Base plate and doubling plate expansion method in explosion welding of large-thickness oxygen-free copper doubling plate

An explosive welding and oxygen-free copper technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high cost, low welding strength, and complicated equipment, so as to improve utilization rate, reliable welding, and eliminate blindness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The cladding plate is a C10100 oxygen-free copper plate with a size of 1800mm×1000mm×23mm, and the substrate is a 316L stainless steel plate with a size of 1800mm×1000mm×90mm.

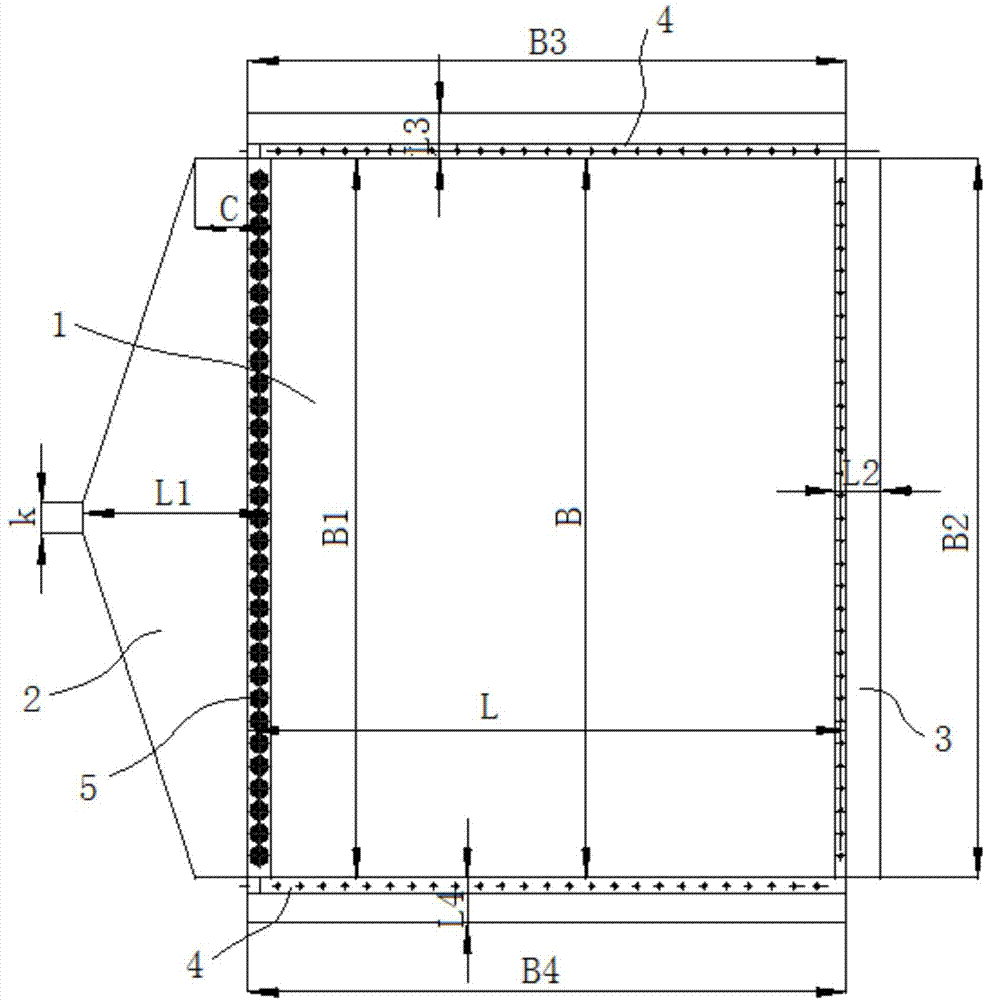

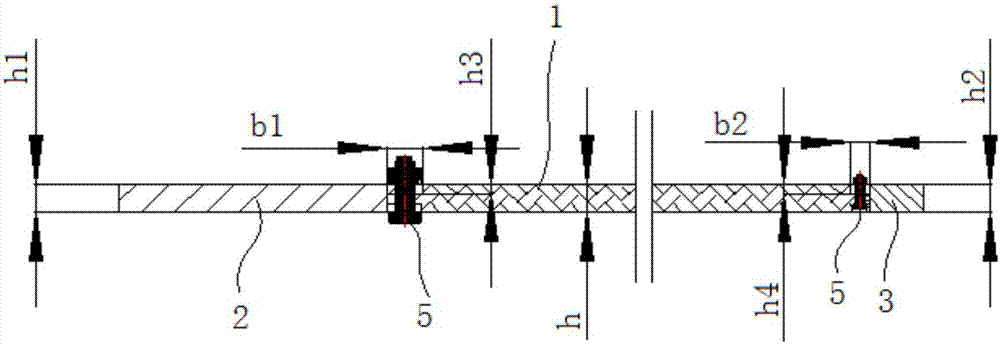

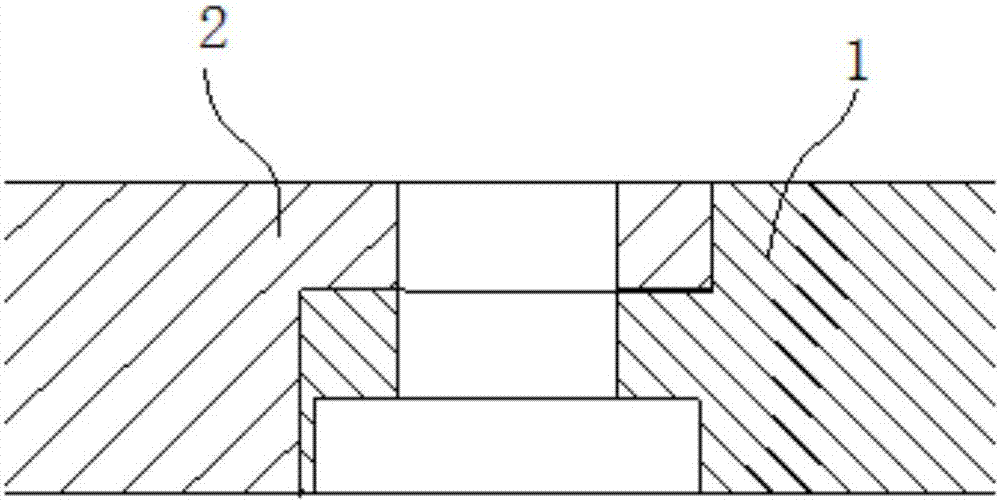

[0038] 1) An extension plate is only added at the initiation end of the cladding plate, and the shape of the extension plate is as follows: figure 1 As shown, the material of the extension board is Q235, the length is 250mm, the width is the same as that of the cladding board, and the thickness is 23mm. The bolts are M16 bolts, the number is 5, and the explosive welding is carried out. The result shows that the welding rate is about 70%. The main dead zone occurs at the ends and both sides.

[0039] 2) The extension plate at the initiation end and the bolts used are the same as above, the width of the extension plate at the end is equal to the width of the cladding plate, and the length is 30mm. The length of the extension board on both sides is equal to the length of the cladding board, and ...

Embodiment 2

[0042] The cladding plate is a C10100 oxygen-free copper plate with a size of 1800mm×1000mm×15mm, and the substrate is a 316L stainless steel plate with a size of 1800mm×1000mm×45mm.

[0043] An extension plate is attached to the initiation end of the cladding plate, and the shape of the extension plate is as follows figure 1 As shown, the material of the extension board is Q235, the length is 220mm, the width is the same as that of the cladding board, and the thickness is 15mm. The bolts are M12 bolts with a pitch of 22mm. The width of the extension board at the end is equal to the width of the cladding board, and the length is 25mm. The length of the extension plate on both sides is equal to the length of the cladding plate, and the width is equal to 25mm; the bolts at the end and on both sides are M4 bolts with a pitch of 8mm.

[0044] Welding method is used to add extension boards with a thickness of 30mm and the same shape, length and width as the cladding extension bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com