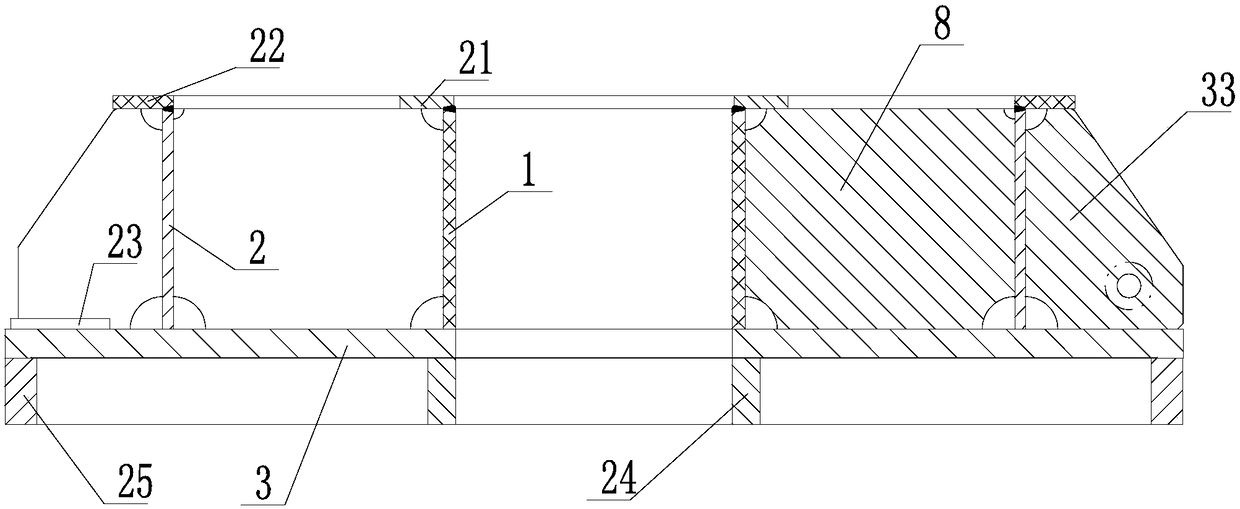

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

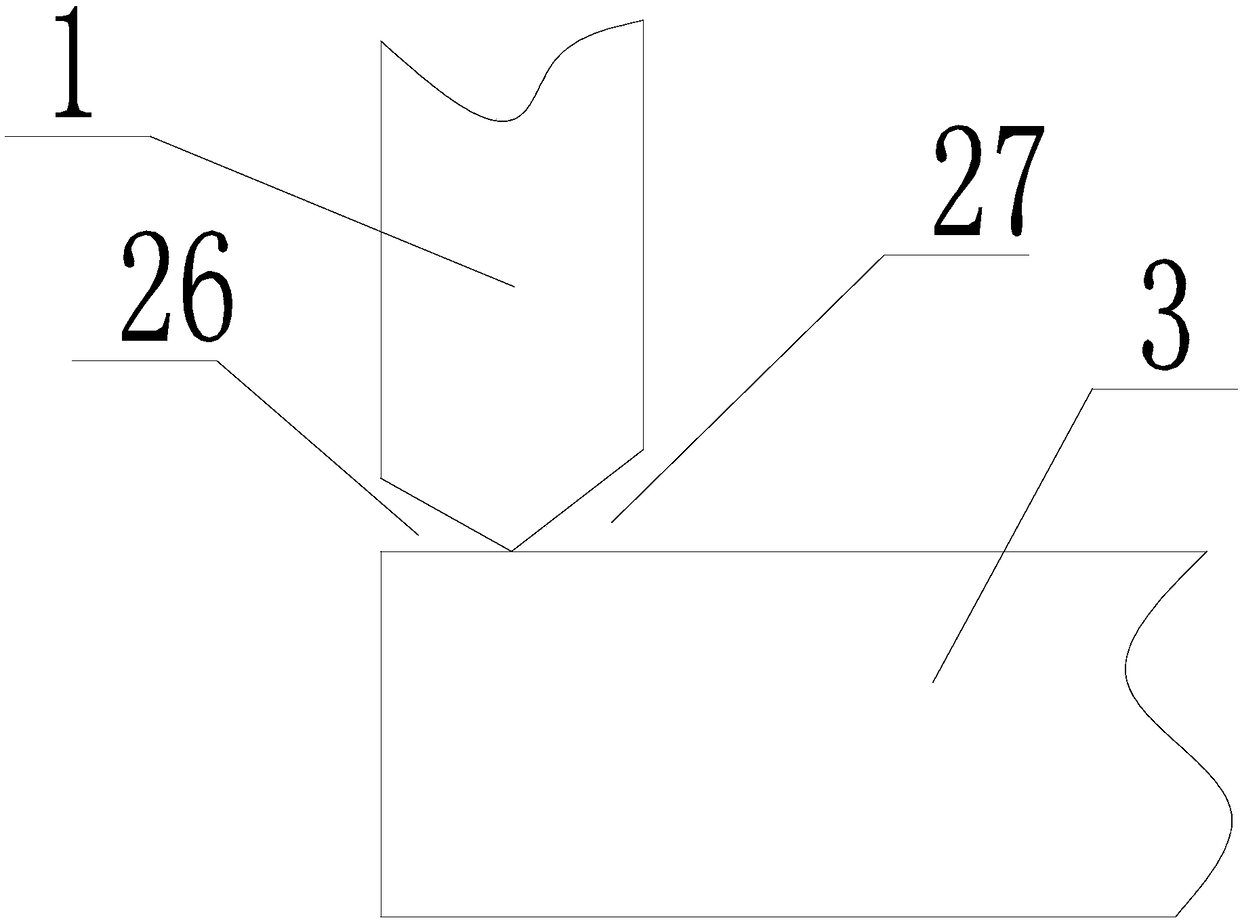

[0026] Such as figure 1 and figure 2 As shown, in the method for welding the base of the lower core shell of the metal reactor internals in the high temperature gas-cooled reactor nuclear power plant according to the present invention, the two inner cylinder tooling 24 and the outer cylinder tooling 25 are placed on the site, and the inner cylinder tooling 24 and the outer cylinder tooling 25 are all cylindrical, and the diameter of outer tube tooling 25 is greater than the diameter of inner tube tooling 24, then base plate 3 is placed on inner tube tooling 24 and outer tube tooling 25, the center of circle of base plate 3 and inner tube tooling 24, outer tube The center of the tooling 25 is concentric. After placing the inner cylinder 1 on the bottom plate 3, preheat the welding parts of the two until it is above 205°C. The first preheating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com