Micro-region in-situ reaction preparation method for high strength fiber-reinforced ceramic matrix composite material

A high-strength fiber and composite material technology, which is applied in the field of micro-region in-situ reaction preparation of high-strength fiber-reinforced ceramic matrix composite materials, can solve the problems of inability to achieve sintering, low strength of composite materials, and low mechanical properties of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The method for preparing high-strength fiber-reinforced ceramic matrix composites of the present invention comprises the following steps:

[0033] (i) Depositing an interface layer on the surface of the composite fiber preform to protect the fiber reinforcement;

[0034] (ii) introducing Si into the pores of the composite fiber preform 3 N 4 a ceramic phase to obtain a composite material preform;

[0035] (iii) Densifying the obtained preform to obtain a ceramic matrix composite material with high density.

[0036] In the present invention, the deposited interface layer includes a PyC interface, a BN interface, a SiC interface and a composite interface formed by the combination of the above interfaces; the thickness of the interface layer is 10-2000nm, preferably 50nm-400nm; in order to improve the composite material matrix With respect to the bonding strength of the interface layer on the surface of the fiber, the outermost layer of the preferred interface layer in ...

Embodiment 1

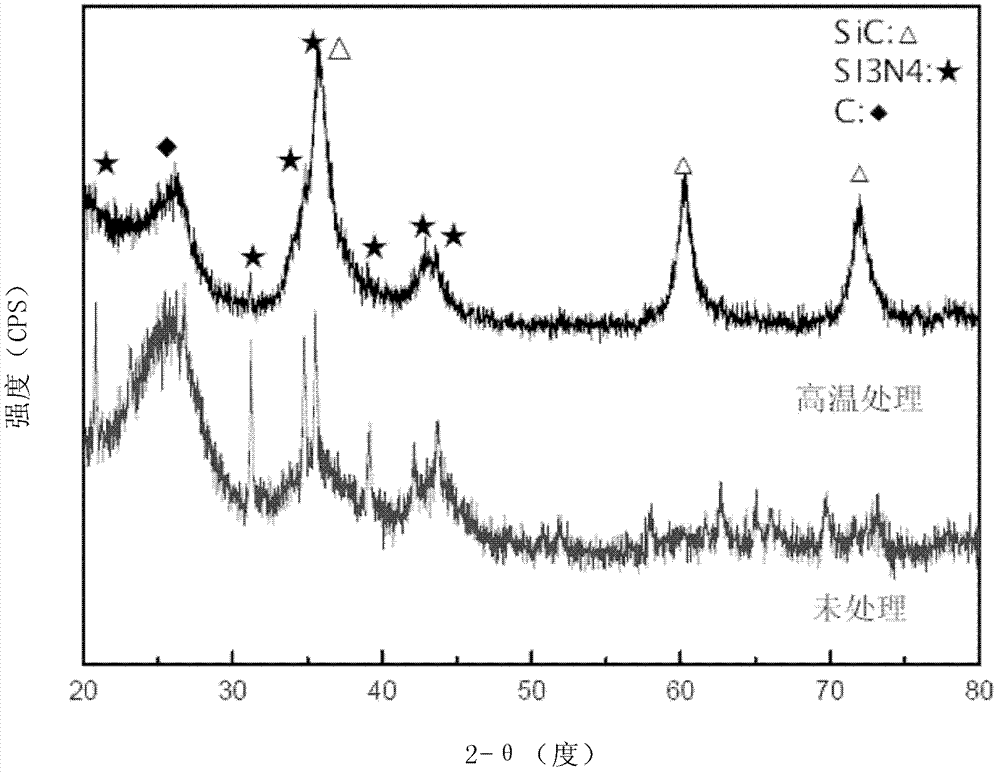

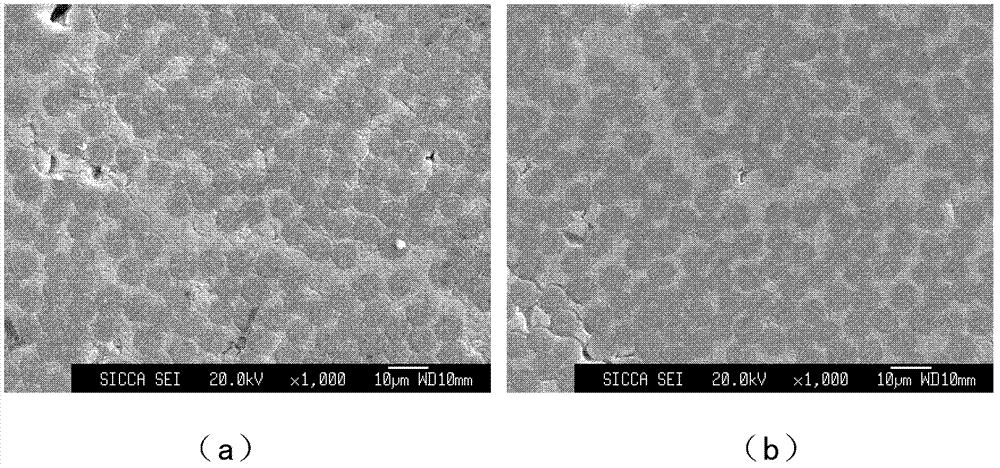

[0056] Mix polycarbosilane, silicon nitride, and divinylbenzene in a mass ratio (1:0.5:0.5), use xylene as a solvent, and form a uniformly dispersed slurry by wet ball milling for 24 hours. The three-dimensional needle-punched carbon fiber preform deposited with a PyC interface layer with a thickness of about 150 nm was vacuum impregnated in the above slurry to make the slurry penetrate into the pores of the fiber preform, and the impregnation time was 6 hours. The impregnated fiber preform was dried and cured in an Ar atmosphere at 120°C for 6 hours, then heated up to 900°C at a rate of 3°C / min for cracking to obtain a composite material preform, and the holding time was 1 hour. The composite fiber preform was kept at 1600 °C for 1 hour in an Ar atmosphere to make the Si 3 N 4 Microdomain in situ reactions occurred between PCS cracked carbon and PyC interface. Then PCS was used as the precursor, and the PIP process was used to densify the composite material until the weight...

Embodiment 2

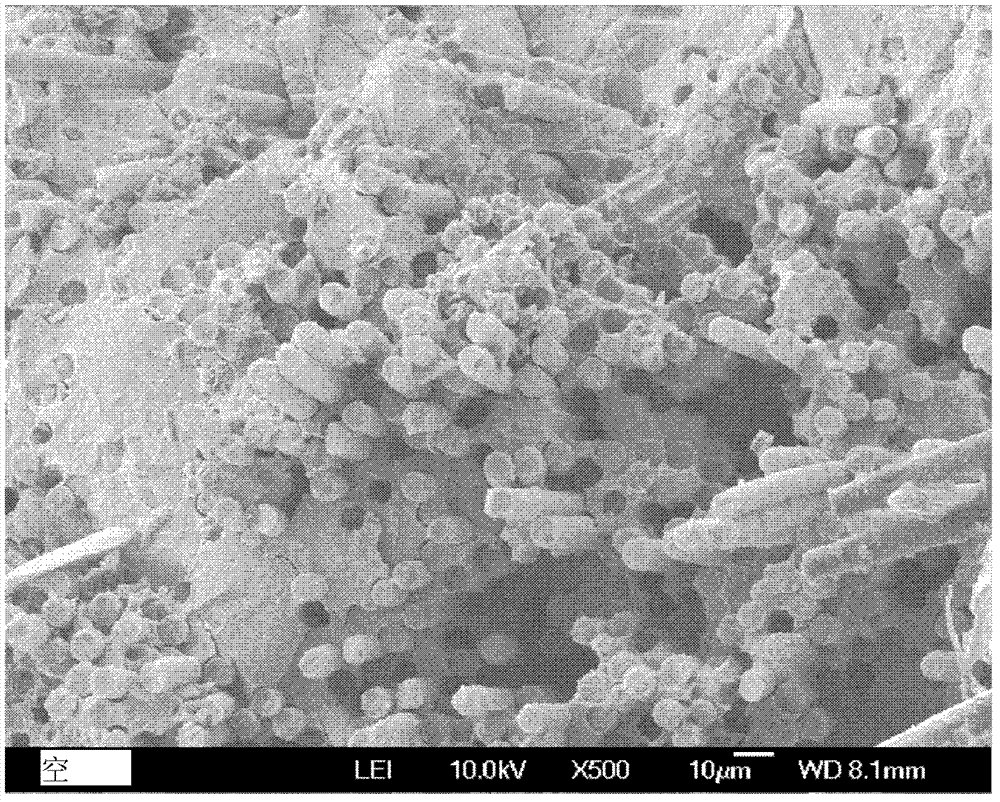

[0058] According to Example 1, after forming the composite material preform, the xylene solution of polycarbosilane and divinylbenzene (mass ratio: 1:0.5) was used to carry out 2 PIP cycles, and then the high-temperature micro-region in-situ reaction was carried out. The composites were subsequently densified by the PIP process using PCS as a precursor. The three-point bending strength of the three-dimensional needle-punched C / SiC prepared by this process is 448 MPa. Due to the introduction of more carbon sources into the composite matrix after 2 PIP cycles, the interfacial layer and Si 3 N 4 The degree of reaction between the phases makes the bonding interface slightly weaker than that of the direct high temperature reaction, and the resulting composite material has a slightly lower strength, which makes the fiber pull out obvious and the pull out length longer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com