Explosive welding method of metal clad plate of super-thick shroud plate

A metal composite board, explosive welding technology, applied in welding equipment, metal processing, metal processing equipment, etc., can solve problems such as unexplained, complicated process, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

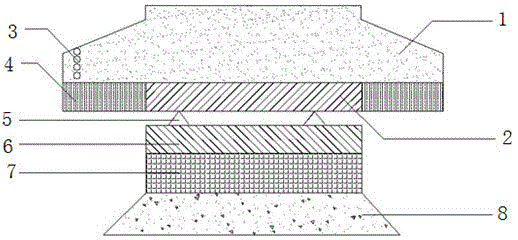

[0053] The material of the blank plate used in this embodiment is Q345R, the specification of the base plate: length 880mm, width 280mm, thickness 50mm; specification of cladding plate: length 880mm, width 280mm, thickness 50mm.

[0054] A kind of explosive welding method of the metal clad plate of ultra-thick clad plate, comprises the following steps:

[0055] (1) Blank pretreatment

[0056] Through the process of leveling, grinding, polishing and cleaning, etc., the rust and oxide on the surface of the blank plate are removed. The roughness of the blank plate is less than 3mm / m, and the roughness of the surface to be bonded is less than 50μm;

[0057] (2) Install extension board

[0058] Spreading plates are set around the cladding plate as tooling for explosive welding.

[0059] The expansion plate generally uses metal materials that are relatively cheap and easy to form welding with the cladding plate. The expansion plate and the cladding plate are generally groove welde...

Embodiment 2

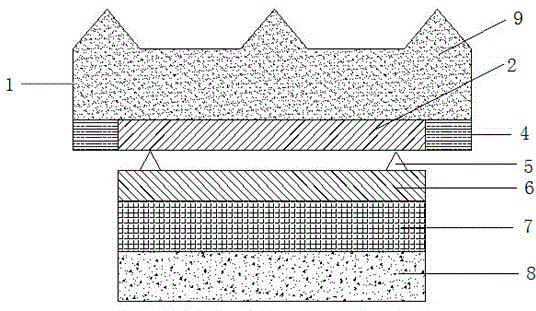

[0153] The material of the blank plate in this embodiment is Q345R, the specification of the substrate: length 880mm, width 280mm, thickness 35mm; specification of cladding plate: length 880mm, width 280mm, thickness 35mm.

[0154] (1) Blank pretreatment:

[0155] Through the processes of leveling, grinding, polishing and cleaning, etc., the rust and oxides on the surface of the blank plate are removed. The roughness of the blank plate is 2.8mm / m, and the roughness of the surface to be bonded is less than 50μm;

[0156] (2) charge

[0157] The explosives placed directly above the cladding plate are the main charge, and the explosives placed above the extension plate are the auxiliary charges. The main charge adopts the "plane + wave" distributing method; the auxiliary charge at the initiation end adopts the "slope (upward)" distributing method, the auxiliary charges on both sides adopt the "mountain-shaped" distributing method, and the auxiliary charge at the end adopts the "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com