Solder joint structure and method for soldering electronic components

a technology of electronic components and solder joints, which is applied in the direction of soldering apparatus, manufacturing tools, printed circuit non-printed electric components association, etc., can solve the problems of serious deformation of reliability of soldering, reduced joint strength, and inability to achieve required reliability of soldering, so as to achieve high reliability of lead-free soldering and reduce the effect of joint strength resulting from the interaction between copper and zin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

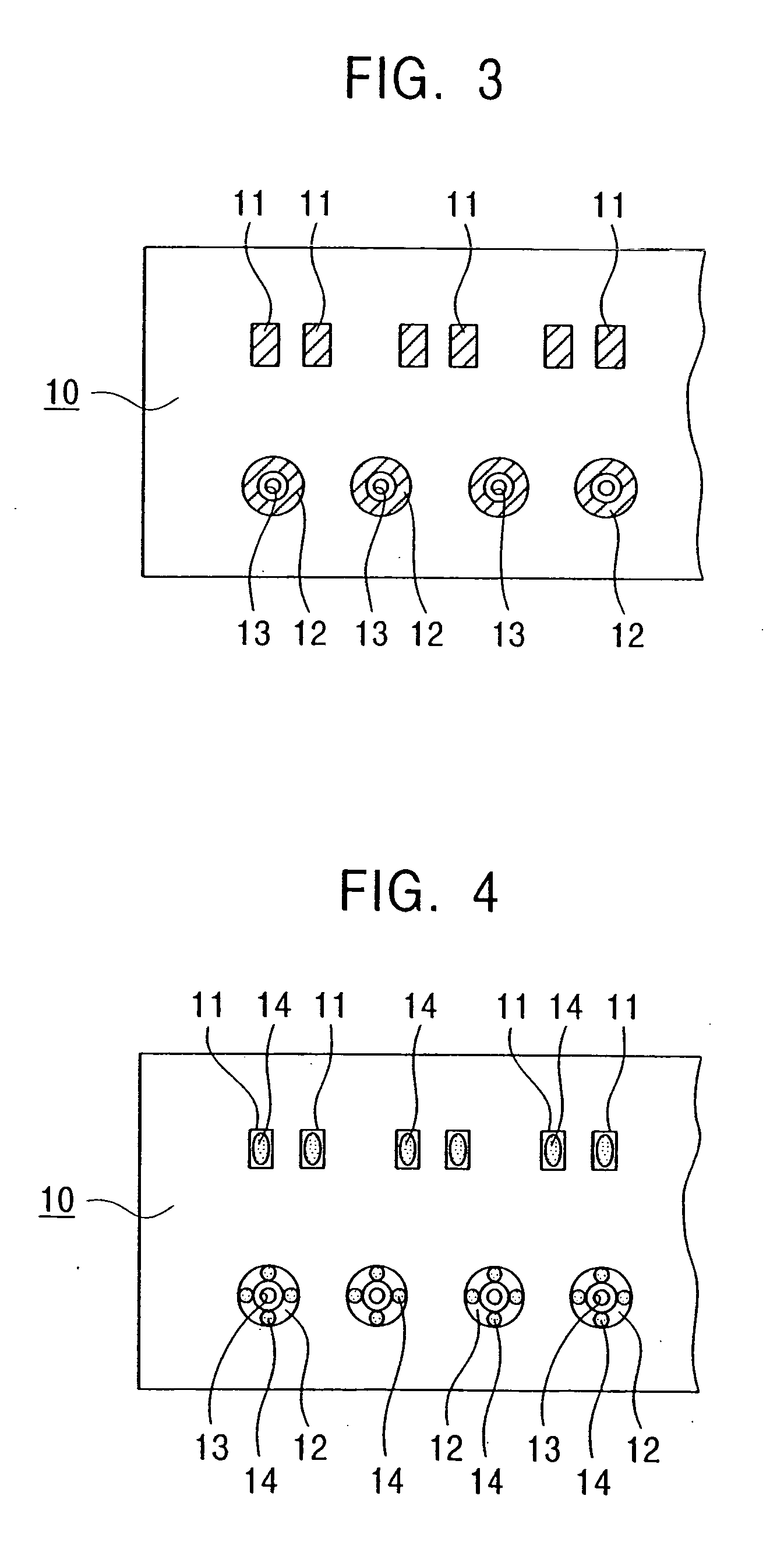

[0023] The preferred embodiments of the present invention will now be described with reference to the drawings. FIG. 1 shows a circuit board having various electronic components mounted thereon according to an embodiment of the present invention. FIG. 2 is a cross-sectional view of a solder joint structure for a lead terminal of a thermolabile electronic component. FIG. 3 shows lands on the circuit board. FIG. 4 shows the lands on the circuit board, which a Sn—Ag—Cu solder material is applied on the lands by printing. FIG. 5 shows the circuit board having electronic component chips mounted thereon. FIG. 6 shows the circuit board having second solder lands for lead terminals, in which a Sn—Zn solder material is applied on the solder lands by printing.

[0024] As shown in FIG. 3, first solder lands 11 for surface mounting and second solder lands 12 for use with lead terminals are formed on the same surface of a circuit board 10. The first solder lands 11 are patterned copper layers. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com