Liquid crystal polymer film and manufacture method

A technology of a liquid crystal polymer and a manufacturing method, applied in the field of material processing, can solve the problems of inability to meet the use requirements of flexible circuit boards, poor tensile strength, etc., and achieve the effects of easy mass production, simple manufacturing method and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

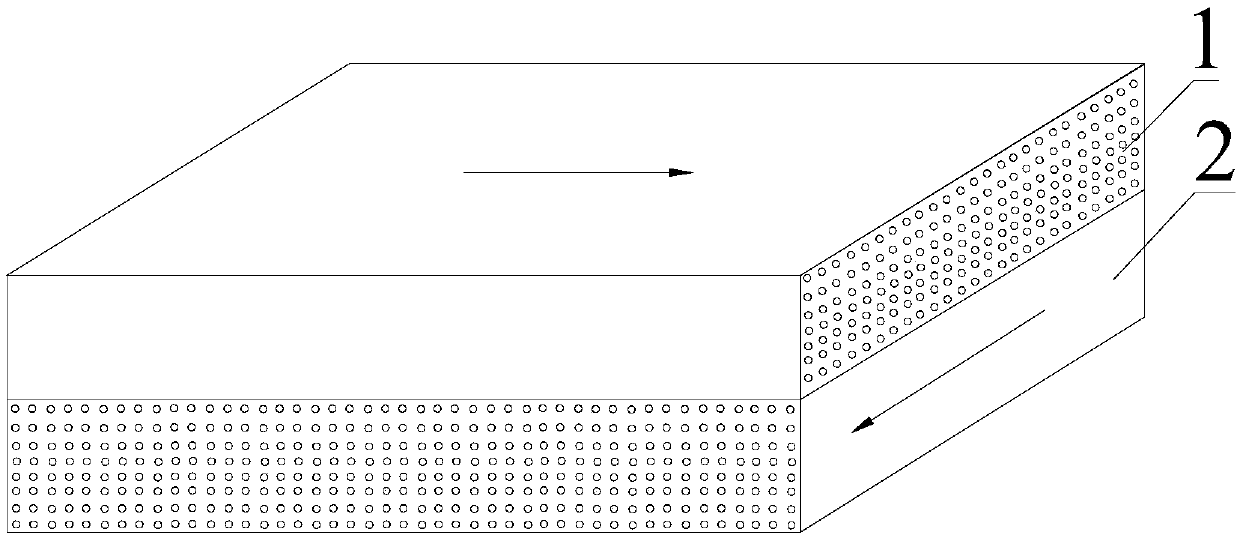

[0033] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0034] A liquid crystal polymer film, comprising a first oriented film 1 and a second oriented film 2 which are sequentially stacked alternately, the orientation direction of the first oriented film 1 and the orientation direction of the second oriented film 2 of two adjacent layers are The directions intersect, and the first alignment film 1 and the second alignment film 2 are thermocompressed to obtain the liquid crystal polymer film. In Figure 1, the orientation directions of the first oriented film 1 and the second oriented film 2 are respectively parallel to the directions indicated by the two arrows. In this embodiment, the thicknesses of the first oriented film 1 and the second oriented film 2 are both 5-100 μm, and the number of layers of the first oriented film 1 and the second oriented film 2 is 1-5 layers, and finally The number of layers of the obtained liquid crystal polymer film is 2-...

Embodiment 2

[0036] A method for manufacturing a liquid crystal polymer film, which is used to manufacture the liquid crystal polymer film in Example 1, mainly includes the following steps:

[0037] The first oriented film and the second oriented film with a thickness of 5 to 100 μm are prepared by extrusion blow molding, extrusion casting or extrusion calendering, and the same batch of films can be used for the first oriented film and the second oriented film, but Different placement directions lead to different final orientation directions.

[0038] The first alignment film and the second alignment film used to manufacture the liquid crystal polymer film are sequentially stacked and arranged so that the alignment direction of the adjacent first alignment film intersects the alignment direction of the second alignment film to obtain a stacked structure. Preferably, the orientation direction of the first oriented film and the orientation direction of the second oriented film of two adjace...

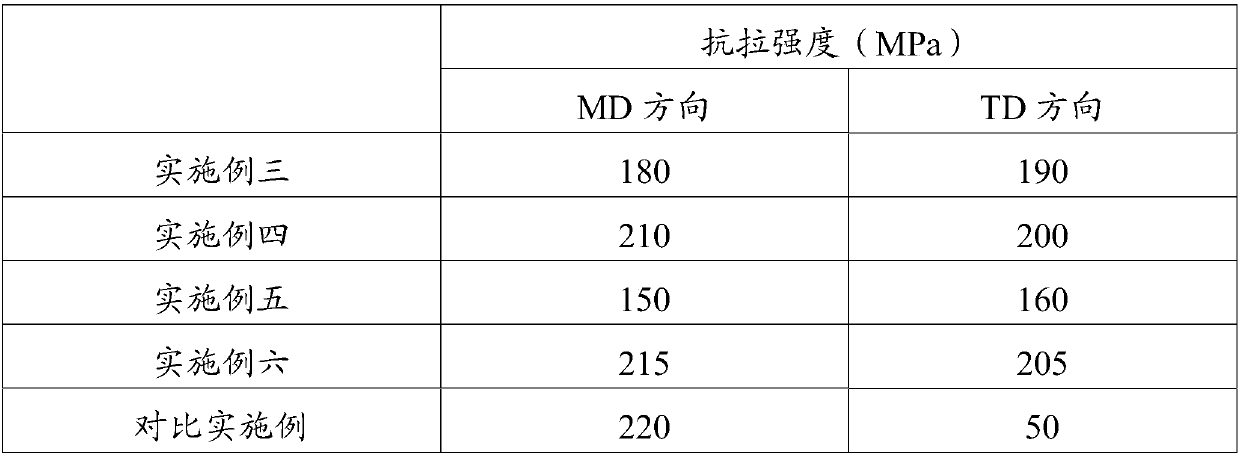

Embodiment 3

[0041] A method for manufacturing a liquid crystal polymer film, the difference from Embodiment 2 is:

[0042] A thermoplastic liquid crystal polymer resin (VECTRA A950) was blown into a film at 310° C. using an extrusion blow molding machine. The screw speed of the extruder was 80 rpm, the diameter of the extrusion die was 60 mm, the gap was 0.8 mm, and the inflation ratio was 1:4 to obtain a first oriented film and a second oriented film with a thickness of about 50 μm.

[0043] Laminate the first oriented film and the second oriented film according to the intersecting direction of MD and TD. The number of laminated layers is 2 layers, and then press them under the laminator. The pressing temperature is 240°C and the pressure is 10MPa to obtain the thickness 100 μm liquid crystal polymer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com