Low-alloy steel heat exchange pipe butt joint automatic welding process for filling molten rings

A welding process and low-alloy steel technology, applied in welding equipment, metal processing, metal processing equipment, etc., can solve the problems of increasing the difficulty of welding operations, small distance between heat exchange tube walls, and small welding operation space, etc., to achieve The effect of good weld formation and welding quality, small pipe wall distance, and small welding operation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] According to the above-mentioned welding process provided by the present invention, the low-alloy steel SA-213T22 heat exchange tube between the low-temperature section of the spiral coil of the high-temperature gas-cooled reactor steam generator and the water supply connection pipe of the space elbow is welded, and the specifications of the two heat exchange tubes are Φ19×3mm, the minimum tube wall spacing of heat exchange tubes is 41mm, and the filling material is IN521 melting ring, the details are as follows:

[0081] Step 1), polish the parts to be welded between the low-alloy steel SA-213T22 heat exchange tube and the IN521 melting ring until metallic luster is seen, and wipe with a white non-woven cloth dipped in acetone until the white cloth does not change color;

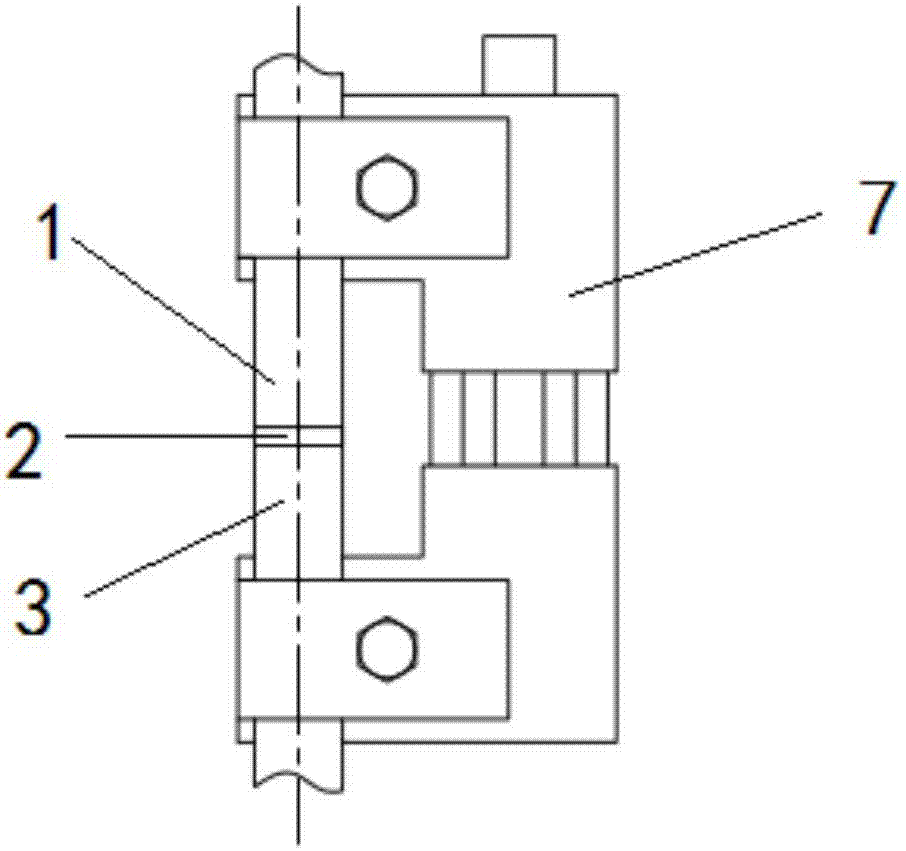

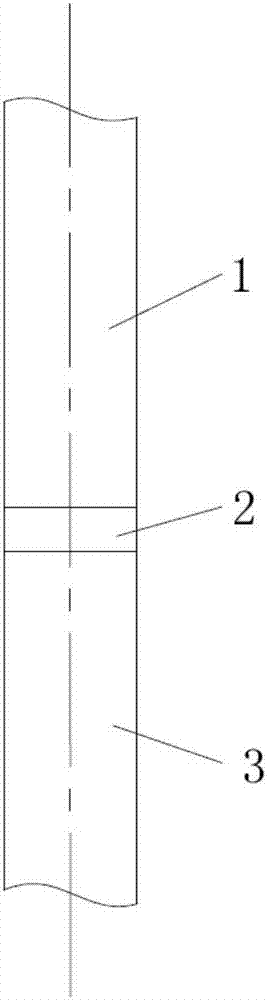

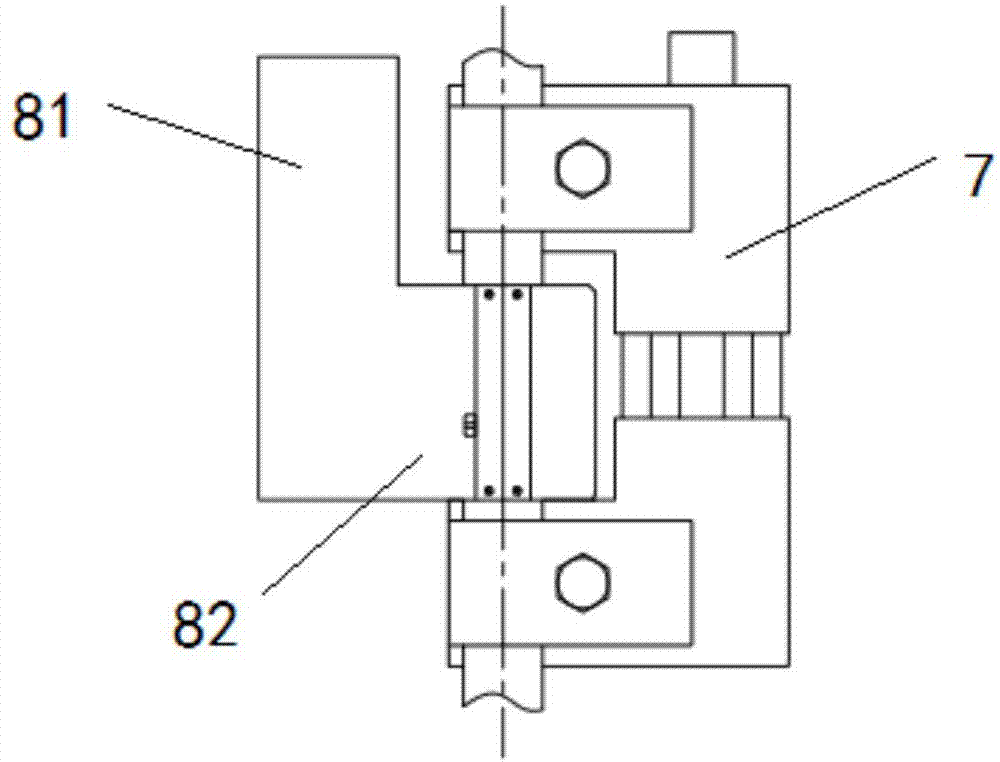

[0082] Step 2), install a pressure plate of the heat exchange tube welding tool 7 on the end of any heat exchange tube, adjust the relative position of the tool 7 and the tube end; The position of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com